Complete gearbox, B207 4WD

|

|

Complete gearbox, B207 4WD

|

|

1.

|

Place covers over the wings to keep the paintwork clean and protect it from damage.

|

|

2.

|

Remove the upper engine cover.

|

|

3.

|

Remove the battery cover.

|

|

4.

|

Disconnect the battery terminals and remove the battery with cooling pipe.

|

|

5.

|

Undo the cable clamp under the battery tray.

|

|

6.

|

Disconnect the bonnet switch.

|

|

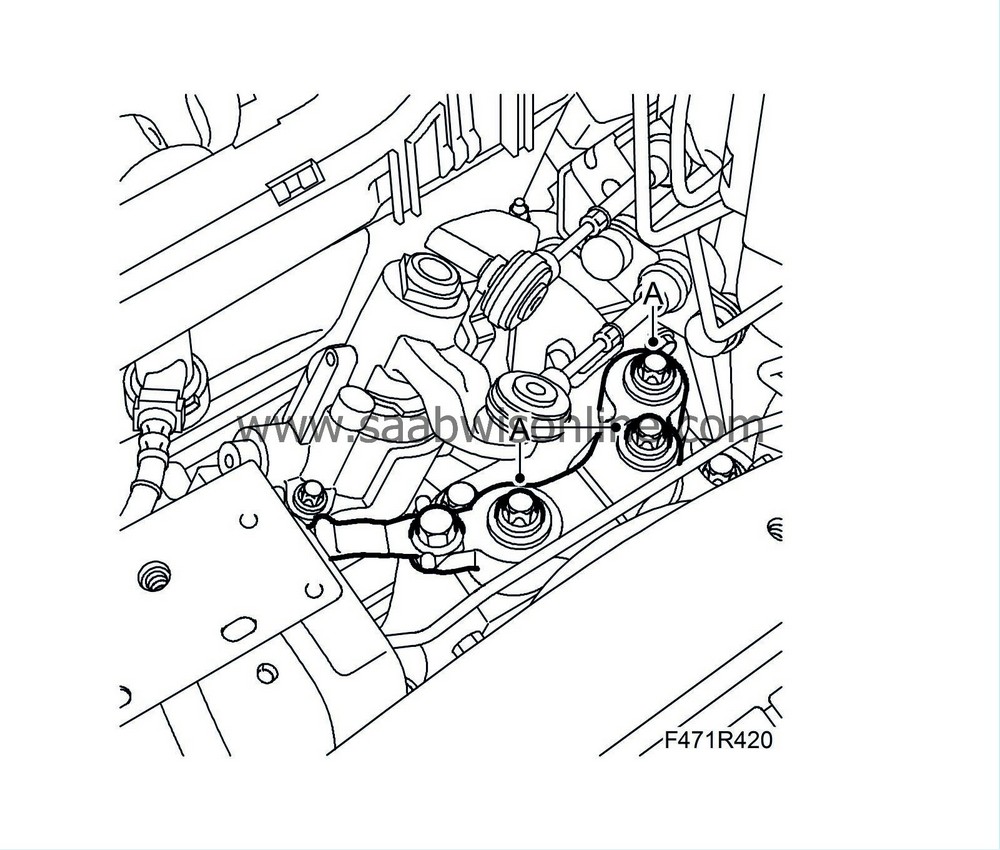

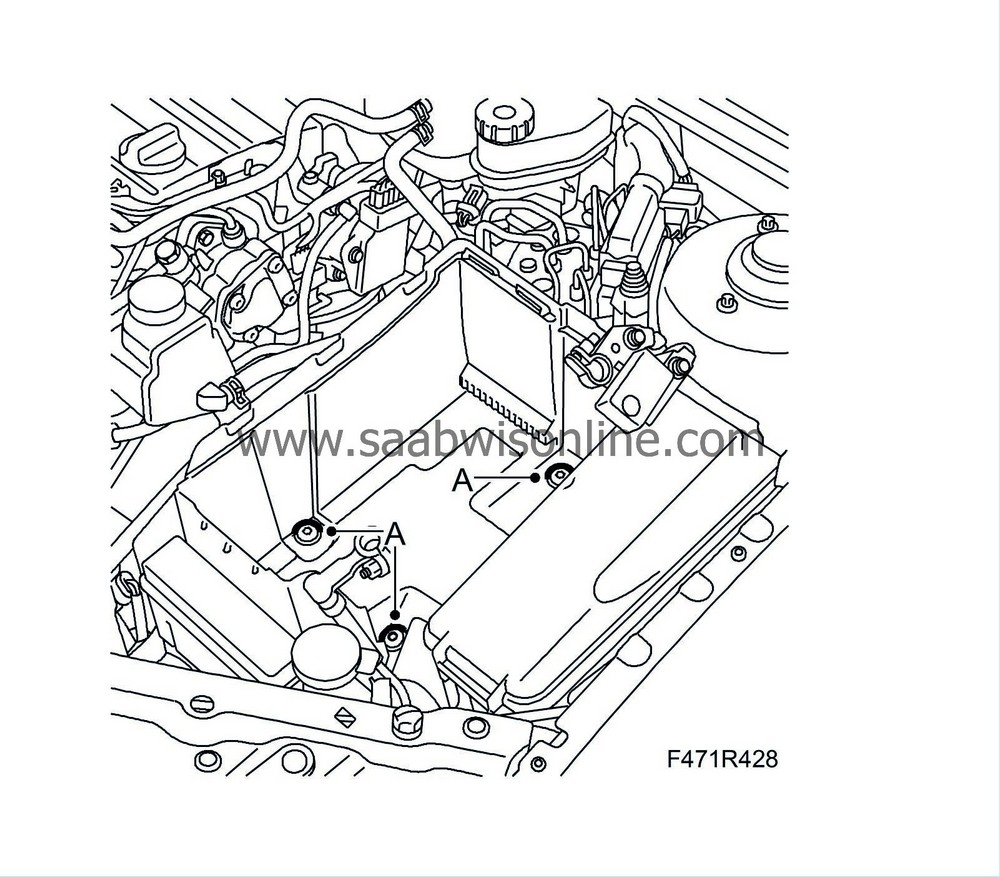

7.

