Folded-Over Wire Repair

| Folded-Over Wire Repair |

Special Tools

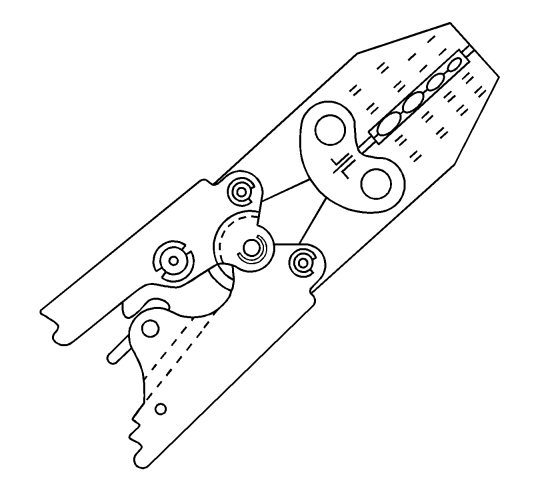

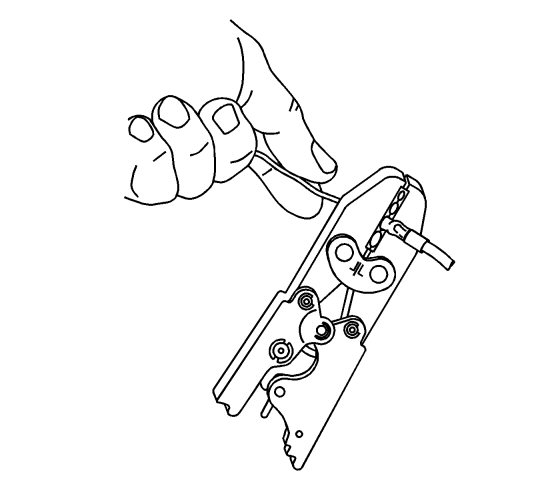

EL-38125-10 Splice Sleeve Crimping ToolFor equivalent regional tools, refer to Special Tools .

The GM global wire repair strategy uses connector assemblies (pigtails) and terminated leads to repair wiring harnesses.

To reduce and manage GM Service Parts proliferation, the service pigtails and terminated leads are designed with the largest wire gauge size that can be held by either the terminal or the connector housing.

The folded over wire repair technique, in which the copper wire strands are folded over before being installed into a splice sleeve, allows the service part to be used when repairing a smaller gauge size wire in a vehicle. This technique has passed all GM testing standards.

Use the folded over wire repair for:

| • |

Splicing wires of 0.35 mm or less (22, 24, 26 gauge sizes) |

|||||||

| • |

Splicing wires of different gauges |

|||||||

Use the Service Information (SI) connector end-views to determine:

| • |

Gauge size of wiring harness

|

|

| • |

Recommended Repair: Terminated Lead or Pigtail

|

|

The following table lists the acceptable variance within the gauge size

Folded-Over Wire Selection Table

| Harness Wire Gauge | Connector Assembly (Pigtail) or Terminated Lead Wire Gauge Size | ||||

| - | Salmon Color Splice Sleeve | Blue Color Splice Sleeve | Yellow Color Splice Sleeve | ||

| Metric | - | 0.35 mm | 0.5-0.8 mm | 1.0-2.0 mm | 3.0-5.0 mm |

| - | Wire Gauge (AWG) | 22 | 20-18 | 16-14 | 12-10 |

| 0.13 mm | 26 | Fold Over Wire | Fold Over Wire | Fold Over Wire | Not Acceptable |

| 0.22 mm | 24 | Fold Over Wire | Fold Over Wire | Fold Over Wire | Not Acceptable |

| 0.35 mm | 22 | Fold Over Wire | Fold Over Wire | Fold Over Wire | Not Acceptable |

| 0.5 mm | 20 | Not Acceptable | Wire to Wire | Fold Over Wire | Not Acceptable |

| 0.75 mm | - | Not Acceptable | Wire to Wire | Fold Over Wire | Not Acceptable |

| 0.8 mm | 18 | Not Acceptable | Wire to Wire | Fold Over Wire | Not Acceptable |

| 1.0 mm | 16 | Not Acceptable | Wire to Wire | Fold Over Wire | Not Acceptable |

| 1.5 mm | - | Not Acceptable | Not Acceptable | Wire to Wire | Fold Over Wire |

| 2.0 mm | 14 | Not Acceptable | Not Acceptable | Wire to Wire | Fold Over Wire |

| 2.5 mm | - | Not Acceptable | Not Acceptable | Wire to Wire | Fold Over Wire |

| 3.0-5.0 mm | 12-10 | Not Acceptable | Not Acceptable | Not Acceptable | Wire to Wire |

