Oil sump in car

| Oil sump in car |

| To remove |

| 1. |

Remove the upper engine cover and insulation.

|

|

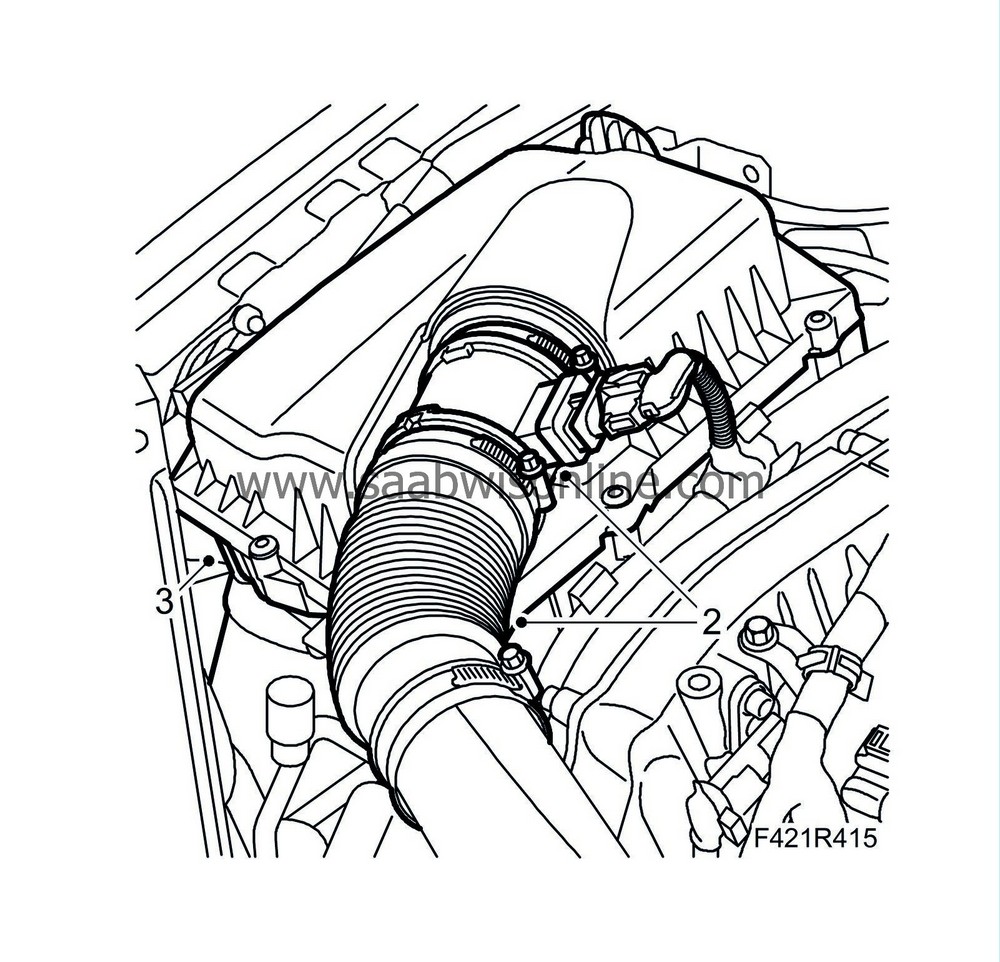

| 2. |

Remove the turbocharger intake hose and unplug the mass air flow sensor connector.

|

|

| 3. |

Remove the air cleaner cover and the air cleaner. Detach the inlet hose and remove the air cleaner casing.

|

|

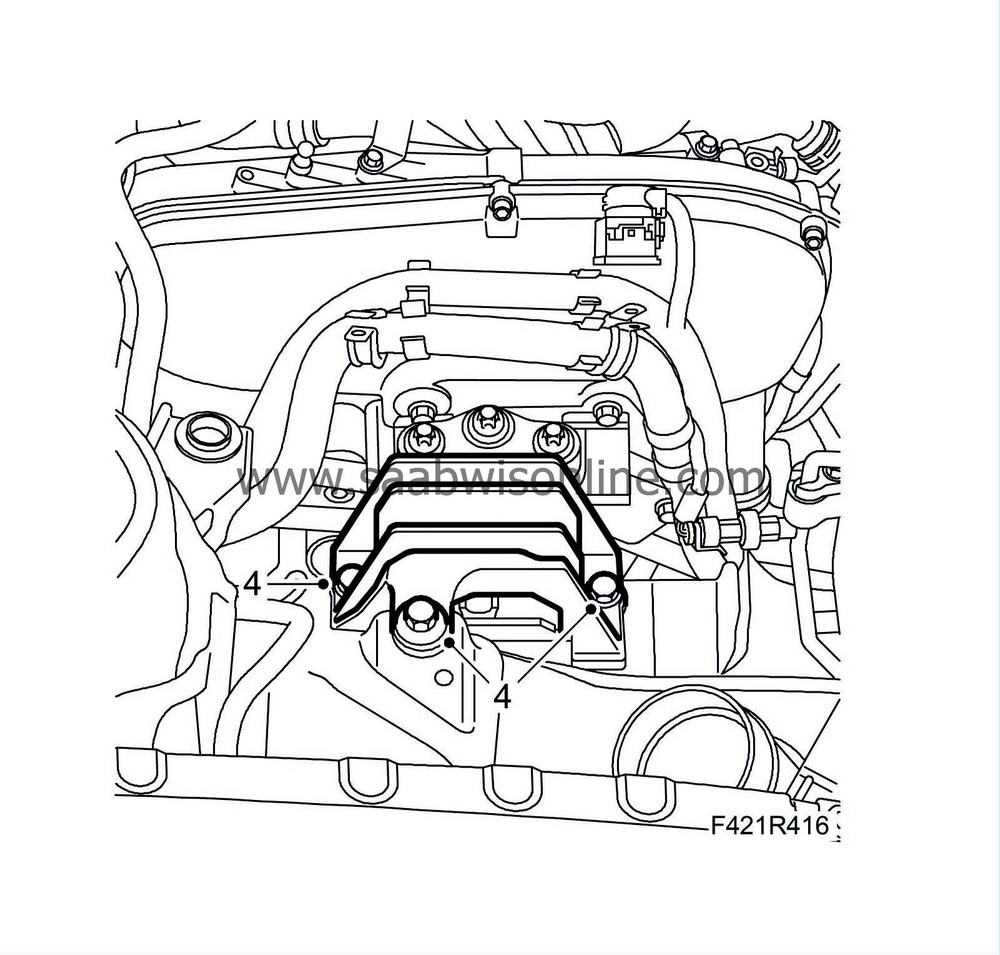

| 4. |

Remove the engine pad bolts from the body.

|

|

| 5. |

Remove the upper retaining screw on the dipstick tube.

|

|

| 6. |

Raise the car and remove the front right wheel.

