Side panel, outer, CV

| Side panel, outer, CV |

Certain welded joints on the car may be MIG brazed with bronze as the filling material. A MIG brazed seam can be identified by the gold colour of the joint. MIG brazing must always be replaced by new MIG brazing.

|

|||||||

| 1. |

Position the car in an aligning bench and cross-measure if necessary.

|

|

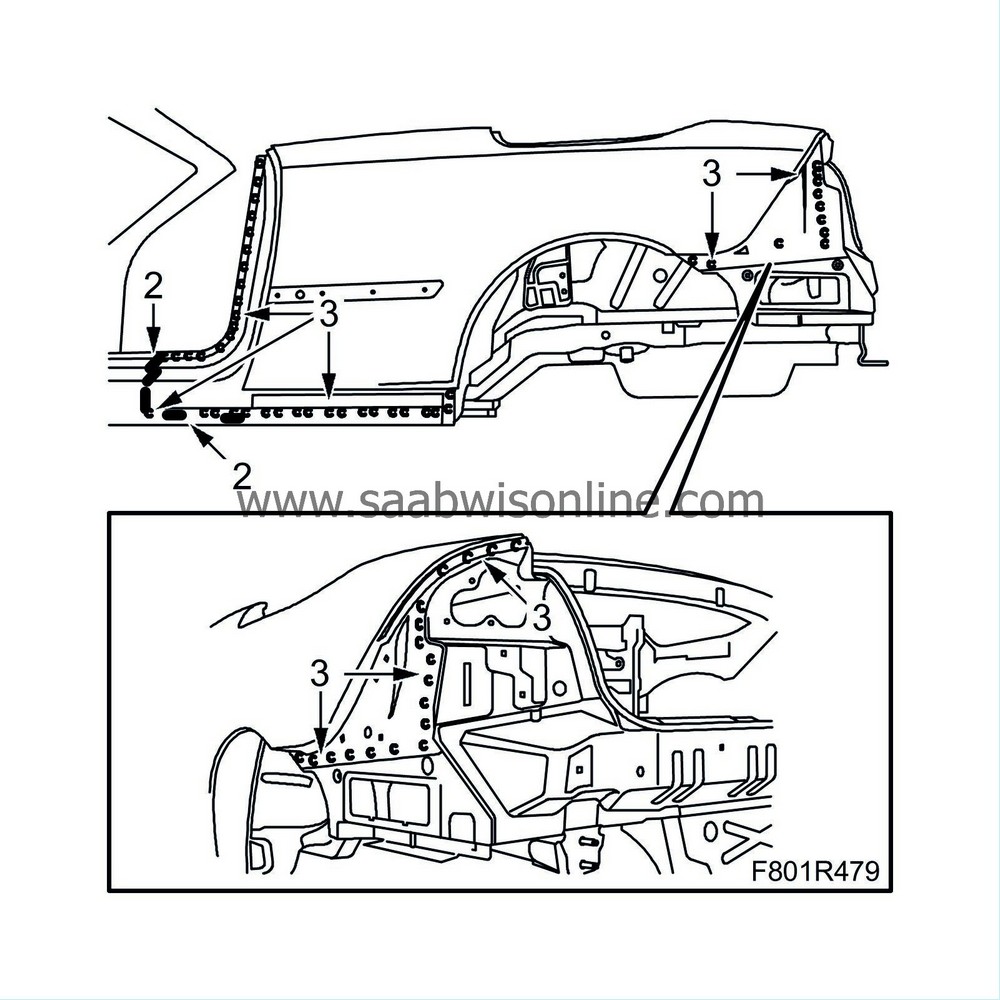

| 2. |

Grind away the MIG brazings to the side panel.

