(TA242-0827) Injector cleaning

|

TECHNICAL ADVICE - Quick information for your help

|

|

Bulletin Nbr:

|

TA242-0827

|

|

Date:

...........

|

November 2008

|

|

Market:

|

Biopower

|

Saab 9-3 and 9-5 with Bio-Power engine.

Injector reduced flow or disturbed spray patterns.

In some cases when the customers don't have follow the advise instruction,

to drive at fuel every 10.000 km and the injectors have reduced flow.

Customers experiencing severe driveability/start behaviors and/or misfire.

A. Deposits clean up procedure using gasoline fuel

|

•

|

Recommended distance between gasoline clean up would be every

8 - 10 000 km for Saab 9-3 and every 25 – 35 000 km for Saab 9-5.

|

|

•

|

Total clean up is reached with gasoline containing < 40% Ethanol.

|

|

•

|

A fuel containing less than 40% Ethanol can be archived by:

Saab 9-5, fill up a minimum of 40 litres of gasoline

Saab 9-3, fill up a minimum of 35 litres of gasoline

|

|

•

|

Customers experiencing severe driveability/start problems and/or

misfire and not able to fill up with the recommended volumes of gasoline needs

an emergency clean up.

|

|

•

|

The use of an external fuel tank to feed gasoline into the fuel

system is a feasible solution for emergency deposit clean up on FlexFuel engines.

|

|

•

|

Even after a emergency clean up it is recommended that the customer

run a tank of gasoline to make sure the complete system is cleaned.

|

B. Deposits clean up procedure using separate gasoline

feed to fuel rail :

(The described method below is valid for 9-3 but in principle same for

9-5)

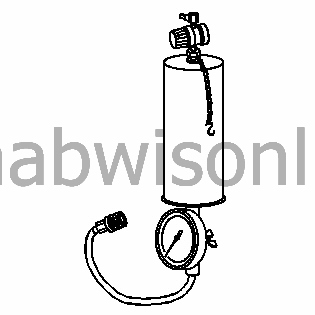

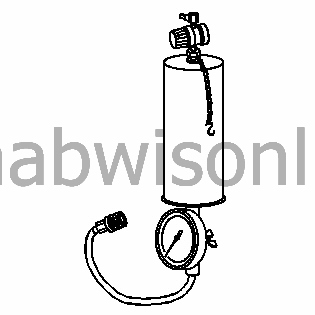

Use the equipment below or similar. All necessary tools below, could

be ordered from Your SPX Distributor.

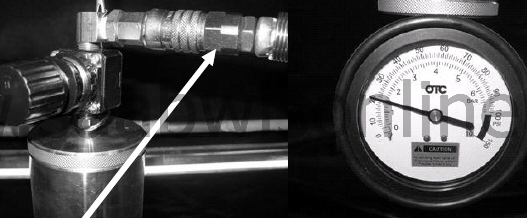

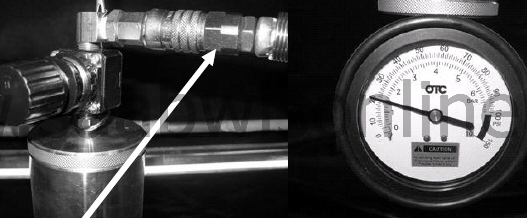

Fuel injector cleaner canister P/NSPX J 35800-A

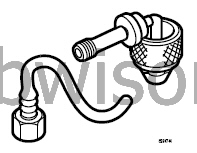

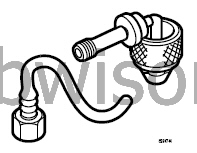

Hose: P/N 8393860

Fuel pressure adapter: P/N 8394744

|

•

|

Have compressed air available.

|

|

1.

|

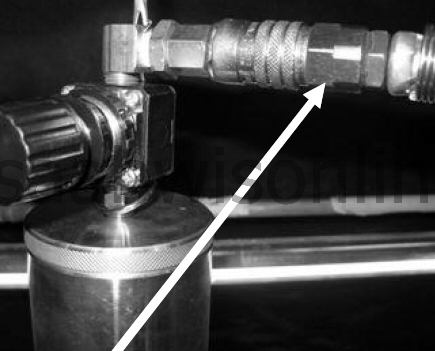

Release the connection nipple in to end of the hose J-35800-A

|

|

2.

|

Connect hose P/N 8393878

|

|

3.

|

Connect fuel pressure adapter P/N 8394744.

OTC 7448 Fuel Injector Cleaner

|

|

4.

|

Disconnect the fuel pump fuse

|

|

5.

