Description of lubrication (A20NFT/LHU)

|

|

Description of lubrication (A20NFT/LHU)

|

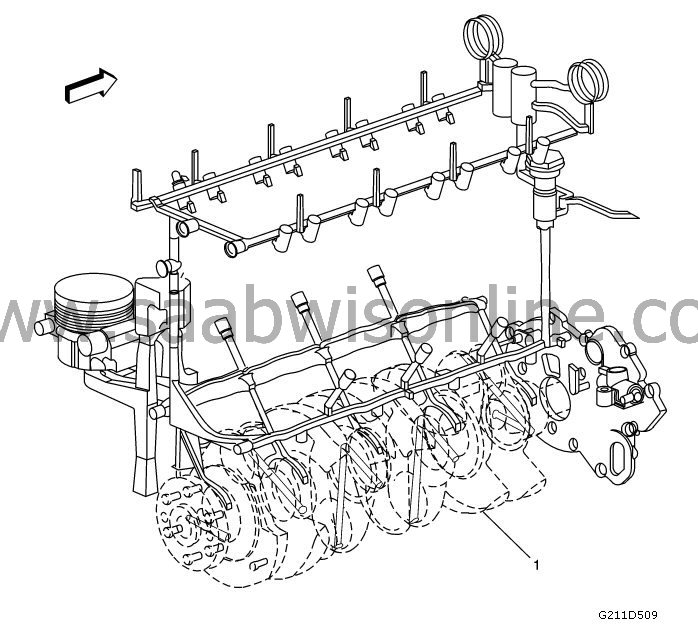

Pressurised oil supplies the crankshaft (1), the connecting rods, the balancer shaft unit, the camshaft bearing surfaces, the tappets and the cam chain's hydraulic tensioning device. All other moving parts are lubricated via a gravitational flow or splash lubrication. Oil enters the gerotor type oil pump via a fixed intake strainer. The oil pump is driven by the crankshaft. The oil pump housing is located in the front engine casing. The pressurised oil from the pump passes through the oil filter. The oil filter is positioned on the right side (front) of the engine block. The oil filter is placed in an embedment which is integrated in the engine block. The oil filter is of single-use cartridge type. An overflow valve in the filter cap permits a continuous flow of oil if the oil filter is blocked. Oil then passes into the ducts, where it is distributed to the balancer shafts, the crankshaft, the camshafts and the cam chain's oil nozzle. The crank bearings are lubricated via oil ducts in the crankshaft which connect the main bearing journals to the crankshaft journals. A groove around each upper main bearing supplies the bored crankshaft passages with oil. The pressurised oil passes through the mouth of the restricting valve of the top cover into the top cover and then into each camshaft supply duct. Cast passages supply every hydraulic tappet and bored passages supply every camshaft bearing surface. A pressure contact or pressure sensor for engine oil is located at the end. Oil returns to the oil pan via passages which are cast in the cylinder head. Oil from timing chain lubrication runs directly down into the oil pan.