|

|

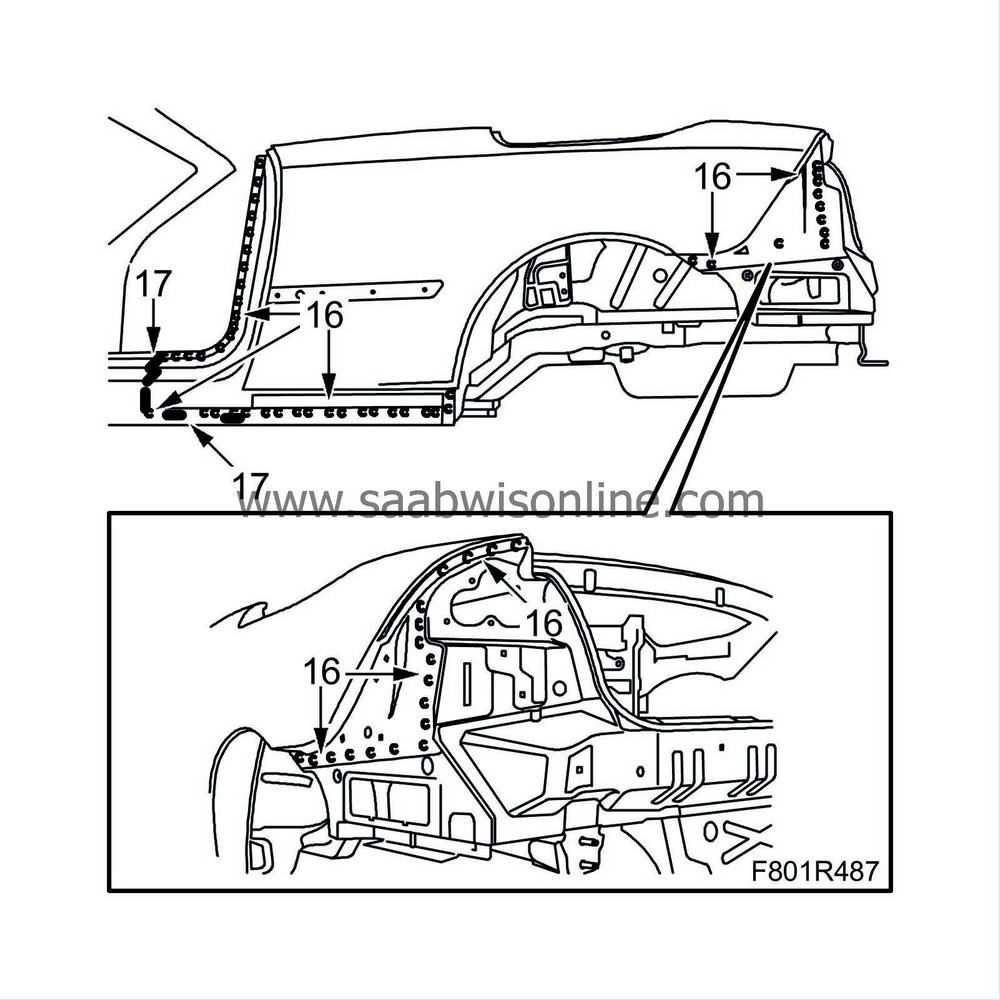

| 3. |

Drill out the spot welds on the outside of the side panel.