|

|

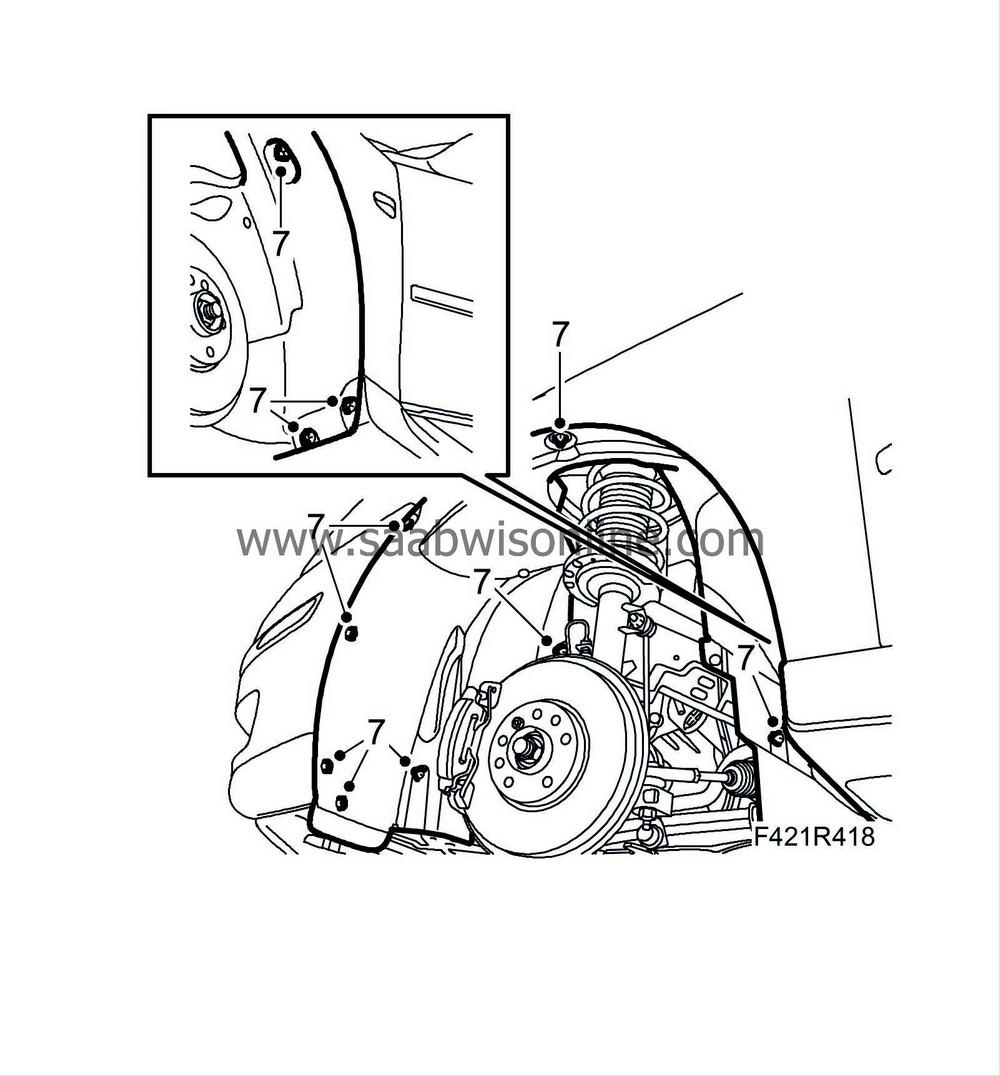

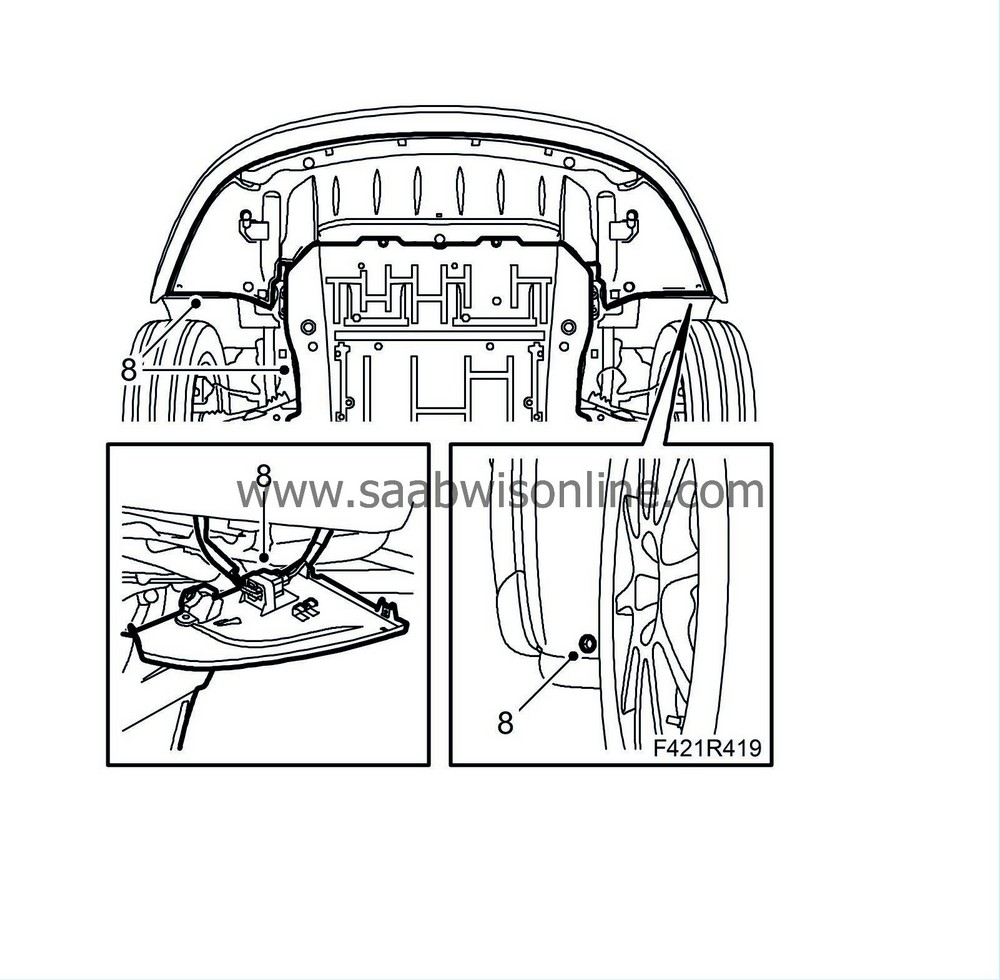

| 7. |

Remove the right wing liner.

|

|

| 8. |

Remove the lower engine cover and the oil sump insulation.

