(210-2402 utg. 2) Procedure to remedy coolant/oil leakage from cylinder head without gasket replacement

Symptom: Visible external coolant/oil leakage from the cylinder head.

| TECHNICAL SERVICE BULLETIN | |

| Bulletin Nbr: | 210-2402 utg. 2 |

| Date: ........... | Juni 2003 |

| Market: | all |

| Procedure to remedy coolant/oil leakage from cylinder head without gasket replacement |

| Cars affected |

Saab 9-5 M98-M01 with engine variants B205 and B235 up to and including Vehicle Identification Number 13055567.

| Background |

The clamping force in the cylinder head bolted joint can decrease after a period of driving. In most cases the leakage is not so great that the quantity of oil or water decreases noticeably. The leakage can be due to a combination of heat, the tightening process in production as well as that the bolts in the process have been treated with anti-friction coating and wax. After the above Vehicle Identification Numbers anti-friction coating and wax treatment have been discontinued and replaced by phosphatising and anti-corrosive oil. The tightening of the cylinder head bolts in the production process has also been adapted to the bolts' new surface treatment and takes place in steps in the same way as in the after-market.

In the case of customer complaint see Procedure.

Symptom description

Visible external coolant/oil leakage from the cylinder head.

| Parts required |

79 71 864 Cable tie (CA: 30509025)

81 24 158 Gasket, 2 pcs/car (CA: 30509682)

| Procedure |

Retightening of bolts is adequate to regain the clamping force in the joint. The gasket is therefore not replaced.

Following the procedure, clean away oil and coolant externally. Check oil and coolant levels and rectify if necessary. Start the engine and check that the leakage has ceased. In the event of significant leakage or if retightening has not remedied the leakage then the gasket must be replaced. Follow the instructions in WIS - Engine - Basic engine, 4-cyl (petrol) - Adjustment/Replacement - Cylinder head.

