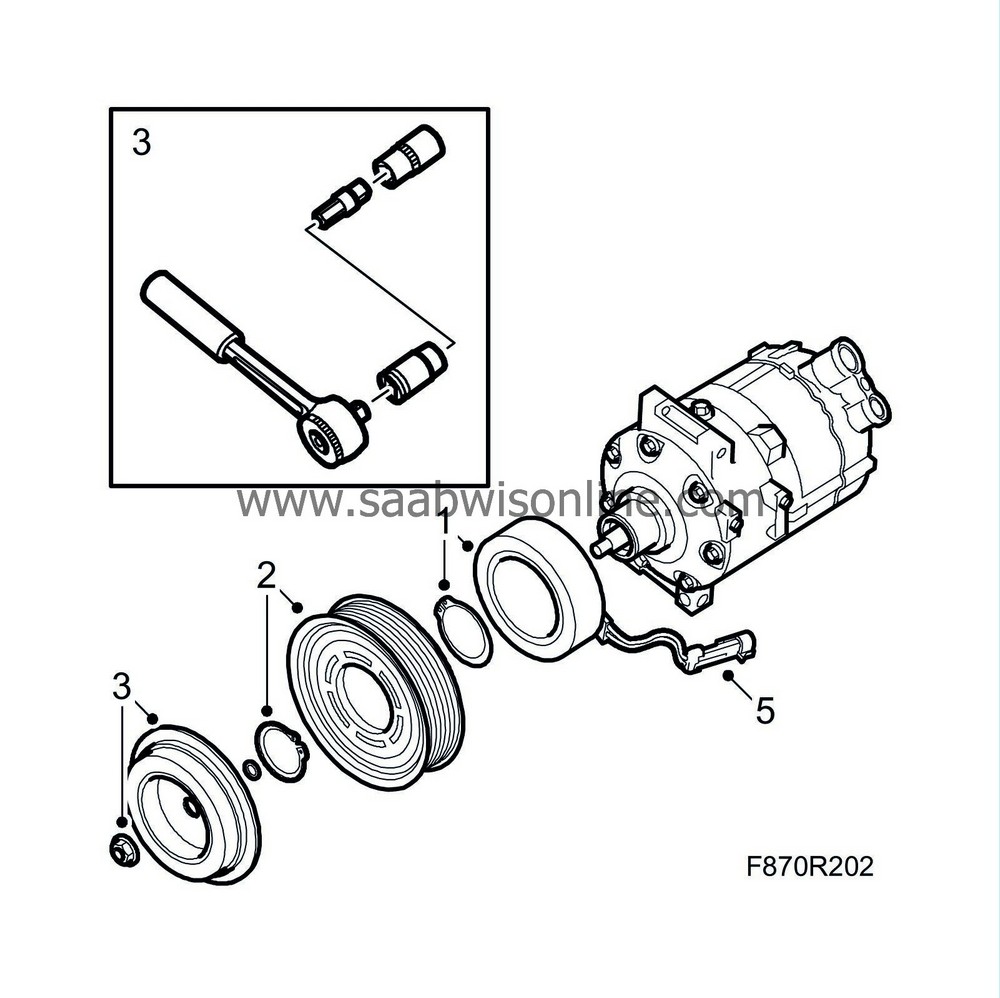

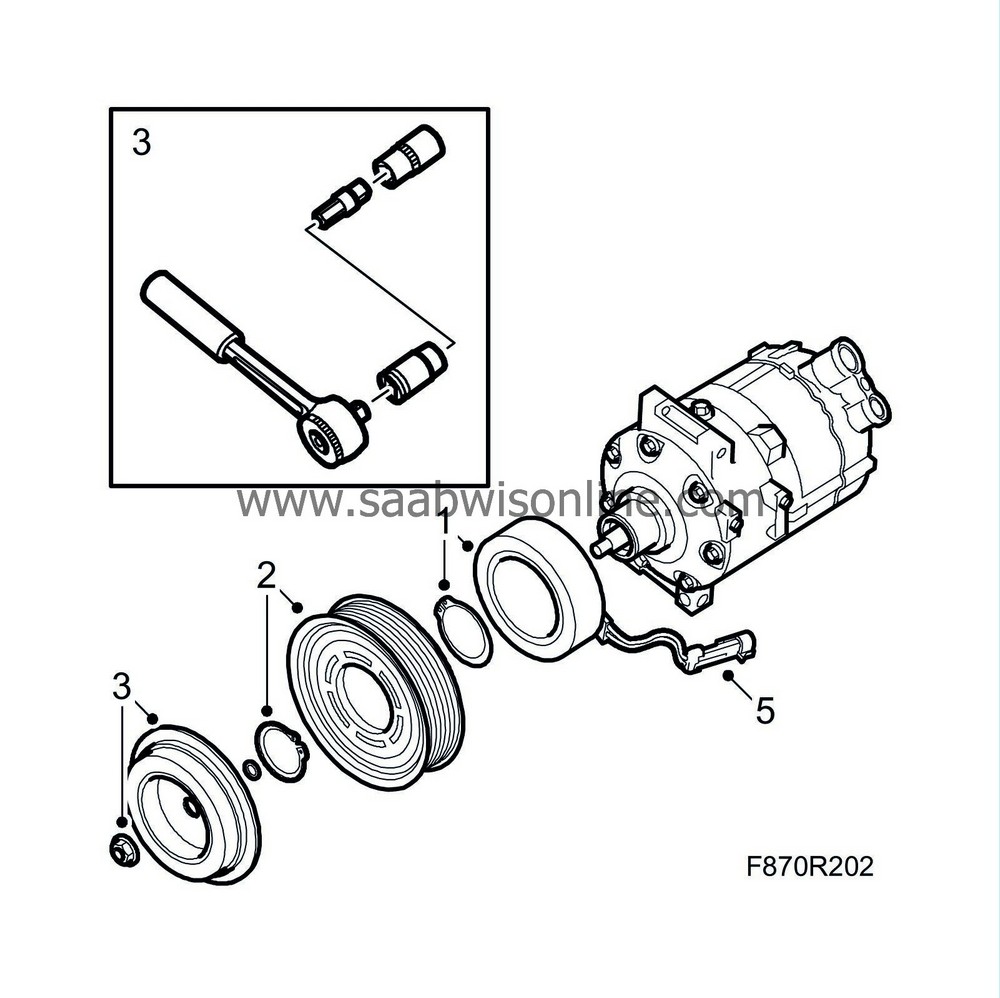

Electromagnetic clutch, A/C compressor, B207

|

|

Electromagnetic clutch, A/C compressor, B207

|

|

Important

|

|

To avoid contaminating the system, clean the area around the parts being function and service life of the system.

|

|

|

|

2.

|

Dismantle the compressor's ground cable and the locking plate from the compressor housing.

|

|

3.

|

Dismantle the driver by using a 14 mm spanner and a suitable support. Pull it out of the shaft.

|

|

4.

|

Dismantle the circlip that holds the belt pulley and lift off the belt pulley.

|

Note

|

|

If the belt pulley jams, knock the edge using a plastic mallet so that it becomes loose.

|

|

|

5.

|

Dismantle the circlip holding the magnet winding and lift off the magnet winding.

|

Note

|

|

If the magnet winding jams, carefully pry using a screwdriver so that the guide pin loosens from the slot.

|

|

|

1.

|

Position the magnet winding in position with the guide pin in the slot on the compressor housing. Check that the cables are routed correctly. Fit the circlip.

|

|

2.

|

Fit the belt pulley and fit the circlip.

|

|

3.

|

Put the shim in the driver and position the driver on the shaft. Tighten the screw.

|

|

4.

|

Measure the play between the driver and the belt pulley using a feeler gauge. The play should be 0.5 ± 0.15 mm. Adjust the play if necessary but changing the shim on the compressor shaft.

|

Note

|

|

The top of the feeler gauge must be angled to measure the play.

|

|

|

5.

|

Fit the compressor's ground cable and locking plate on the compressor housing.

|