|

|

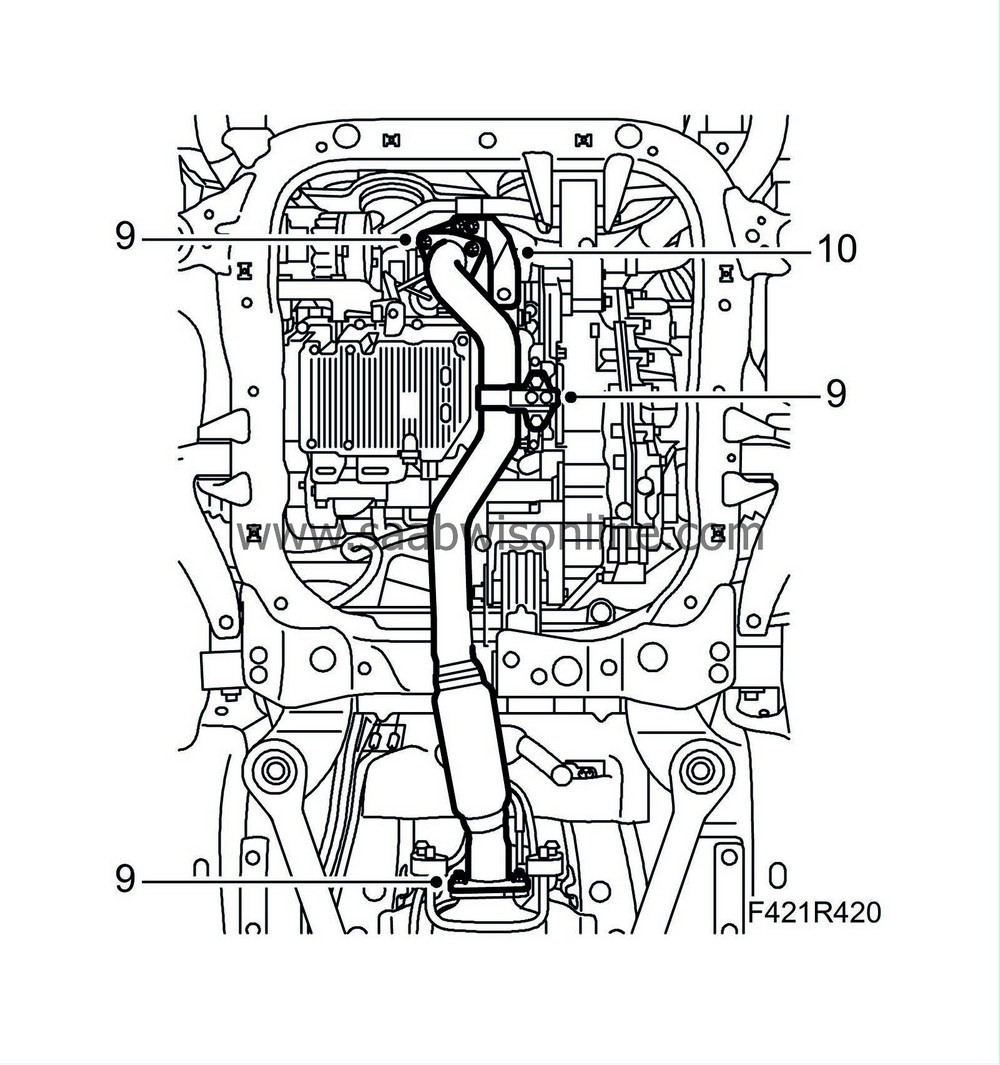

| 9. |

Remove the front exhaust pipe.

|

|

| 10. |

Remove the catalytic converter lower mounting.

|

|

| 11. |

Place a receptacle under the car and drain the engine oil.

|

|

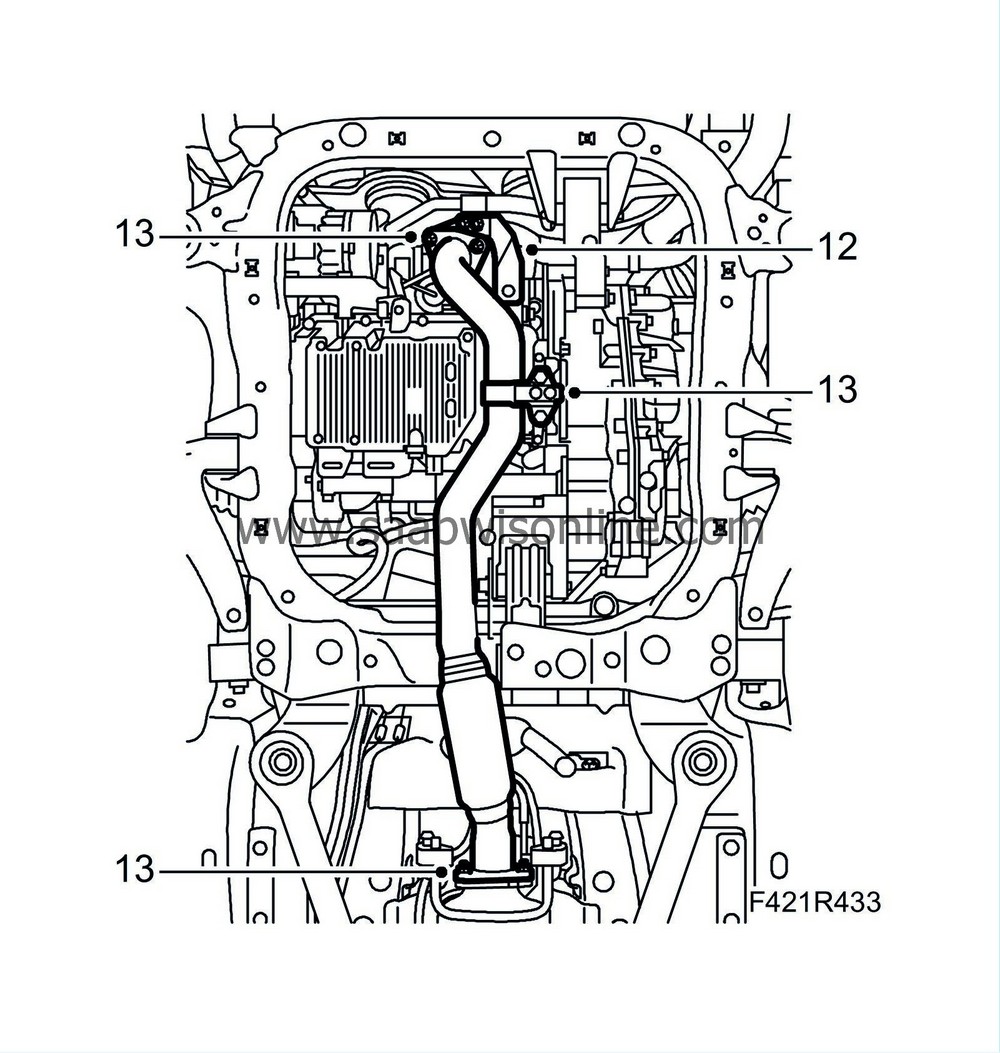

| 12. |

Fit the oil plug with a new seal.