|

|

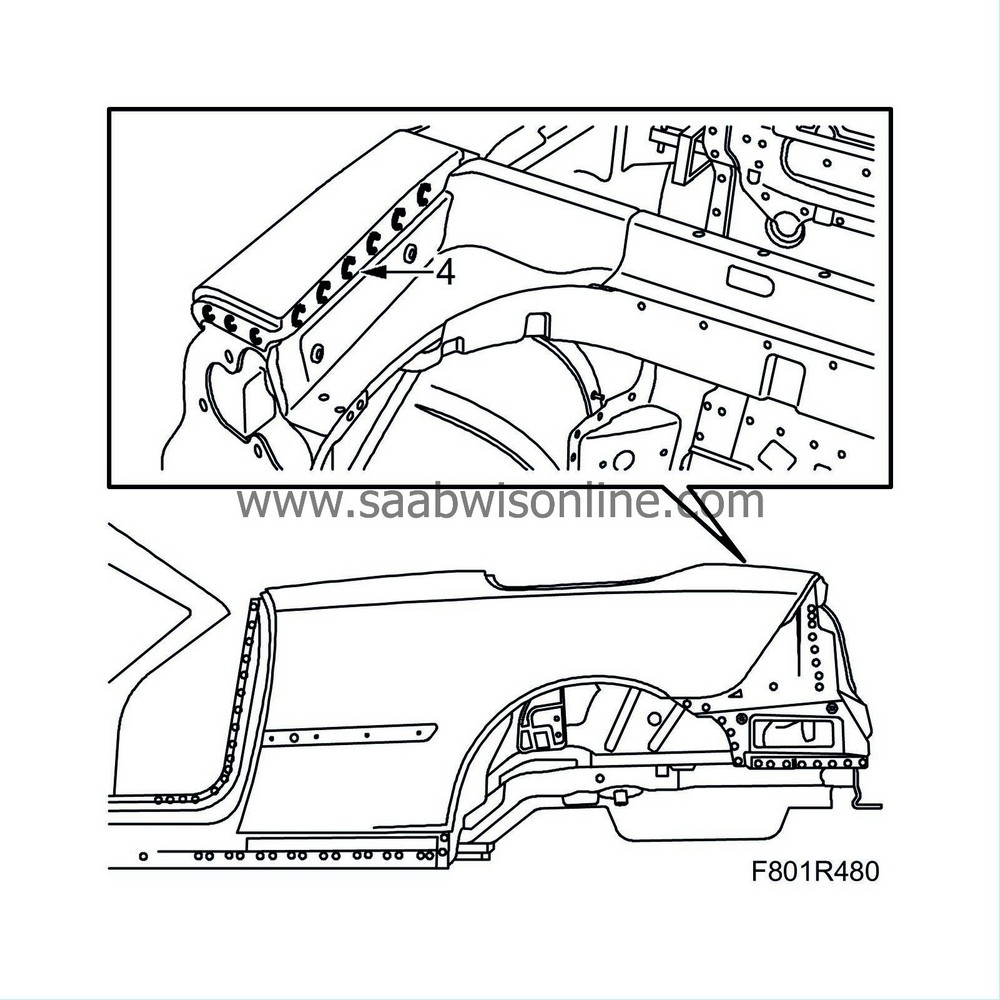

| 4. |

Drill out the spot welds on the side panel.

|

|

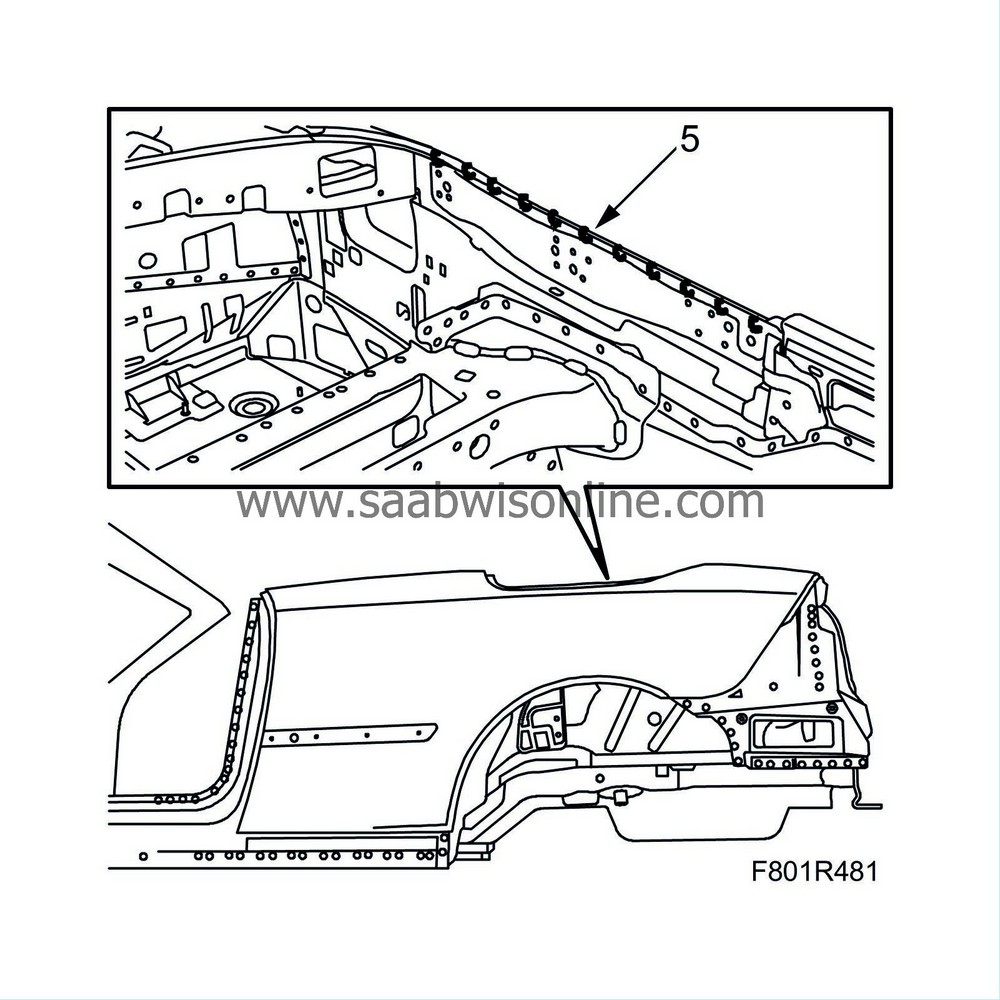

| 5. |

Drill out the spot welds.