Retightening of cylinder head

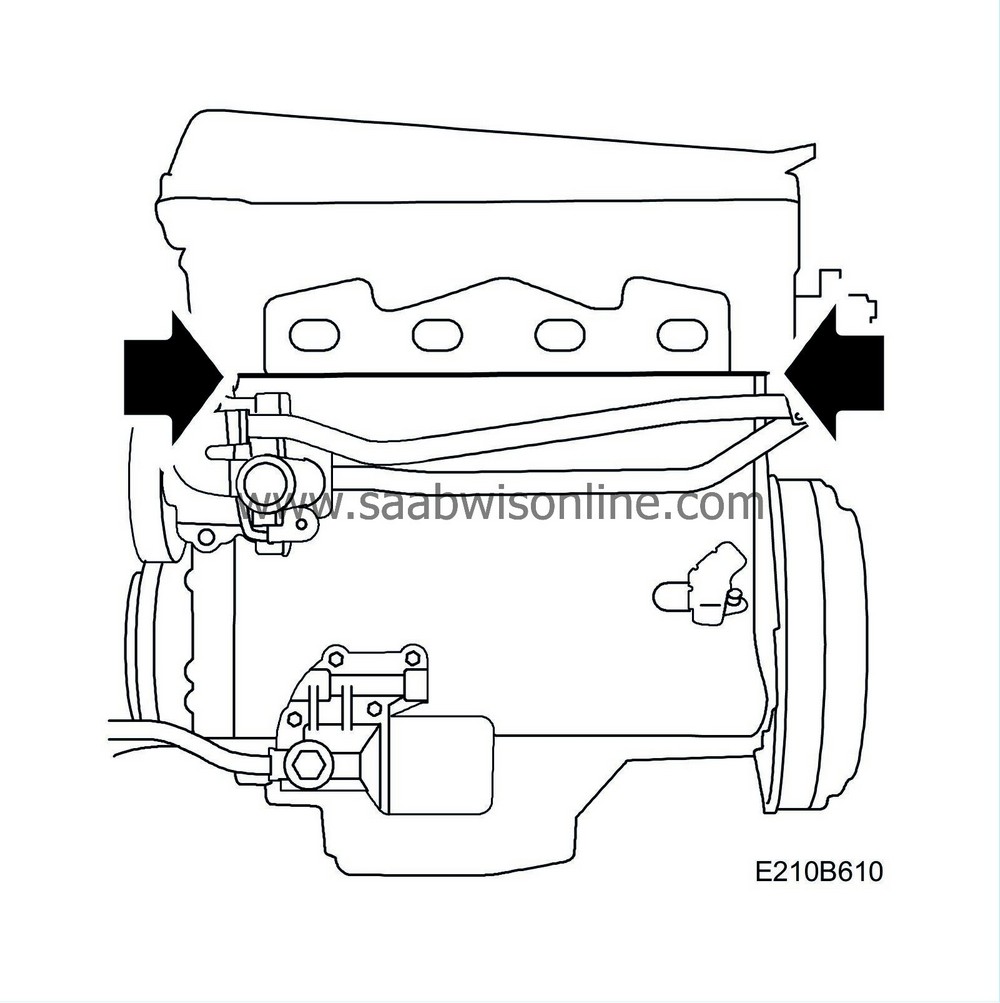

| 1. |

Remove the upper engine cover.

|

|

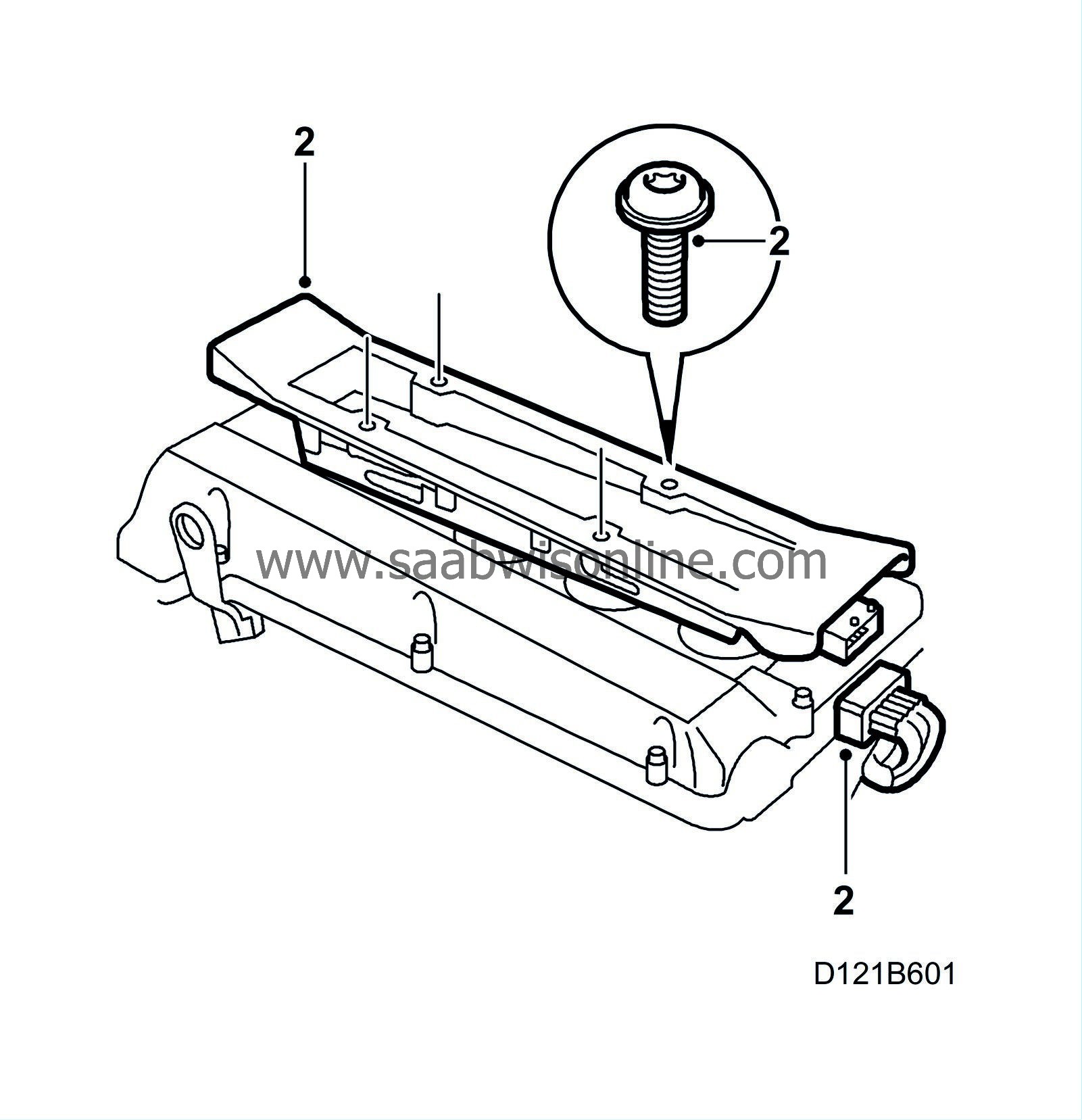

| 2. |

Remove the connector and remove the ignition discharge module.