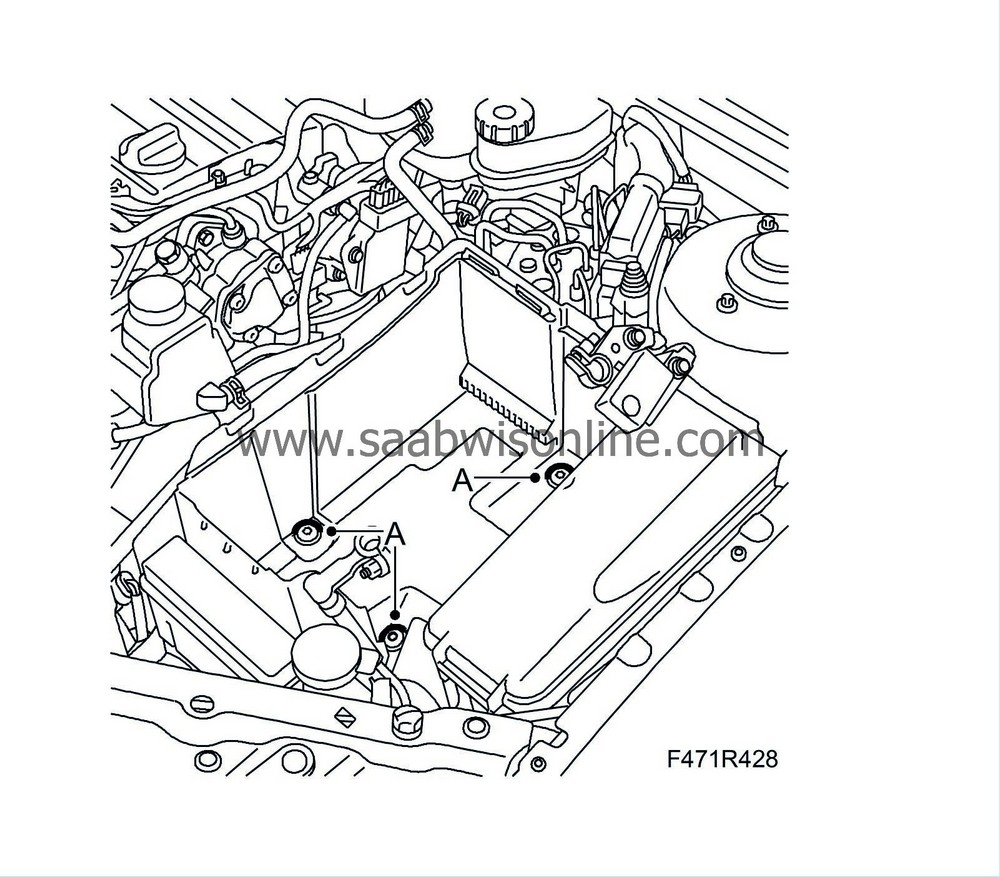

|

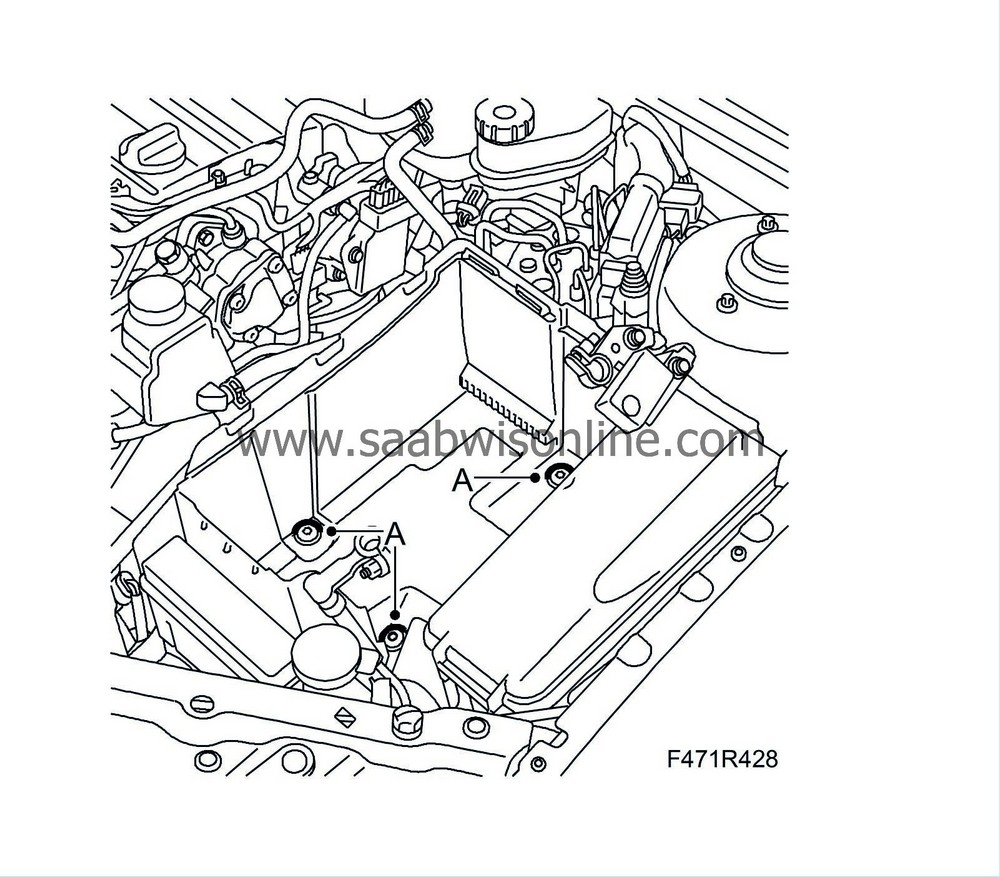

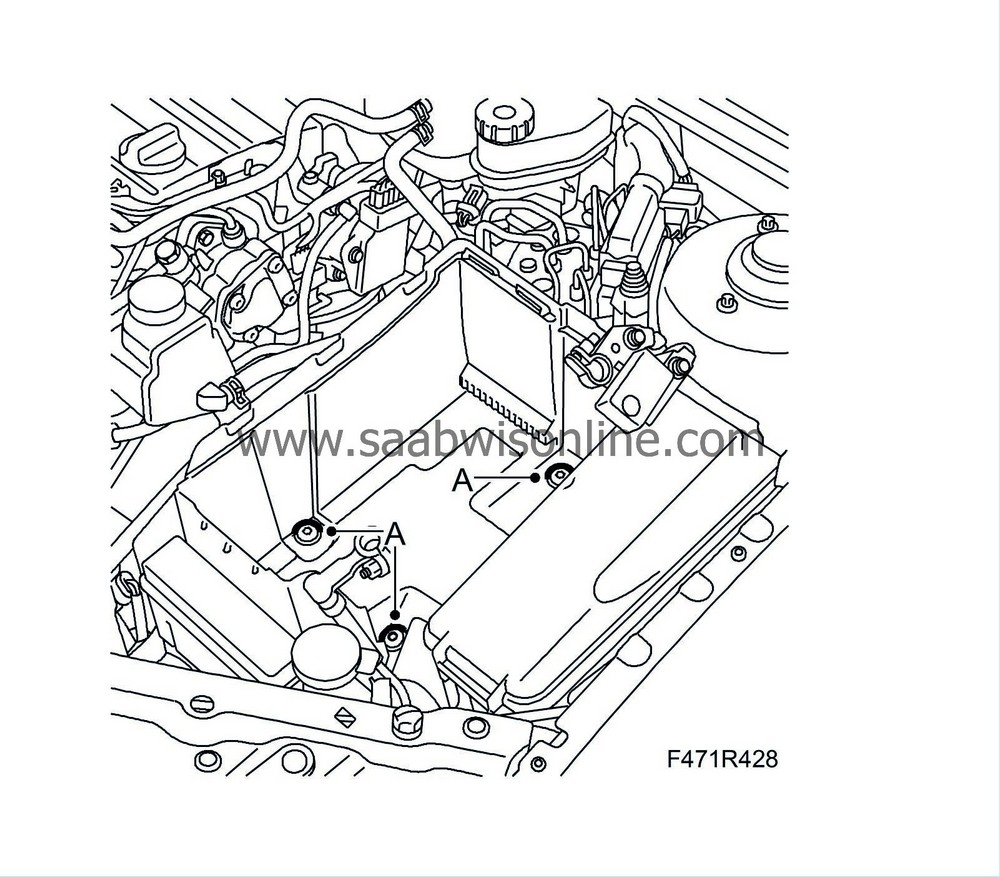

Remove the battery tray (A).

