MIG brazing, CV (EU)

| MIG brazing, CV (EU) |

Plate damage where MIG brazing exists involves a new method and requires a new type of equipment. Before Saab workshops have been trained and have procured new equipment, damaged cars with MIG brazing must be taken to the closest Opel workshop which has MIG brazing equipment. A list of "Opel dealer MIG Brazing equipment" is in our database IRIS under Service Information - Technical News - Group 8 Body- MIG-Brazing. The list will be updated regularly and will be found under "What's New?" in IRIS. Where appropriate where Opel authorised workshops do not have suitable equipment, contact one of the six approved suppliers for support. The list of "MIG- Brazing equipment suppliers" is in our database IRIS under Service Information - Technical News - Group 8 Body- MIG-Brazing.

Different settings for the welding machine, the so-called "welding parameters" are required depending on equipment and plate thickness. The following documents contain parameters for six approved pieces of equipment. Ensure that the Opel authorised workshops and the independent workshops engaged have the parameters for the localised areas and relevant method from WIS. Pure argon gas must be used in all cases and the welding rod must be 1 mm.

|

|||||||

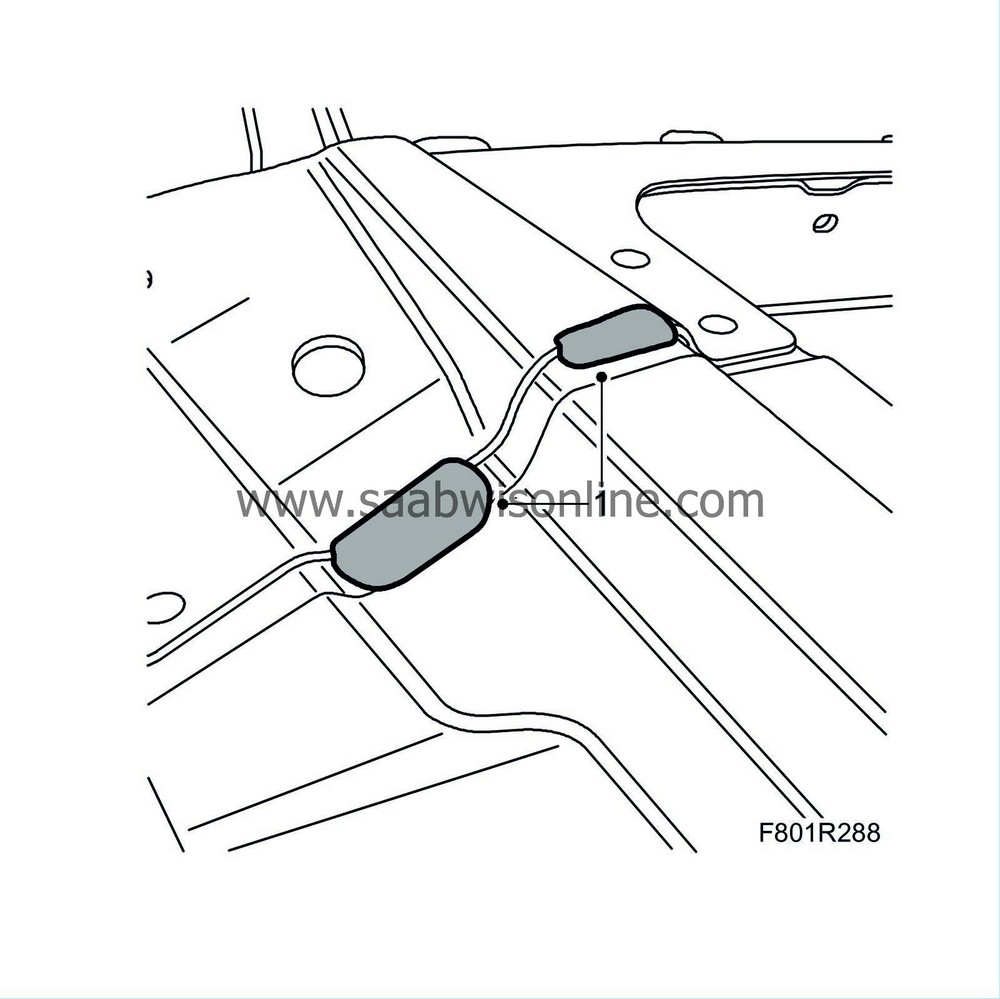

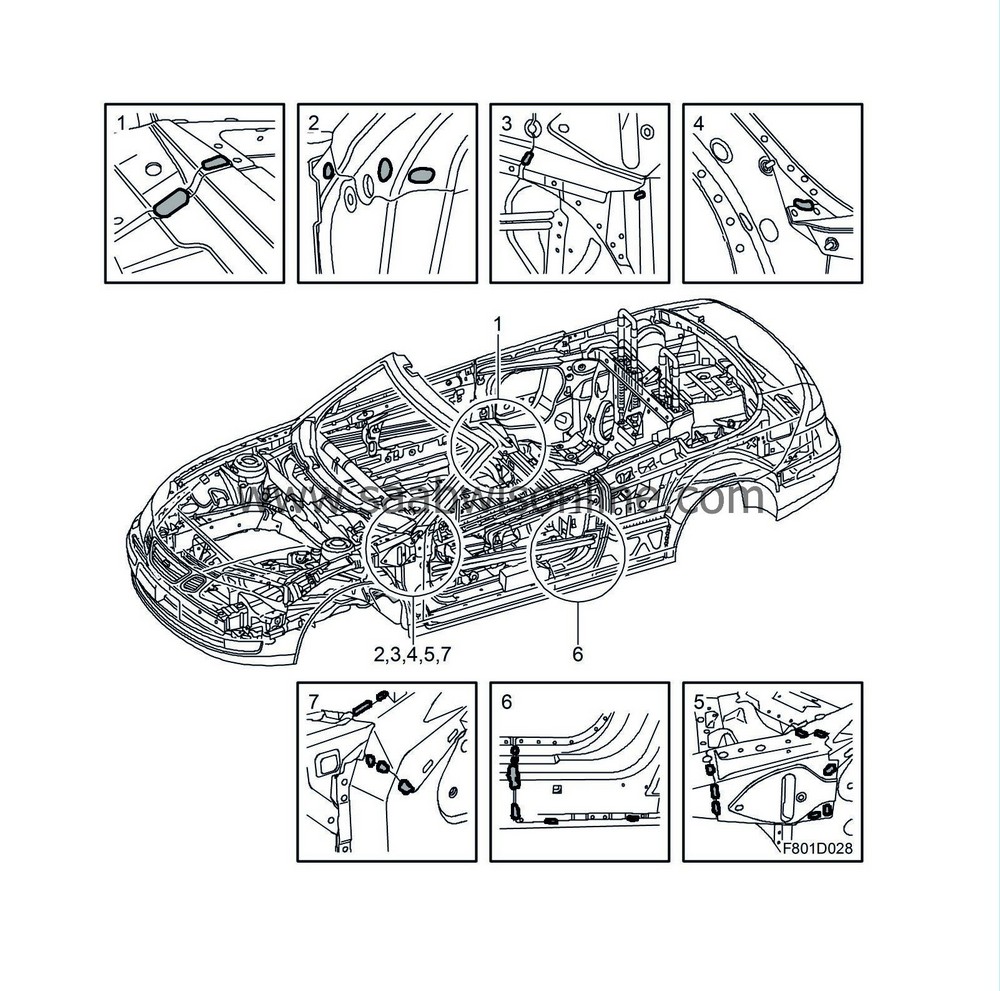

| Parameters for upper windscreen frame |

|

Area

|

Weld joint type

|

Plate combination

|

Program

|

Method

|

Rod feed

|

Ampere

|

Manufacturer

|

| 1 | Overlap | 2.0/1.0 | 4 | Pulse | 2.6 | Kemppi | |

| 1 | Overlap | 2.0/1.0 | 6 | 5 | Cloos | ||

| 1 | Overlap | 2.0/1.0 | 2 | Short-arc | 4 | ElmaTech | |

| 1 | Overlap | 2.0/1.0 | Pulse | 60 (Trim -2) | Car-o-Liner | ||

| 1 | Overlap | 2.0/1.0 | 4 | Pulse | 3.3 | Fronius | |

| 1 | Overlap | 2.0/1.0 | 4 | Pulse | 4.3 | Wieländer |