|

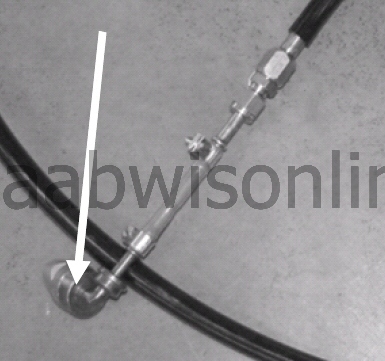

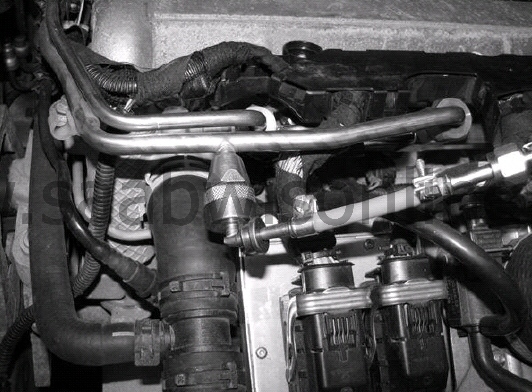

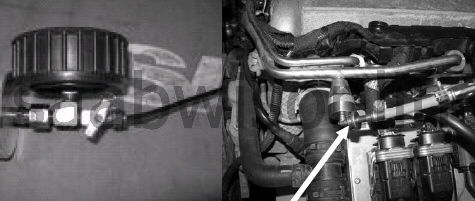

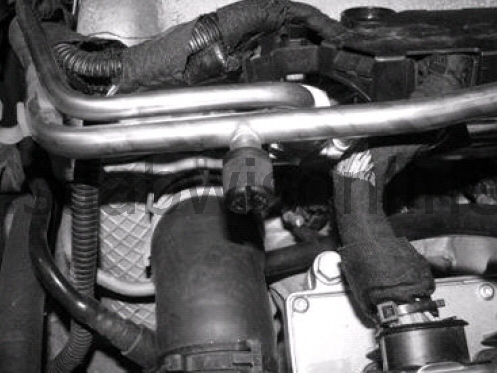

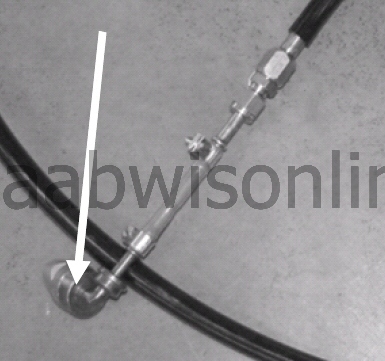

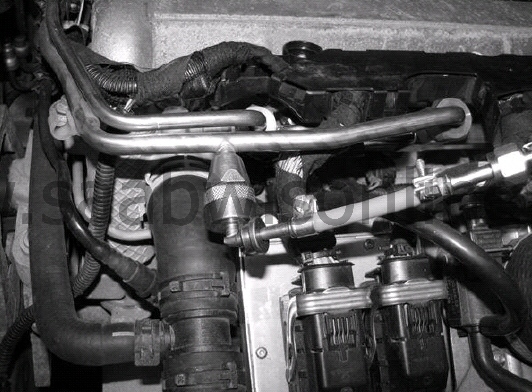

Adapting the equipment fuel hose to fit vehicle fuel line inspection

valve.

Connection preferably closed when connecting/disconnecting the valve.

|

|

6.

|

Start by closing the bottom fuel feed valve.

|

|

7.

|

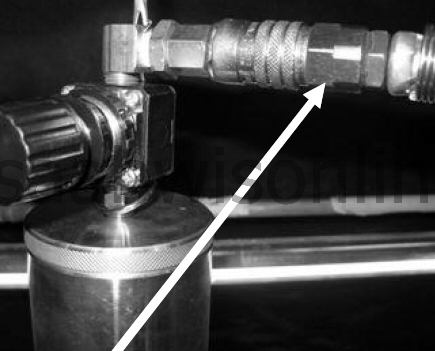

Fill with 0,3 – 0,4 litre of gasoline into the equipment.

Check the filler cap sealing and close cap tightly.

|

|

8.

|

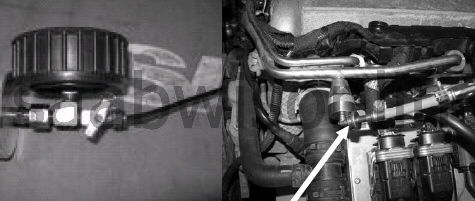

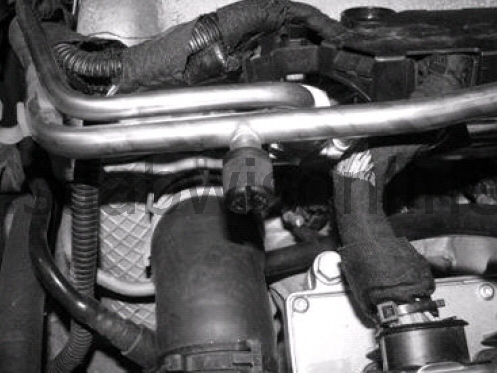

Place the equipment in a suitable place, preferably as in picture.

|

|

9.

|

Find the inspection valve on the fuel system and remove the valve

cap.

|

|

10.

|

Connect the equipment fuel hose to the vehicle fuel line.

|

|

11.

|

Connect the compressed air hose and adjust the pressure to 1,2

– 1,4 bar.

|

|

12.

|

Open both valves.

|

|

|

•

|

Make sure the vehicle is standing securely.

|

|

|

•

|

If indoor, connect exhaust suction hose to exhaust pipe.

|

|

|

•

|

Start vehicle and run on idle. If needed adjust fuel pressure

to get smooth idle, range should be between 1,2 to 1,4 bar.

|

|

|

•

|

Run on idle until fuel tank is empty, or a minimum of 5 minutes.

|

|

|

•

|

Stop the engine, turn off the ignition key.

|

|

13.

|

Disconnect the compressed air hose.

|

|

14.

|

Close both valves, and disconnect the equipment fuel hose from

the vehicle fuel line, notice that there is a risk of fuel leak.

|

|

15.

|

Return the inspection valve cap.

|

|

16.

|

Fit the fuel pump fuse, the clean up is done!

|