Camshaft Position Actuator Installation - Right Side Exhaust

|

|

Camshaft Position Actuator Installation - Right Side Exhaust

|

|

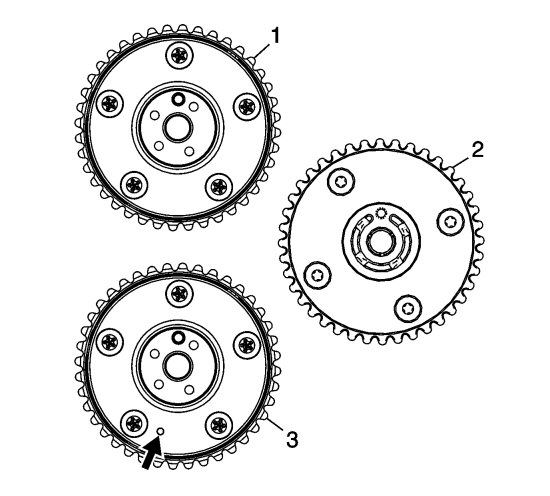

1.

|

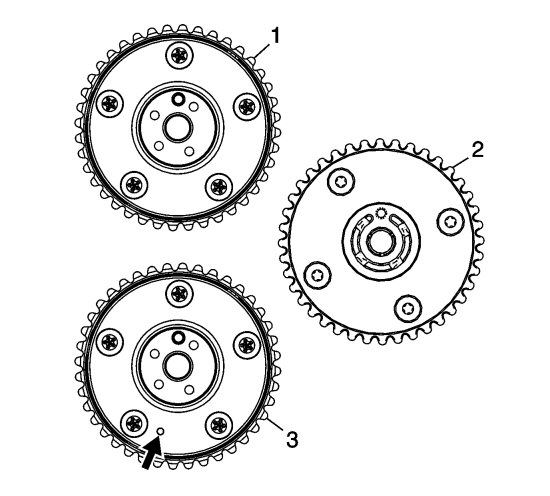

Ensure the proper camshaft position actuator is installed. Observe the body of the camshaft position actuator for the "EX" marking (1). The marking is for an exhaust camshaft position actuator.

|

|

2.

|

Ensure the proper timing mark is used. Observe the outer ring of the camshaft position actuator for the triangle marking (2). The marking is for alignment to the highlighted timing chain link on the right side of the engine.

|

|

4.

|

|

Note

|

|

•

|

The camshaft position actuator will vary depending on application.

|

|

•

|

Some applications do not use a camshaft thrust washer.

|

Ensure the proper camshaft thrust washer is used, if applicable. Use a 1.6 mm (0.063 in) thrust washer on applications that have 5 attaching screws on the back side of the camshaft position actuator without an identification dot (1). Use a 1.1 mm (0.043 in) thick thrust washer with yellow speckles on applications that have 4 attaching screws on the back side of the camshaft position actuator (2) and on applications that have 5 attaching screws on the back side of the camshaft position actuator with an identification dot (3).

|

|

5.

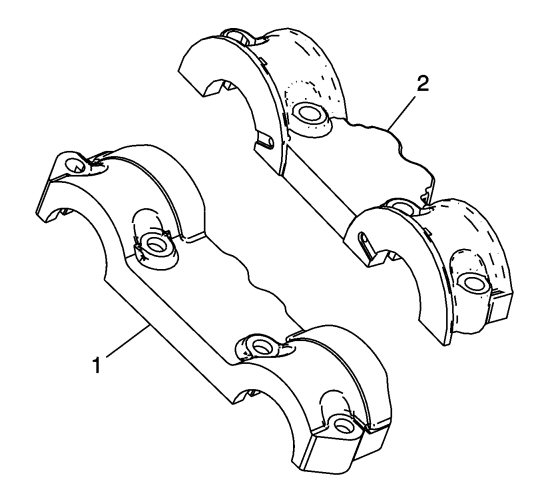

|

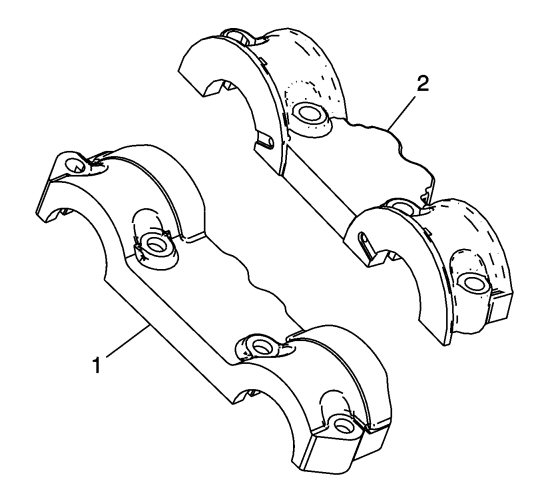

There are first design (1) and second design (2) camshaft front bearing caps. Applications that have a second design camshaft bearing cap (2) do not use thrust washers.

