Crankshaft and Bearing Removal

|

|

Crankshaft and Bearing Removal

|

Special Tools

|

•

|

GE 6125-1B

Slide Hammer Adapter

|

|

•

|

EN 49102

Crankshaft Bearing Cap Remover

|

For equivalent regional tools, refer to

Special Tools

.

|

Crankshaft End Play Measurement

|

|

1.

|

Place a dial indicator at the crankshaft nose.

|

|

2.

|

Gently force the crankshaft to the extreme front and rear positions with a pry tool while monitoring the movement of the dial indicator.

|

|

5.

|

Replace the thrust bearing or crankshaft as necessary.

|

|

1.

|

Remove the crankshaft bearing cap side bolts.

|

|

2.

|

Remove the crankshaft bearing cap outer bolts.

|

|

3.

|

Remove the crankshaft bearing cap inner bolts.

|

|

4.

|

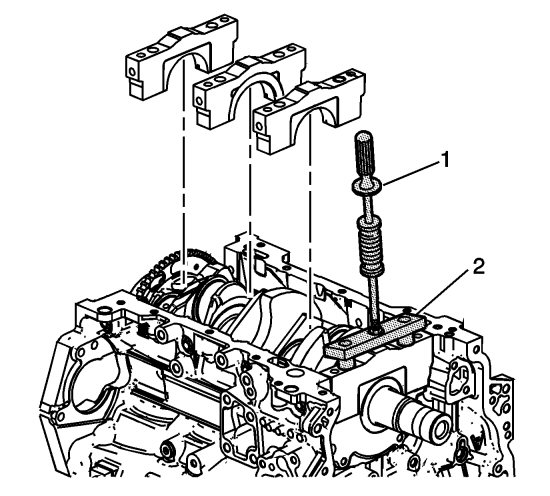

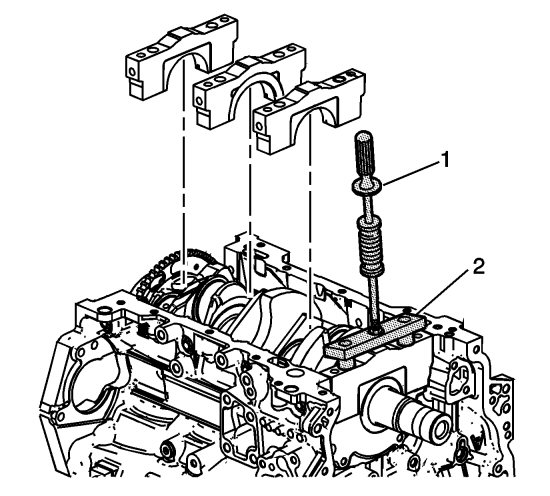

Remove the crankshaft bearing caps using the

GE 6125-1B

adapter (1) and

EN 49102

remover (2).

|

|

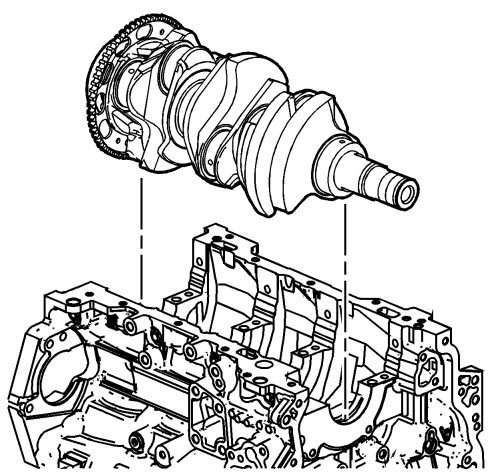

5.

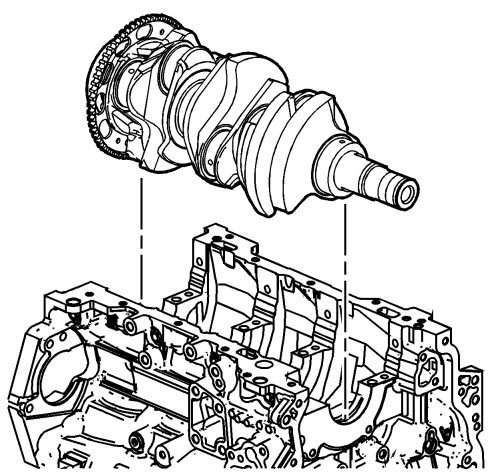

|

Using two hands, lift the crankshaft straight up from the engine block.

|

|

6.