|

|

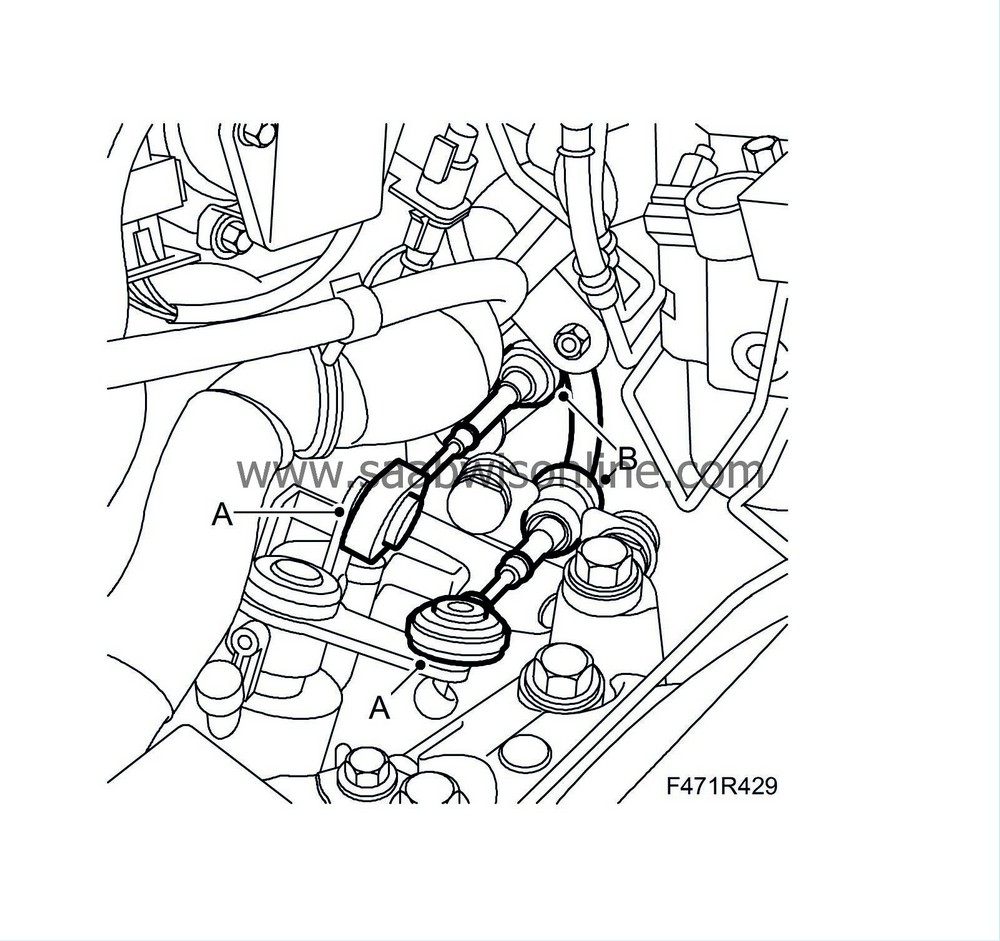

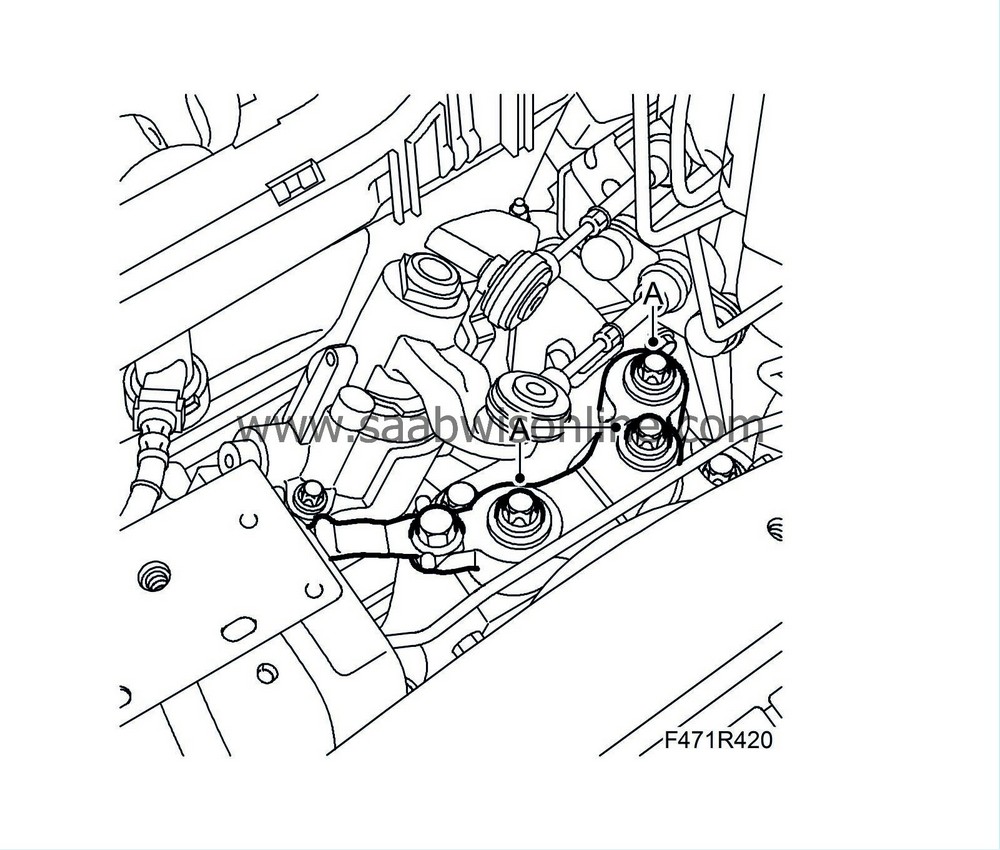

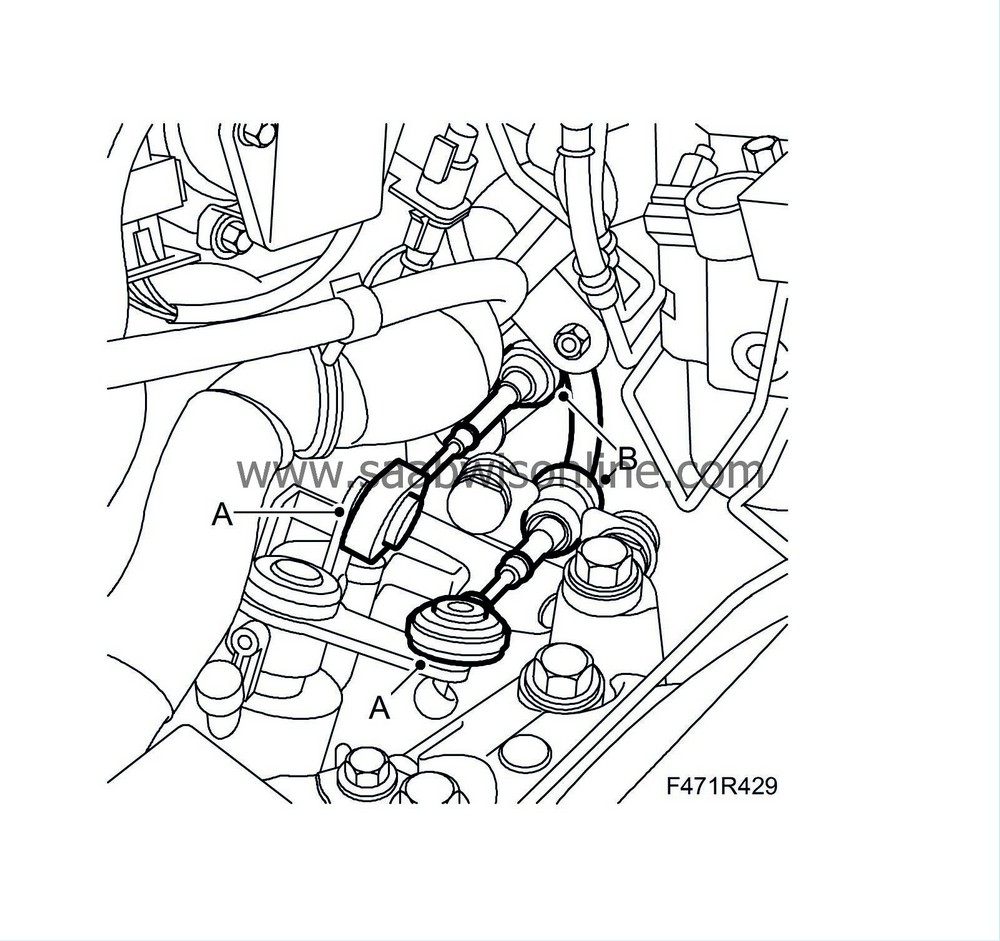

8.

|

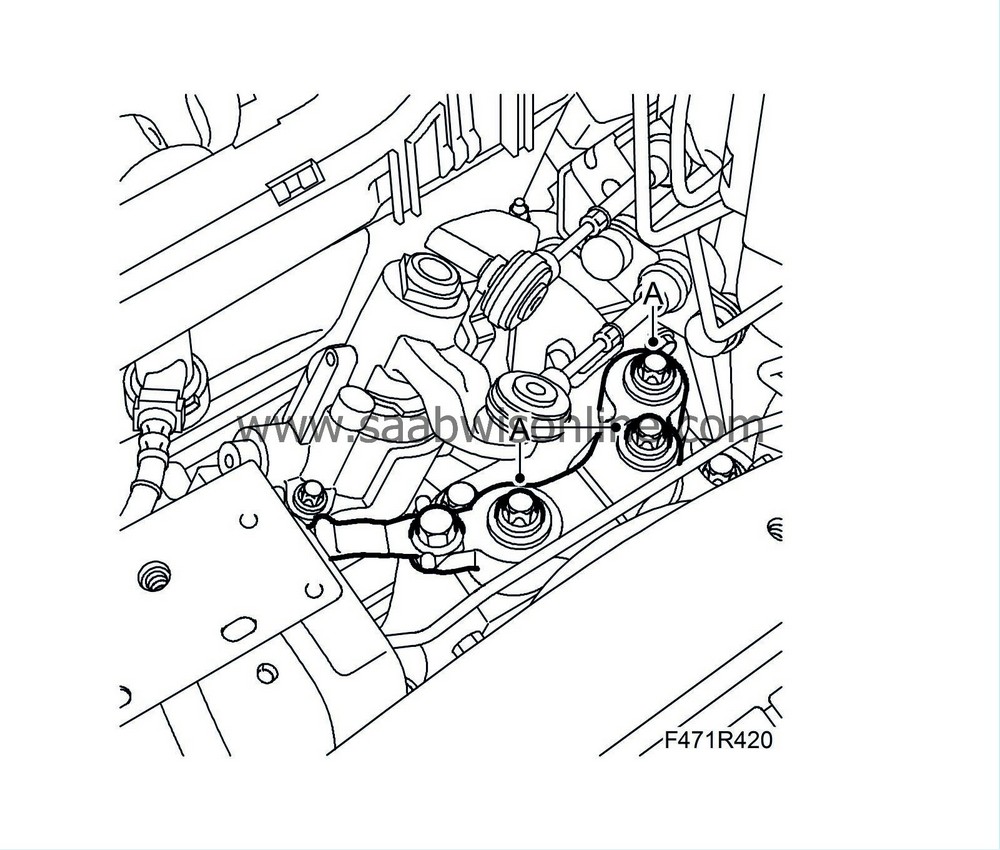

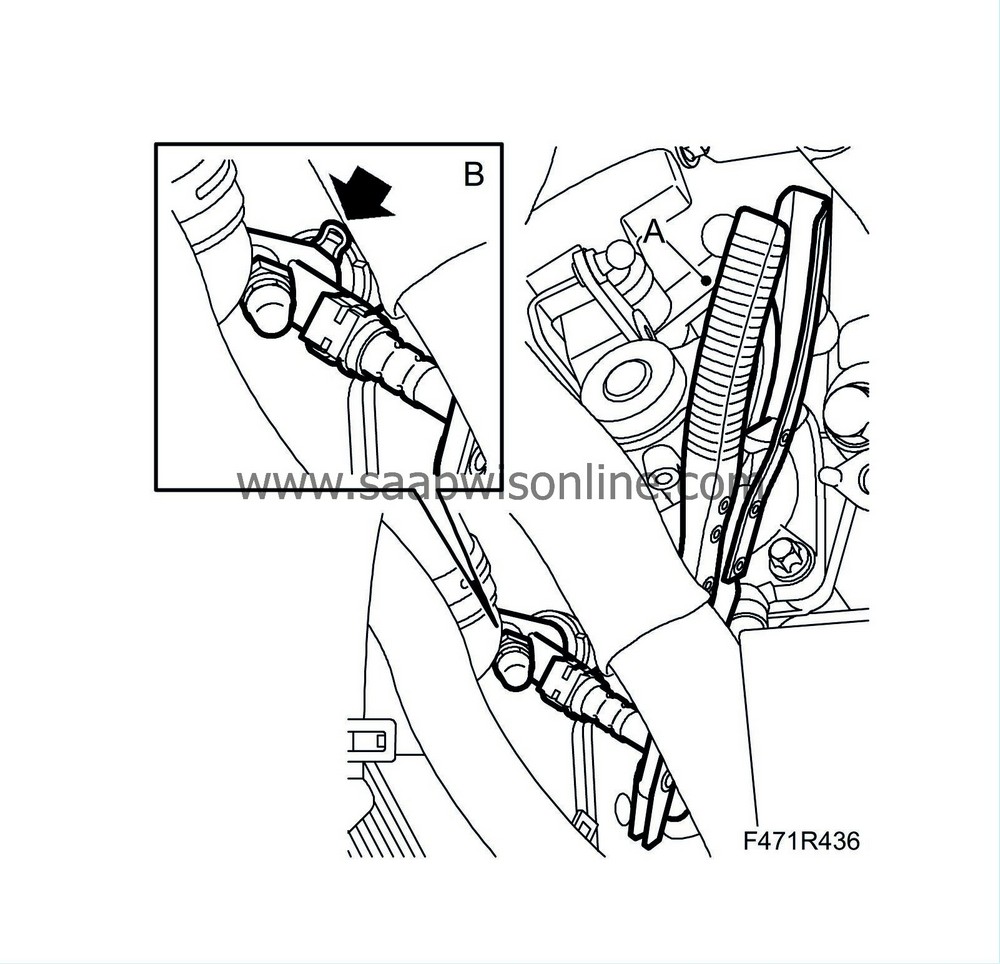

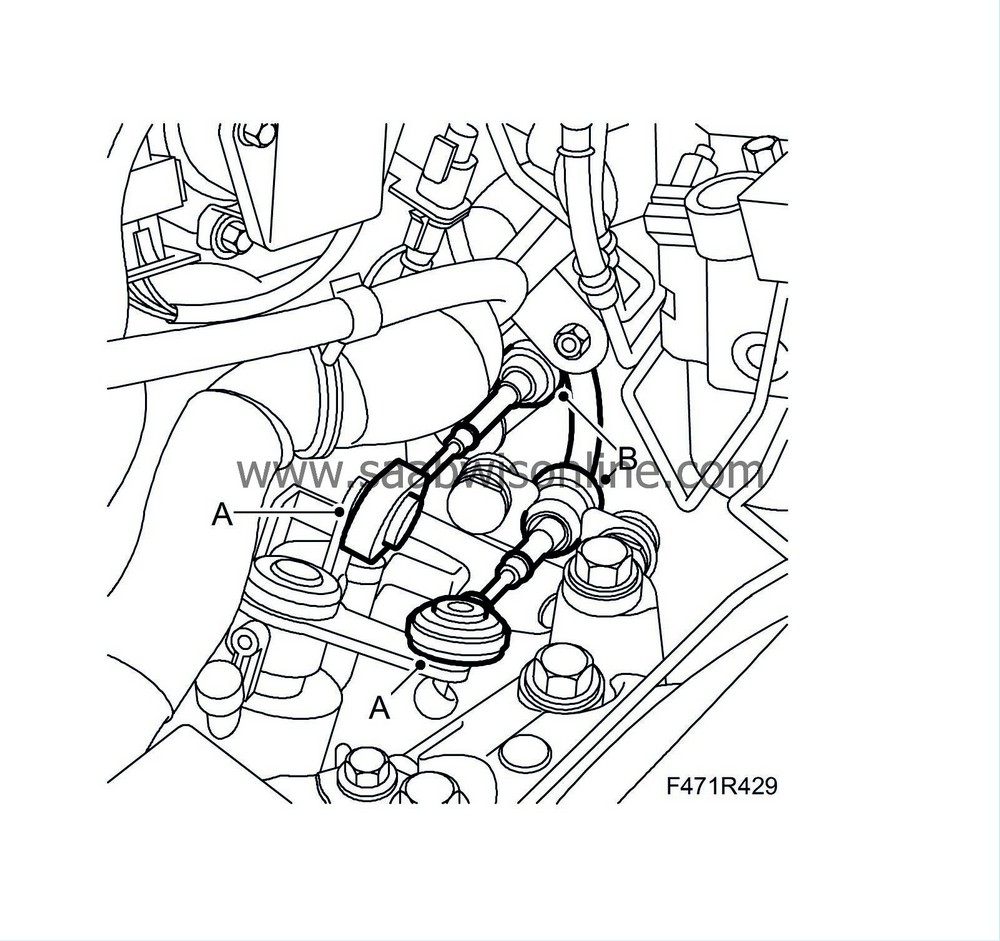

Lift up the cables (A) from the levers.

