Liftgate Hydraulic System Refilling

|

|

Liftgate Hydraulic System Refilling

|

Refer to

Eye Protection Warning

.

Refer to

Battery Disconnect Warning

.

|

Note

|

|

•

|

The actuator/hose assemblies are shipped full with fluid. In this case the pump fluid reservoir should only be filled to the normal + sign. Do not overfill to compensate for an empty actuator/hose assembly.

|

|

•

|

Symptoms of a low fluid condition will be a jerking liftgate and an abnormal hydraulic pump noise whilst the liftgate is opening. The liftgate will not open to the full open position. The liftgate will reverse before reaching the full open position if not operating properly.

|

|

•

|

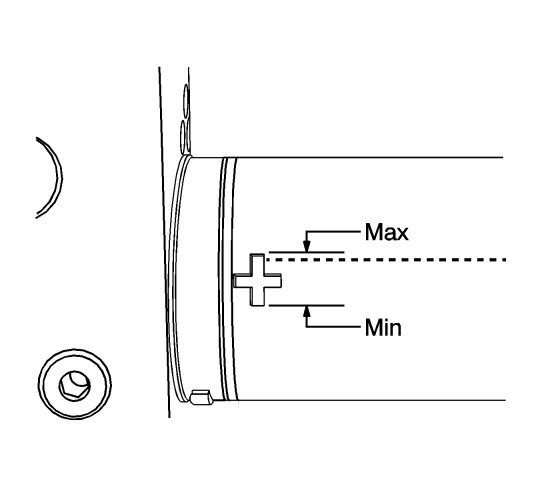

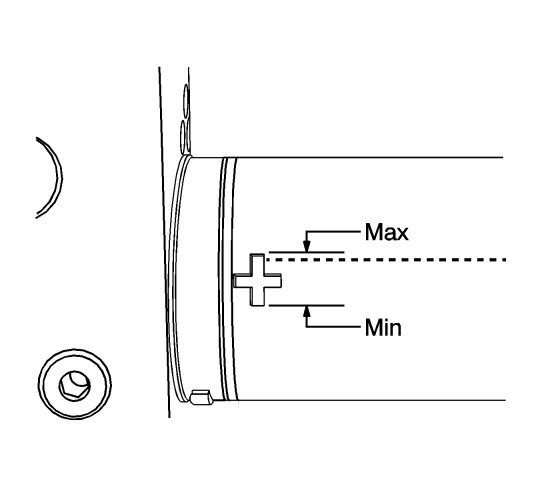

Inspection of the hydraulic fluid level and/or refilling may only be completed if the liftgate hydraulic actuator pump is removed from the vehicle and placed on a clean/level workbench. The liftgate hydraulic actuator pump +- marks must be positioned horizontally before the hydraulic fluid level is inspected and if necessary topped up. The liftgate hydraulic actuator pump must rest in the horizontal position for one minute before the hydraulic fluid level is inspected. The level must be above the + mark.

|

|

•

|

The liftgate hydraulic system components must be tested for proper operation before reinstalling the trim panels that cover the liftgate hydraulic actuator pump and actuator/hose assemblies so the fluid level can be recheck after cycling the liftgate 3-5 times to ensure proper fluid level. Rechecking the fluid level will require removal of the liftgate hydraulic pump.

|

|

2.