Example

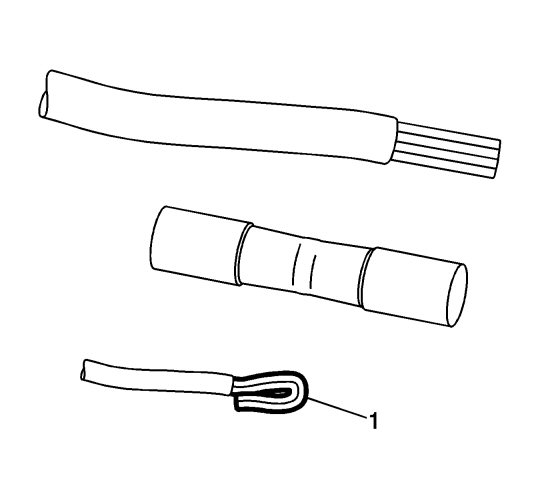

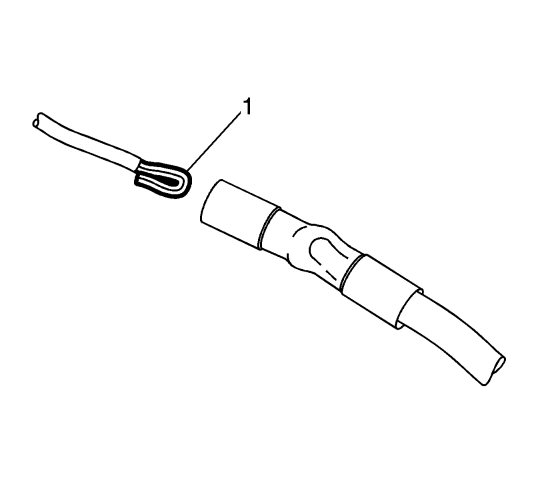

For an IP Harness of 0.22 mm (24 gauge on left side of table) wire size, the SI connector end-view recommends a pigtail with leads of 0.8 mm (18 gauge on the top of the table) with a salmon colored DuraSeal splice sleeve of 0.5-1.0 mm (20-16 gauge).Follow these steps to use the folded over wire (1) technique on an IP Harness.

Strip twice the amount of insulation on the smaller (1) wire (IP Harness is the lower wire) than normally required. Normally, the terminated leads have 5 mm of insulation stripped off the wire.

| 1. |

For wiring repair, refer to Splicing Copper Wire Using Splice Sleeves .

|

|||||||

| 3. |

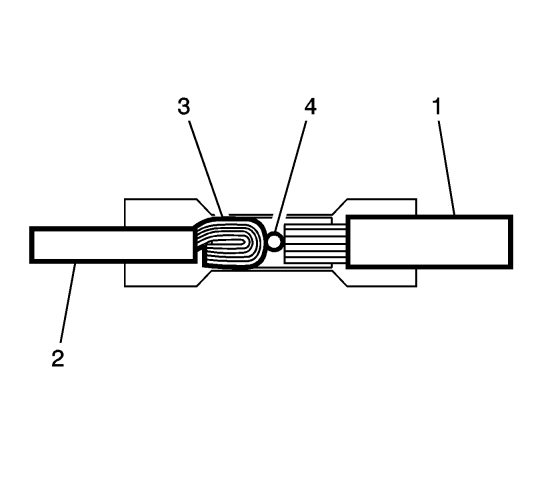

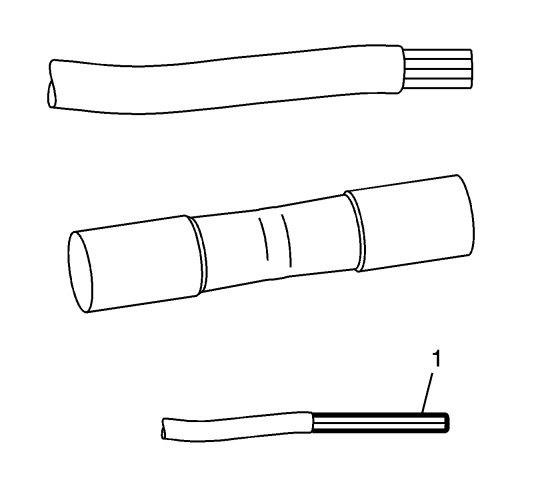

Insert the folded over wire (1) into the splice sleeve.

|

|

| 4. |

Use the proper crimp tool to crimp the splice sleeve to the smaller wire (harness side of repair). Complete the crimp as usual (using the heat tool to shrink the tube).

|

|