|

|

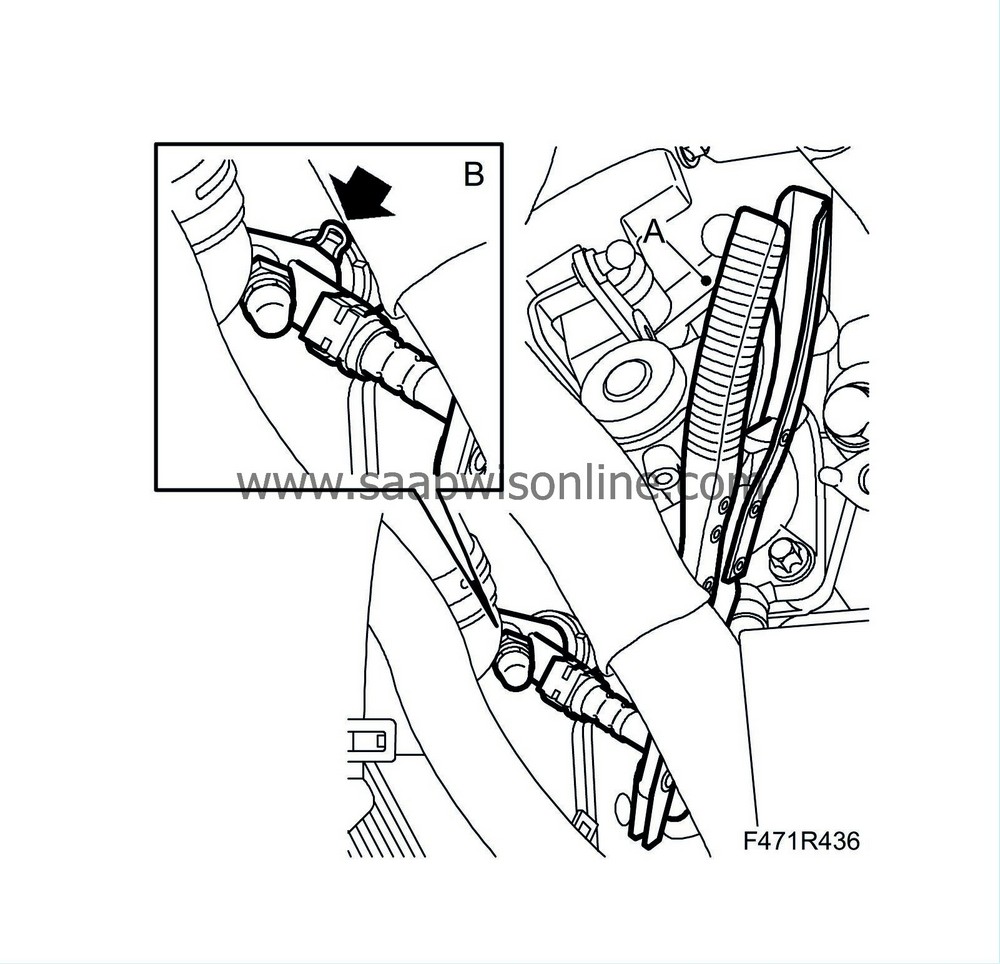

9.

|

Remove the gear cables from the gearbox by pulling back on the locking sleeves (B).

|

|

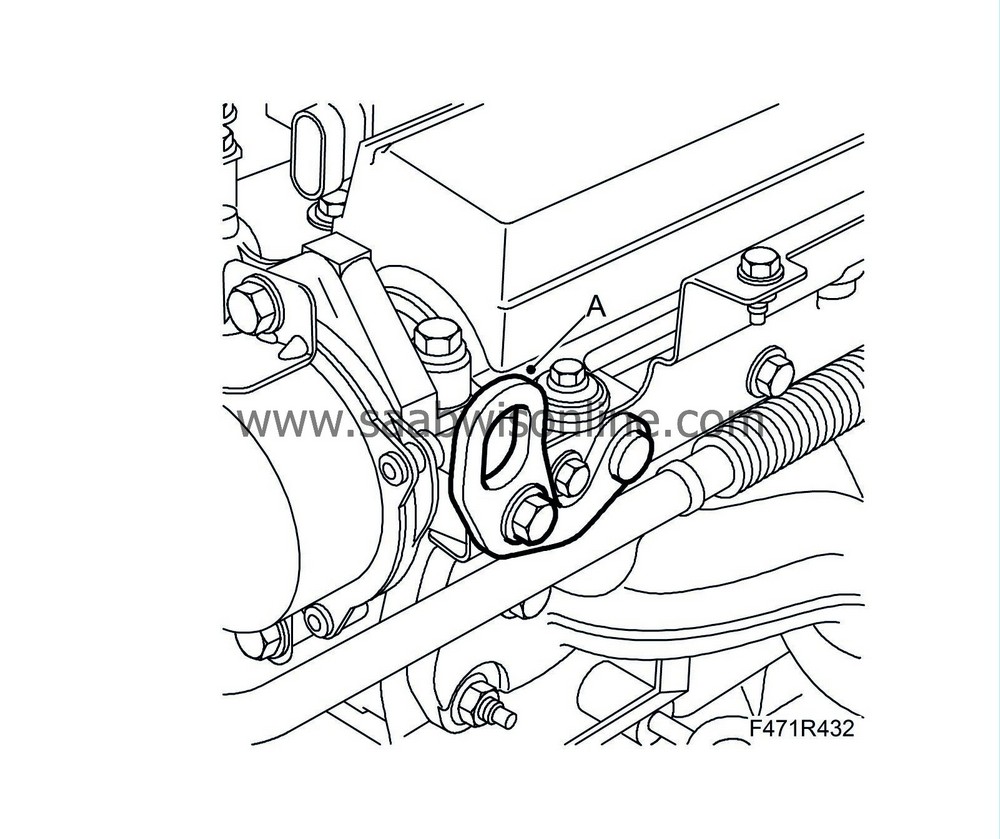

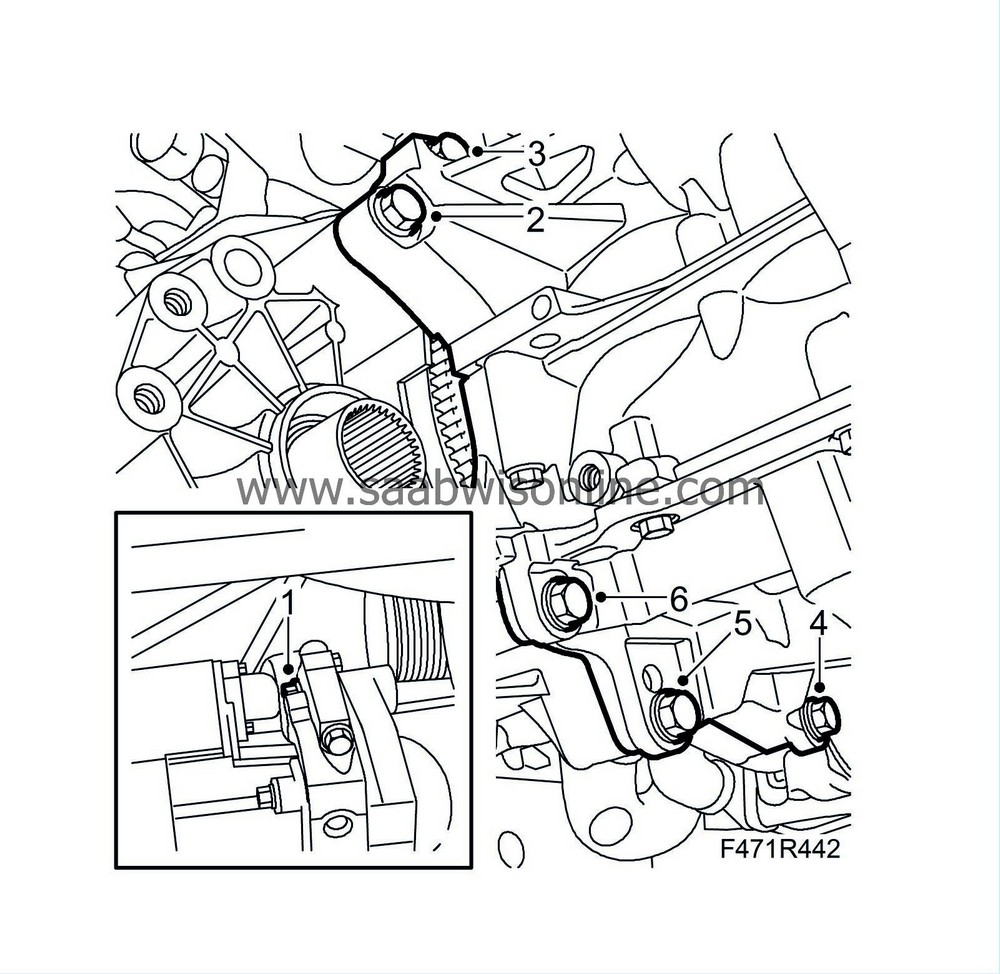

11.