|

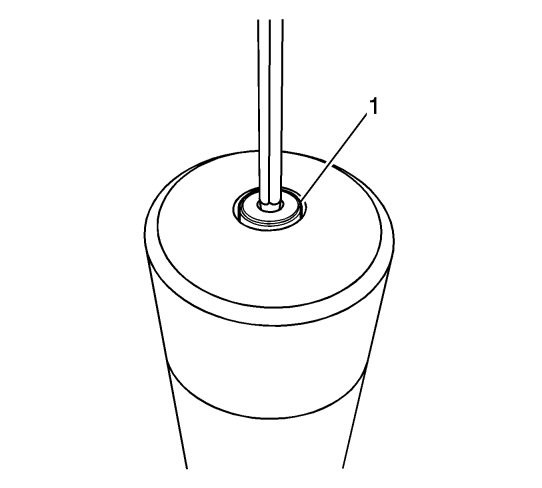

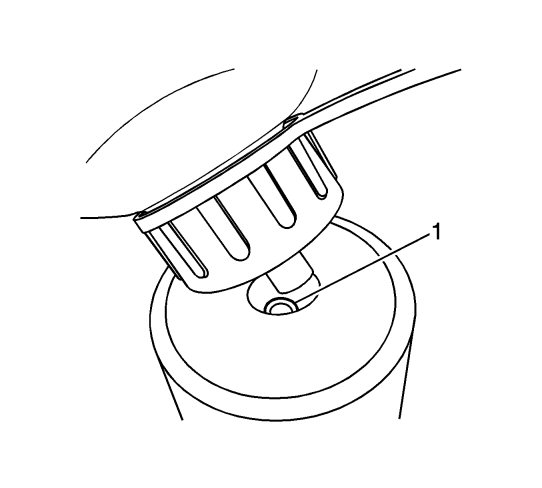

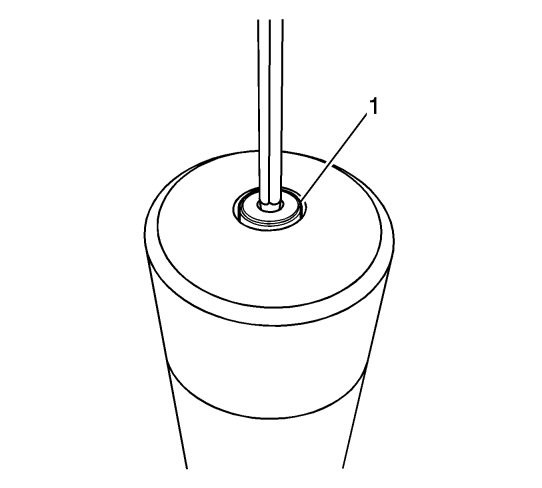

Position the pump with the fluid reservoir in a vertical position with the filler screw (1) in the up and/or on top position.

|

|

3.

|

Wipe the surface around the filler screw clean.

|

|

4.

|

Remove the filler screw (1) and place on a clean, lint and dust free surface.

|

|

6.

|

Refer to

Fastener Caution

.

Install the filler screw and tighten to

1.3 Nm (12 lb in)

.

|

|

7.

|

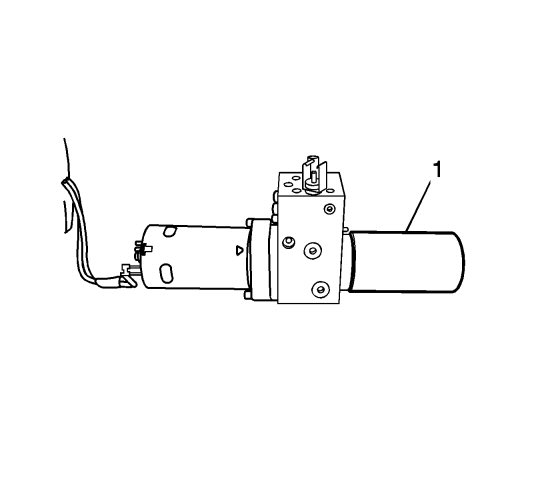

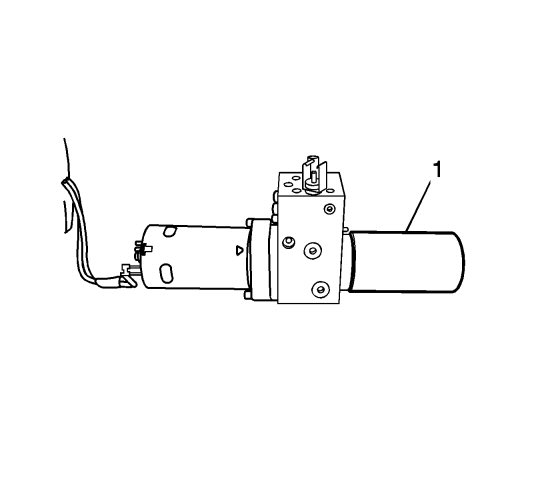

Position the liftgate hydraulic actuator pump (1) on a clean/level workbench horizontally to the + sign to accurately inspect and add fluid as needed.

|

|

8.

|

The liftgate hydraulic actuator pump must rest in the horizontal position for one minute before the hydraulic fluid level is inspected. The level must be above the + mark.

|

|

9.

|

Install the pump without the trim and inspect for proper operation and fluid level. The fluid level can be checked after cycling the liftgate 3-5 times to ensure proper fluid level. If the fluid is still low repeat the procedure.

|