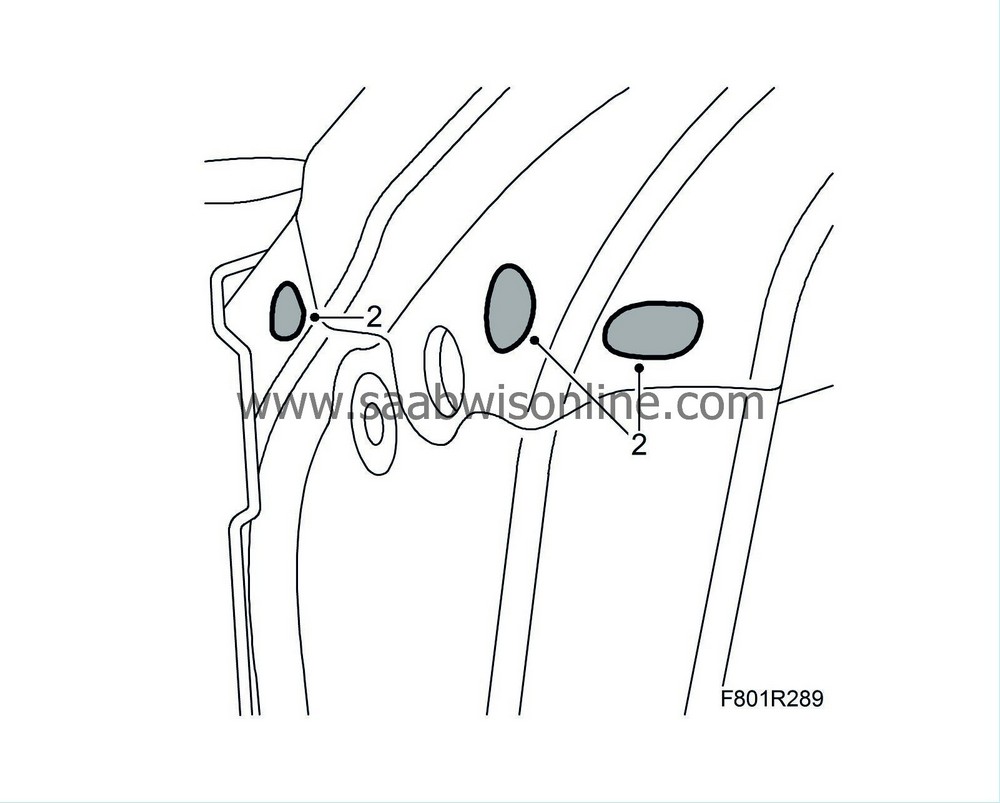

| Parameters for A-pillar/door opening |

|

Area

|

Weld joint type

|

Plate combination

|

Program

|

Method

|

Rod feed

|

Ampere

|

Manufacturer

|

| 2 | Plug weld | 1.2/2.2 | 4 | Pulse | 2.6 | Kemppi | |

| 2 | Plug weld | 1.2/2.2 | 6 | 5 | Cloos | ||

| 2 | Plug weld | 1.2/2.2 | 2 | Short-arc | 4 | ElmaTech | |

| 2 | Plug weld | 1.2/2.2 | Pulse | 60 (Trim -2) | Car-o-Liner | ||

| 2 | Plug weld | 1.2/2.2 | 4 | Pulse | 3.3 | Fronius | |

| 2 | Plug weld | 1.2/2.2 | 4 | Pulse | 4.3 | Wieländer |

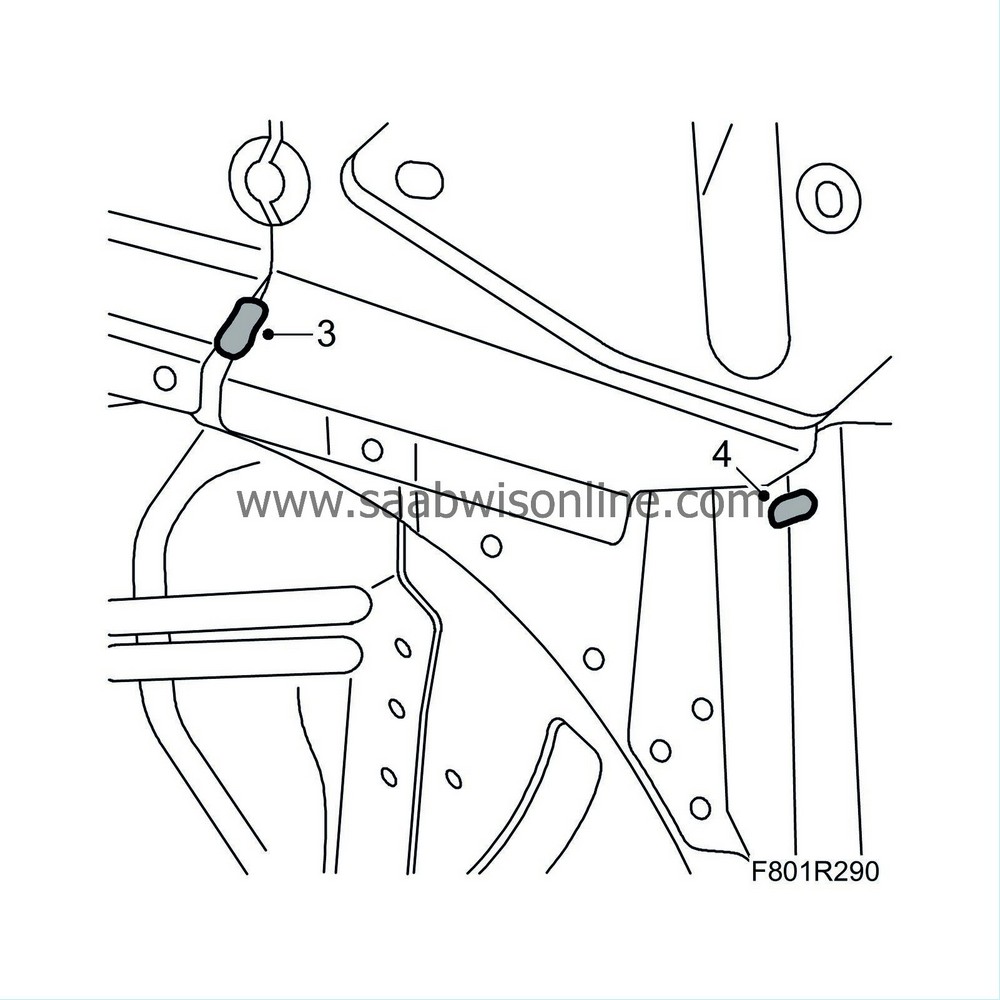

| Parameters for extension piece member, lower area |

|

Area

|

Weld joint type

|

Plate combination

|

Program

|

Method

|

Rod feed

|

Ampere

|

Manufacturer

|

| 3 | Overlap | 1,1/1.2 | 5 | Pulse | 2.9 | Kemppi | |

| 4 | Overlap | 1.1/2.2 | 4 | Pulse | 2.7 | Kemppi | |

| 3 | Overlap | 1.1/1.2 | 5 | 5 | 97 | Cloos | |