|

Remove the upper bolts from the gearbox (A).

|

|

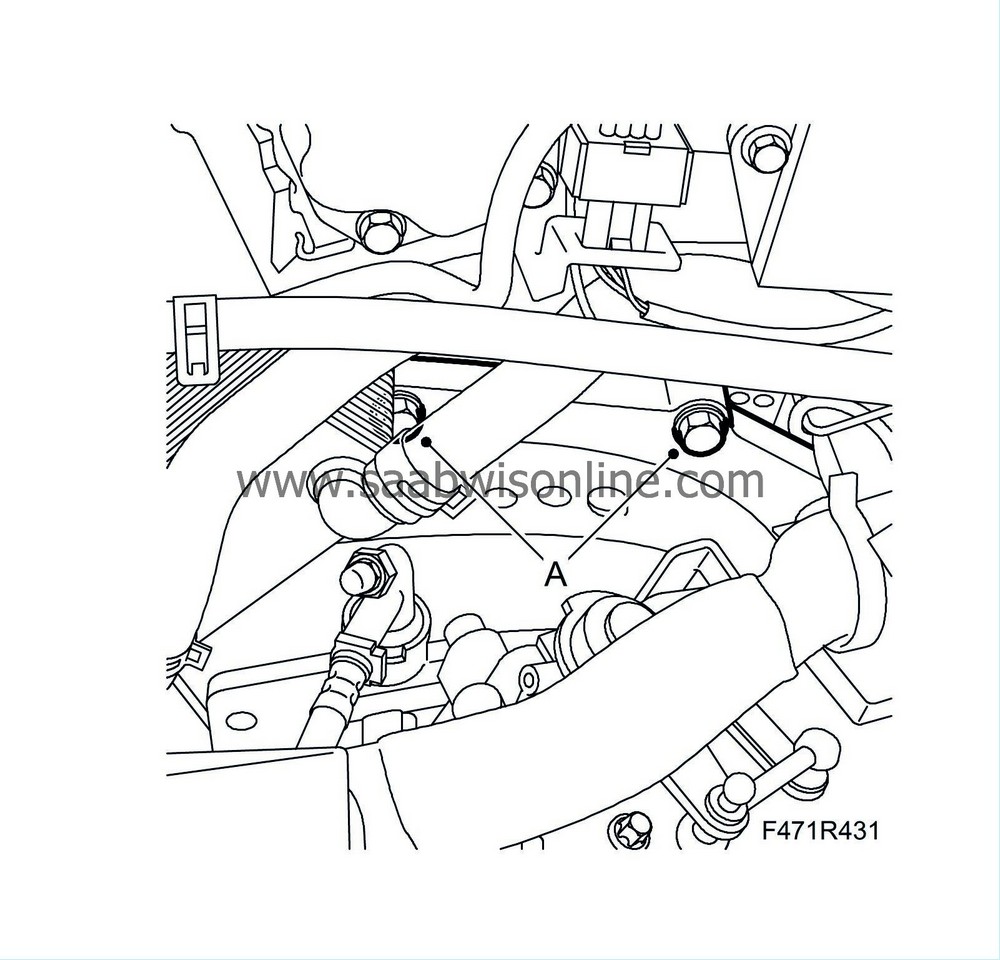

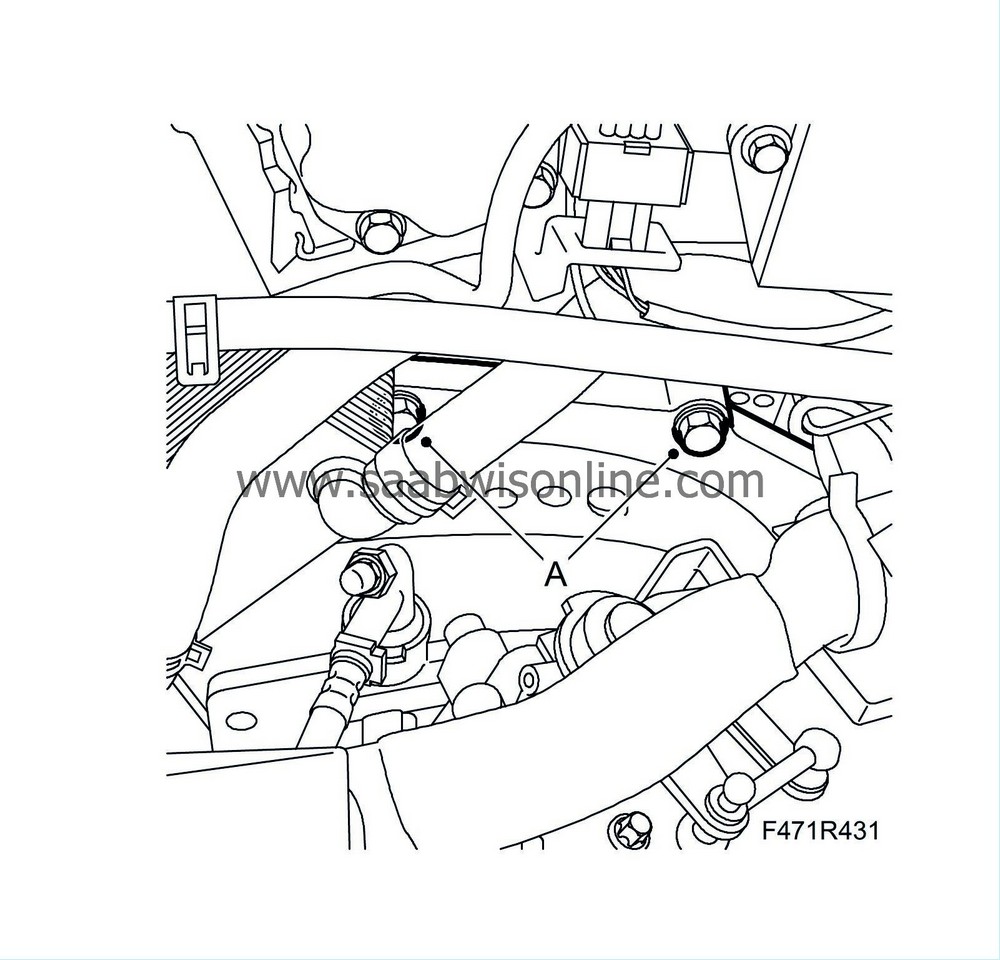

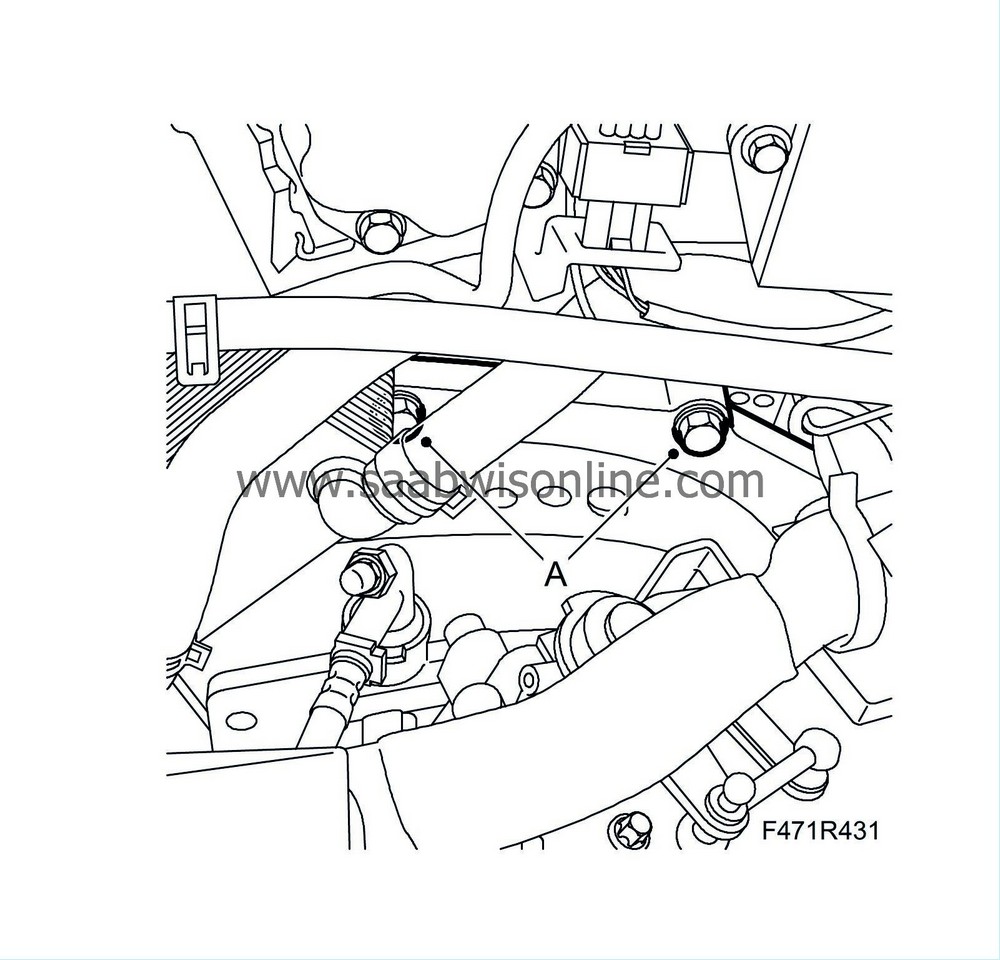

15.

