Oil sump, Z19DTR

| Oil sump, Z19DTR |

| To remove |

| 1. |

Place the engine on a stand.

|

|

| 2. |

Drain the engine oil.

|

|

| 3. |

Rotate the engine 180° on the stand.

|

|

| 4. |

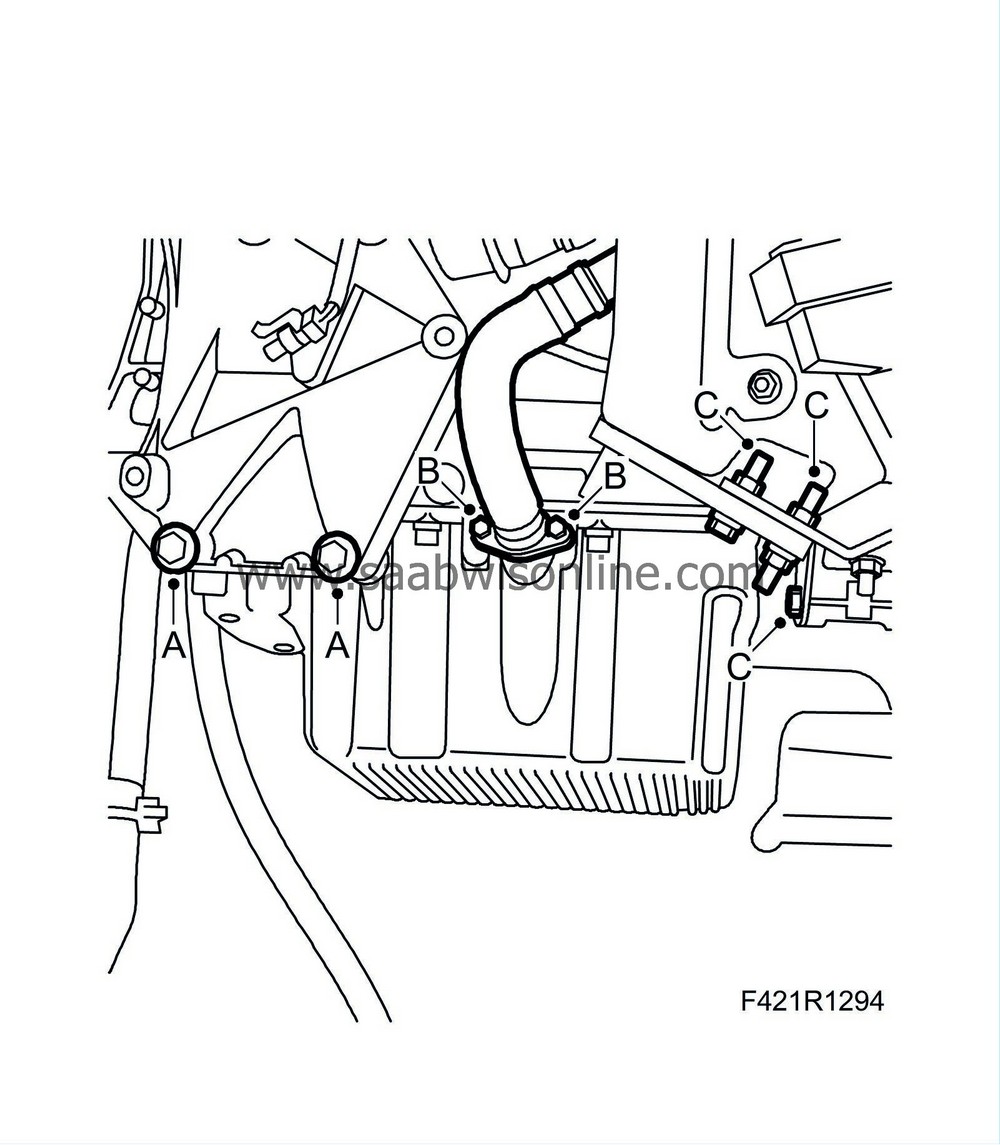

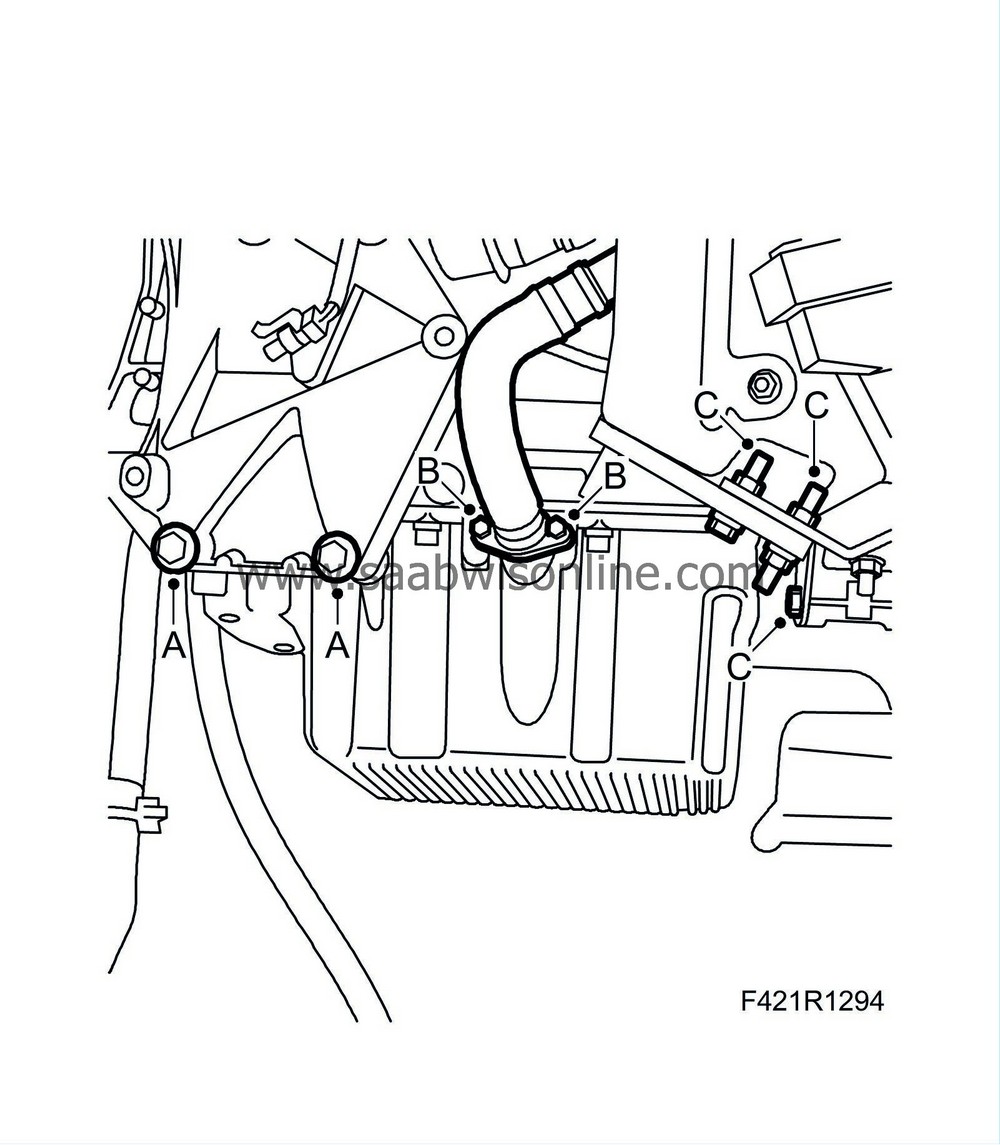

Remove the following on the front of the engine:

|

|

| • |

Remove the bolts (A) of the AC pump mounting.

|

| • |

Remove the bolts (B) of the turbocharger oil return pipe.

|

| • |

Remove the bolts (C) of the catalytic converter's lower mounting.

|

| 5. |

Remove the oil sump.

