(771-2460 utg.2) Tightening wheel bolts

Symptom: An incorrect tightening process can result in incorrect clamping force at which the steel wheels can be deformed.

|

TECHNICAL SERVICE BULLETIN

|

|

Bulletin Nbr:

|

771-2460 utg.2

|

|

Date:

...........

|

April 2004

|

|

Market:

|

all

|

Saab 9-3 (9440), M03 -

The tightening process for pressed steel and aluminium wheels is different. For this reason it is important that the following method is used when tightening.

Symptom description

An incorrect tightening process can result in incorrect clamping force at which the steel wheels can be deformed.

|

1.

|

Clean the contact surface between the wheel and the brake disc from dirt and rust.

|

|

2.

|

Brush 30 06 442 White high-pressure grease paste onto the hub.

|

|

3.

|

Aluminium wheel:

Apply oil to the bolt threads and on the conical surface of the bolts.

|

|

4.

|

Hang the wheel in position. Fit the bolts and tighten them alternately by hand so that the wheel is centred.

|

|

5.

|

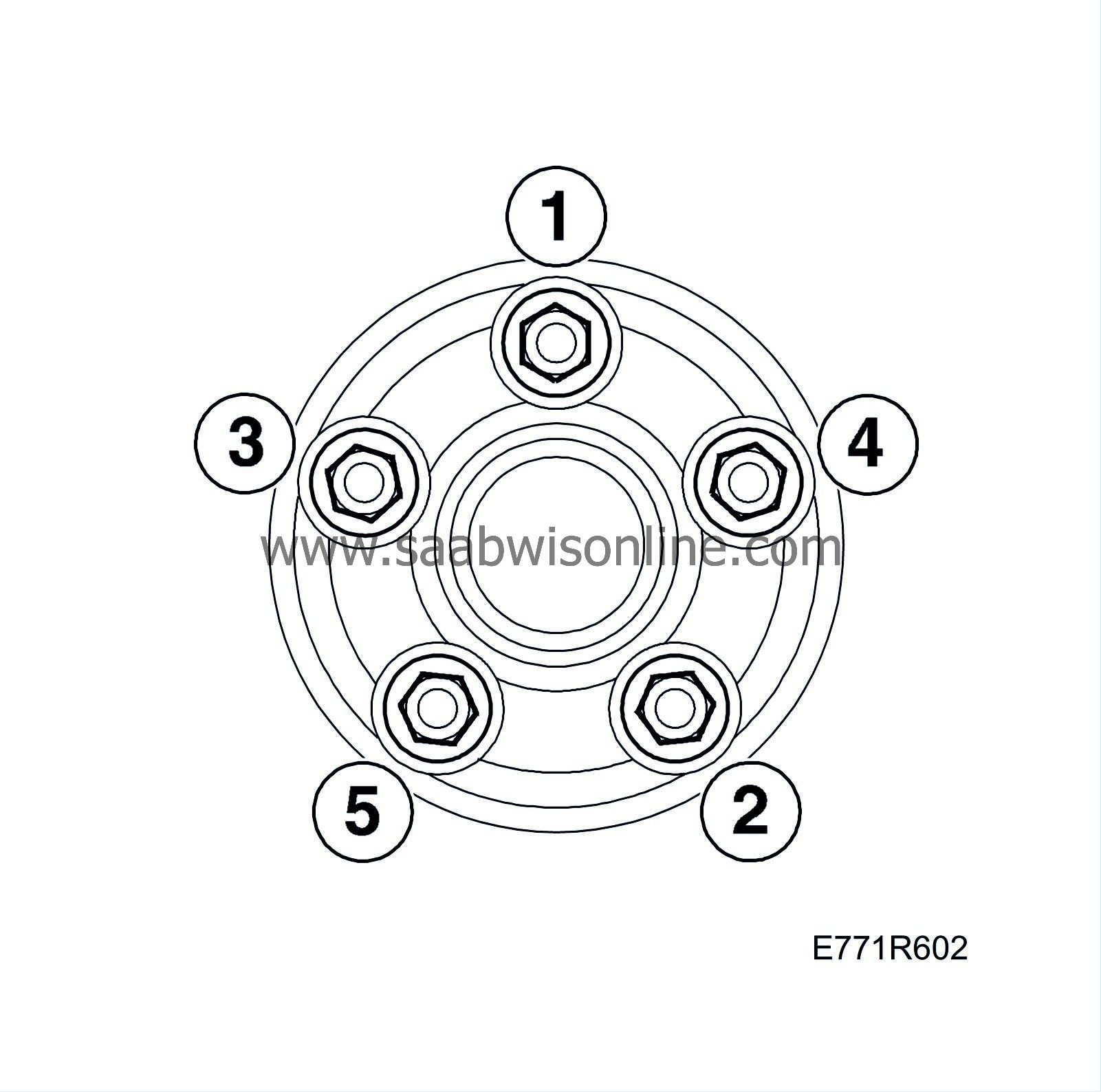

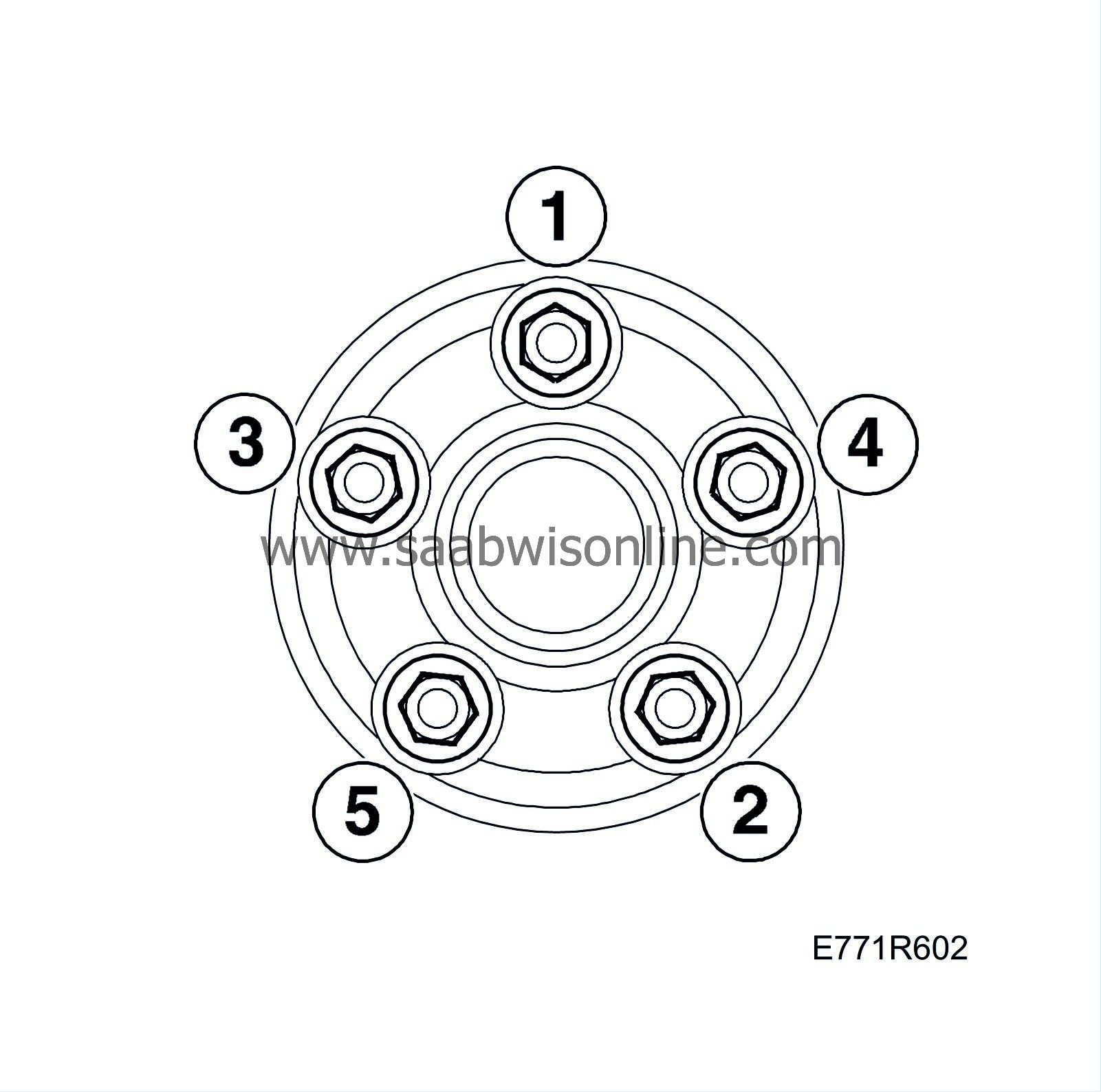

Tighten the bolts alternately twice.

Tightening torque, aluminium wheel, 110 Nm (81 lbf ft)

Tightening torque, pressed steel wheel, 50 Nm +90

°

+90

°

, max. 110 Nm (37 lbf ft +90

°

+90

°

, max. 81 lbf ft)

|

Note

|

|

In order to avoid the bolts being tightened too hard when fitting

pressed steel wheels

the angle tightening must be carried out with a torque wrench set at 110 Nm (81 lbf ft). If the torque wrench indicates that 110 Nm (81 lbf ft) has been reached then the angle tightening must be stopped.

|

|

|

Warranty/Time Information

|