|

|

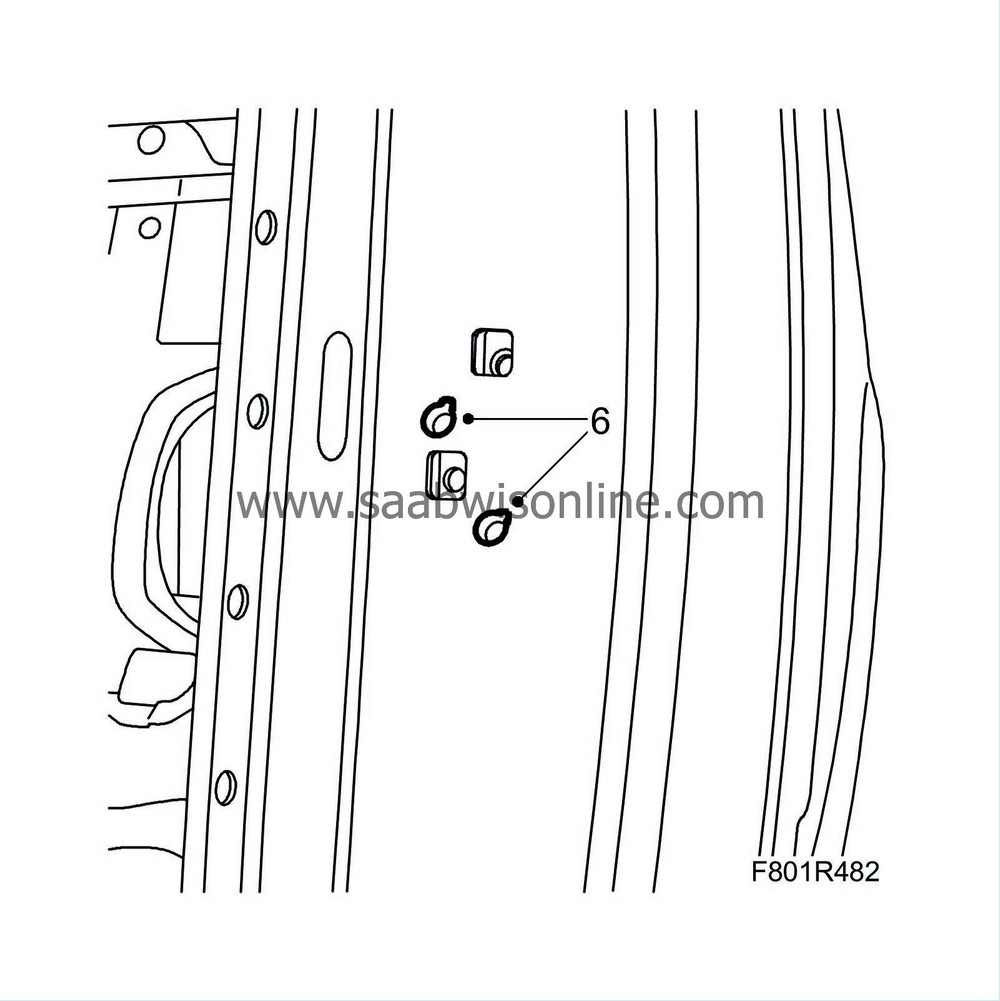

| 6. |

Drill out the spot welds for the nut washer to the striking plate.

