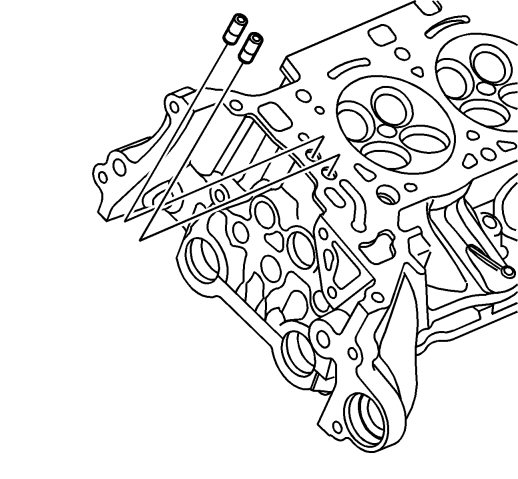

Cylinder Head Disassemble (LAU or LBW)

|

|

Cylinder Head Disassemble (LAU or LBW)

|

Special Tools

|

•

|

EN 384

Valve Spring Compressor - Head Off

|

|

•

|

EN 46116

Valve Stem Seal Remover/Installer

|

|

•

|

EN 46117

Valve Stem Key Remover/Installer

|

|

•

|

EN 46119

Off-Vehicle Valve Spring Compressor Adapter

|

|

•

|

EN 46122

Camshaft Position Actuator Check-Ball Valve Remover/Installer

|

For equivalent regional tool, refer to

Special Tools

.

|

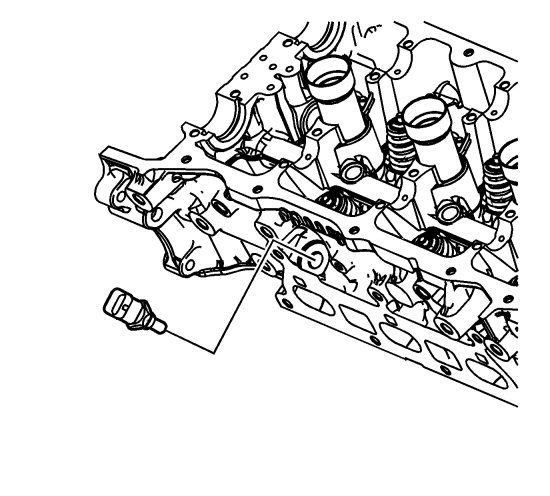

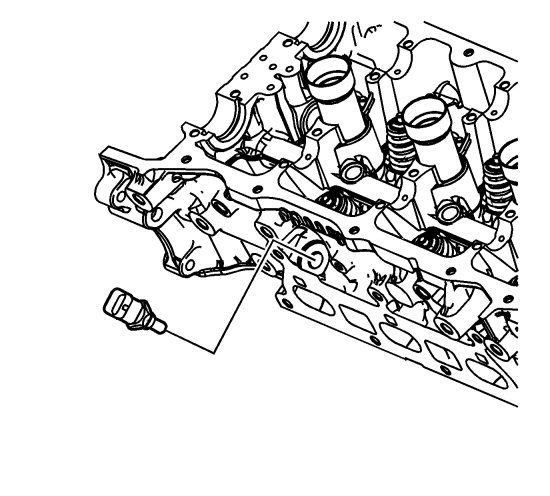

1.

|

Remove the engine coolant temperature (ECT) sensor.

|

|

2.

|

Remove the spark plugs.