|

|

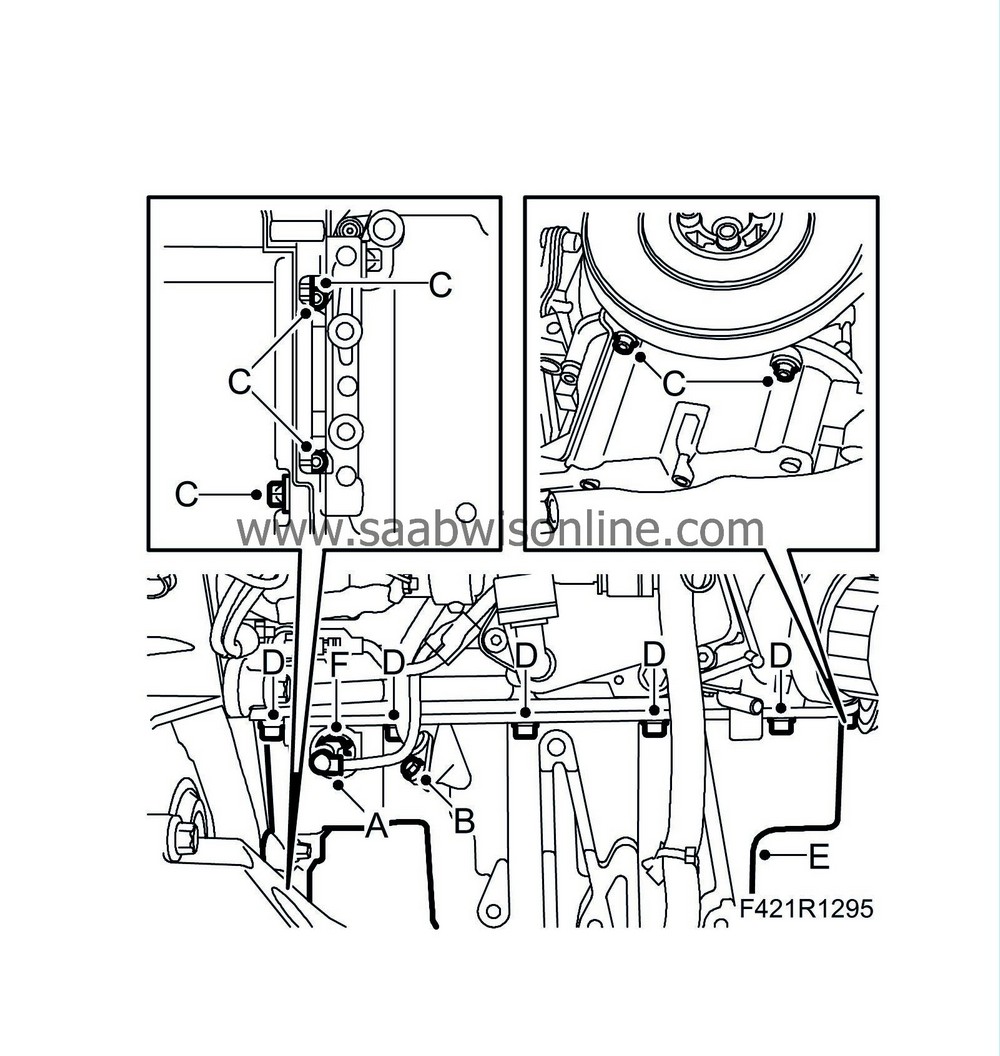

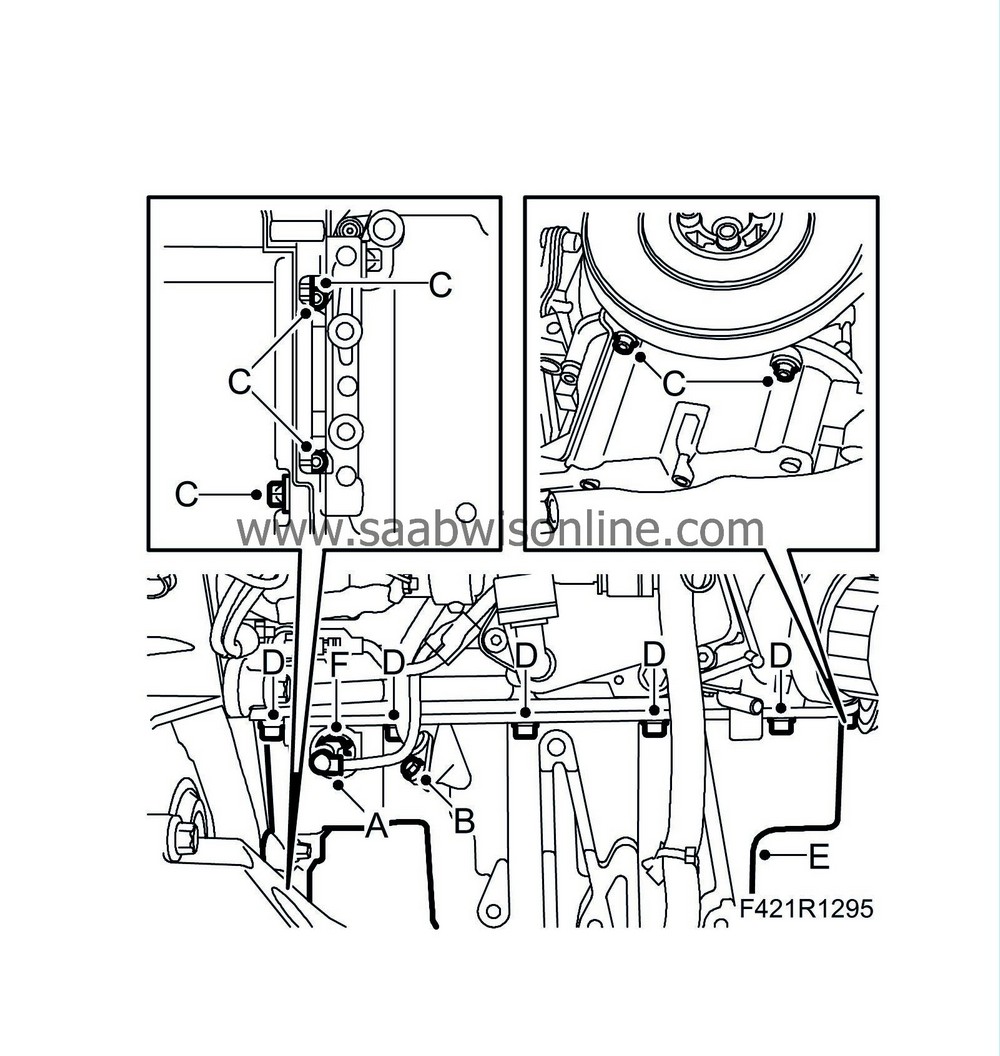

| • |

Unplug the oil level sensor (A) connector.

|

| • |

Detach the crankcase ventilation pipe (B).

|

| • |

Remove the front and rear bolts (C) from the oil sump using

32 025 015 Extension piece Ribe M7

.

|

| • |

Remove the side bolts (D) on the oil sump using

32 025 016 Extension piece Ribe M8

.

|

| • |

Place a screwdriver between the sump and the timing cover at the AC compressor bracket and carefully prise the oil sump loose.

|

| • |

Turn the sump ninety degrees and lift it down.

|

| 6. |

With oil sump replacement

: Remove the oil separator cover and the oil level sensor.

|

|

| To fit |

| Note | ||

|

Clean the sealing surfaces of the oil sump and engine. |

| 1. |

With oil sump replacement

: Fit the oil separator cover in the oil sump. Fit the oil level sensor.

|

|

| 2. |

Fit the oil sump.

|

|

| • |

Apply 90 543 772 Silicone flange sealant to the oil sump sealing surface.

|

| • |

Fit the oil sump (E) carefully so that the sealing compound is not disturbed.

|

| • |

Fit the side bolts (D) using

32 025 016 Extension piece Ribe M8

. Tighten the front and rear bolts (C) with

32 025 015 Extension piece Ribe M7.

Tightening torque, M6, 9 Nm (7 lbf ft) Tightening torque, M8 25 Nm (18 lbf ft) Tightening torque, M10 40 Nm (30 lbf ft) |

| • |

Fit the crankcase ventilation pipe (B).

|

| • |

Fit the oil level sensor connector (A).

|

| 3. |

Fit the following on the front of the engine:

|

|

| • |

Fit the bolts (C) of the catalytic converter's lower mounting.

|

| • |

Fit the bolts (B) of the turbocharger oil return pipe

Tightening torque 25 Nm (18 lbf ft) |

| • |

Fit the bolts (A) of the AC pump mounting.

|

| 4. |

Remove the engine from the engine stand.

|

|||||||