Steering gear, B207 RHD

| Steering gear, B207 RHD |

| To remove |

| Important | ||

|

Scrupulous cleanliness must always be observed during all work with hydraulic components. |

||

| 1. |

Clamp the return hose using

30 07 739 Hose pinch-off pliers

.

|

|

| 2. |

Remove the pipes from the bracket on top of the steering gear.

|

|

| 3. |

Position the wheels and steering wheel straight ahead. Fix the steering wheel to the dashboard with woven tape or lock it with the steering wheel lock.

|

|

| 4. |

Raise the car.

|

|

| 5. |

Remove the front wheels.

|

|

| 6. |

CV:

Remove

Chassis reinforcement, front subframe, CV, B207

.

|

|

| 7. |

Remove the nut holding the track rod ends to the steering swivel members on both sides. Remove the track rods using

87 91 287 Puller, 150 mm

.

|

|

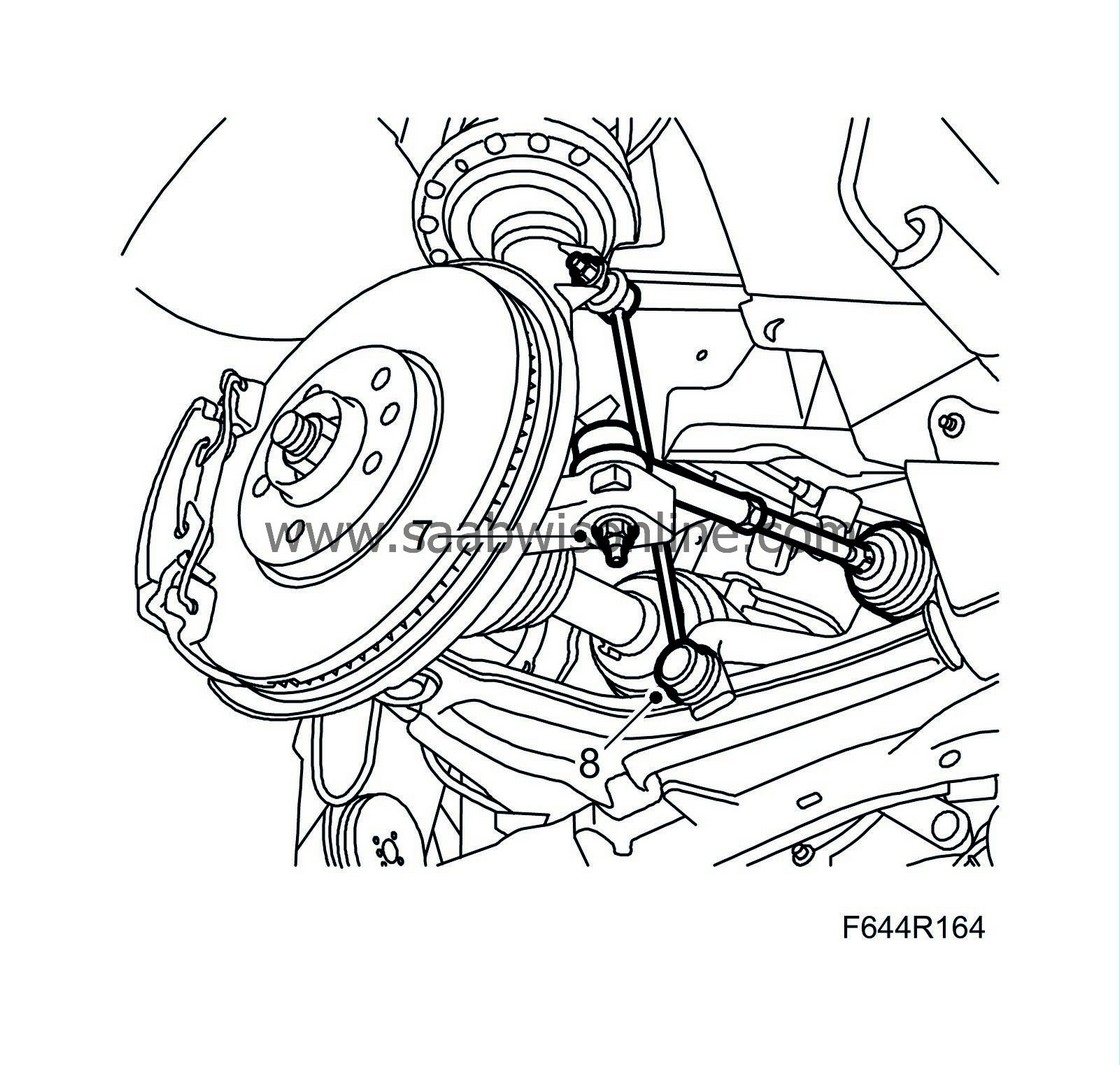

| 8. |

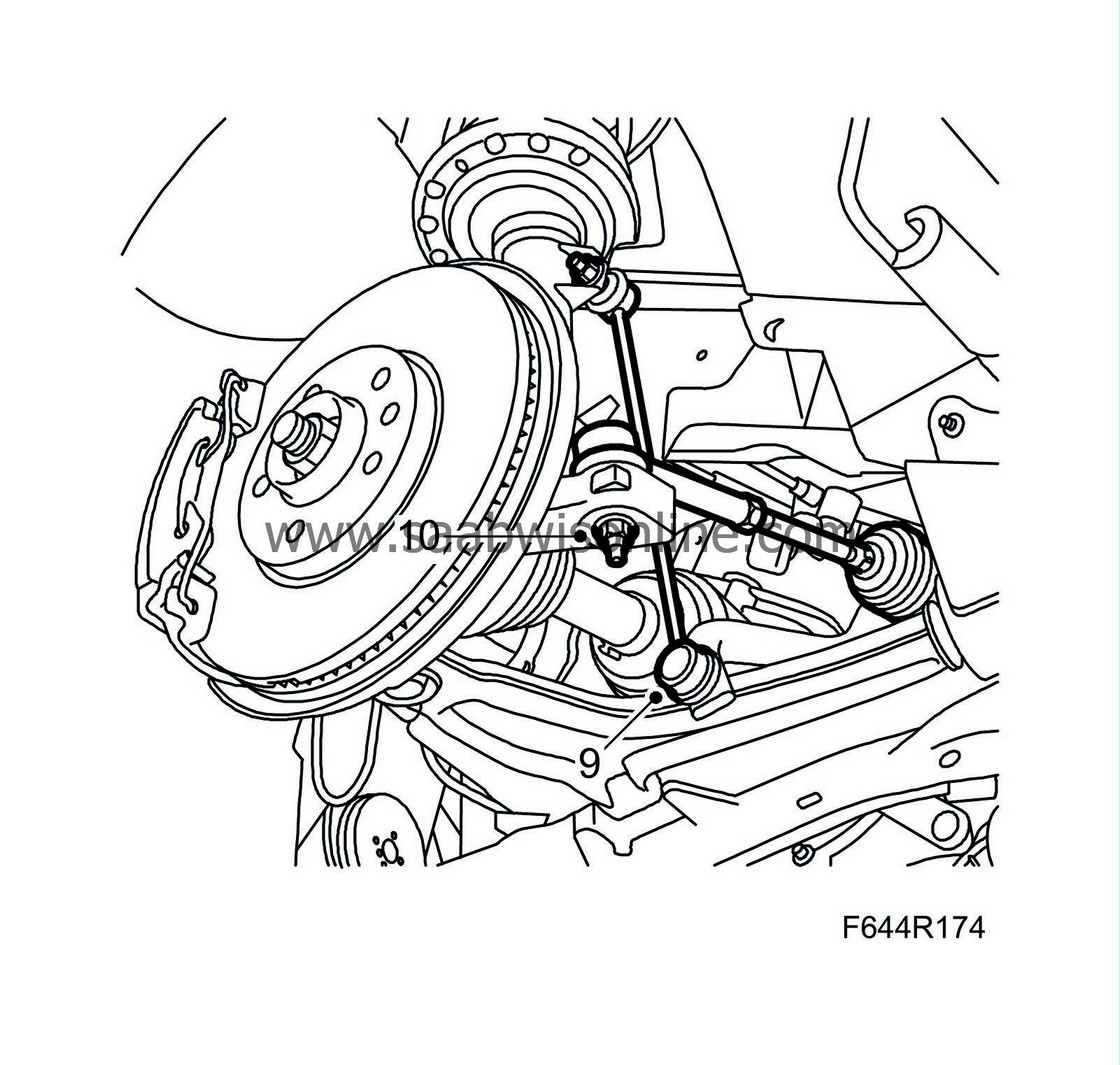

Remove the anti-roll bar links from the anti-roll bar. Hold with a thin 17 mm open wrench so that the ball joint does not turn.