Tightening torque 25 Nm (18 lbf ft)

|

|

| 13. |

Man:

Drain the gearbox oil.

|

|

| 14. |

Man:

Fit the gearbox oil plug.

Tightening torque 25 Nm (18 lbf ft) |

|

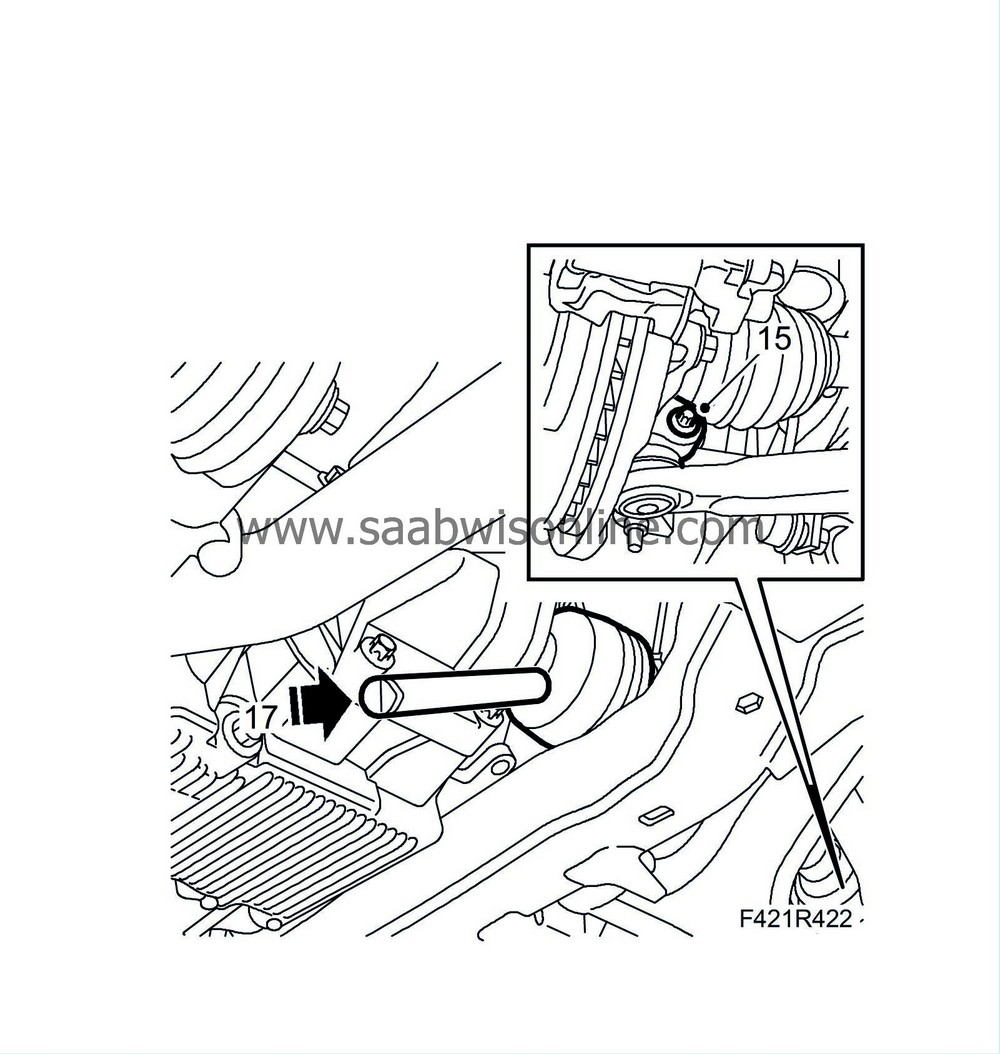

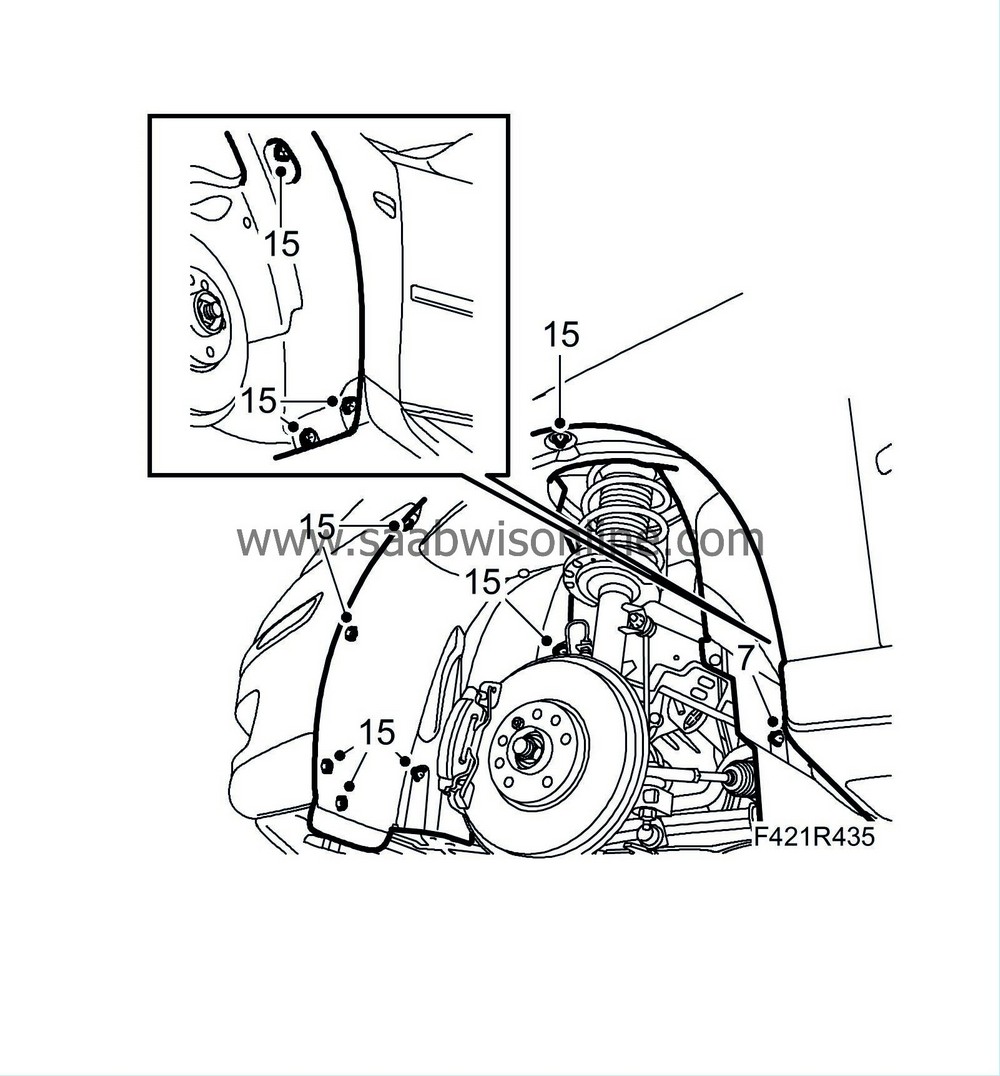

| 15. |

Remove the outer ball joint form the suspension arm.