|

|

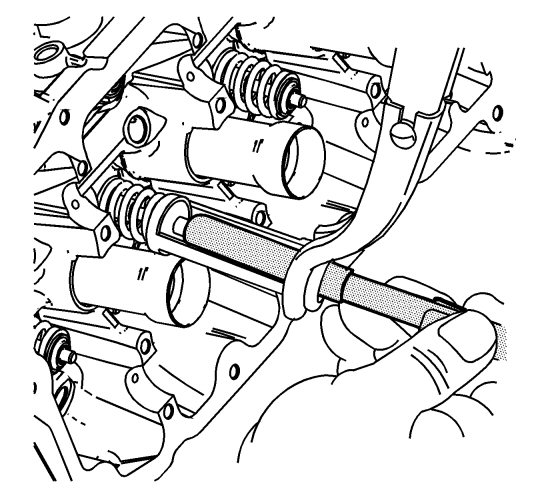

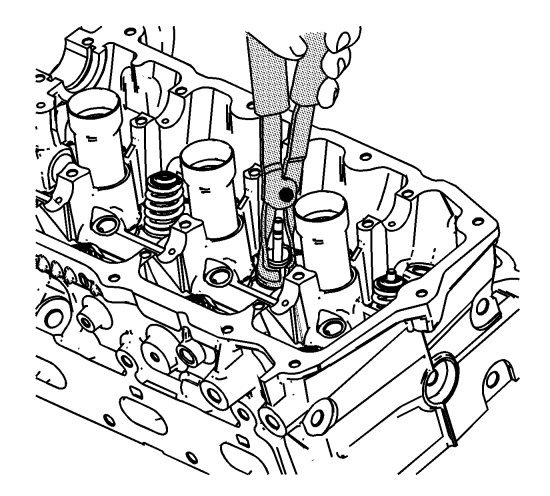

3.

|

|

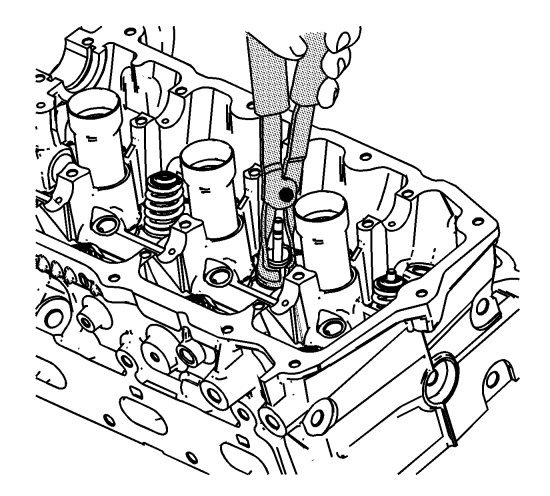

Note

|

|

Ensure valve heads will not contact anything during the following step in order to avoid bending or damage.

|

Using an appropriately sized deep socket and a plastic hammer, lightly tap on the valve spring retainer to loosen the valve keepers.

|

|

4.

|

Warning

Warning

|

|

Compressed valve springs have high tension against the valve spring compressor. Valve springs that are not properly compressed by or released from the valve spring compressor can be ejected from the valve spring compressor with intense force. Use care when compressing or releasing the valve spring with the valve spring compressor and when removing or installing the valve stem keys. Failing to use care may cause personal injury.

|

|

|

|

|

|

Warning

Warning

|

|

Do not compress the valve springs to less than 24.0 mm (0.943 in). Contact between the valve spring retainer and the valve stem oil seal can cause potential valve stem oil seal damage.

|

|

|

|

|

|

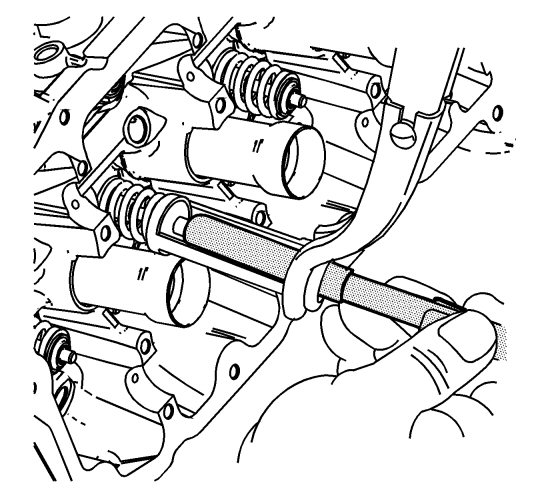

Compress the valve spring using the

EN 384

compressor and the

EN 46119

adapter.