|

|

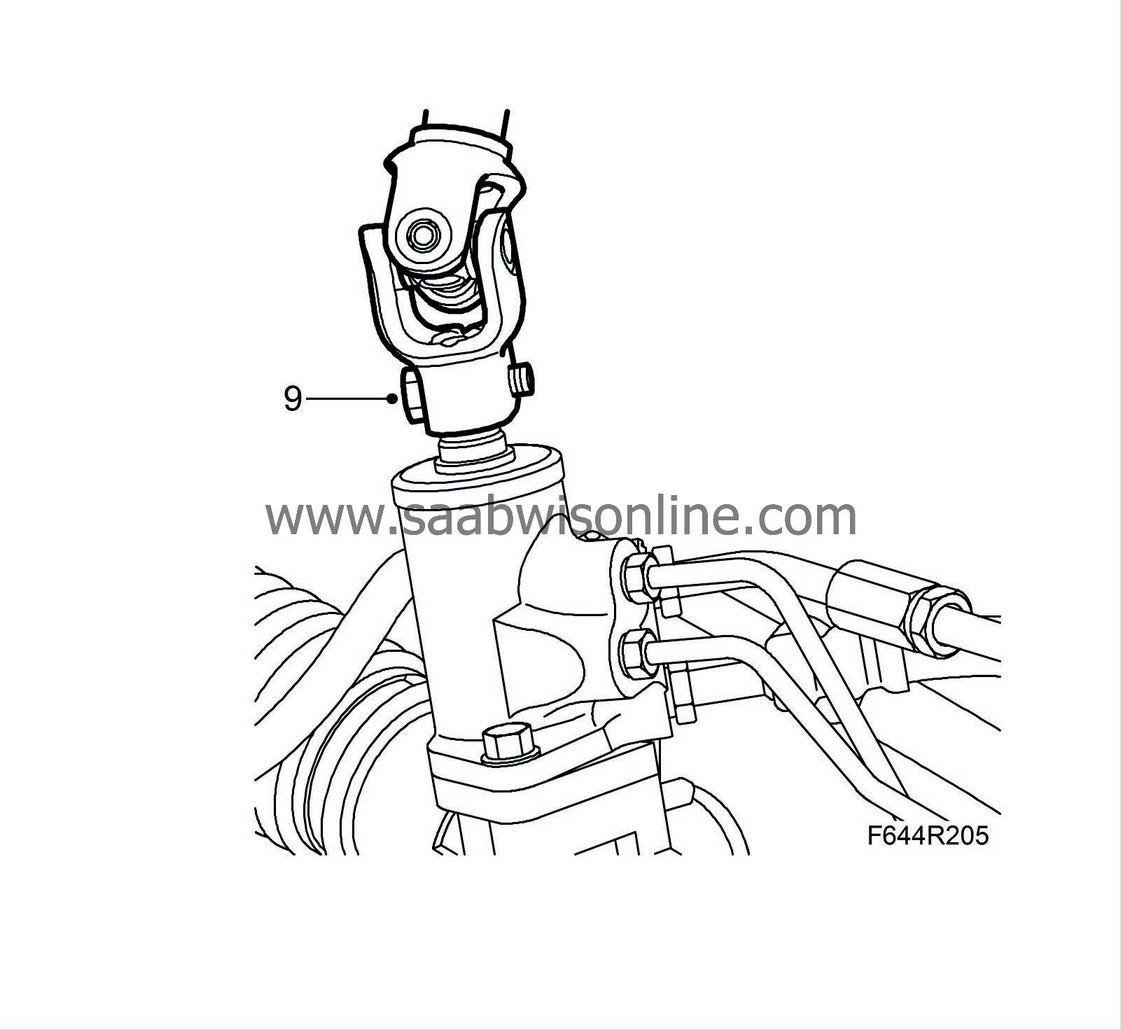

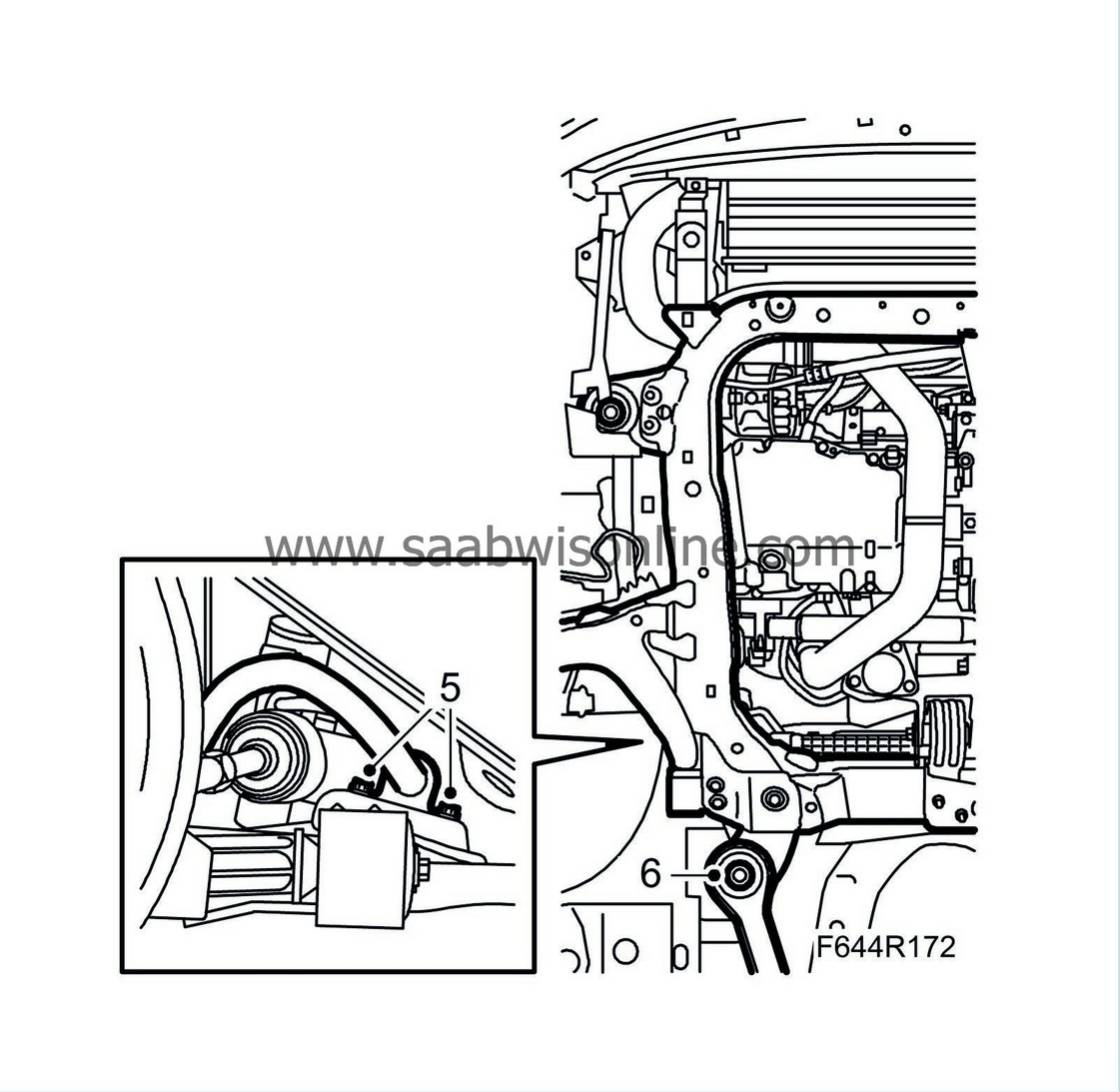

| 9. |

Remove the steering shaft joint from the steering gear.

|

|

| 10. |

Remove the exhaust pipe flange and front exhaust pipe mountings. Relieve the load on the flex membrane using

83 95 212 Strap

.