|

|

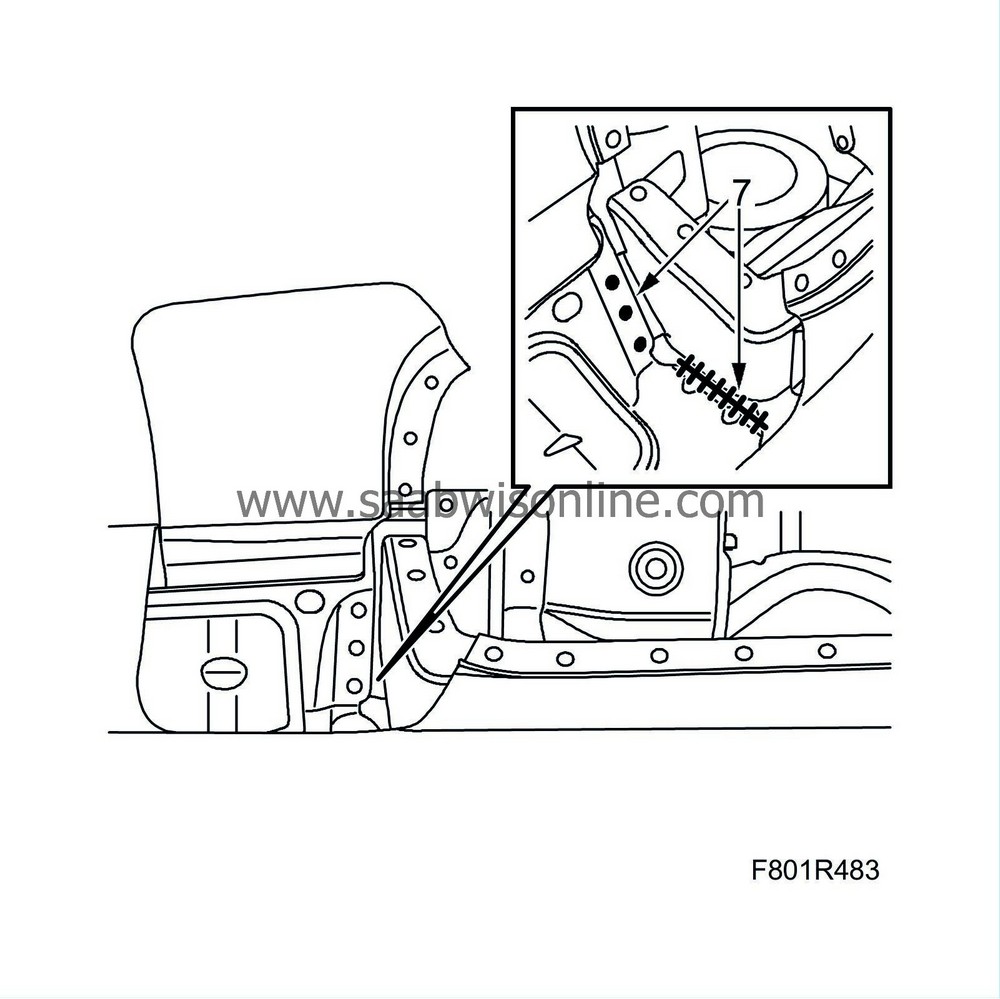

| 7. |

Saw out a hatch for access to the underlying spot welds and cutting.

|

|

| 8. |

Knock away the side panel and break it loose from the adhesive. Align any deformed metal.

|

|

| 9. |

Grind all surfaces that are to be welded.

|

|

| 10. |

Drill all the holes for plug-welding in the spare part

|

|

| 11. |

Position the spare part and check the fit. Adjust as necessary.

|

|

| 12. |

Lift away the spare part.

|

|

| 13. |

Apply welding primer to the surfaces to be spot and plug welded. Use Teroson Zink Spray.