|

|

| 16. |

Let down the suspension arm and lay a

83 95 238 Wedge

between the anti-roll bar and the suspension arm.

|

|

| 17. |

Knock out the inner drive shaft universal joint with a mallet and brass drift.

|

|

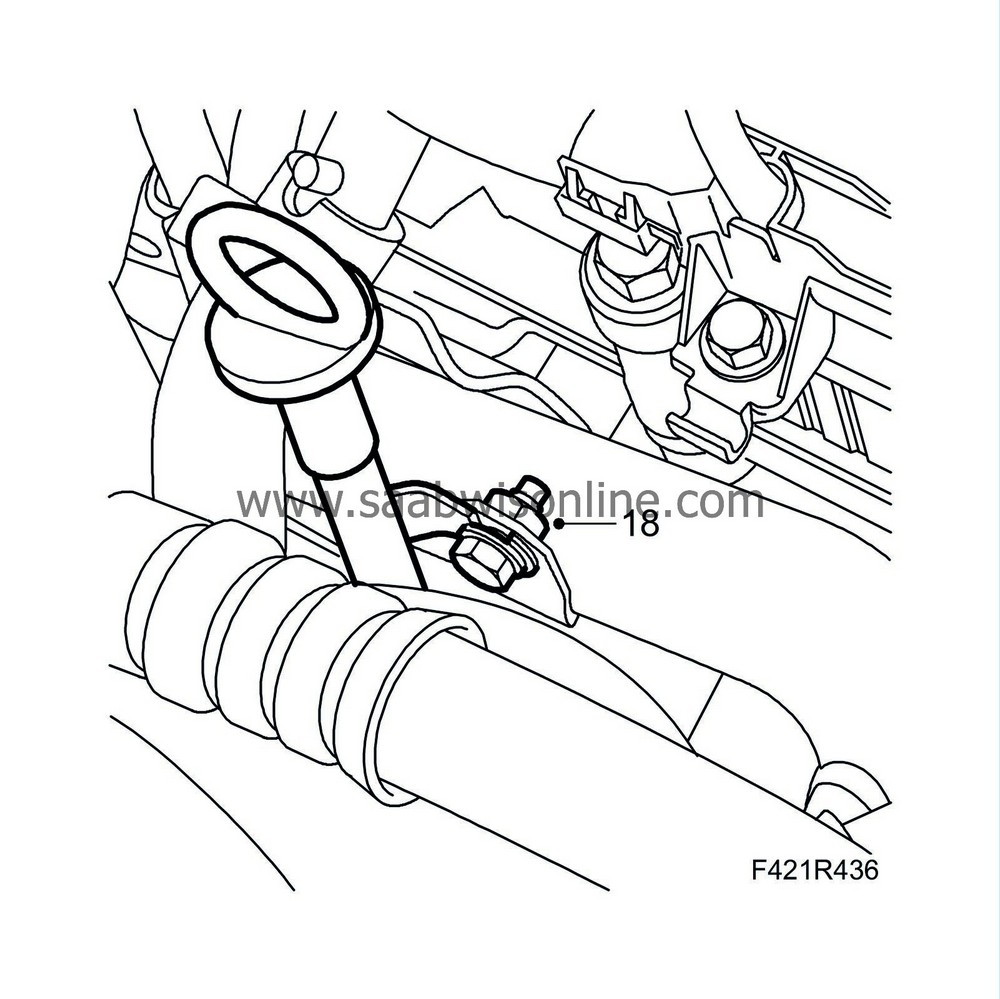

| 18. |

Remove the bolts and pull out the intermediate shaft.

|

|

| 19. |

Remove the intermediate shaft bracket.

