Brake Pipe Replacement

| Brake Pipe Replacement |

Special Tools

CH-45405 Brake Pipe Flaring KitFor equivalent regional tools, refer to Special Tools .

| 1. |

Refer to

Brake Fluid Irritant Warning

.

Refer to Brake Fluid Effects on Paint and Electrical Components Caution .

Inspect the area of brake pipe to be repaired or replaced.

|

||||||||||||||||||||||||

| 2. |

Release the brake pipe to be replaced from the retainers, as required.

|

|

| 3. |

Select an appropriate location to section the brake pipe, if necessary.

|

|

| • |

Allow adequate clearance in order to maneuver the

CH-45405

Brake Pipe Flaring Kit.

|

| • |

Avoid sectioning the brake pipe at bends or mounting points.

|

| 4. |

Using a string or wire, measure the length of the pipe to be replaced including all pipe bends.

|

|

| 5. |

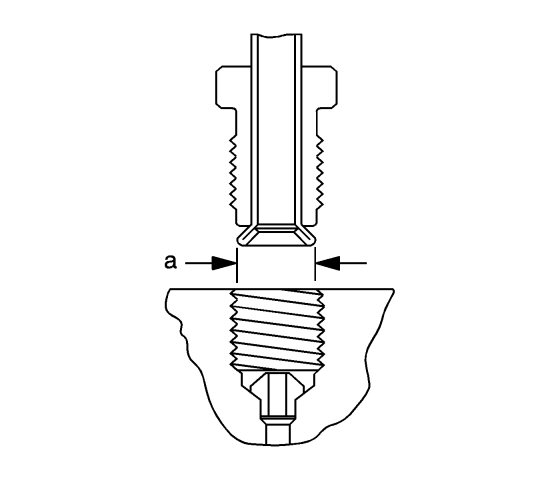

Add to the measurement taken the appropriate additional length required for each flare to be created.

Specification

|

||||||||||

| 1. |

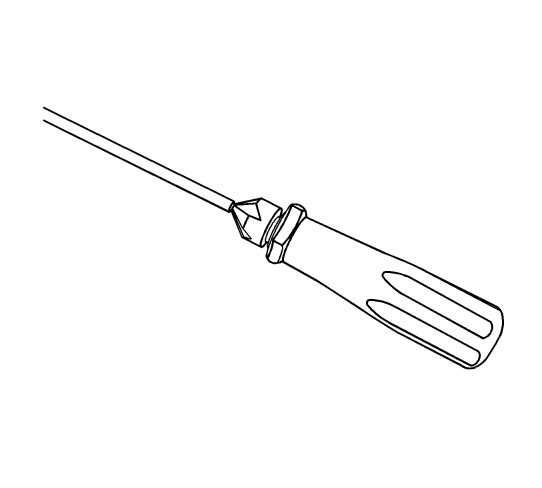

Using the pipe cutter included in the CH-45405 Brake Pipe Flaring Kit, cut the brake pipe carefully and squarely. |

|||||||

| 2. |

Remove the sectioned brake pipe from the vehicle.

|

|

| 3. |

Select the appropriate size of brake pipe and tube nuts, as necessary. The brake pipe outside diameter determines brake pipe size.

|

|

| 4. |

Strip the nylon coating from the brake pipe end to be flared, if necessary.

|

|

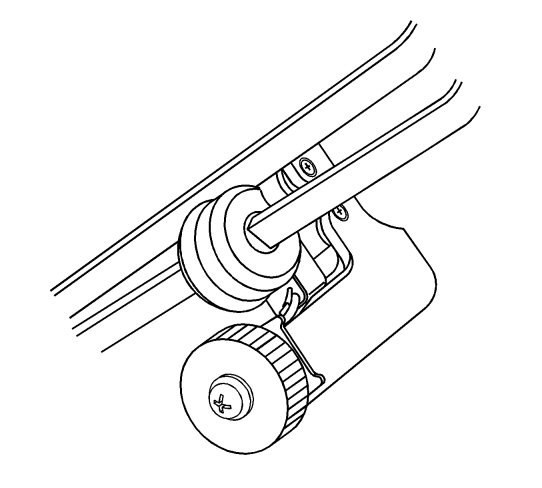

| • |

Select the appropriate blade on the coating stripping tool included in the

CH-45405

brake pipe flaring kit. Unscrew the blade block from the stripping tool and install the block with the desired blade facing the tool rollers.