| 4 | Overlap | 1.1/2.2 | 6 | 5 | 89 | Cloos | |

| 3 | Overlap | 1.1/1.2 | 4 | Short-arc | 5.2 | ElmaTech | |

| 4 | Overlap | 1.1/2.2 | 2 | Short-arc | 4.0 | ElmaTech | |

| 3 | Overlap | 1.1/1.2 | Pulse | 58 (Trim -1) | Car-o-Liner | ||

| 4 | Overlap | 1.1/2.2 | Short-arc | 63 (Trim 0.3) | Car-o-Liner | ||

| 3 | Overlap | 1.1/1.2 | 4 | Pulse | 3.3 | Fronius | |

| 4 | Overlap | 1.1/2.2 | 2 | Short-arc | 2.3 | Fronius | |

| 3 | Overlap | 1.1/1.2 | 4 | Pulse | 4.3 | Wieländer | |

| 4 | Overlap | 1.1/2.2 | 4 | Pulse | 4.3 | Wieländer |

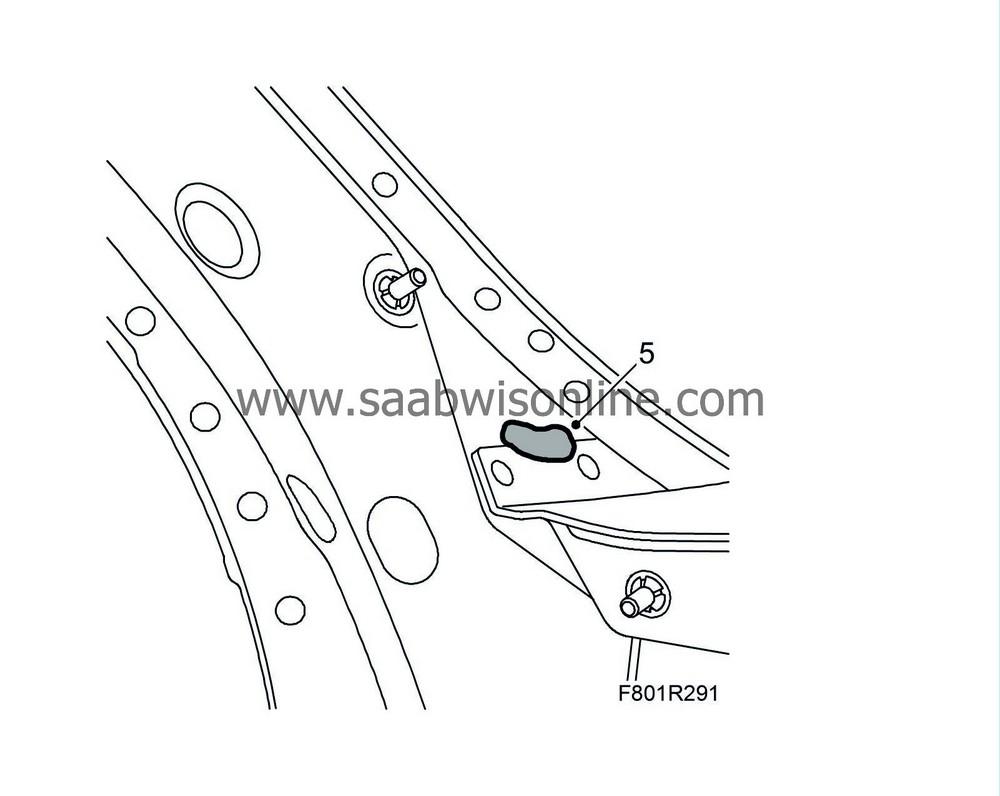

| Parameters for inner A-pillar |

|

Area

|

Weld joint type

|

Plate combination

|

Program

|

Method

|

Rod feed

|

Ampere

|

Manufacturer

|

| 5 | Overlap | 1.0/2.5 | 5 | Pulse | 3 | Kemppi | |

| 5 | Overlap | 1.0/2.5 | 5 | 5 | 97 | Cloos | |

| 5 | Overlap | 1.0/2.5 | 4 | Short-arc | 5.2 | ElmaTech | |

| 5 | Overlap | 1.0/2.5 | Pulse | 58 (Trim -1) | Car-o-Liner | ||