|

|

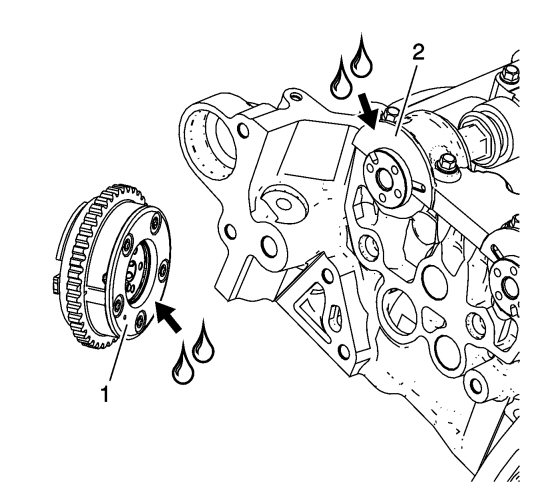

6.

|

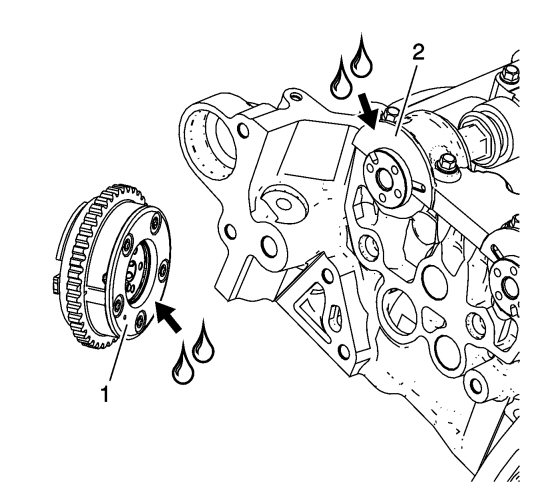

For applications without a camshaft thrust washer, apply a liberal amount of lubricant to the back of the camshaft position actuator (1) and front of the camshaft bearing cap (2). Refer to

Adhesives, Fluids, Lubricants, and Sealers

for recommended lubricant.

|

|

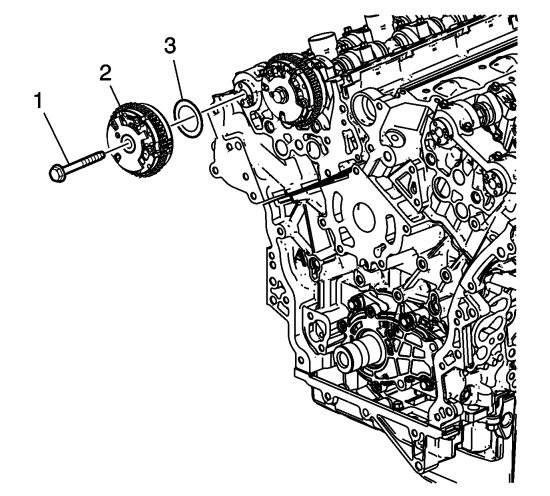

7.

|

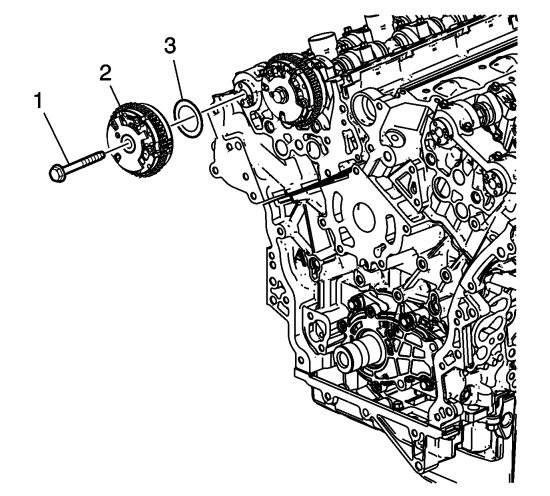

Install the thrust washer (3), if applicable.

|

|

8.

|

Install the right exhaust camshaft position actuator (2).

|

|

9.

|

Refer to

Fastener Caution

.

Install the camshaft's position actuator bolt (1) and tighten to

58 Nm (43 lb ft)

.

|