|

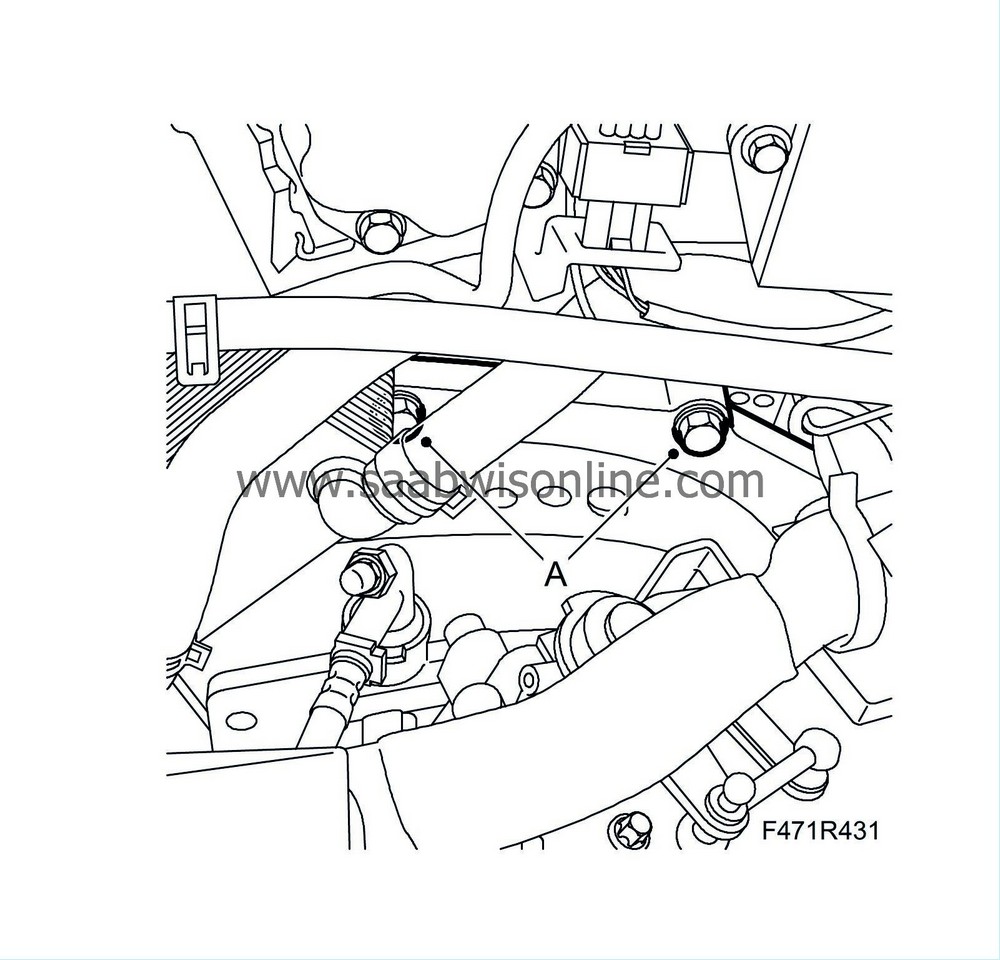

Lower the car and mark the location of the bolts on the left engine mounting with a marker pen to ensure correct refitting and then remove the screws (A) from the mounting.

|

|

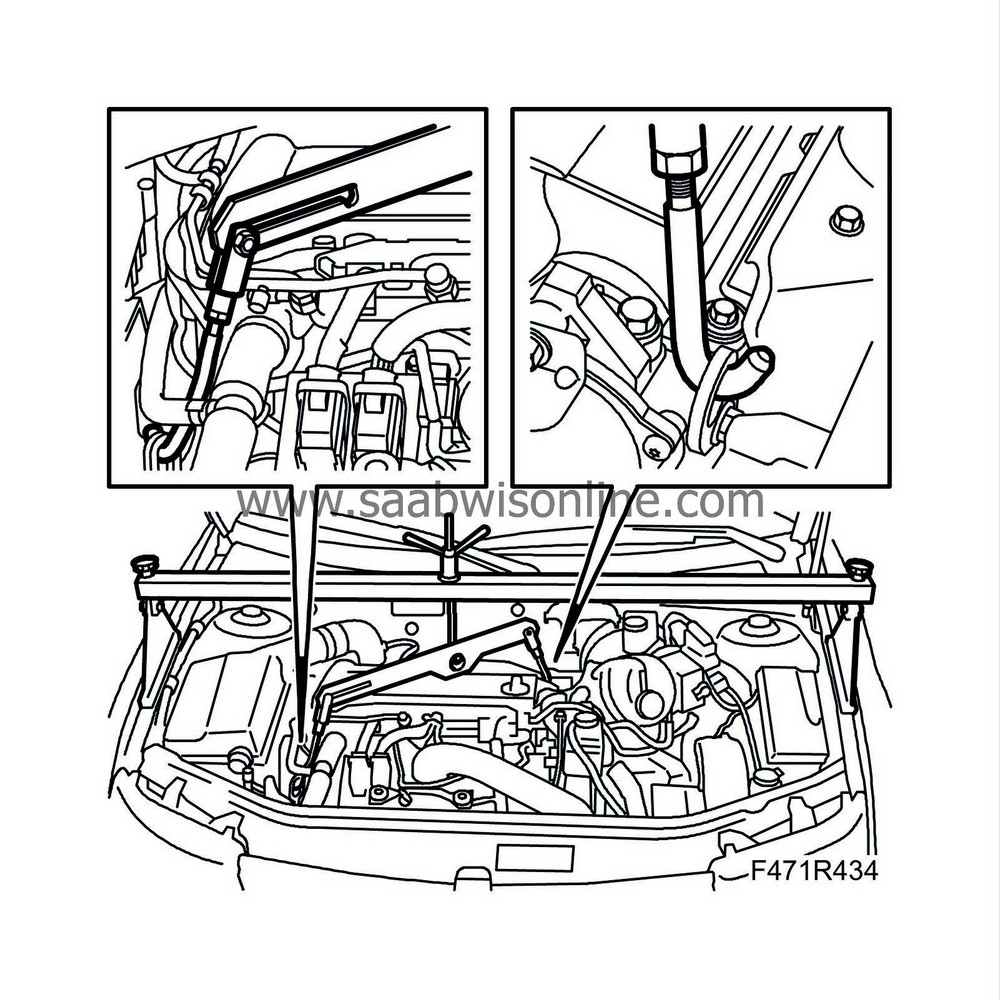

16.

|

Lower the drive unit approx. 70 mm from the lifting beam to facilitate the removal of the gearbox. Measure the distance at the left-hand engine mounting.

|

|

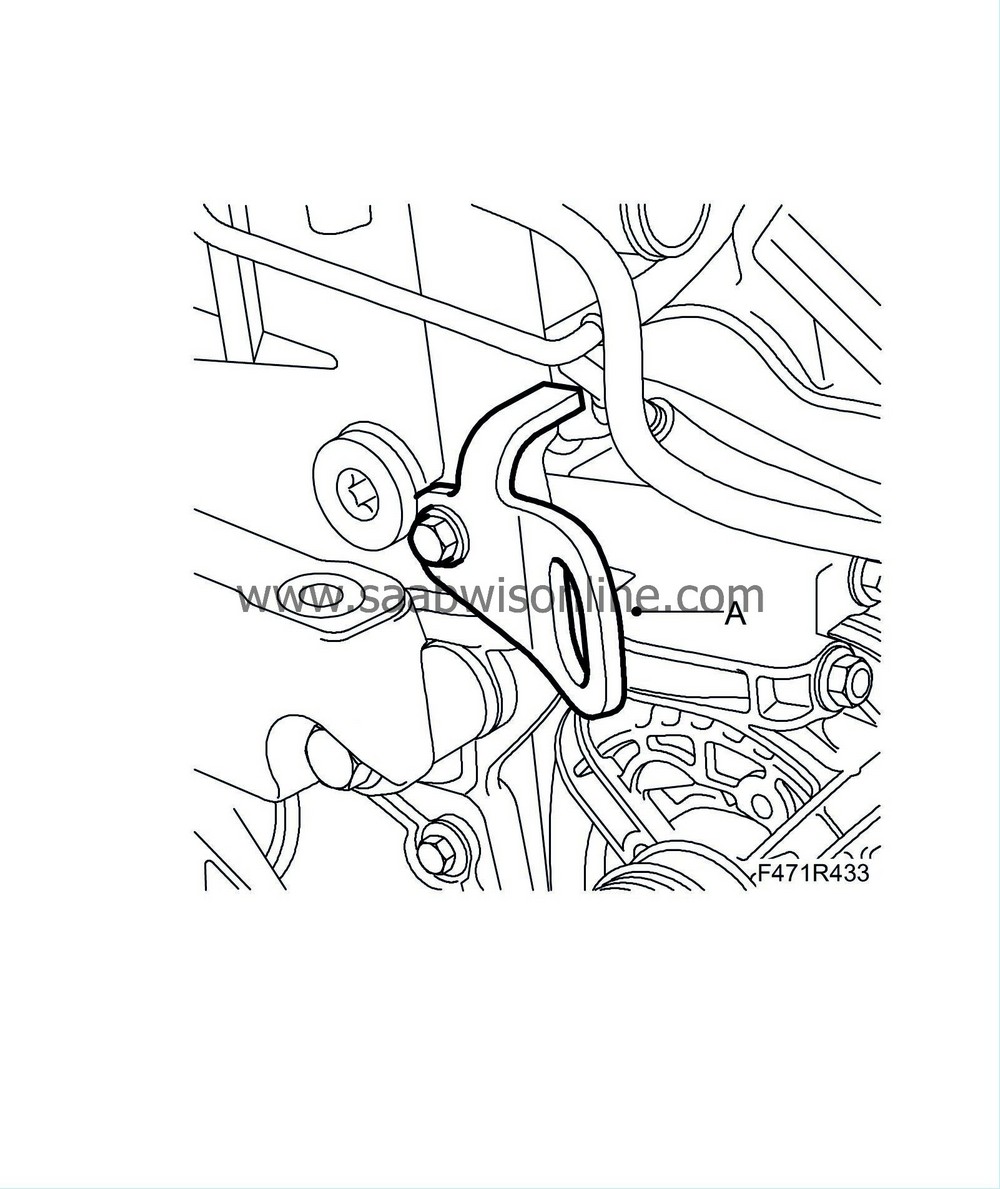

18.

|

When replacing the gearbox, remove the front torque rod bracket from the gearbox.

|

|

19.