|

|

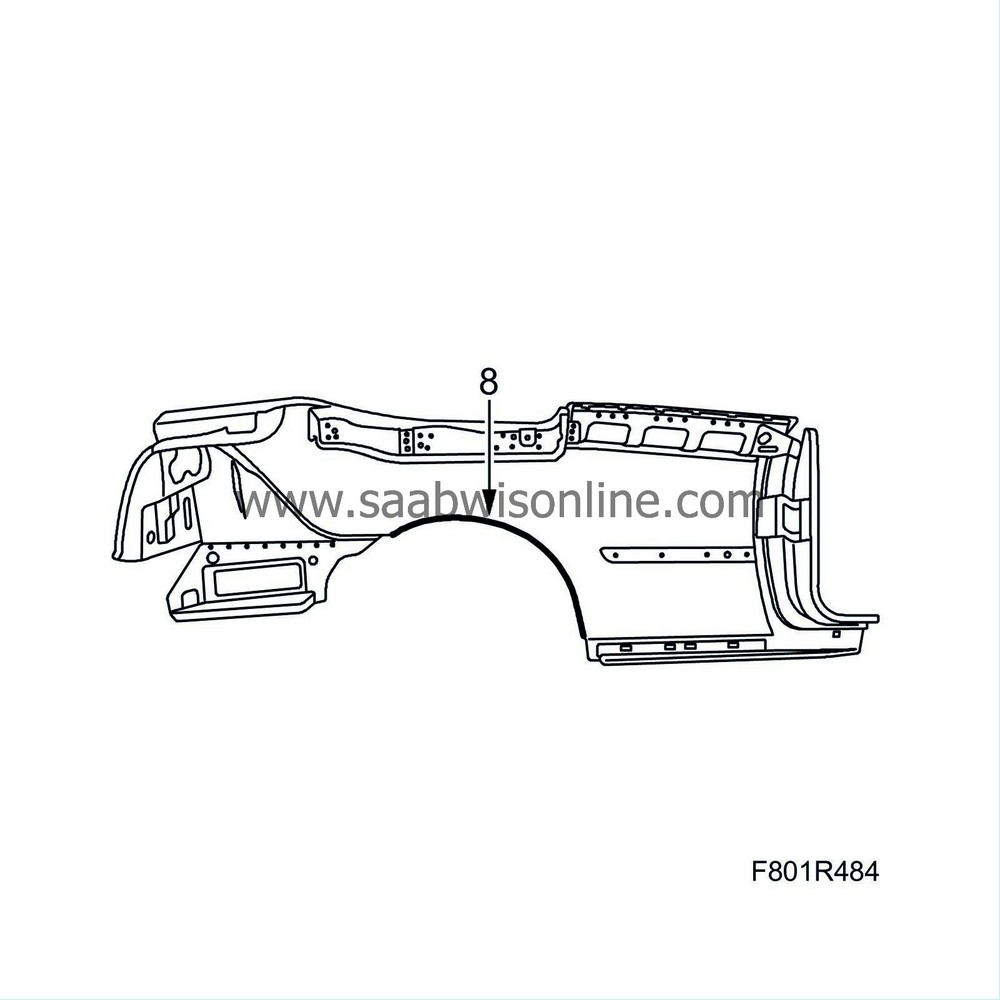

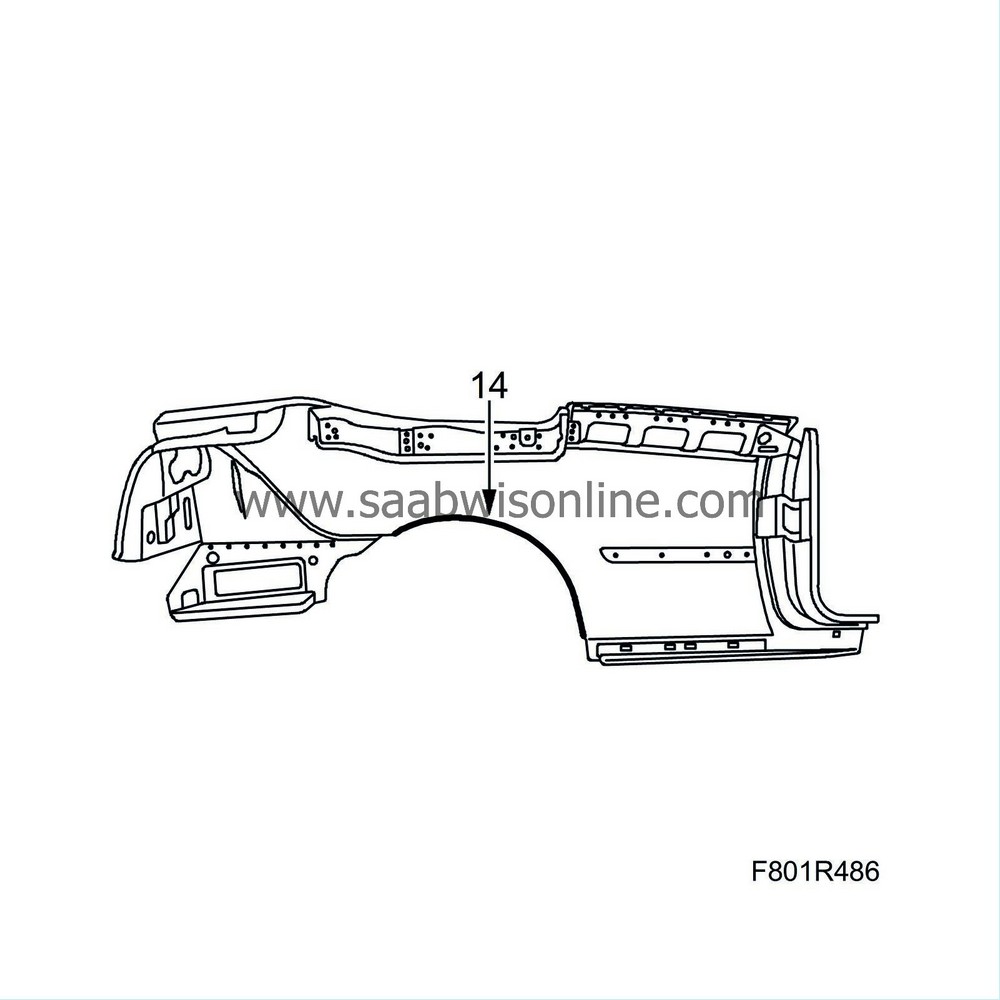

| 14. |

Apply body adhesive as illustrated. Use Teromix 6700.

|

|

| 15. |

Put the side panel in place. Position it precisely and fix with welding clamps.

|

|

| 17. |

Seam weld the side panel. Note that the seam welds must be MIG brazed.