| 5 | Overlap | 1.0/2.5 | 4 | Pulse | 3.3 | Fronius | |

| 5 | Overlap | 1.0/2.5 | 4 | Pulse | 4.3 | Wieländer |

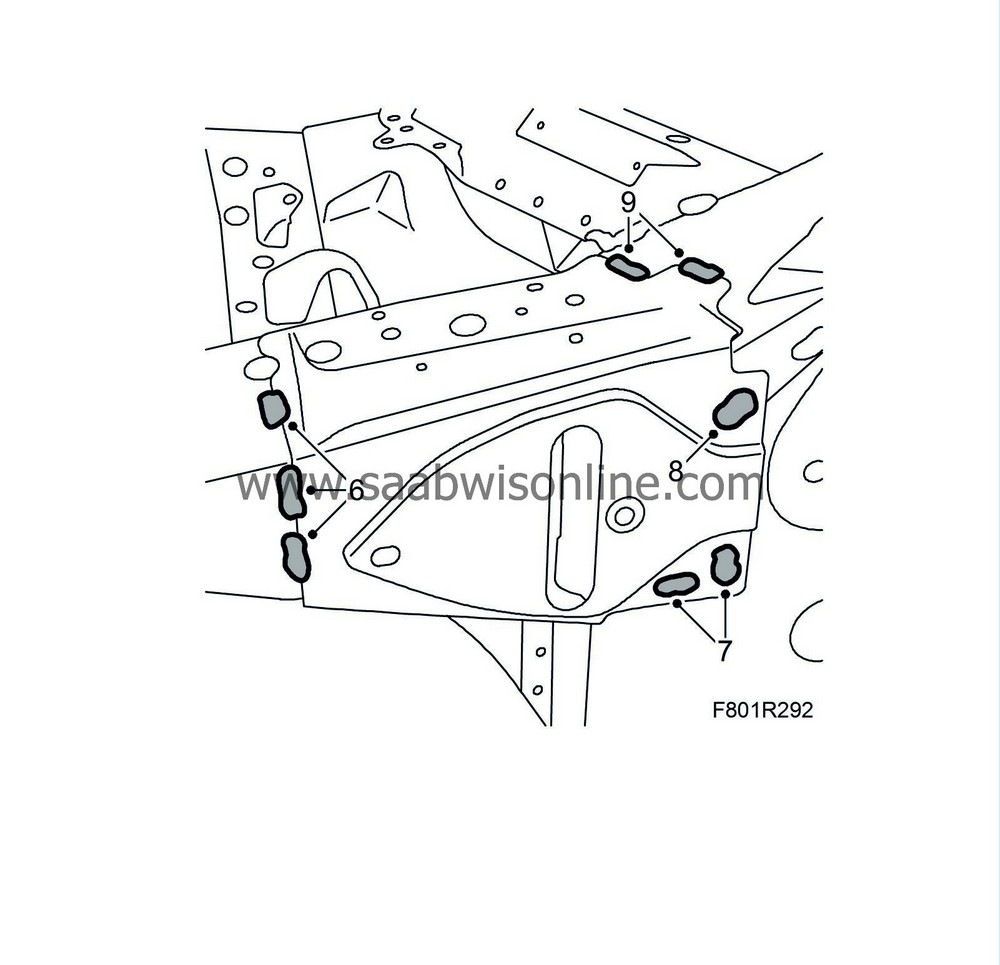

| Parameters for extension piece member, upper area |

|

Area

|

Weld joint type

|

Plate combination

|

Program

|

Method

|

Rod feed

|

Ampere

|

Manufacturer

|

| 6 | Overlap | 1.1 / 1.2 | 4 | Pulse | 2.7 | Kemppi | |

| 7 | Plug weld | 1.1 / 2.2 | 4 | Pulse | 2.7 | Kemppi | |

| 8 | Plug weld | 1.1 / 1.2 / 2.2 | 5 | Pulse | 3.0 | Kemppi | |

| 9 | Overlap | 1.1 / 1.2 | 4 | Pulse | 2.7 | Kemppi | |

| 6 | Overlap | 1.1 / 1.2 | 6 | 5 | Cloos | ||

| 7 | Plug weld | 1.1 / 2.2 | 6 | 5 | Cloos | ||

| 8 | Plug weld | 1.1 / 1.2 / 2.2 | 5 | 5 | 97 | Cloos | |

| 9 | Overlap | 1.1 / 1.2 | 6 | 5 | Cloos | ||

| 6 | Overlap | 1.1 / 1.2 | 2 | Short-arc | 4 | ElmaTech | |

| 7 | Plug weld | 1.1 / 2.2 | 2 | Short-arc | 4 | ElmaTech | |