|

|

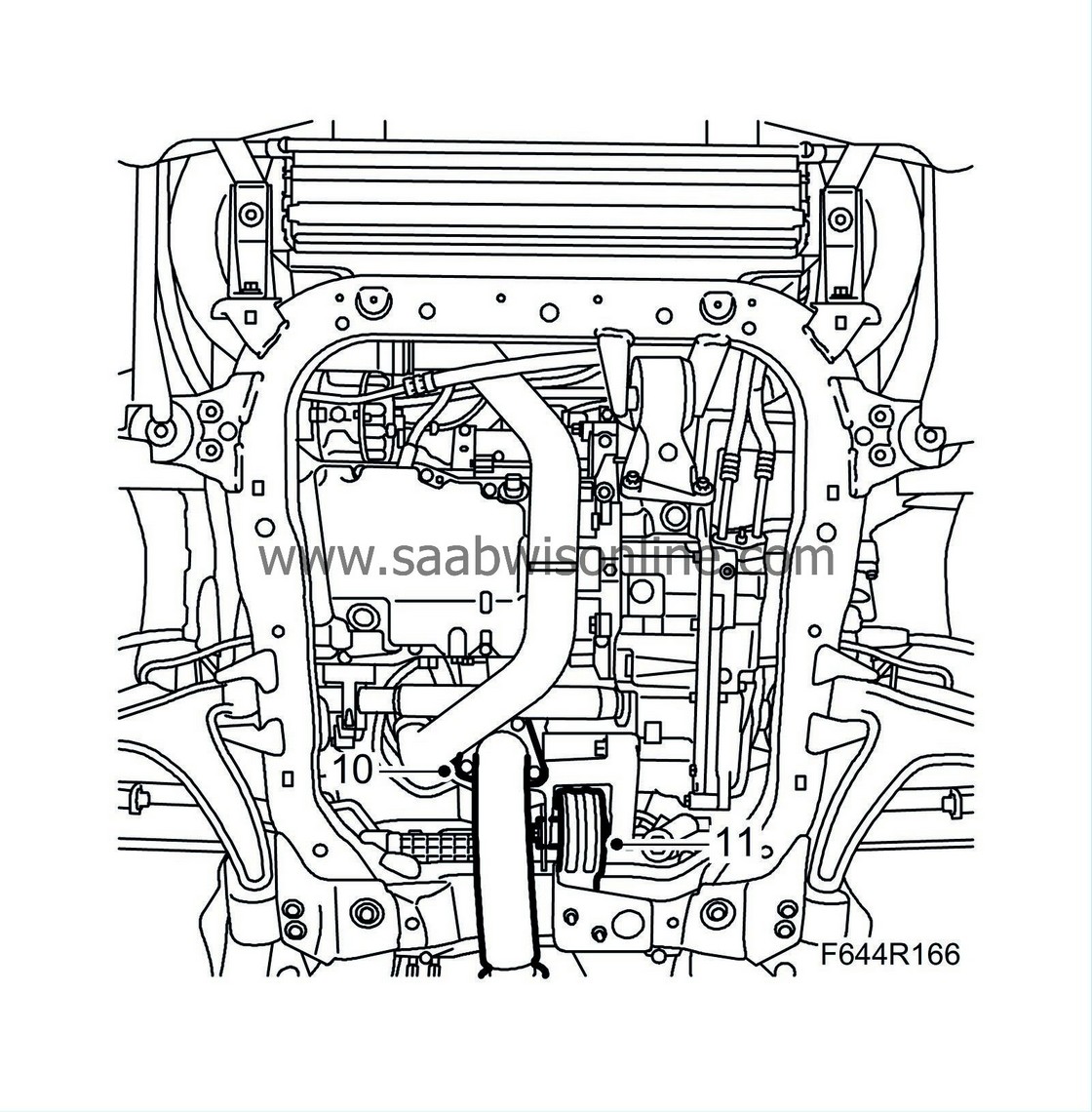

| 11. |

Remove the rear torque rod bolt.