Specification |

| • |

Insert the brake pipe end to be flared into the stripping tool to the depth of the ledge on the tool rollers.

|

| • |

While holding the brake pipe firmly against the stripping tool roller ledges, rotate the thumbwheel of the tool until the blade contacts the brake pipe coated surface.

|

| • |

Rotate the stripping tool in a clockwise direction, ensuring that the brake pipe end remains against the tool roller ledges. |

|||||||

| • |

After each successive revolution of the stripping tool, carefully rotate the thumbwheel of the tool clockwise, in order to continue stripping the coating from the brake pipe until the metal pipe surface is exposed.

|

| • |

Loosen the thumbwheel of the tool and remove the brake pipe.

|

|||||||

| • |

Inspect the stripped end of the brake pipe to ensure that the proper amount of coating has been removed.

Specification |

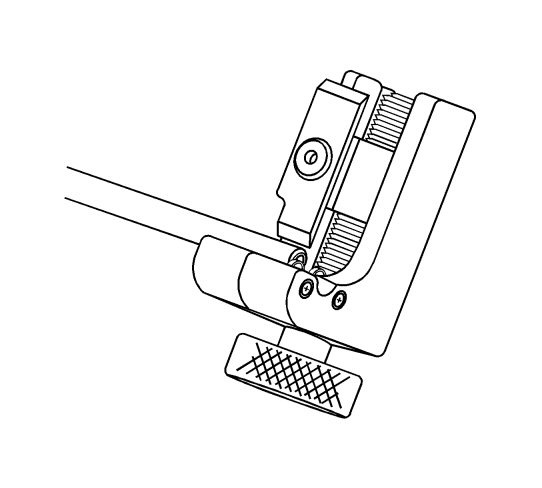

| 1. |

Chamfer the inside and outside diameter of the pipe with the de-burring tool included in the

CH-45405

Brake Pipe Flaring Kit.

|

|

| 2. |

Install the tube nuts on the brake pipe, noting their orientation.

|

|

| 3. |

Clean the brake pipe and the

CH-45405

Brake Pipe Flaring Kit of lubricant, contaminants, and debris.

|

|

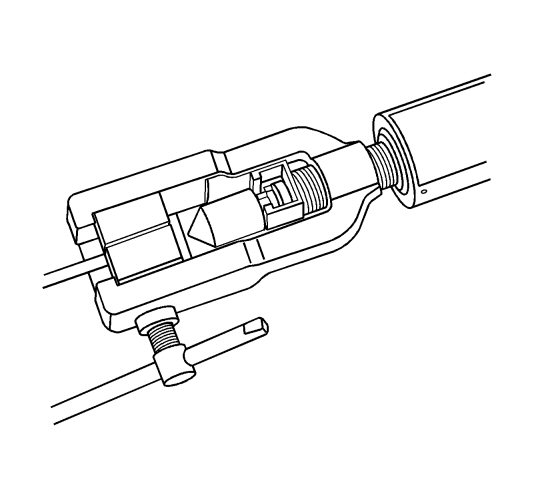

| 4. |

Loosen the die clamping screw of the

CH-45405

Brake Pipe Flaring Kit.

|

|

| 5. |

Select the corresponding die set and install the die halves into the die cage with the full, flat face of one die facing the clamping screw, and the counterbores of both dies facing the forming ram.

|

|

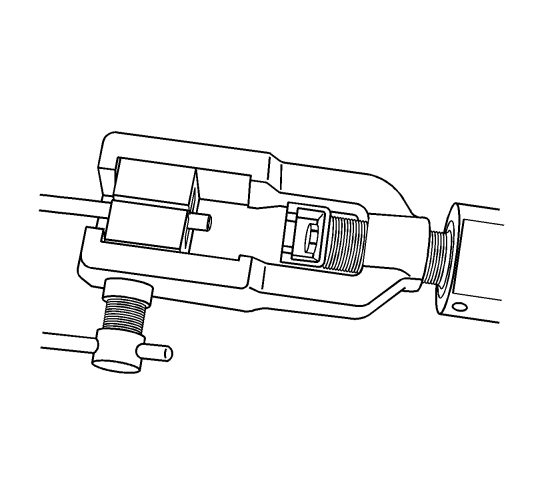

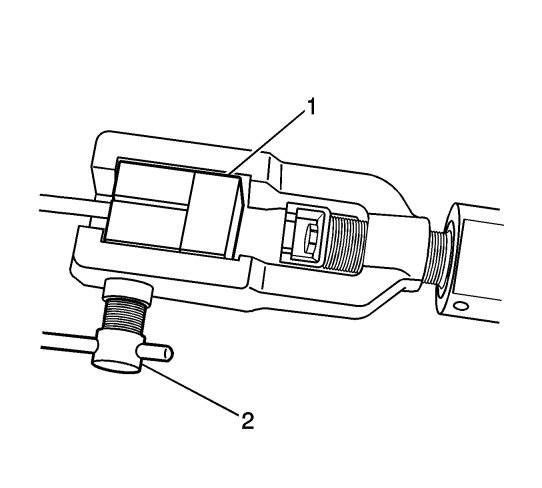

| 6. |

Place the flat face of an unused die (1) against the die halves in the clamping cage and hold firmly against the counterbored face of the dies.