|

|

5.

|

Use the magnet of the

EN 46117

remover in order to remove the valve keepers.

|

|

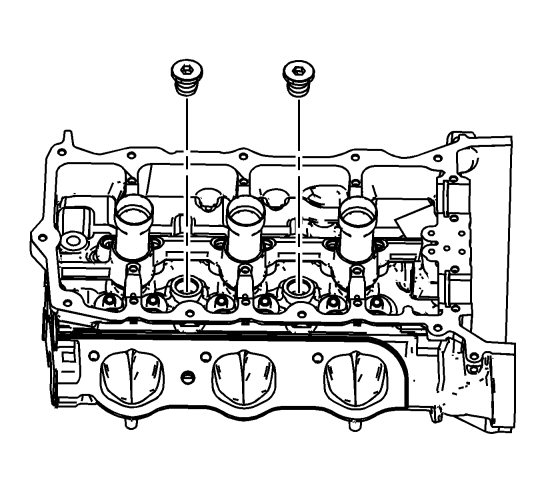

6.

|

Remove the valve spring compressor and the adapter.

|

|

7.

|

Remove the valve spring retainer.

|

|

8.

|

Remove the valve spring.

|

|

9.

|

Remove the valve.

|

|

10.

|

|

Note

|

|

NEVER reuse a valve stem oil seal.

|

Remove the valve stem oil seal using the

EN 46116

remover/installer and discard.

|

|

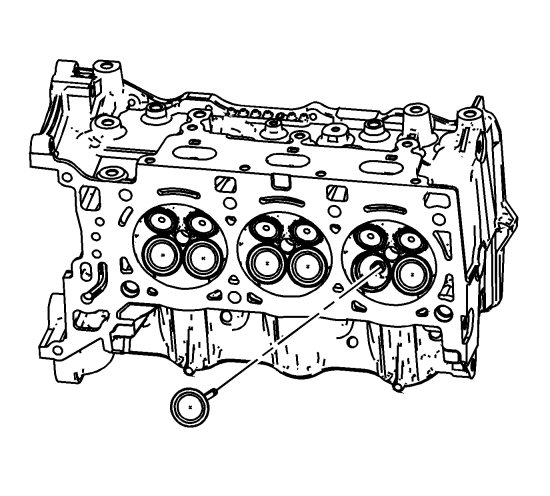

11.

|

Repeat these procedures for the remaining valves.

|

|

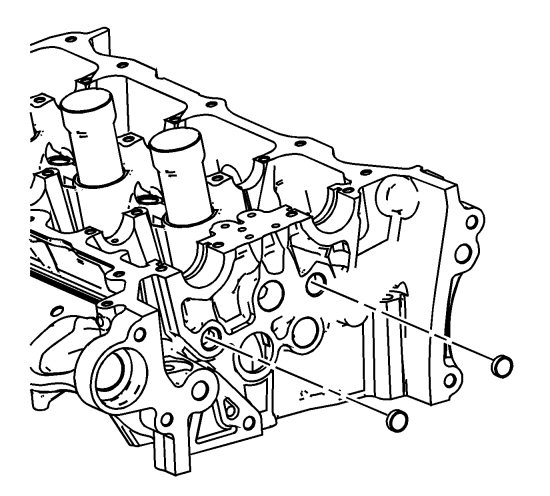

12.

