Short description

| Short description |

| 1. |

Fuel tank

|

|

| 2. |

Fuel pump unit (689)

|

|

| 3. |

Fuel filter

|

|

| 4. |

Fuel line, delivery

|

|

| 5. |

Fuel distribution pipe

|

|

| 6. |

Injector (206A-F)

|

|

| 7. |

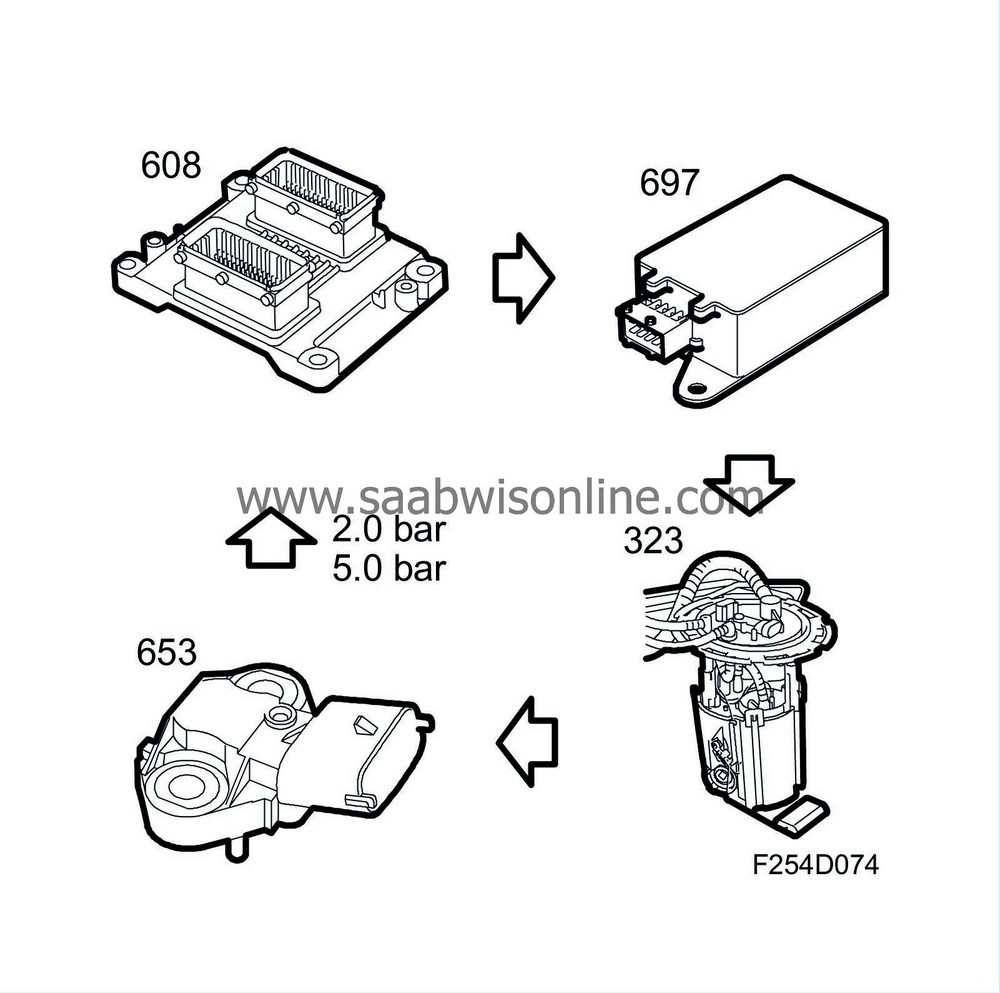

Control module, fuel pump (697)

|

|

| 8. |

Fuel pressure sensor (653)

|

|

| Description |

The fuel system is non-return with variable pressure. An electric fuel pump is situated in the tank. Pump speed and thereby fuel pressure is varied by supplying the pump PWM voltage. ECM regulates a power amplifier mounted near the fuel tank. This supplies the pump PWM voltage. ECM calculates the requested fuel pressure for each given operating point. A pressure sensor on the fuel rail measures current fuel pressure. The requested and actual fuel pressure are compared. If necessary, PWM to the fuel pump is adjusted to obtain the correct pressure.

In US/CA, there is a filter mounted in the fuel pump unit. In other markets, the filter is external. Fuel is led in a steel pipe from the bulkhead, at which point the line becomes a hose. The hose feeds the fuel rail. By allowing fuel pressure to vary based on engine need, injection capacity can be stretched over a large area. Furthermore, the fuel is subjected to less heating, which is beneficial from an emissions standpoint.

The injectors are mounted in the intake manifold and point/inject toward the intake values - two jets toward each valve. ECM regulates the opening duration of the injectors through electrical impulses.