|

Place the crankshaft in a secure place.

|

|

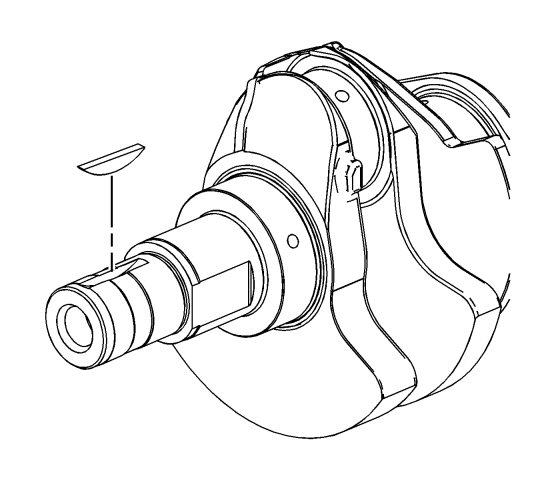

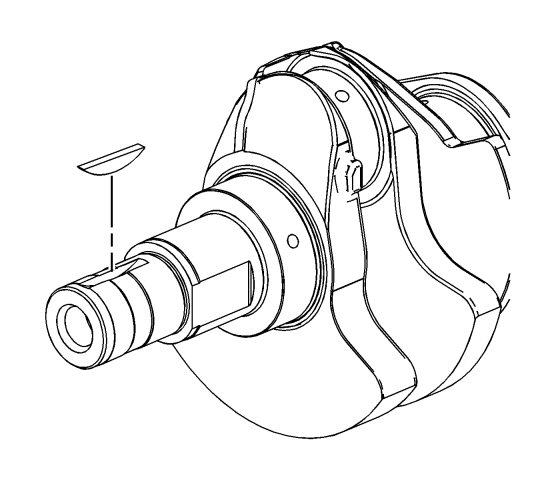

7.

|

Remove the crankshaft key from the nose of the crankshaft, if damaged.

|

|

Crankshaft Bearing Removal

|

|

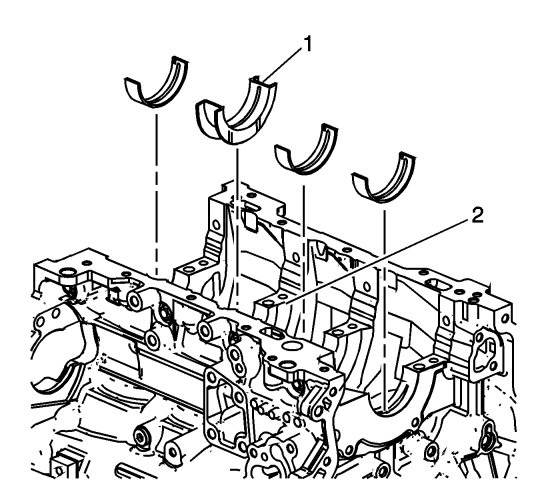

1.

|

Prepare a piece of cardboard or equivalent, numbered 1-4 for bearing identification. Main bearing journals are numbered from the front of the engine.

|

|

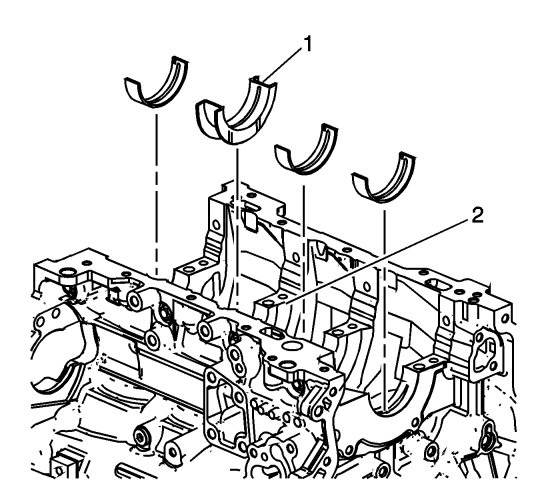

2.

|

Remove the crankshaft upper bearing halves from the cylinder block. Note the position of the thrust bearing (1) at the number 3 journal (2).

|

|

3.

|

Place the crankshaft upper bearing halves on the cardboard in the correct positions. Note that the number 3 bearing is the thrust bearing.

|

|

4.

|

Remove the crankshaft lower bearing halves from the crankshaft bearing caps.

|

|

5.

|

Place the crankshaft lower bearing halves in the correct positions on the cardboard.

|