|

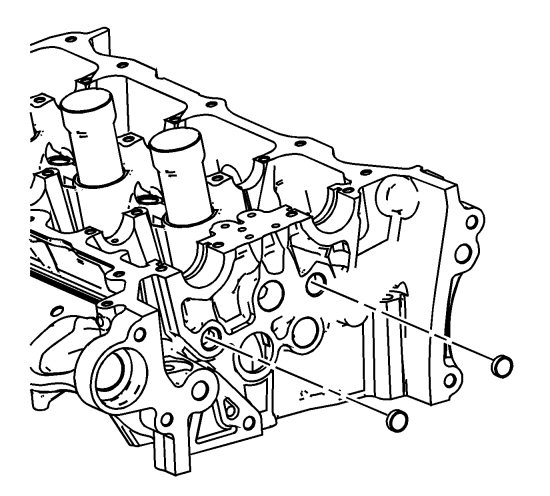

Remove the cylinder head oil gallery expansion plugs.

|

|

13.

|

Remove the cylinder head coolant threaded plugs.

|

|

14.

|

Inspect the camshaft position actuator oil feed check valves. Damaged, restricted or clogged check valves must be replaced. If check valves are OK, disregard remaining steps which detail replacing the check valves.

|

|

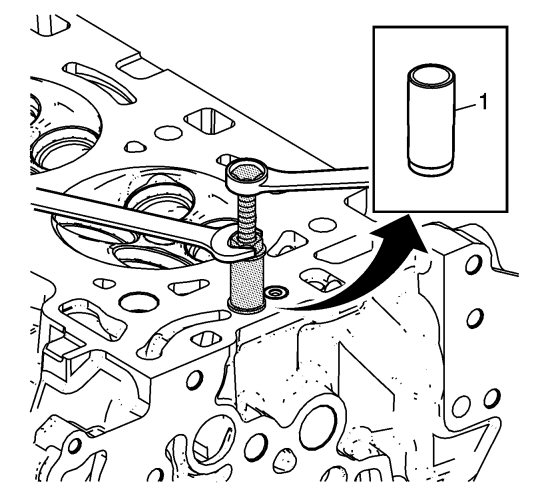

15.

|

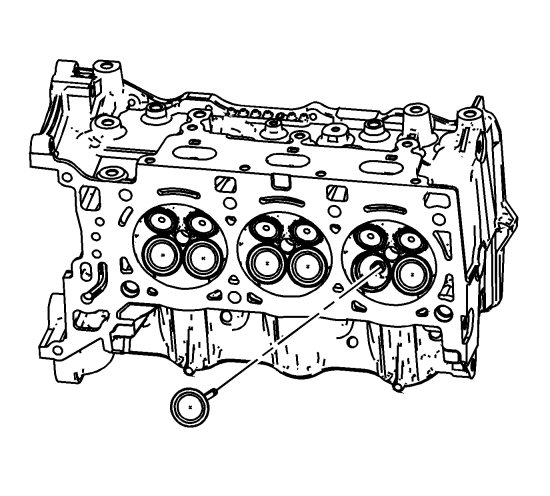

Place cylinder head on firm surface with check valves (1) facing up. Protect all cylinder head components and machined surfaces.

|

|

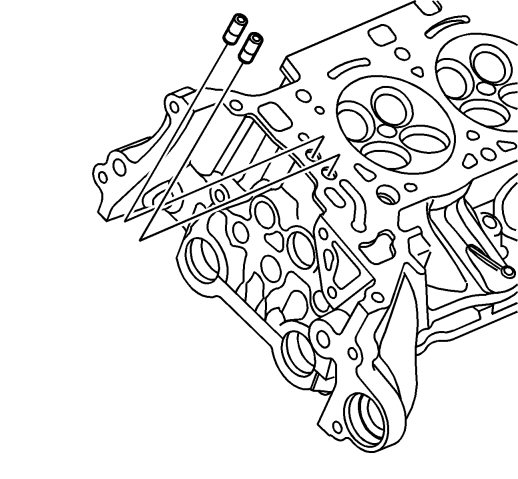

16.