|

|

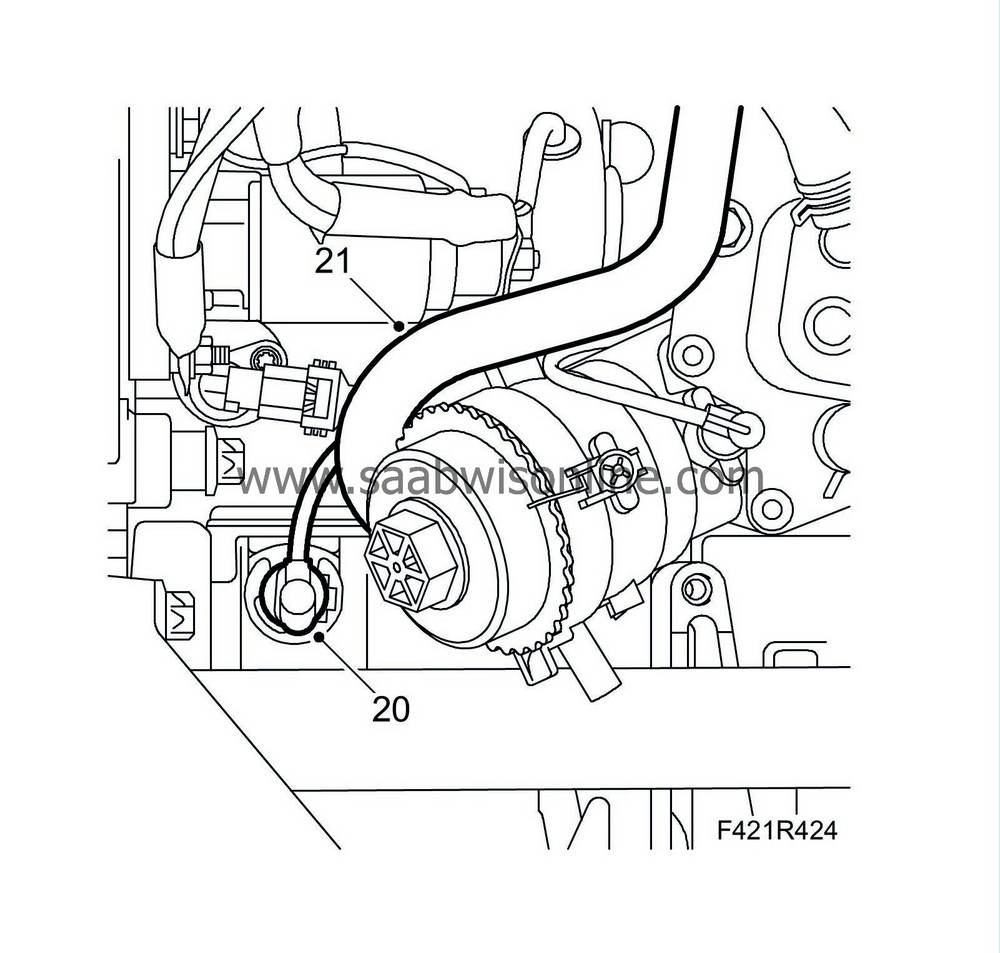

| 20. |

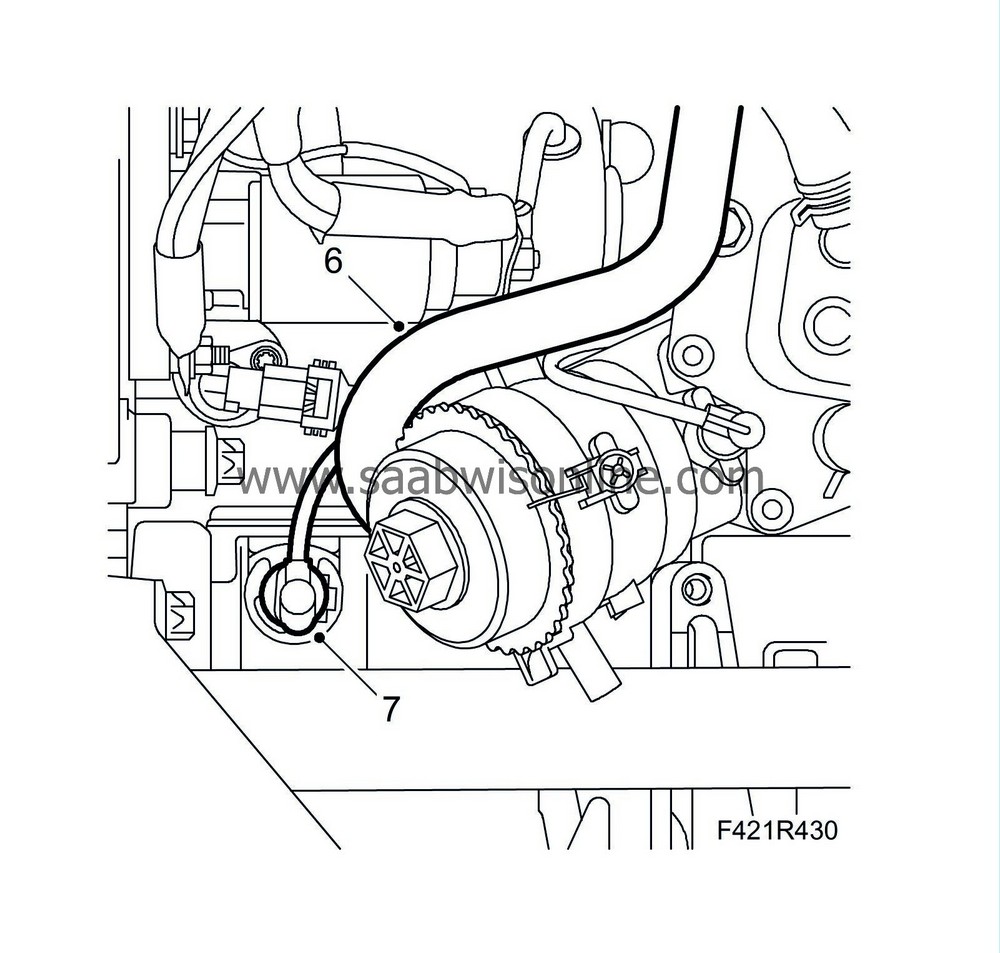

Detach the connector to the oil level sensor.

|

|

| 21. |

Remove the crankcase ventilation hose from the oil sump.

|

|

| 22. |

Remove the lower bolts from the A/C compressor bracket.

|

|

| 23. |

Remove the lower retaining screw on the dipstick tube.