|

|

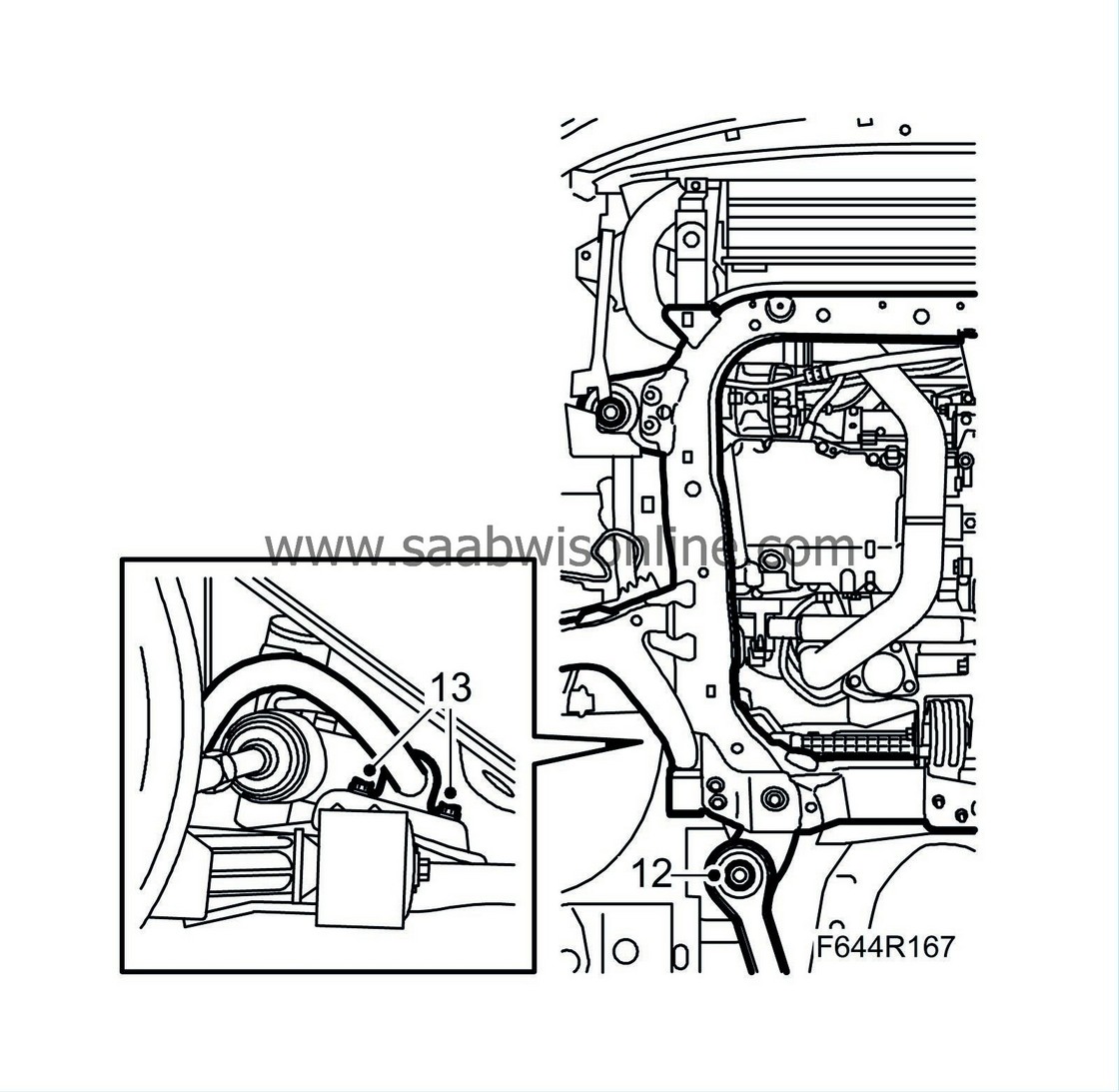

| 12. |

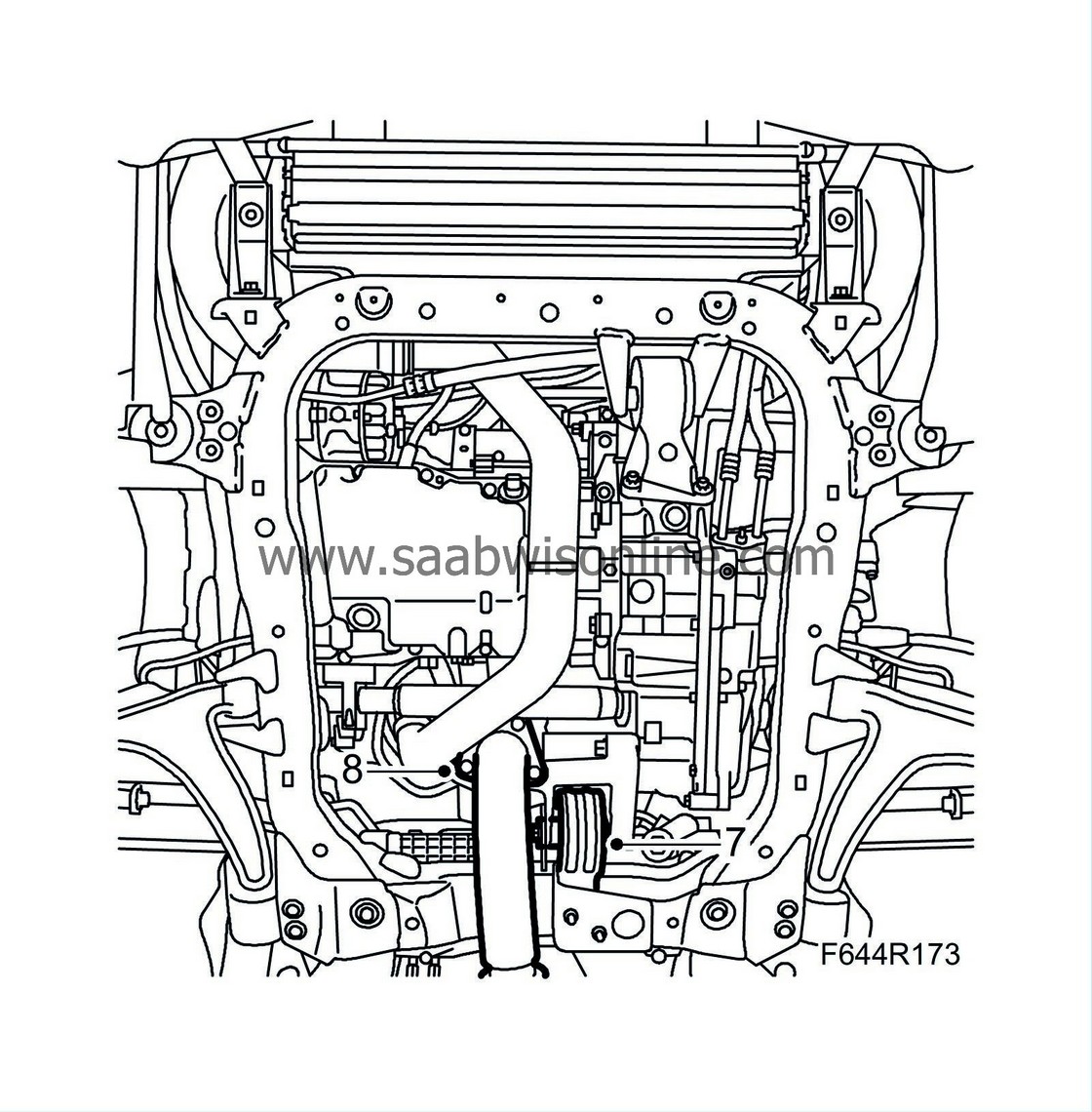

Use a column jack to relieve the load on the subframe. Remove the rear bolts and rod.

