Tire and Wheel Assembly Isolation Test

|

|

Tire and Wheel Assembly Isolation Test

|

Force variation refers to a radial or lateral movement of the tire and wheel assembly which acts much like runout, however, force variation has to do with variations in the construction of the tire. These variations in tire construction may actually cause vibration in a vehicle, even though the tire and wheel assembly runout and balance may be within specifications.

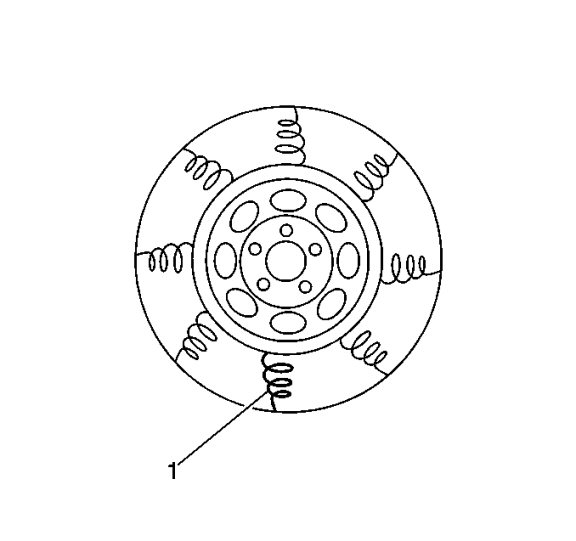

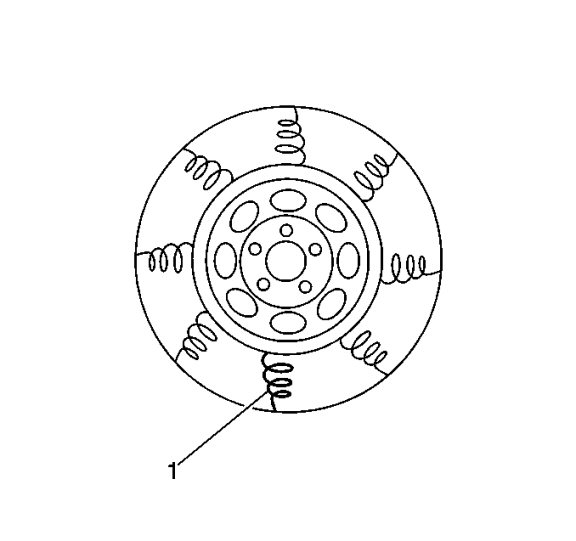

Radial force variation refers to the difference in the stiffness of a tire sidewall as the tire rotates and contacts the road. Tire sidewalls have some stiffness due to splices in the different plies of the tire, but these stiffness differences do not cause a problem unless the force variation is excessive. Stiff spots (1) in a tire sidewall can deflect a tire and wheel assembly upward as the assembly contacts the road.

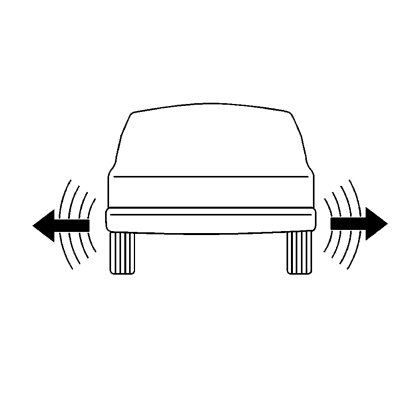

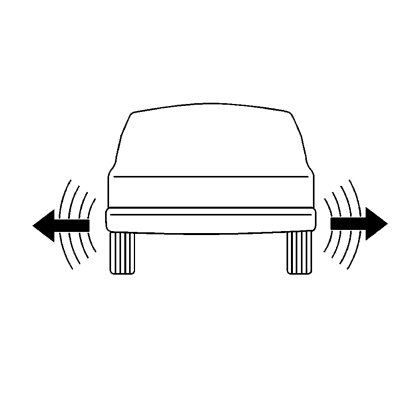

Lateral force variation refers to the difference in the stiffness or conformity of the belts within a tire as the tire rotates and contacts the road. Tire belts may have some stiffness or conformity differences, but these differences do not cause a problem unless the force variation is excessive. These variations in the belts of the tire can deflect the vehicle sideways or laterally. A shifted belt inside a tire may cause lateral force variation.

In most cases where excessive lateral force variation exists, the vehicle will display a wobble or waddle at low speeds, 8-40 km/h (5-25 mph), on a smooth road surface.

Perform the following test in order to determine if force variation is present in the vehicle.

|

3.

|

If the vibration is still present while using the known good set of tire and wheel assemblies, then force variation is not the cause of the vibration.

|

|

5.

|

Continue the process of installing the original tire and wheel assemblies one at a time, then road testing the vehicle, until the tire and wheel assembly, or assemblies which is causing the vibration has been identified.

|