|

|

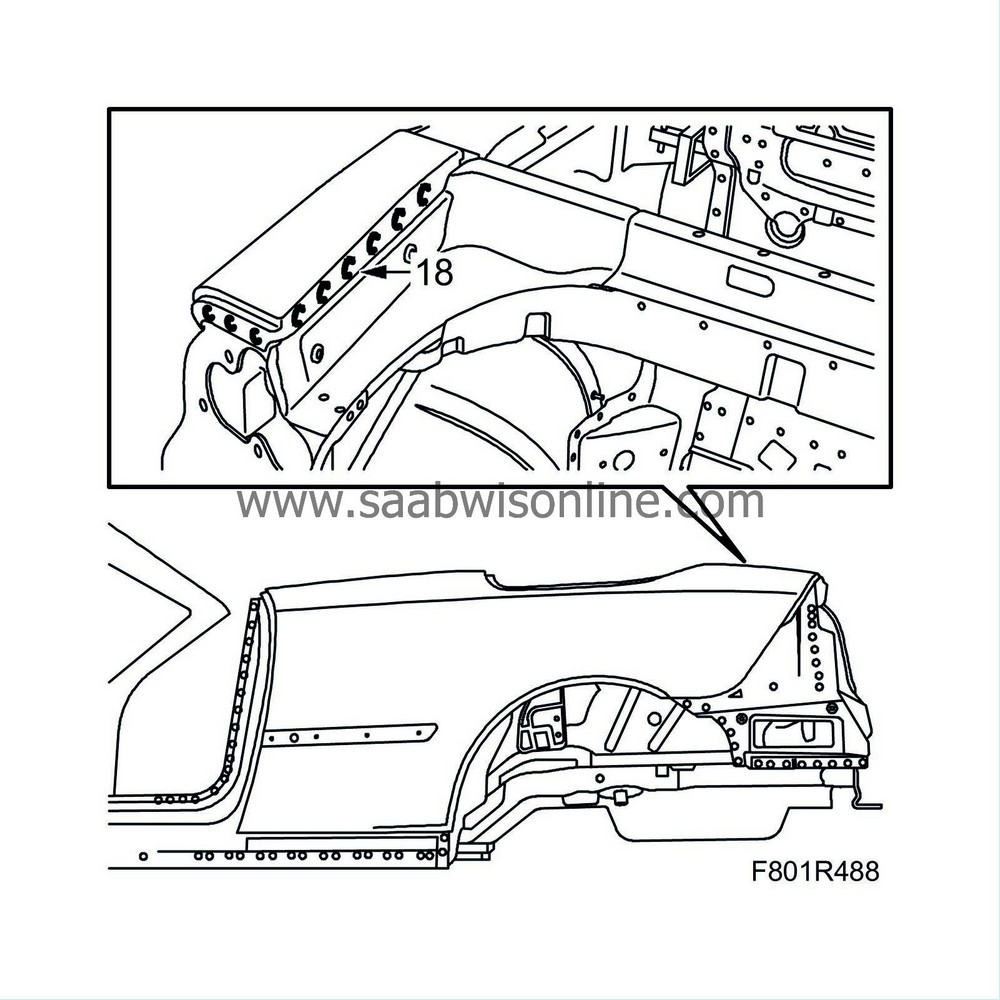

| 18. |

Spot and plug weld the side panel.