|

|

| 13. |

Remove the anti-roll bar mountings from the subframe.

|

|

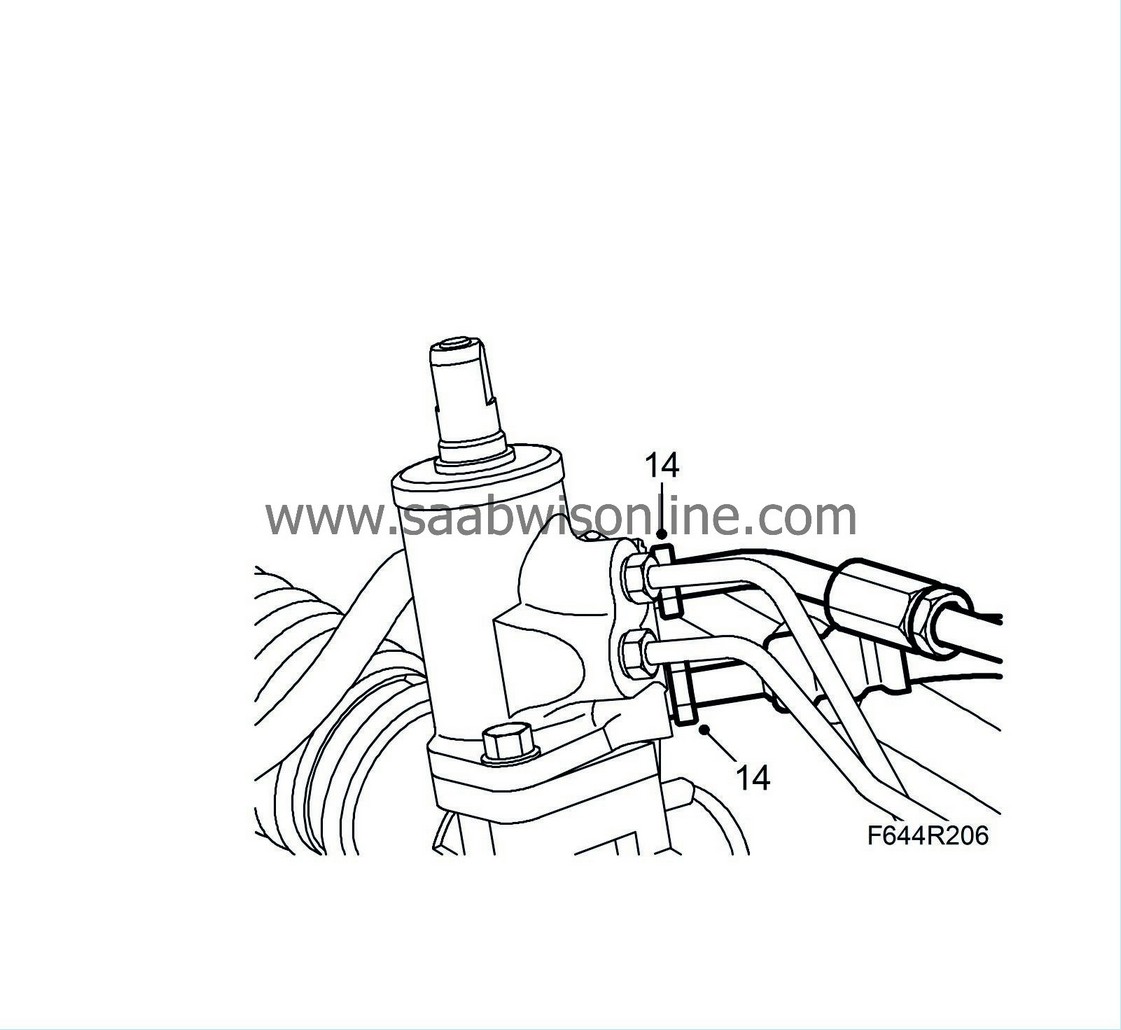

| 14. |

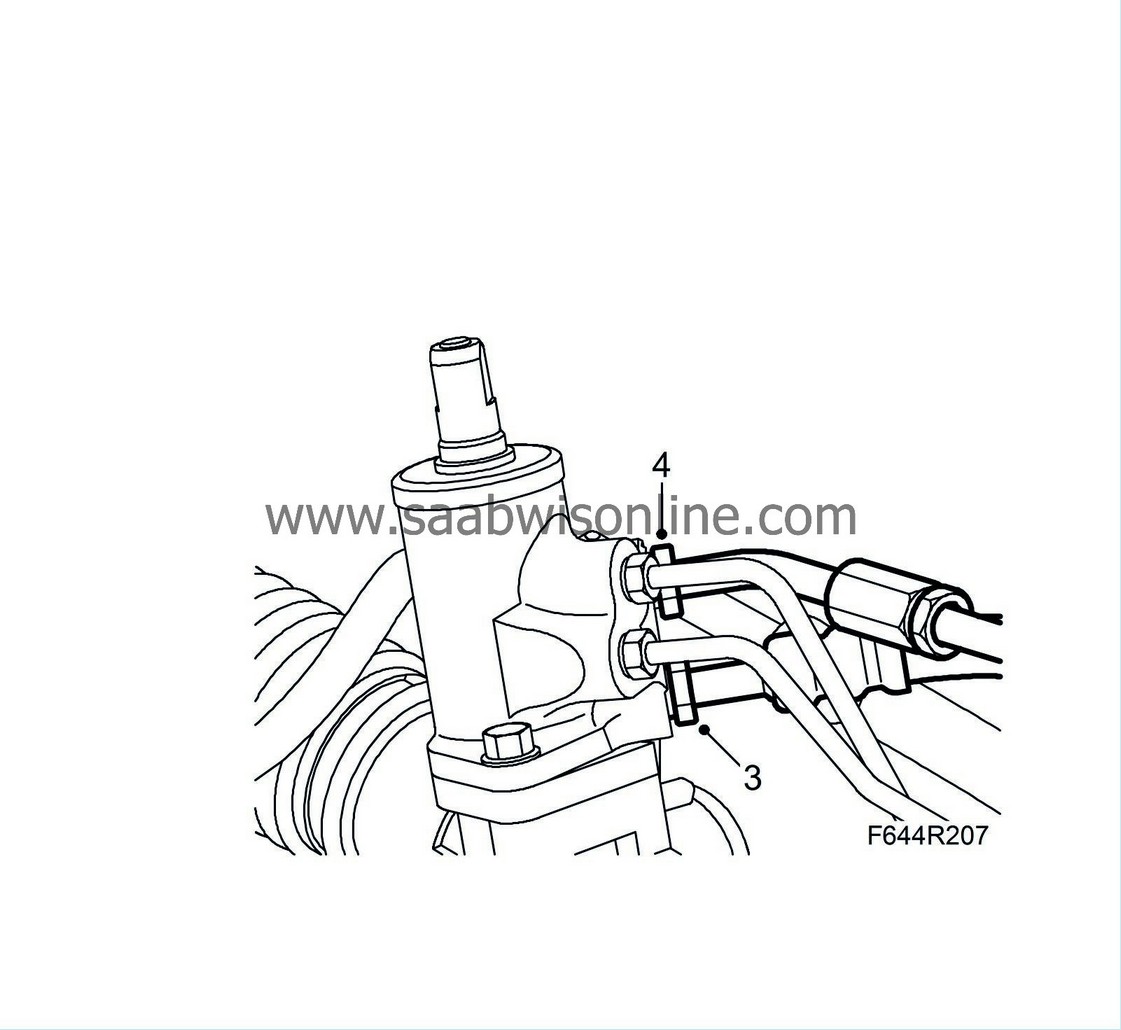