|

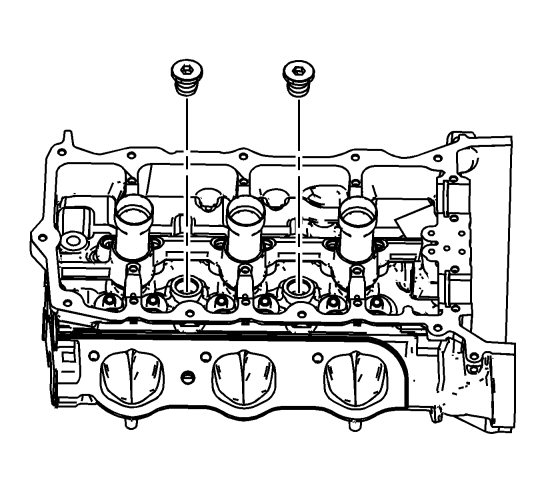

Using drill bit EN-46122-3, drill out top portion of check valve to expose internal check ball.

|

|

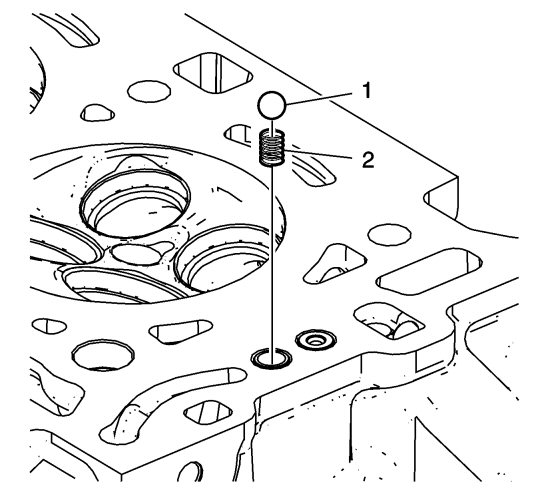

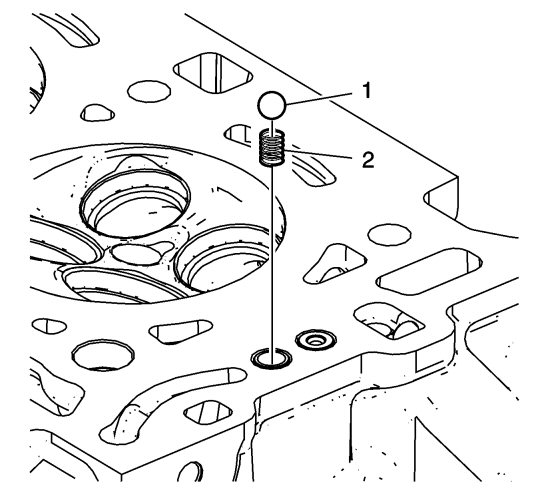

17.

|

Remove check ball (1) and check ball spring (2) from inside of check valve.

|

|

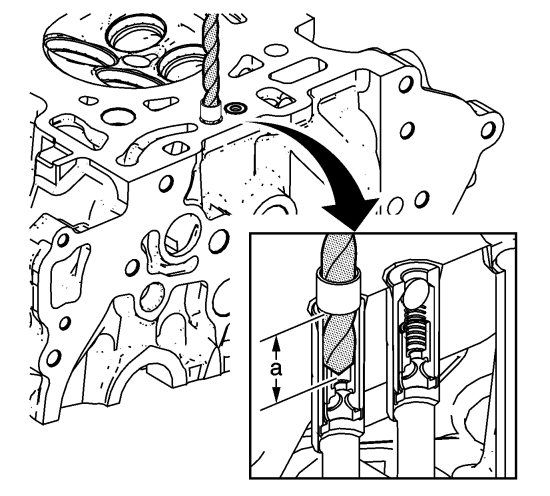

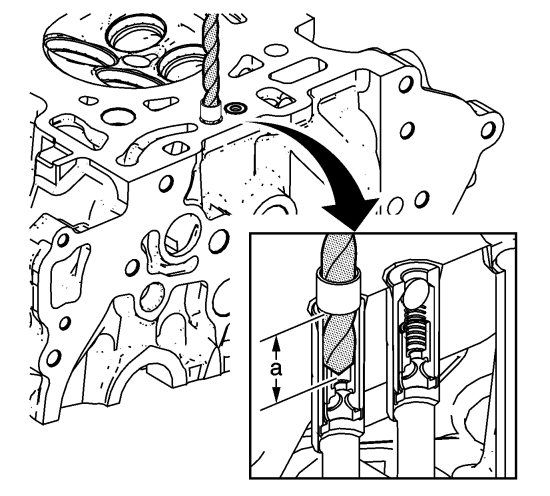

18.