|

|

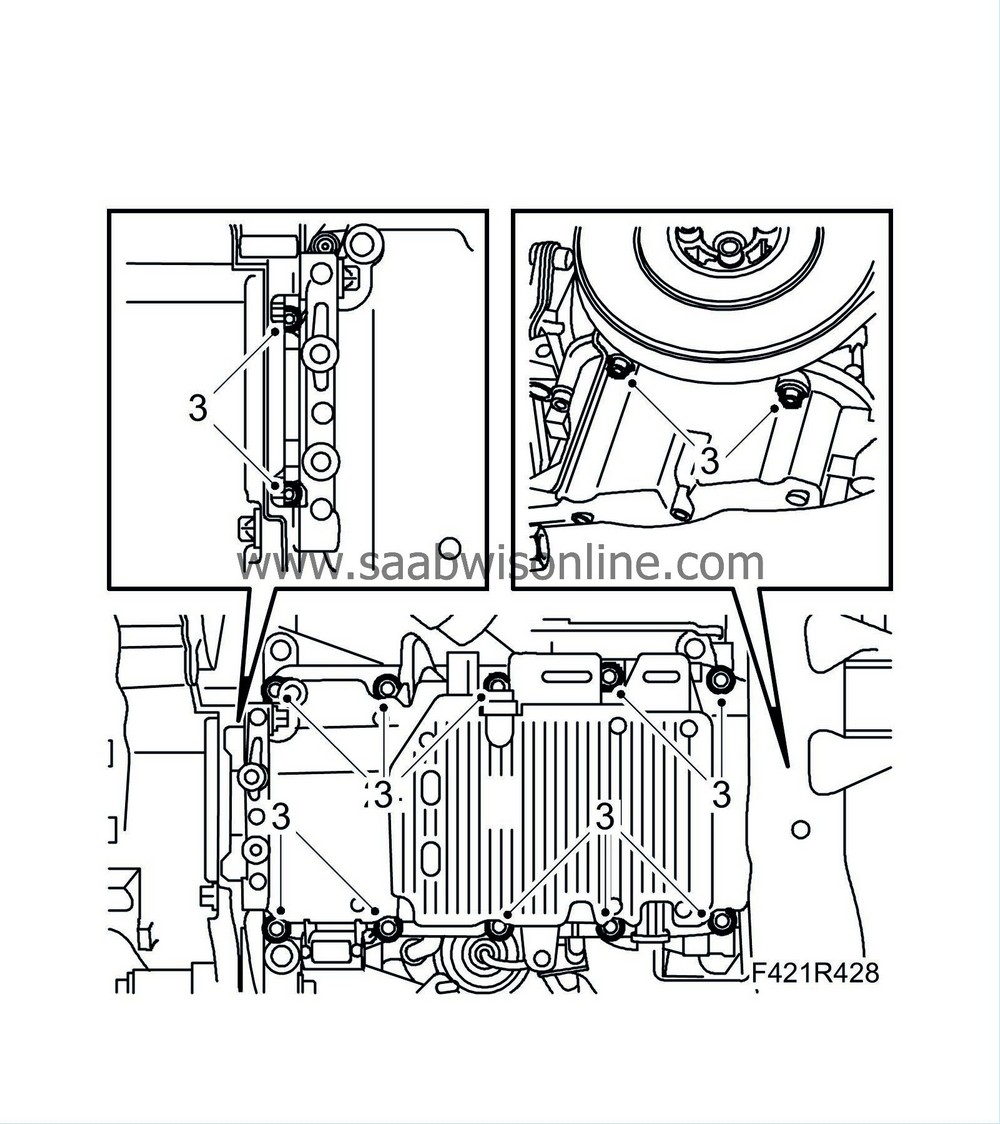

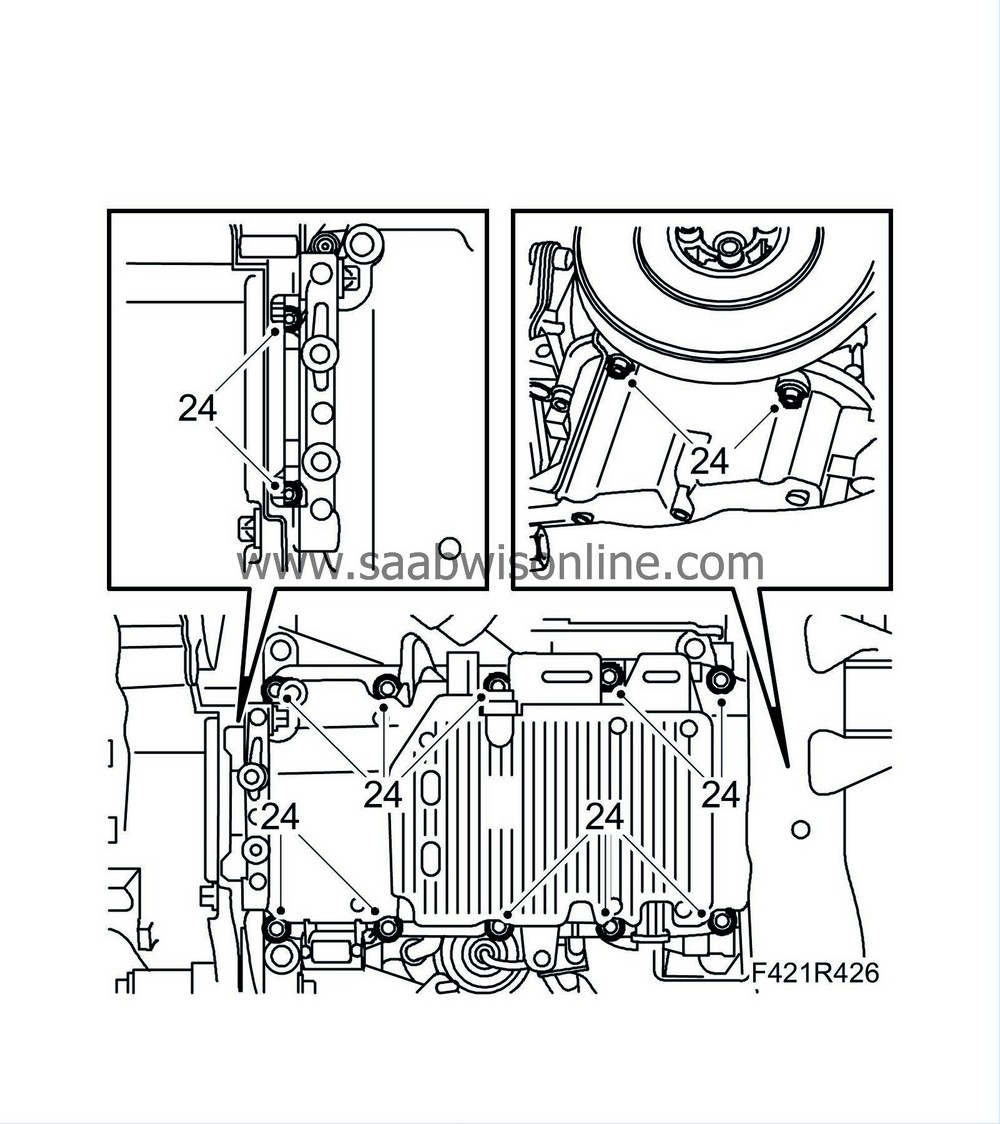

| 24. |

Remove the plugs from the gearbox openings. Remove the oil sump's screws. Use

32 025 015 Extension piece Ribe M7

and

32 025 016 Extension piece Ribe M8

. Use the former behind the flywheel/driver plate.

|

||||||||||

| 25. |

Place a screwdriver between the sump and the timing cover at the AC compressor bracket and carefully prise the oil sump loose.

|

|

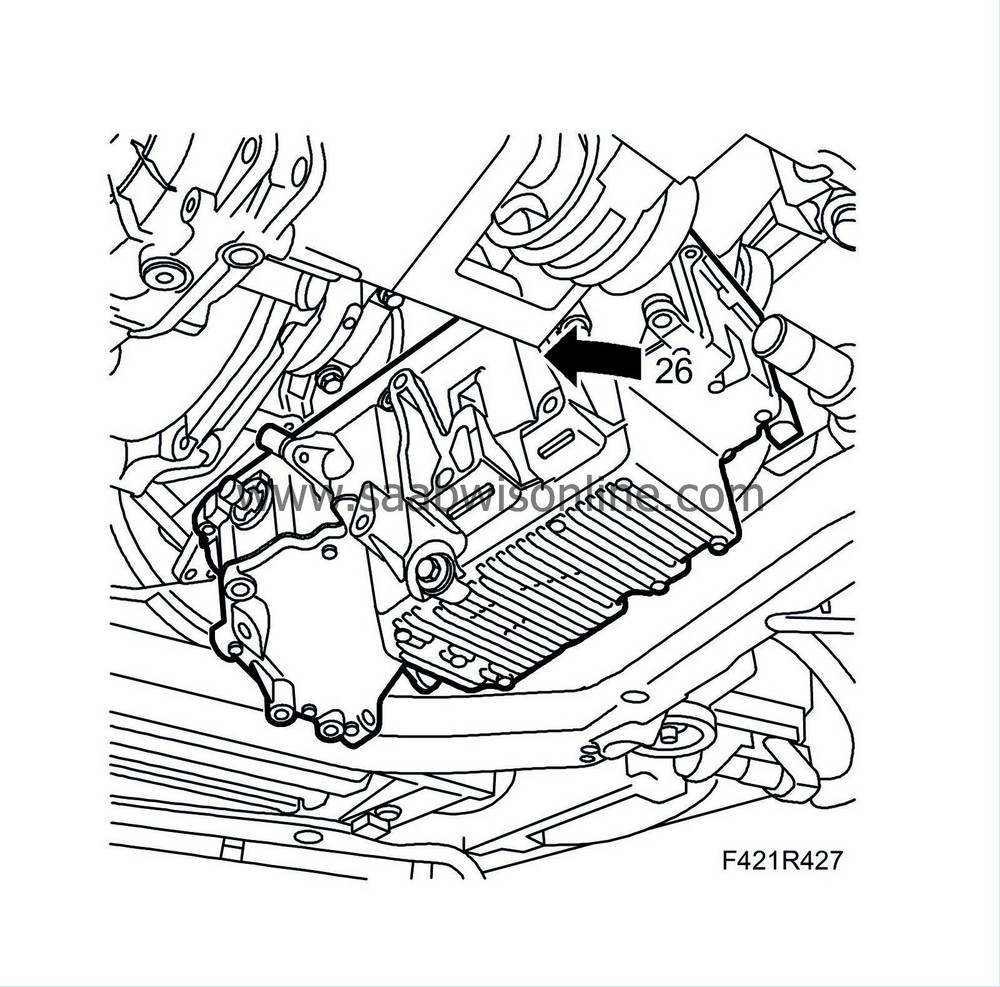

| 26. |

Place a gearbox lift under the A/C compressor bracket and raise the engine about 20 mm. Turn the sump a quarter of a turn and lift it down.