Place a receptacle under the car. Detach the delivery line and the return line from the steering gear. Plug the lines.

|

|

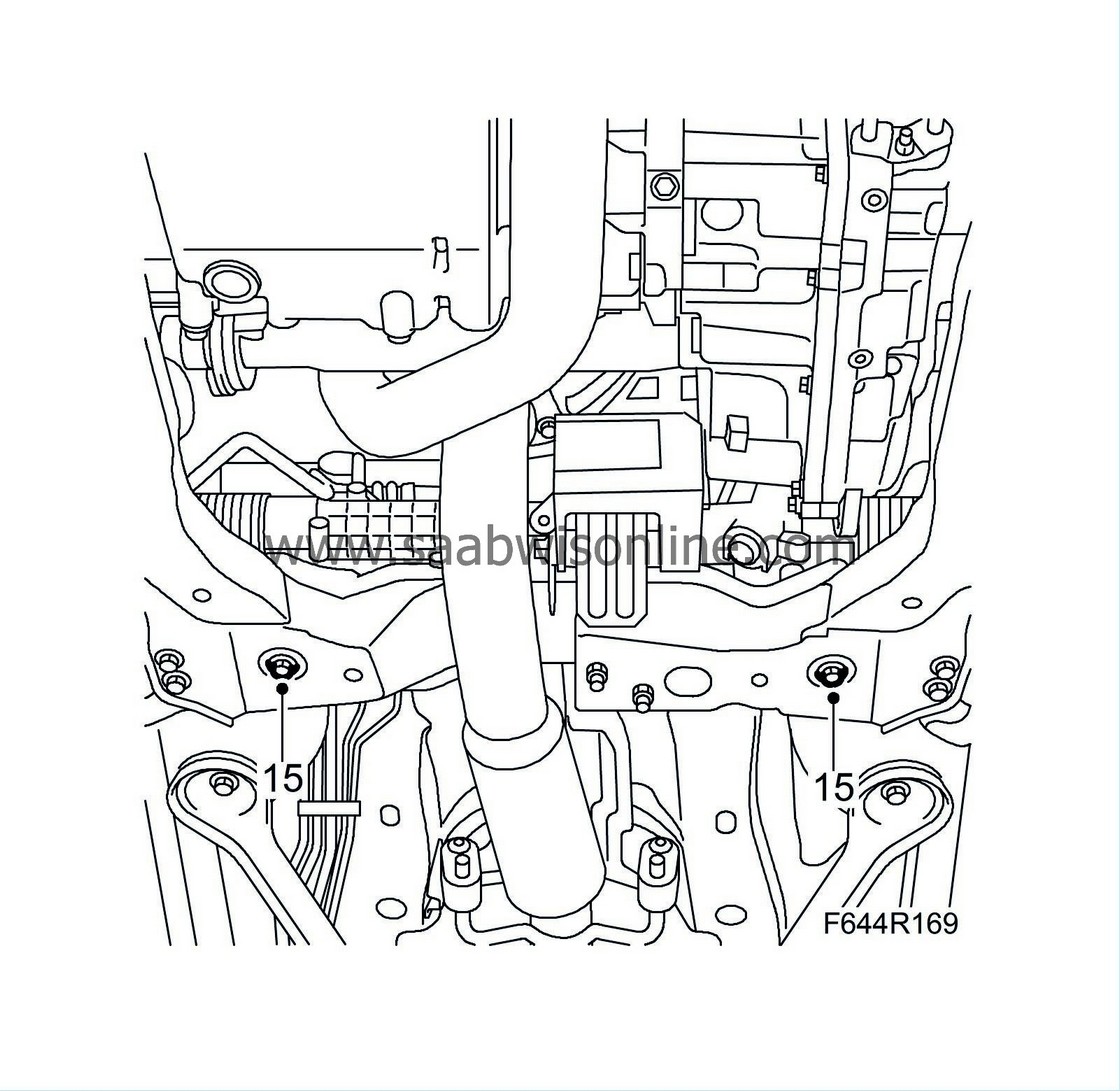

| 15. |

Remove the steering gear bolts, nuts and washers.