| 8 | Plug weld | 1.1 / 1.2 / 2.2 | 4 | Short-arc | 5.2 | ElmaTech | |

| 9 | Overlap | 1.1 / 1.2 | 2 | Short-arc | 4 | ElmaTech | |

| 6 | Overlap | 1.1 / 1.2 | Short-arc | 63 (Trim 0.3) | Car-o-Liner | ||

| 7 | Plug weld | 1.1 / 2.2 | Short-arc | 63 (Trim 0.3) | Car-o-Liner | ||

| 8 | Plug weld | 1.1 / 1.2 / 2.2 | Pulse | 58 (Trim -1) | Car-o-Liner | ||

| 9 | Overlap | 1.1 / 1.2 | Short-arc | 63 (Trim 0.3) | Car-o-Liner | ||

| 6 | Overlap | 1.1 / 1.2 | 2 | Short-arc | 2.3 | Fronius | |

| 7 | Plug weld | 1.1 / 2.2 | 2 | Short-arc | 2.3 | Fronius | |

| 8 | Plug weld | 1.1 / 1.2 / 2.2 | 4 | Pulse | 3.3 | Fronius | |

| 9 | Overlap | 1.1 / 1.2 | 2 | Short-arc | 2.3 | Fronius | |

| 6 | Overlap | 1.1 / 1.2 | 4 | Pulse | 4.3 | Wieländer | |

| 7 | Plug weld | 1.1 / 2.2 | 4 | Pulse | 4.3 | Wieländer | |

| 8 | Plug weld | 1.1 / 1.2 / 2.2 | 4 | Pulse | 4.3 | Wieländer | |

| 9 | Overlap | 1.1 / 1.2 | 4 | Pulse | 4.3 | Wieländer |

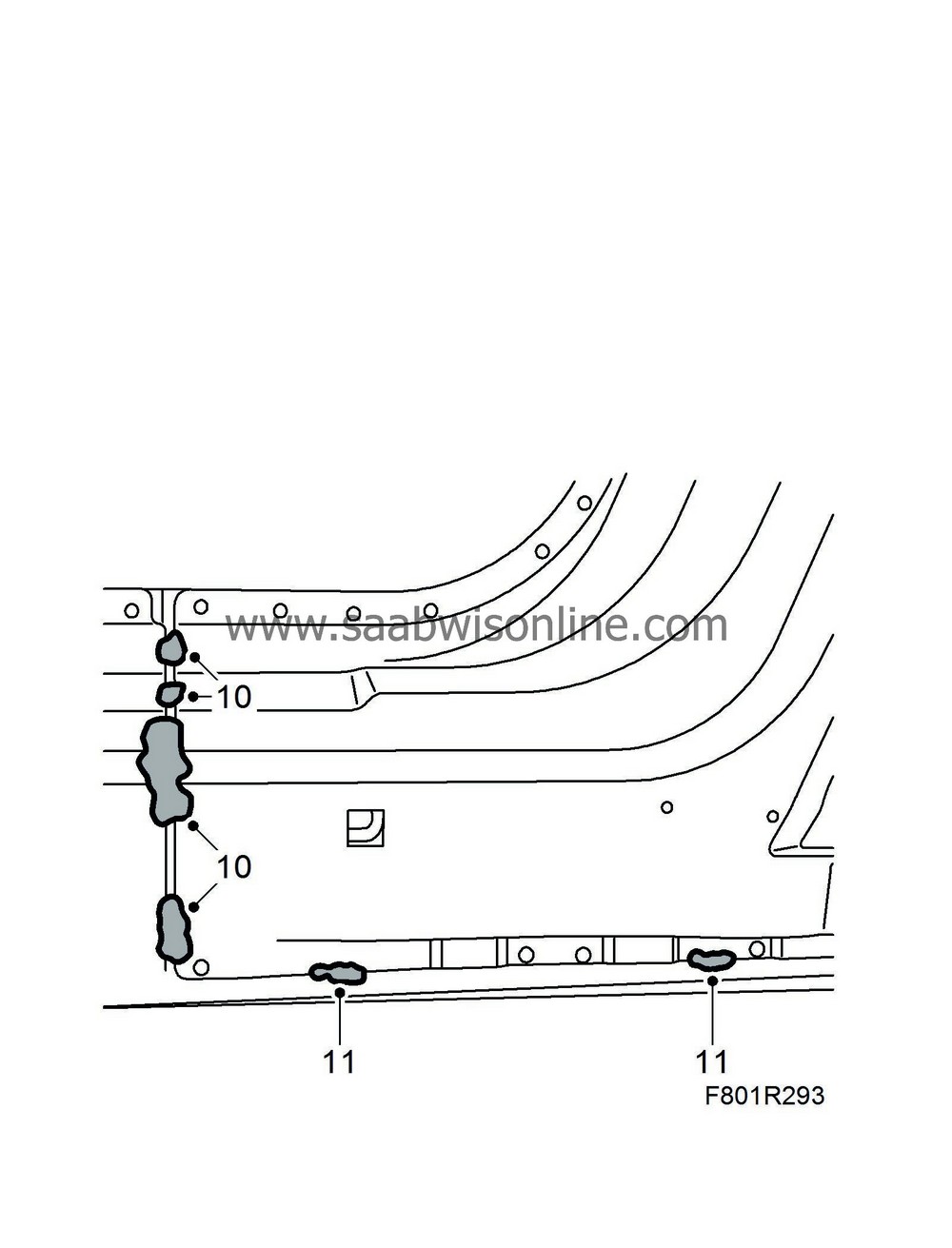

