Terminal Removal

| Terminal Removal |

Special Tools

| • |

EL-38125-580

Terminal Release Tool Kit

|

|

| • |

EL-35616

Terminal Test Probe Kit

|

|

For equivalent regional tools, refer to Special Tools .

| Note | ||

|

All repairs near the engine manifold, turbo engine and all exhaust pipes should follow the High Temperature Wiring Repair procedures. |

| 1. |

Find the correct connector end view in the section with end views. The end view contains the following information:

|

|

| • |

Diagnostic probe tool

|

| • |

Terminal release tool

|

| • |

Terminal/terminated lead part numbers

|

| 2. |

Determine if a terminal is damaged. |

|||||||

| • |

Locate the diagnostic tool in the contact's end view. The contact end view describes the color and part number to help the technician find and use the correct tool.

|

| • |

Connect the probe tool to the Digital Multimeter.

|

| • |

Insert the probe tool into the cavity and follow the procedures from the

Troubleshooting with a Digital Multimeter

.

|

| 3. |

Disconnect the connector body to perform the repair.

|

|

| 4. |

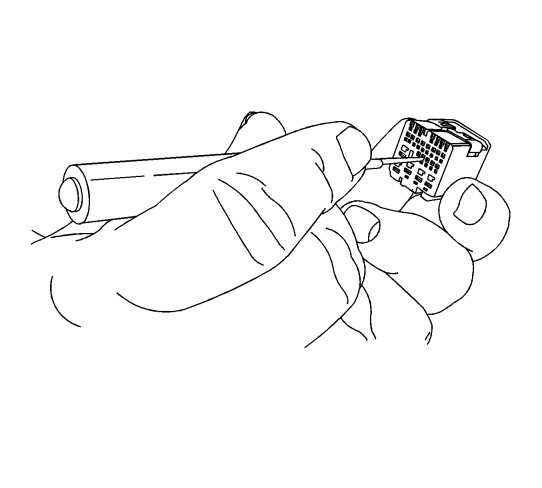

Use the following procedure to remove the terminal from the connector body.

|

|||||||

| • |

The terminal position assurance (TPA) and connector position assurance (CPA) should be removed before releasing the terminal for the connector body.

|

| • |

Look at the connector end view to locate the cavity of the damaged terminal and find the proper terminal release tool from the terminal release tool kit.

|

| • |

Insert the terminal release tool into the cavity. |

|||||||||||||

| 5. |

Gently pull the wire out of the back of the connector.

|

|

| 6. |

Repair the terminal by following the

Repairing Connector Terminals (Terminated Lead Repair)

Repairing Connector Terminals (Terminal Repair)

procedure.

|

|

| 7. |

Insert the repaired terminal back into the cavity. Repeat the diagnostic procedure to verify the repair and reconnect the connector bodies.

|

|