|

|

| 16. |

Raise the anti-roll bar as high as possible and lift out the steering gear through the wheel housing on the left side.

|

|

| To fit |

| 1. |

Lift the steering gear into place through the wheel housing on the left side.

|

|

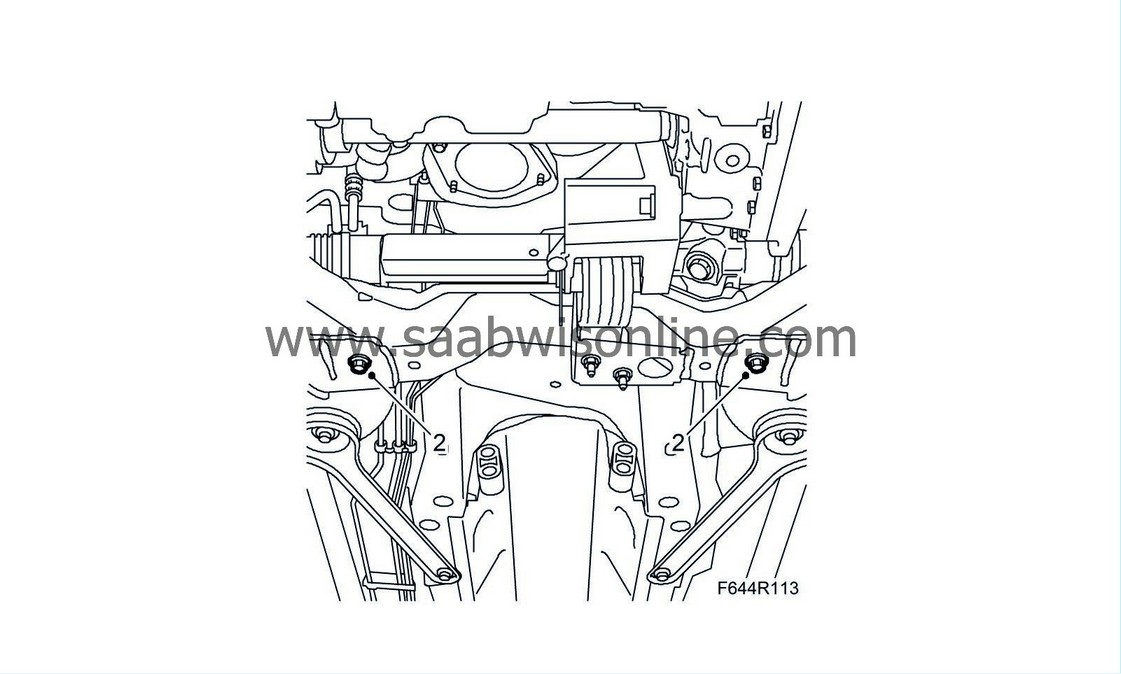

| 2. |

Fit the steering gear to the subframe.

Tightening torque 50 Nm +60° (37 lbf ft +60°)

|

|

| 4. |

Fit the delivery line to the steering gear. Fit new O-rings. Make sure the lines are correctly positioned at the bracket on the top of the steering gear.

Tightening torque 28 Nm (21 lbf ft) |

|

| 5. |

Fit the anti-roll bar to the subframe.

Tightening torque: 18 Nm (14 lbf ft)

|

|

| 6. |

Raise the subframe using

83 95 311 Trolley lift

with

83 94 801 Parent fixture

and

83 96 137 Centring tool, subframe - body

. Fit the tool against the guide holes in the body. Fit the rods and tighten the bolts.

Tightening torques Subframe: 75 Nm + 135° (55 lbf ft + 135°) Torque rod: 90 Nm + 45° (67 lbf ft + 45°) |

|

| 7. |

Fit the torque rod bolt.

Tightening torque: 80 Nm (59 lbf ft)

|

|

| 8. |

Fit the exhaust pipe flange and exhaust pipe mountings.

Tightening torque 30 Nm (22 lbf ft) |

|

| 9. |

Fit the anti-roll bar links to the anti-roll bar. Hold with a thin 17 mm open wrench so that the ball joint does not turn.

Tightening torque 64 Nm (47 lbf ft)

|

|

| 10. |

Fit the track rod ends to the steering swivel members.

Tightening torque 35 Nm (26 lbf ft) |

|

| 11. |

Put the wheels in the straight-ahead position and fit the steering shaft joint to the steering gear. Clean the threads and apply

Threadlock, Loctite 242

to the threads.

Tightening torque 30 Nm (22 lbf ft)

|

|||||||||

| 12. |

CV:

Install

Chassis reinforcement, front subframe, CV, B207

.

|

|

| 13. |

Wipe clean the subframe from any oil.

|

|

| 14. |

Lower the car to the floor.

|

|

| 15. |

Refit the

wheels

.

|

|

| 16. |

Fit the pipes to the bracket on top of the steering gear.

|

|

| 17. |

Remove the hose pinch-off pliers and fill with

power steering fluid

.

|

|

| 18. |

Remove the tape or other means used to prevent the steering wheel from moving.

|

|

| 19. |

Bleed the power steering system and check the sealing integrity. See

Bleeding the power steering system

.

|

|

| 20. |

Carry out a

wheel alignment

.

|

|

Warning

Warning