|

|

| To fit |

| 1. |

Clean the engine block and sump sealing surfaces. Remove any contaminants in the oil sump.

|

|

| 2. |

Apply a bead of

90 543 772 Silicone flange sealant

to the oil sump sealing surface.

|

|

| 4. |

Fit the dipstick tube with a new seal and tighten the screw.

|

|

| 5. |

Fit the lower bolts to the A/C compressor bracket.

|

|

| 6. |

Fit the crankcase ventilation hose to the oil sump.

|

|

| 7. |

Plug in the oil level sensor connector.

|

|

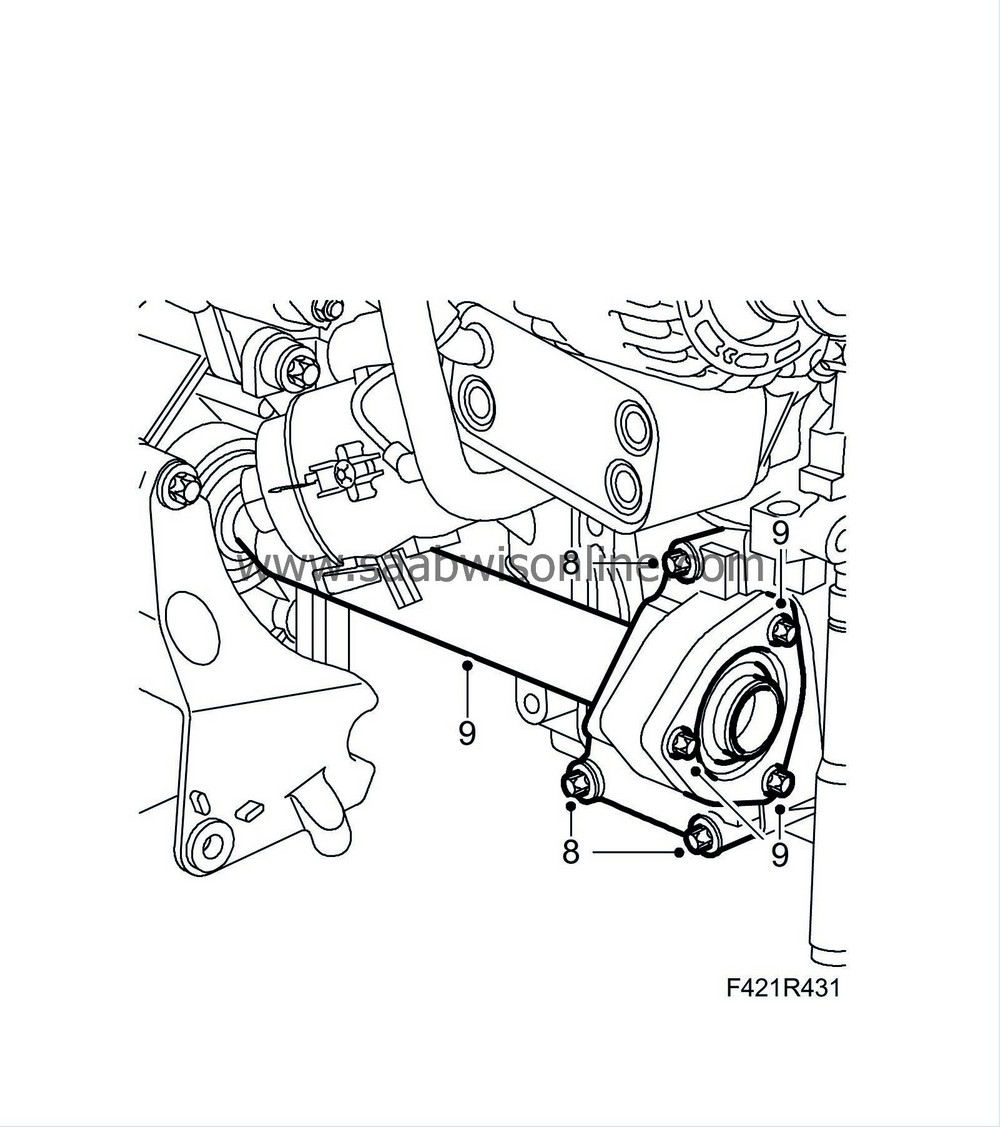

| 8. |

Fit the intermediate shaft bracket.

Tightening torque 55 Nm (41 lbf ft).

|

|

| 9. |

Position

83 95 162 Protective collar, drive shafts

in the shaft seal. Insert the intermediate shaft into the gearbox until approximately 20 mm of the shaft remains. Pull out the collar and push in the rest of the intermediate shaft. Fit the bolts.

Tightening torque 55 Nm (41 lbf ft). |

|

| 10. |

Lubricate the drive shaft splines with

90 513 210 Universal paste

and make sure the rubber seal is in place on the shaft.

|

|

| 12. |

Fit the catalytic converter lower mounting.

|

|

| 13. |

Fit the front exhaust pipe and the oil sump insulation.

Tightening torque 25 Nm (18 lbf ft) |

|

| 14. |

Fit the lower engine cover.

|

|

| 15. |

Refit the right wing liner.

|

|

| 16. |

Lower the car somewhat and fit the front right wheel. See

Wheels

.

|

|

| 17. |

Fill oil in the gearbox.

Man: see Filling/changing the gearbox oil Aut: see Checking/adjusting oil level . |

|

| 18. |

Fit the upper retaining screw on the dipstick tube.

|

|

| 19. |

Tighten the bolts between the engine pad and the body.

Tightening torque, body, 40 Nm + 60° (30 lbf ft + 60°).

|

|

| 20. |

Fit the air cleaner casing and intake hose.

|

|

| 21. |

Fit the air cleaner and air cleaner cover. Connect mass air flow sensor connector.

|

|

| 22. |

Fit the turbocharger inlet hose.

|

|

| 23. |

Fill with engine oil as specified, see

Recommended oil quality

.

|

|

| 24. |

Fit the insulation and the upper engine cover.

|

|

| 25. |

Connect an exhaust extractor and start the engine. Switch off the engine and wait 2-5 minutes. Check the oil level and adjust if necessary.

|

|