|

|

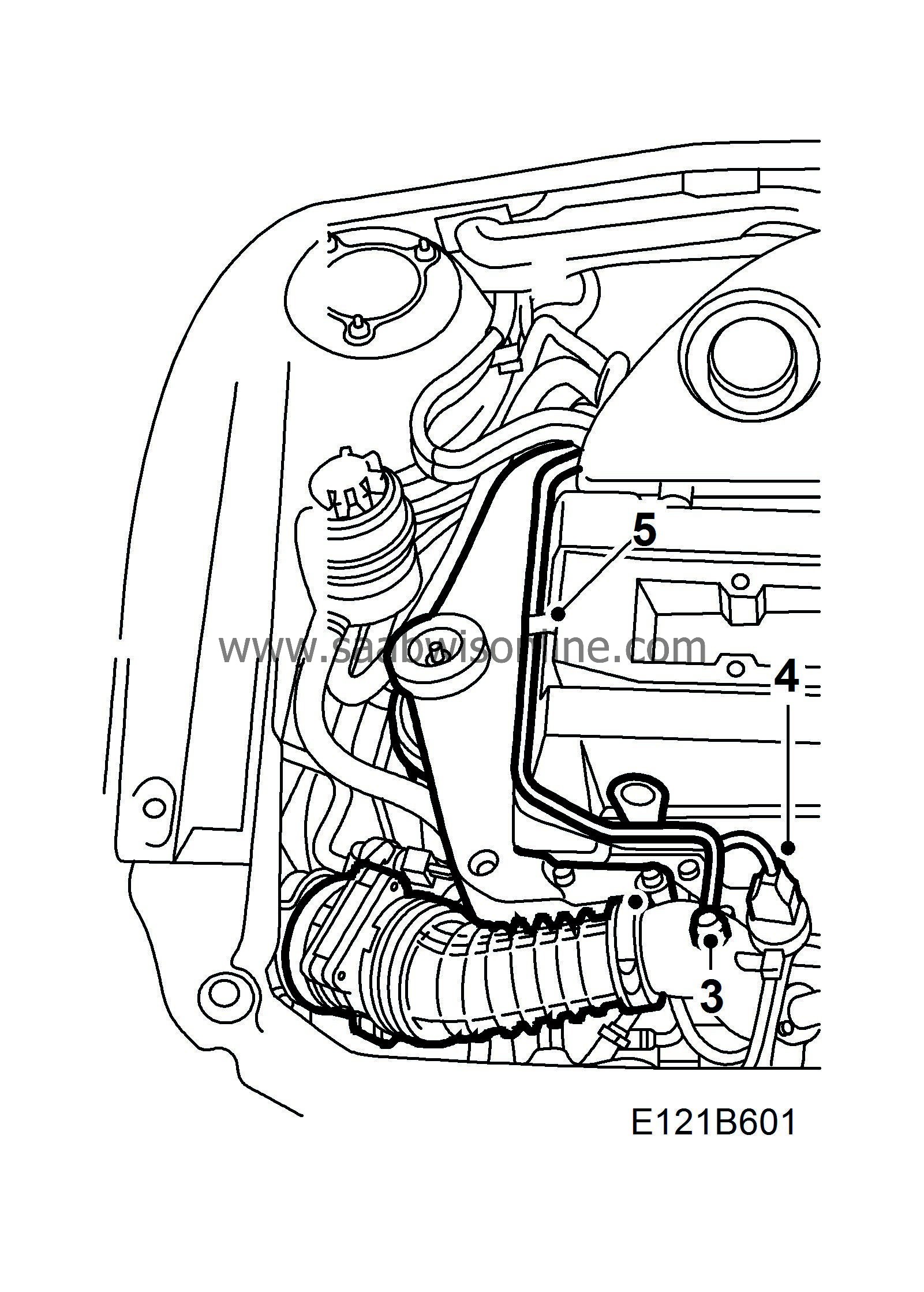

| 3. |

Remove the crankcase ventilation pipe banjo screw.