| Parameters for outer sill |

|

Area

|

Weld joint type

|

Plate combination

|

Program

|

Method

|

Rod feed

|

Ampere

|

Manufacturer

|

| 10 | Overlap | 0.8 / 2.2 | 4 | Pulse | 2.7 | Kemppi | |

| 11 | Overlap | 0.8 / 2.2 | 4 | Pulse | 2.7 | Kemppi | |

| 10 | Overlap | 0.8 / 2.2 | 6 | 5.0 | Cloos | ||

| 11 | Overlap | 0.8 / 2.2 | 6 | 5.0 | Cloos | ||

| 10 | Overlap | 0.8 / 2.2 | 2 | Short-arc | 4.0 | ElmaTech | |

| 11 | Overlap | 0.8 / 2.2 | 2 | Short-arc | 4.0 | ElmaTech | |

| 10 | Overlap | 0.8 / 2.2 | Short-arc | 63 (Trim 0.3) | Car-o-Liner | ||

| 11 | Overlap | 0.8 / 2.2 | Short-arc | 63 (Trim 0.3) | Car-o-Liner | ||

| 10 | Overlap | 0.8 / 2.2 | 2 | Short-arc | 2.3 | Fronius | |

| 11 | Overlap | 0.8 / 2.2 | 2 | Short-arc | 2.3 | Fronius | |

| 10 | Overlap | 0.8 / 2.2 | 4 | Pulse | 4.3 | Wieländer | |

| 11 | Overlap | 0.8 / 2.2 | 4 | Pulse | 4.3 | Wieländer |

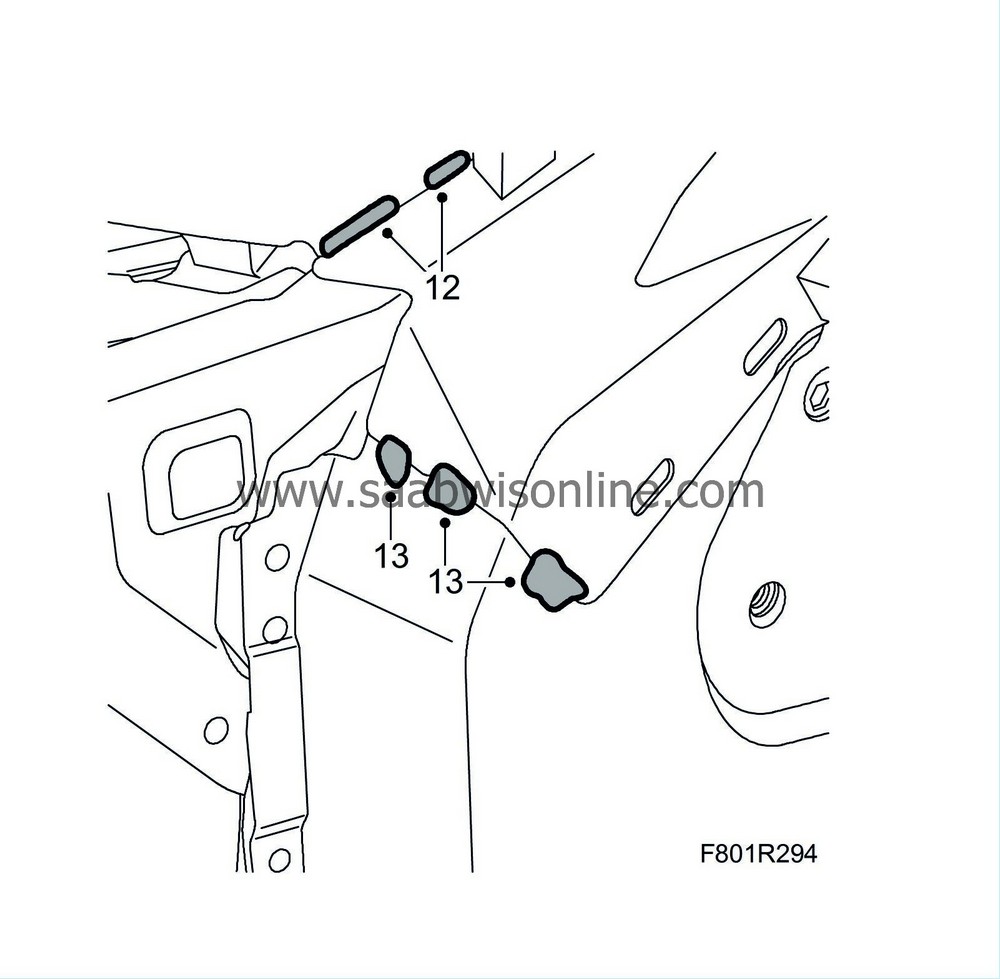