|

Continue drilling down in check valve sleeve to a depth of approx. 19 mm (0.75 in) (a) . Place tape on the drill bit to indicate the depth. It is not necessary or desirable to drill completely through the bottom of the check valve.

|

|

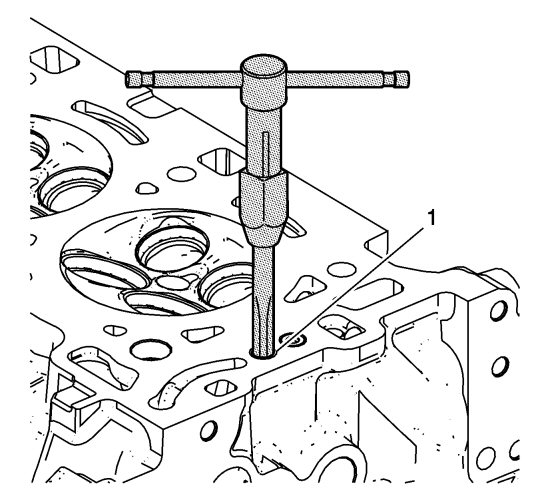

19.

|

Lubricate tap EN-46122-4 with lubricant included in

EN 46122

remover/installer. Tap drilled out portion of check valve (1) remaining in cylinder head. Tap to full depth possible until tap bottoms out in head.