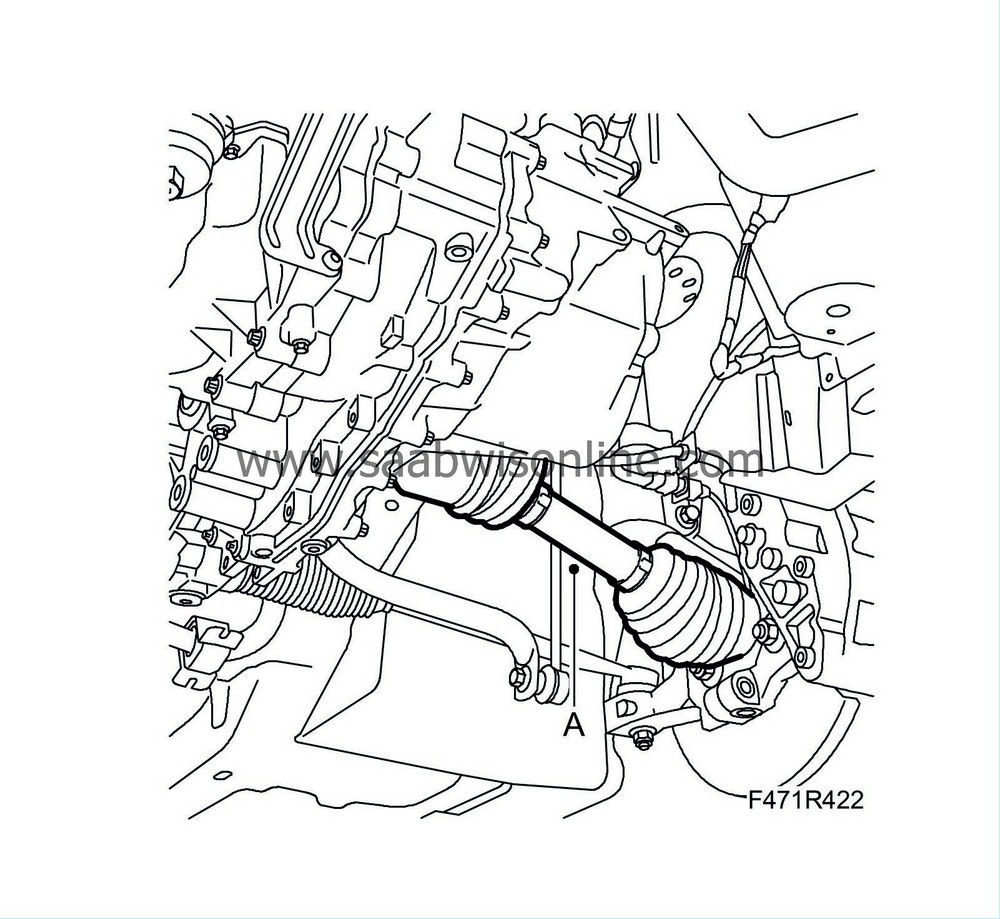

|

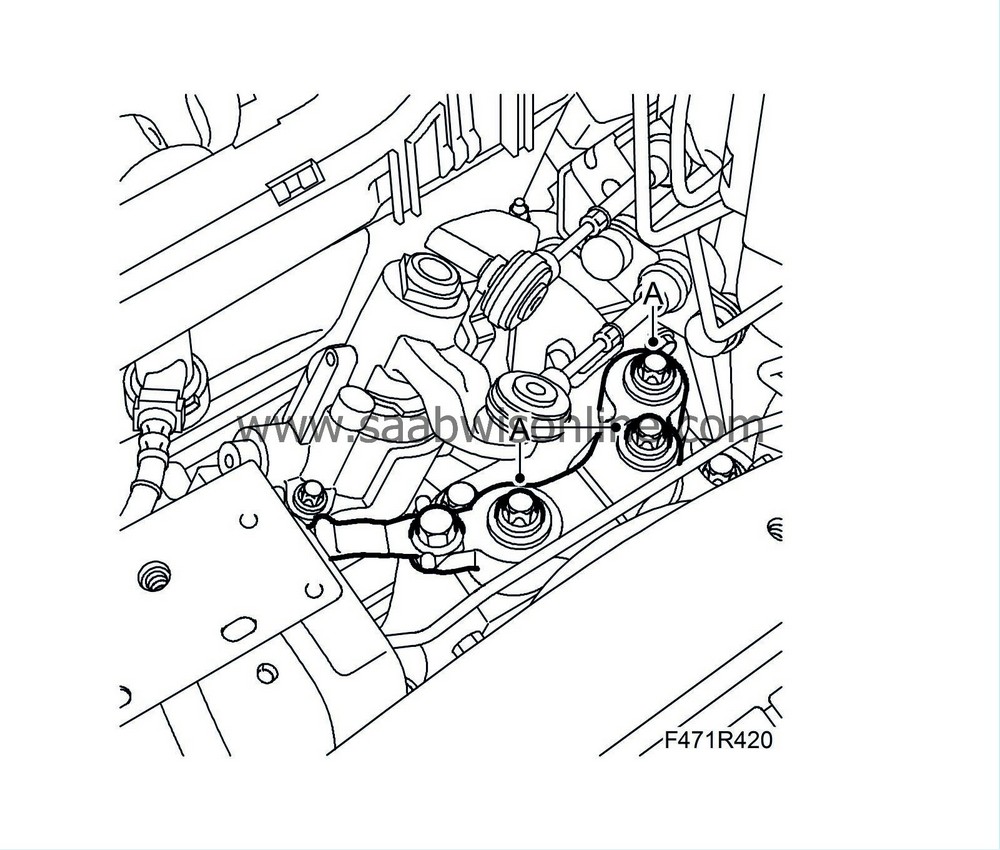

Remove the lower gearbox bolts (A). Leave one bolt in place.

|

|

23.

|

Remove the last bolt, pull out the transmission and lower it.

|

Important

|

|

The jack can tip over. Be careful.

|

|

|

|

|

24.

|

Lift the transmission down from the column jack with an engine lift and

87 92 442 Lifting cable

while undoing the lifting tool from the transmission.

|

|

1.

|

When replacing the gearbox, transfer the cable bracket and engine mounting.

Tightening torque nuts 22 Nm (16 lbf ft)

Tightening torque, bolts 70 Nm +45° (52 lbf ft +45°)

|

|

3.

|

Lubricate the primary shaft splines, see List of lubricants and sealants.

|

|

4.

|

Lubricate the guide sleeves on the engine with anti-corrosion agent.

|

|

6.

|

Fit the gearbox with the lifting tool on the column jack.

|

Important

|

|

Make sure the gear cables are positioned correctly when lifting the gearbox.

|

|

|

|

|

7.

|

Fit the rest of the gearbox. Turn the crankshaft if necessary to get the gearbox in place.

|

Important

|

|

The jack can tip over. Be careful.

|

|

|

|

|

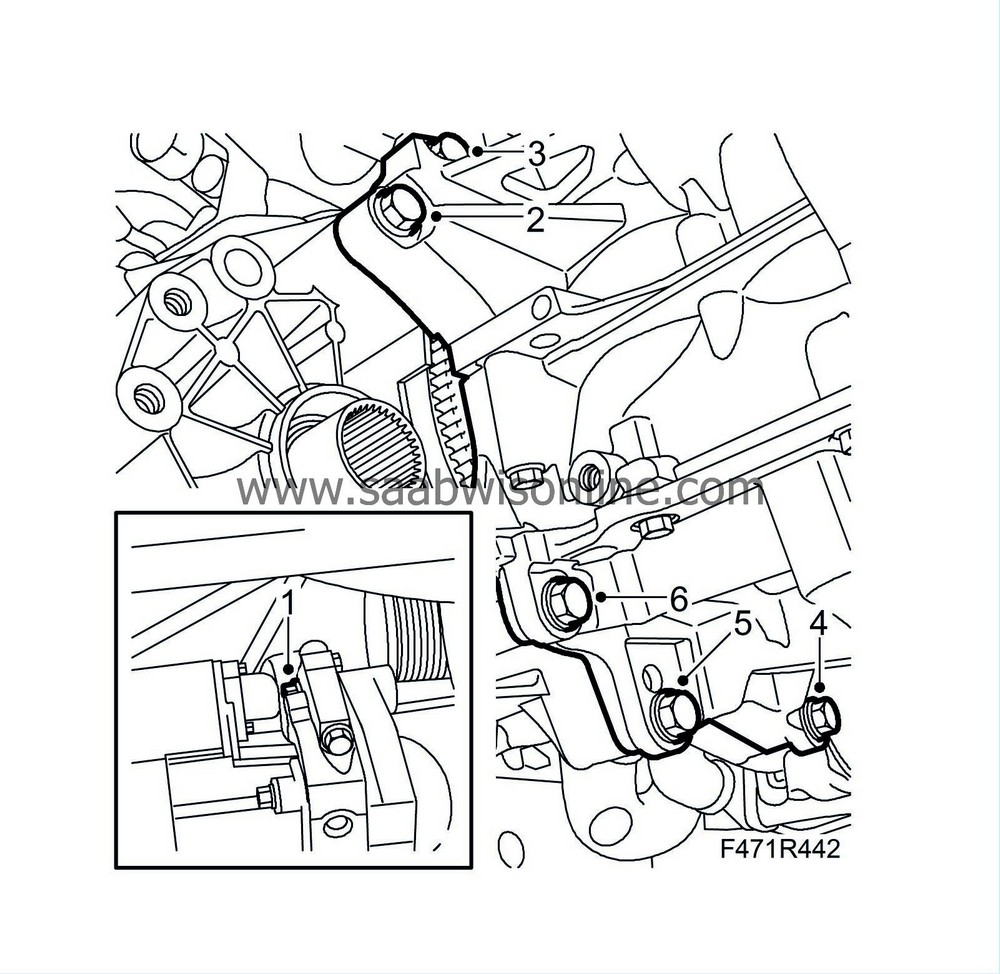

8.

|

Fit the lower bolts between engine and gearbox in the sequence illustrated.

Tightening torque, M10 bolts 40 Nm (30 lbf ft)

Tightening torque, M12 bolts 70 Nm (52 lbf ft)

|

|

9.

|

Remove the lifting tool from the gearbox and move away the jack.

|

|

10.

|

Lower the car. Lift in place the power train with the lifting beam until it meets the engine mounting.

|

|

11.

|

Fit the bracket (A) for the engine mounting according to the marks made earlier.

Tightening torque 70 Nm +45° (52 lbf ft +45°)

|

|

12.

|

Remove the holder, lifting beam and lifting eyes.

|

|

13.

|

Fit the coolant reservoir.

|

|

14.

|

Fit the upper bolts from the gearbox (A).