|

|

| 7. |

Insert the prepared end of the pipe to be flared through the back of the dies until the pipe is seated against the flat surface of the unused die (1).

|

|

| 8. |

Remove the unused die (1).

|

|

| 9. |

Ensure that the rear of both dies are seated firmly against the enclosed end of the die cage.

|

|

| 10. |

Firmly hand tighten the clamping screw (2) against the dies.

|

|

| 11. |

Select the appropriate forming mandrel and place into the forming ram.

|

|

| 12. |

Rotate the hydraulic fluid control valve clockwise to the closed position.

|

|

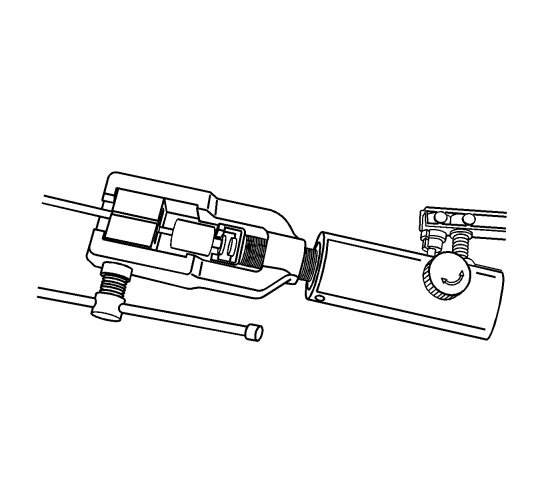

| 13. |

Rotate the body of the

CH-45405

Brake Pipe Flaring Kit until it bottoms against the die cage.

|

|

| 14. |

While guiding the forming mandrel into the exposed end of pipe to be flared, operate the lever of the

CH-45405

Brake Pipe Flaring Kit until the forming mandrel bottoms against the clamping dies.

|

|

| 15. |

Rotate the hydraulic fluid control valve counterclockwise to the open position to allow the hydraulic forming ram to retract.

|

|

| 16. |

Insert the finishing cone into the forming ram.

|

|

| 17. |

Rotate the hydraulic fluid control valve clockwise to the closed position.

|

|

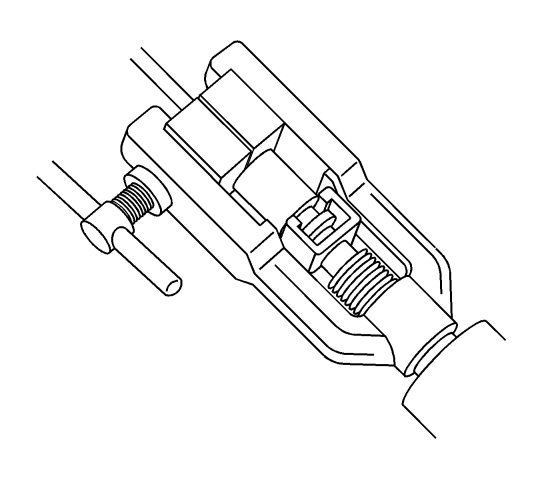

| 18. |

Rotate the body of the

CH-45405

Brake Pipe Flaring Kit until it bottoms against the die cage.

|

|

| 19. |

While guiding the finishing cone into the exposed end of pipe to be flared, operate the lever of the

CH-45405

Brake Pipe Flaring Kit until the finishing cone bottoms against the dies.

|

|

| 20. |

Rotate the hydraulic fluid control valve counterclockwise to the open position to allow the hydraulic forming ram to retract.

|

|

| 21. |

Loosen the die clamping screw and remove the dies and pipe.

|

|

| 22. |

If necessary, lightly tap the dies until the die halves separate.

|

|

| 1. |

If necessary, using the removed section of brake pipe as a template, shape the new pipe with a suitable brake pipe bending tool.

|

|||||||

| 2. |

Install the pipe to the vehicle with the appropriate brake pipe unions, as required.

|

|

| 3. |

If previously released, secure the brake pipe to the retainers.

|

|

| 4. |

Bleed the hydraulic brake system. Refer to

Hydraulic Brake System Bleeding (Manual)

Hydraulic Brake System Bleeding (Pressure)

.

|

|

| 5. |

With the aid of an assistant, inspect the brake pipe flares for leaks by starting the engine and applying the brakes.

|

|

Warning

Warning