|

|

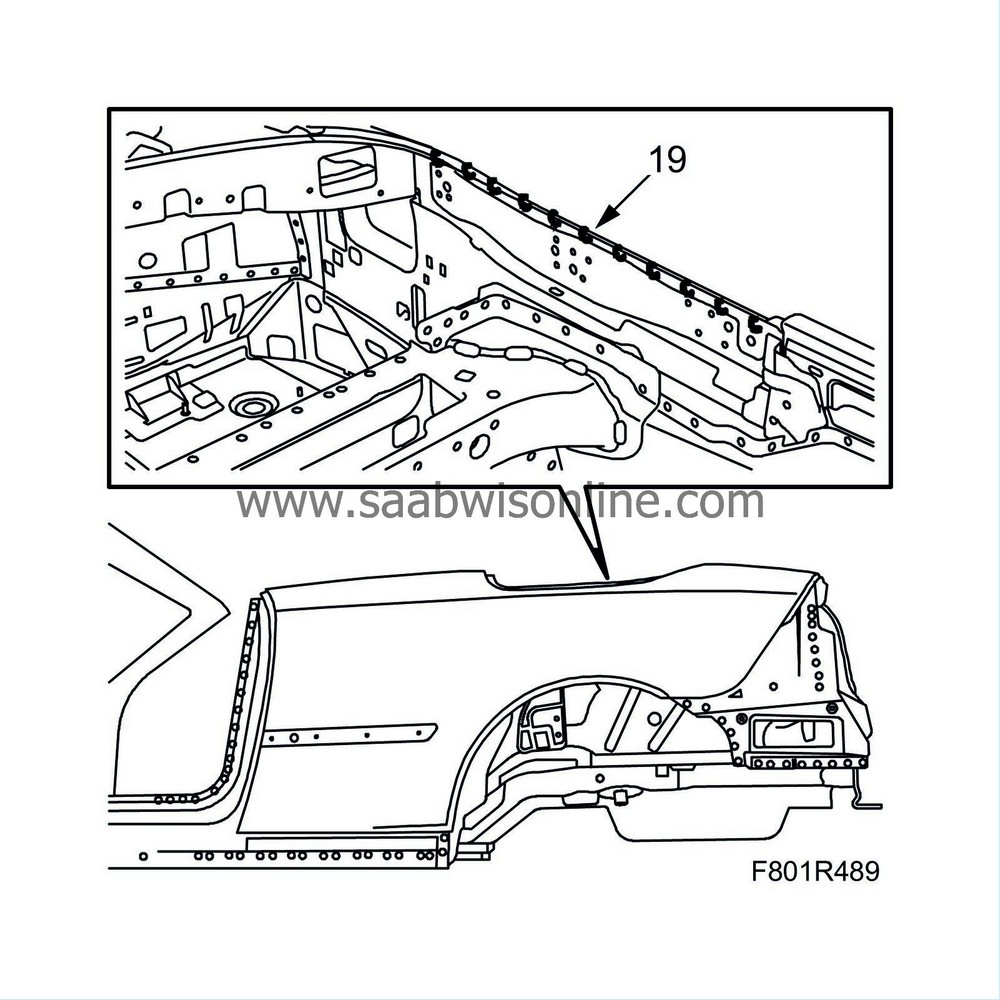

| 19. |

Spot and plug weld the side panel.

|

|

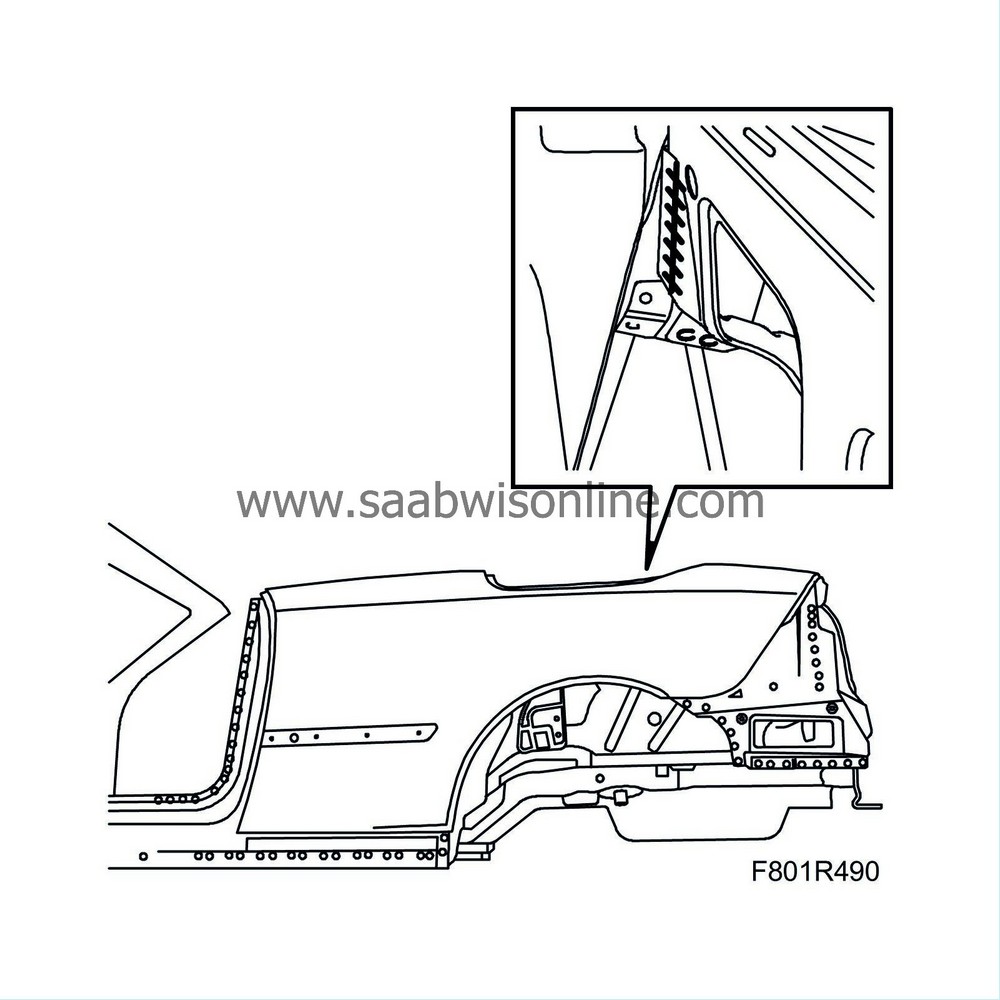

| 20. |

Plug and seam weld the inside.

|

|

| 21. |

Remove any remaining welding primer. Welding primer reduces adhesion of paint, filler and sealant.

|

|

| 22. |

Apply primer to all bare metal surfaces. Use Standox 1K.

|

|

| 23. |

Seal joints and sheet metal flanges with sealant. Use 1K-PUR.

|

|

| 24. |

Apply anti-corrosion agent to internal surfaces after painting. Use Terotex HV 400.

|

|

Warning

Warning