Tightening torque 70 Nm (52 lbf ft)

|

|

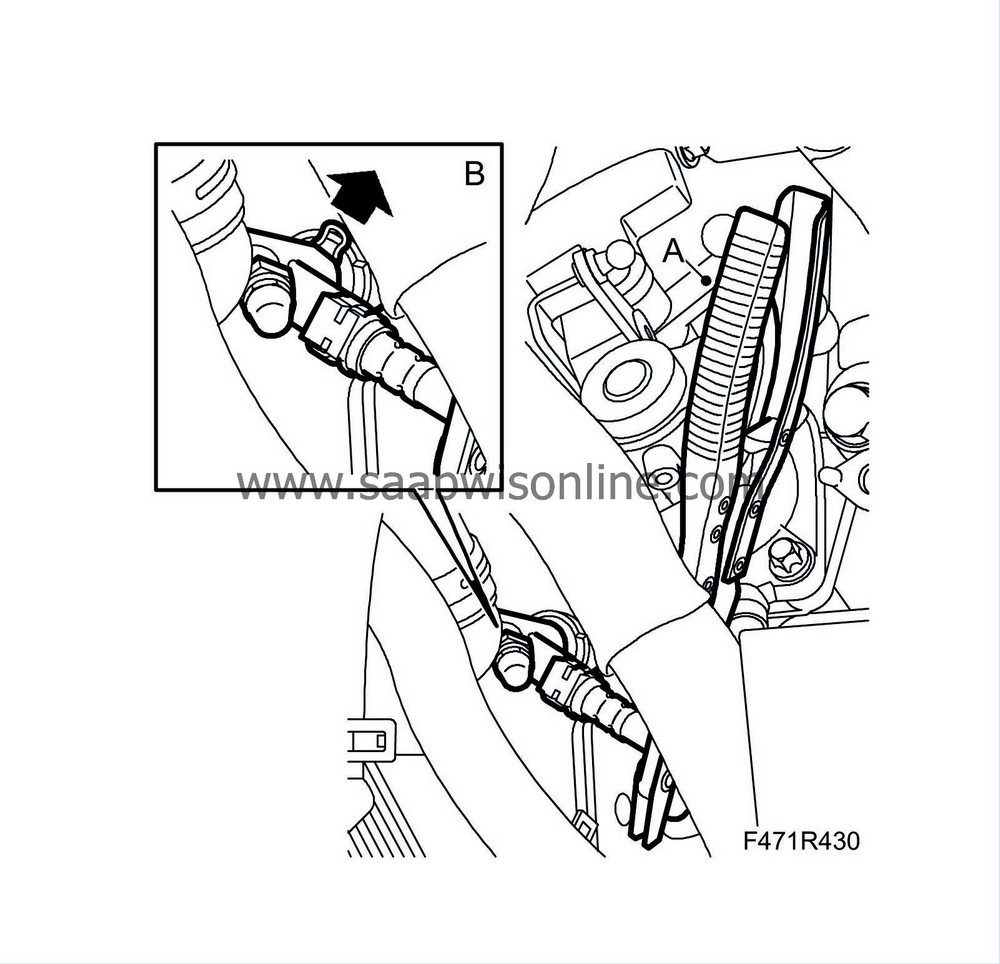

15.

|

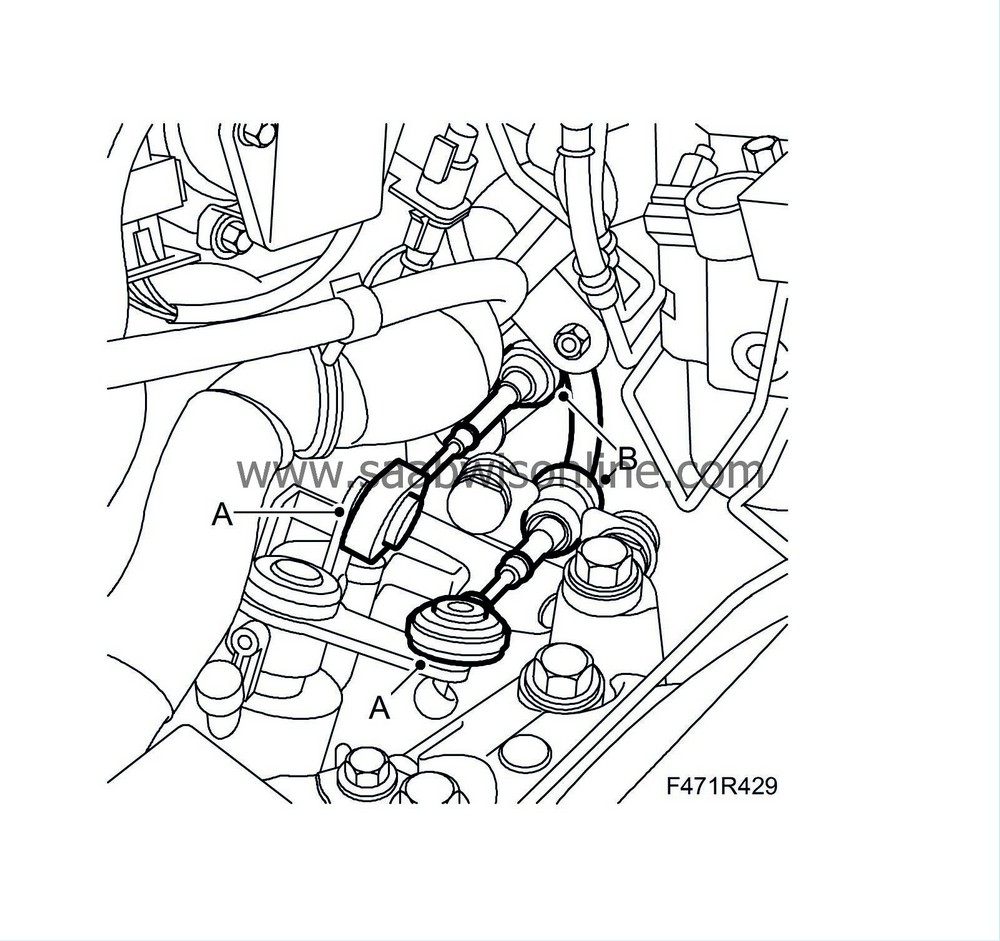

Fit the quick-release coupling (A) to the clutch slave cylinder. Remove the hose pinch-off pliers (B). Make sure the connection is secured in the correct position. Bleed the clutch. See

Bleeding the clutch hydraulic system in the car

.

|

|

16.

|

Plug in the reversing light switch.

|

|

17.

|

Fit the cables to the cable retainers by pulling back on the locking sleeves (B).

|

|

18.

|

Fit the gear cables (A) to the gear selector arms.

|

|

21.

|

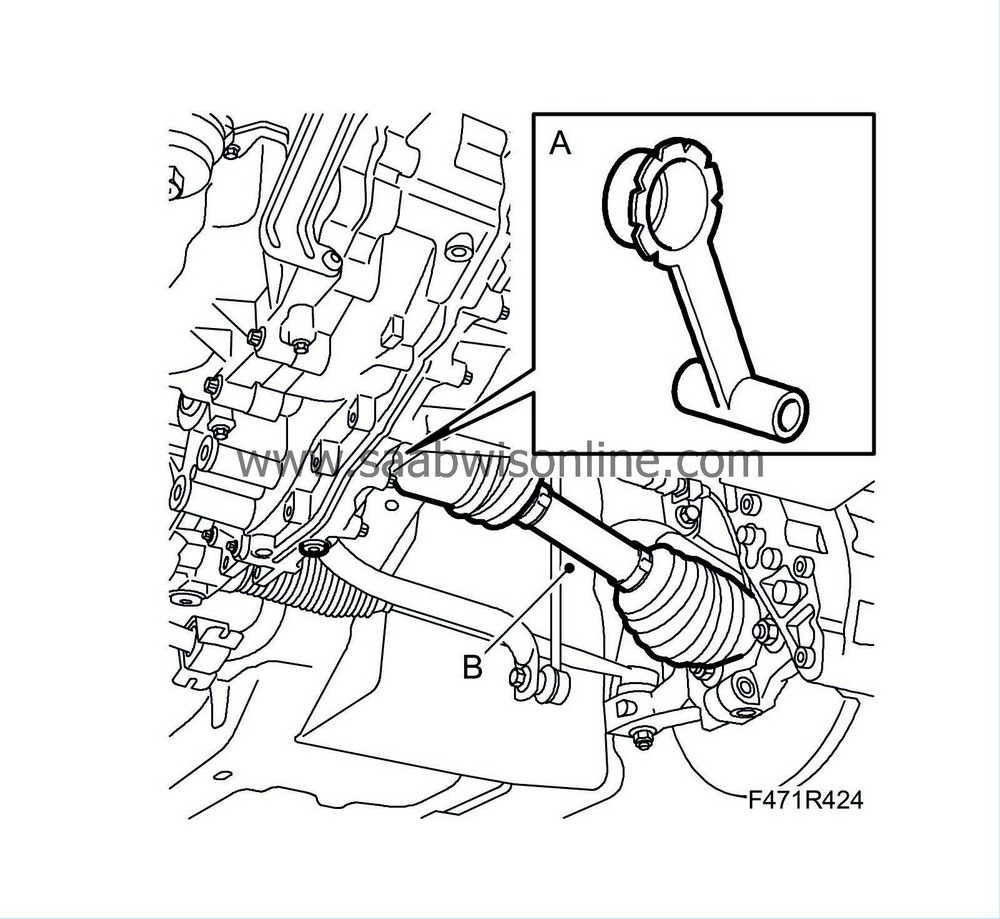

Make sure that the drive shaft (B) is clean and then align it with the tool (A).

|

Important

|

|

Fit the driver in the gearbox until approx.20 mm are remaining and pull out the tool before the sealing surface of the shaft reaches the shaft seal.

|

|

|

|

|

22.

|

Push in the rest of the drive shaft into the gearbox until the circlip clicks in.

|

|

23.

|

Attach the ABS cable to the clip.

|

|

24.

|

Fit the front torque rod bracket to the gearbox.

Tightening torque 80 Nm (59 lbf ft)

|

|

27.

|

Fit the battery tray (A) and the bonnet switch connector.

|

|

28.

|

Fit the cooling pipe and the battery.

|

|

29.

|

Fit the battery cover.

|

|

30.

|

Fit the upper engine cover.

|

|

31.

|

Remove the wing covers.

|

|

33.

|

Test drive the car. Check the position of the steering wheel when driving straight ahead on a level road. Adjust if needed.

|