|

|

| 4. |

Remove the solenoid valve connector.

|

|

| 5. |

Remove the screw for the crankcase ventilation pipe on the camshaft cover.

|

|

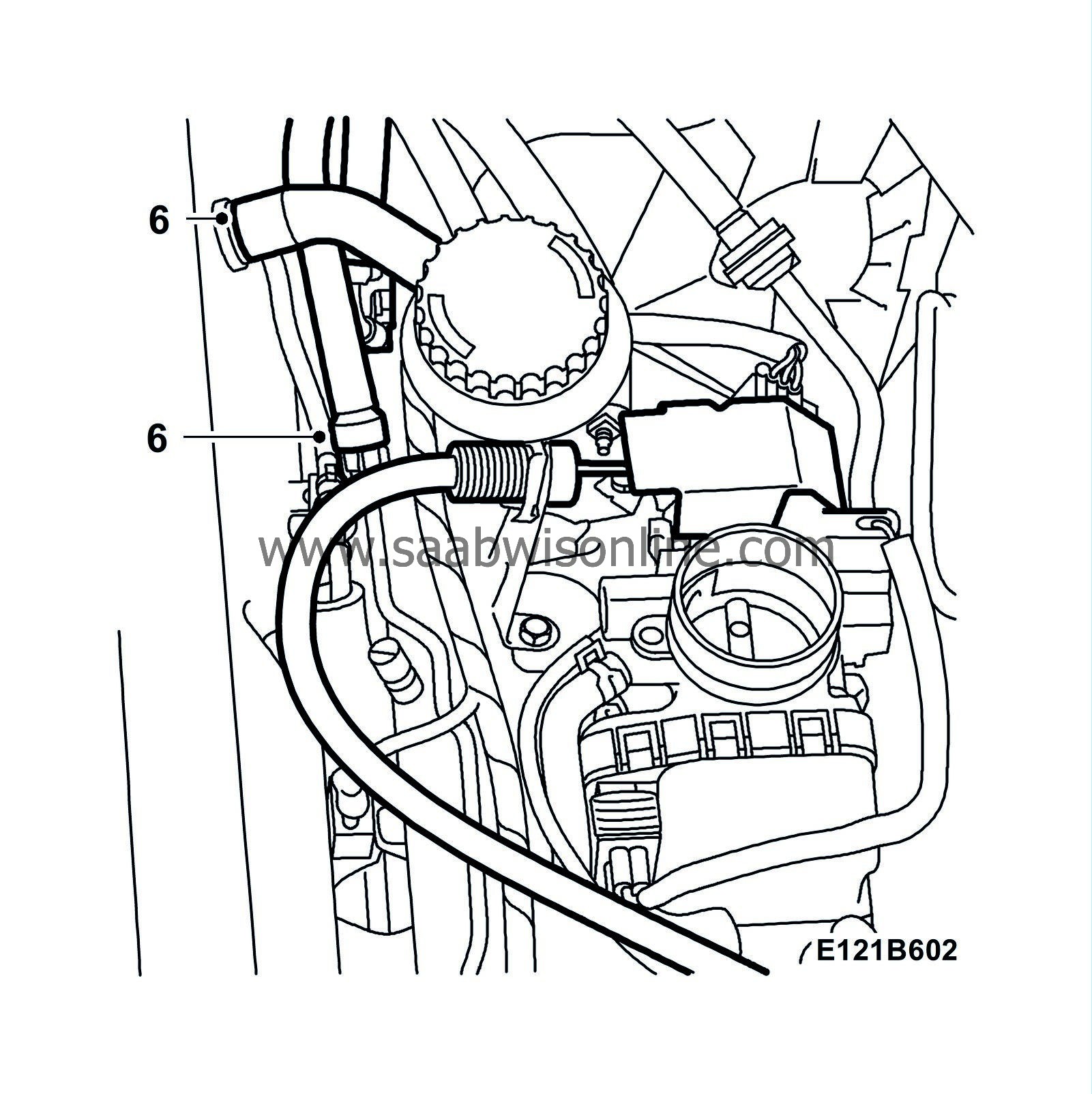

| 6. |

Remove the nipple for the crankcase ventilation from the camshaft cover and cut off the cable tie at the non-return valve.

|

|

| 7. |

Remove the camshaft cover.

