Description of crankcase ventilation system (A20NFT/LHU)

|

|

Description of crankcase ventilation system (A20NFT/LHU)

|

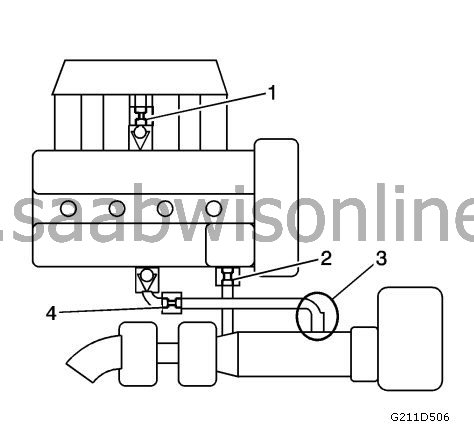

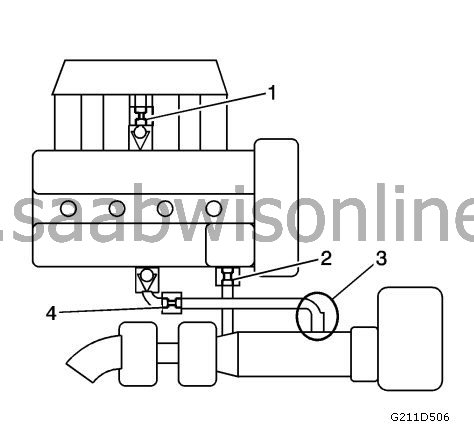

A crankcase ventilation system is used to combust the crankcase fumes in the combustion process instead of releasing them out to the air. Fresh air from the intake system is fed to the crankcase, mixed with blowby gases and then fed via a calibrated nozzle to the intake manifold.

The primary flow passes through the positive crankcase ventilation (PCV) nozzle (1), the flow of which is dependent on the intake vacuum. The PCV nozzle is an integral part of the camshaft casing. At a higher engine load, large quantities of blowby gases can flow through the crankcase ventilation apertures (2, 4) into the intake system before then being combusted.

There is a non-return valve (3) in the intake pipe to prevent the crankcase from being pressurised by positive pressure in the intake pipe during supercharging. Without the non-return valve, oil and PCV gases would be forced out through the camshaft cover and into the intake system via the hose to the camshaft cover. This can cause coking in the throttle body and intake system and can reduce the efficiency of the combustion and charge air cooler system. During normal operation, PCV gases are pulled into the air flow after the charge air cooler.