|

|

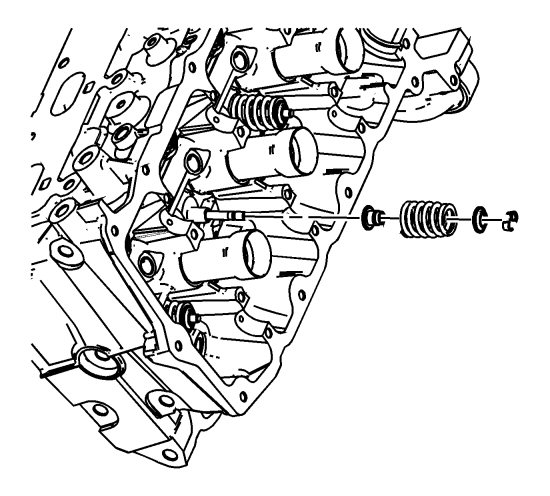

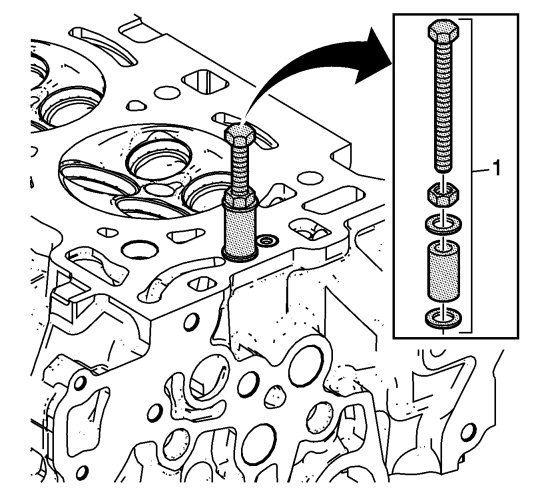

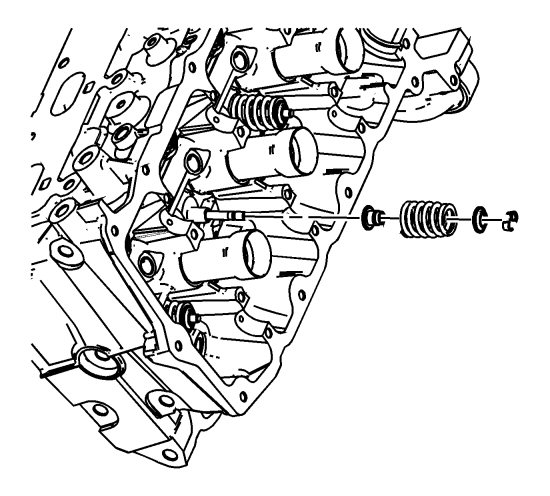

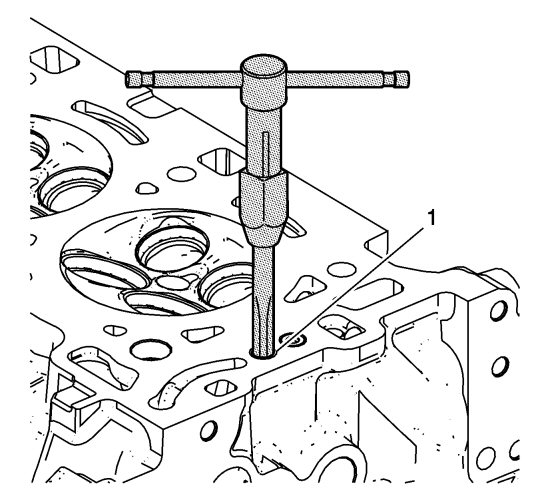

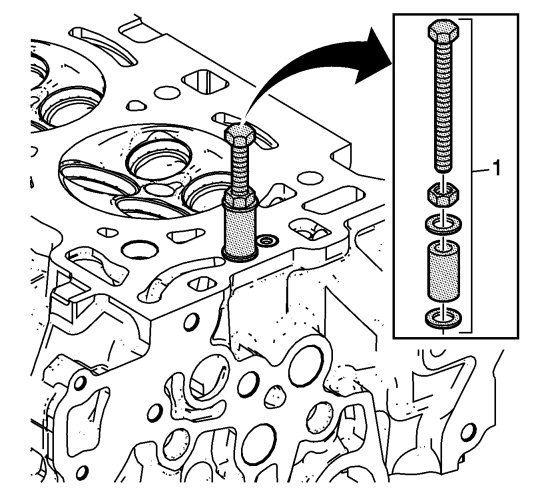

20.

|

Assemble bolt, nut, washers, and collar EN-46122-2 (1) as shown. Position collar with slightly-larger inside diameter DOWN toward the cylinder head.

|

|

21.

|

Screw bolt by hand fully down into threaded check valve sleeve, then lightly tighten nut against washer.

|

|

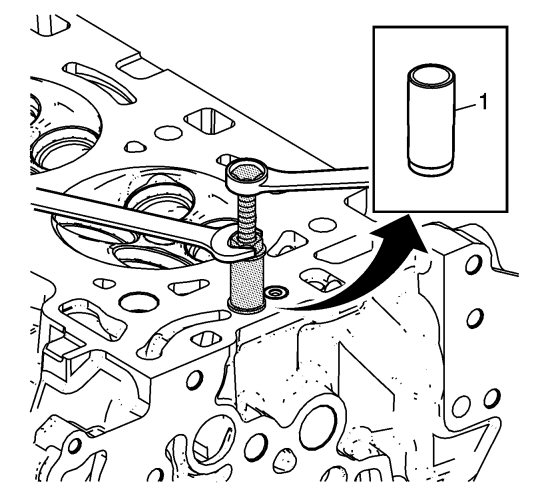

22.

|

Hold bolt with one wrench, and use another to tighten the nut until the check valve sleeve (1) is removed from the cylinder head.

|

|

23.

|

Clean check valve bore and related passages thoroughly to remove any drilling chips or other debris.

|

Warning

Warning