| Parameters for windscreen frame, lower section |

|

Area

|

Weld joint type

|

Plate combination

|

Program

|

Method

|

Rod feed

|

Ampere

|

Manufacturer

|

| 12 | Overlap | 1.2 / 1.0 | 4 | Pulse | 2.7 | Kemppi | |

| 13 | Overlap | 1.2 / 2.2 | 4 | Pulse | 2.7 | Kemppi | |

| 12 | Overlap | 1.2 / 1.0 | 6 | 5.0 | Cloos | ||

| 13 | Overlap | 1.2 / 2.2 | 6 | 5.0 | Cloos | ||

| 12 | Overlap | 1.2 / 1.0 | 2 | Short-arc | 4.0 | ElmaTech | |

| 13 | Overlap | 1.2 / 2.2 | 2 | Short-arc | 4.0 | ElmaTech | |

| 12 | Overlap | 1.2 / 1.0 | Short-arc | 63 (Trim 0.3) | Car-o-Liner | ||

| 13 | Overlap | 1.2 / 2.2 | Short-arc | 63 (Trim 0.3) | Car-o-Liner | ||

| 12 | Overlap | 1.2 / 1.0 | 2 | Short-arc | 2.3 | Fronius | |

| 13 | Overlap | 1.2 / 2.2 | 2 | Short-arc | 2.3 | Fronius | |

| 12 | Overlap | 1.2 / 1.0 | 4 | Pulse | 4.3 | Wieländer | |

| 13 | Overlap | 1.2 / 2.2 | 4 | Pulse | 4.3 | Wieländer |

Warning

Warning