|

|

| 8. |

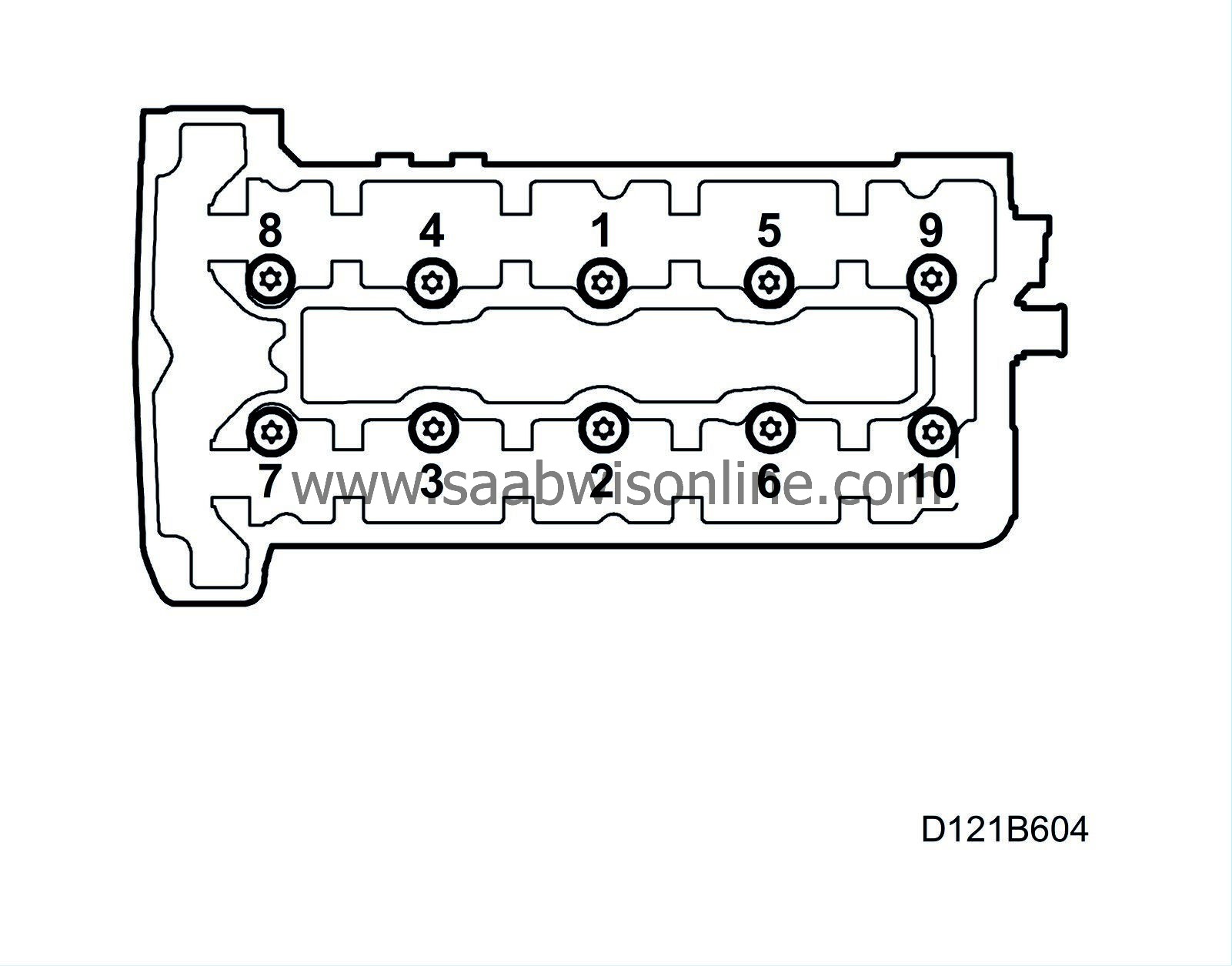

Undo bolt number 1 and tighten it. Repeat this in turn for the other bolts and in fitting order as per the illustration.

Tightening torque 40 Nm (30 lbf ft).

|

|

| 9. |

Tighten the bolts again in step I in fitting order as per the illustration. Tighten the bolts one more time in step II.

Tightening torque step I, 60 Nm (44 lbf ft) Tightening torque step II, 90° |

|

| 10. |

Clean the sealing face on the camshaft cover and the cylinder head using benzine.

|

|

| 11. |

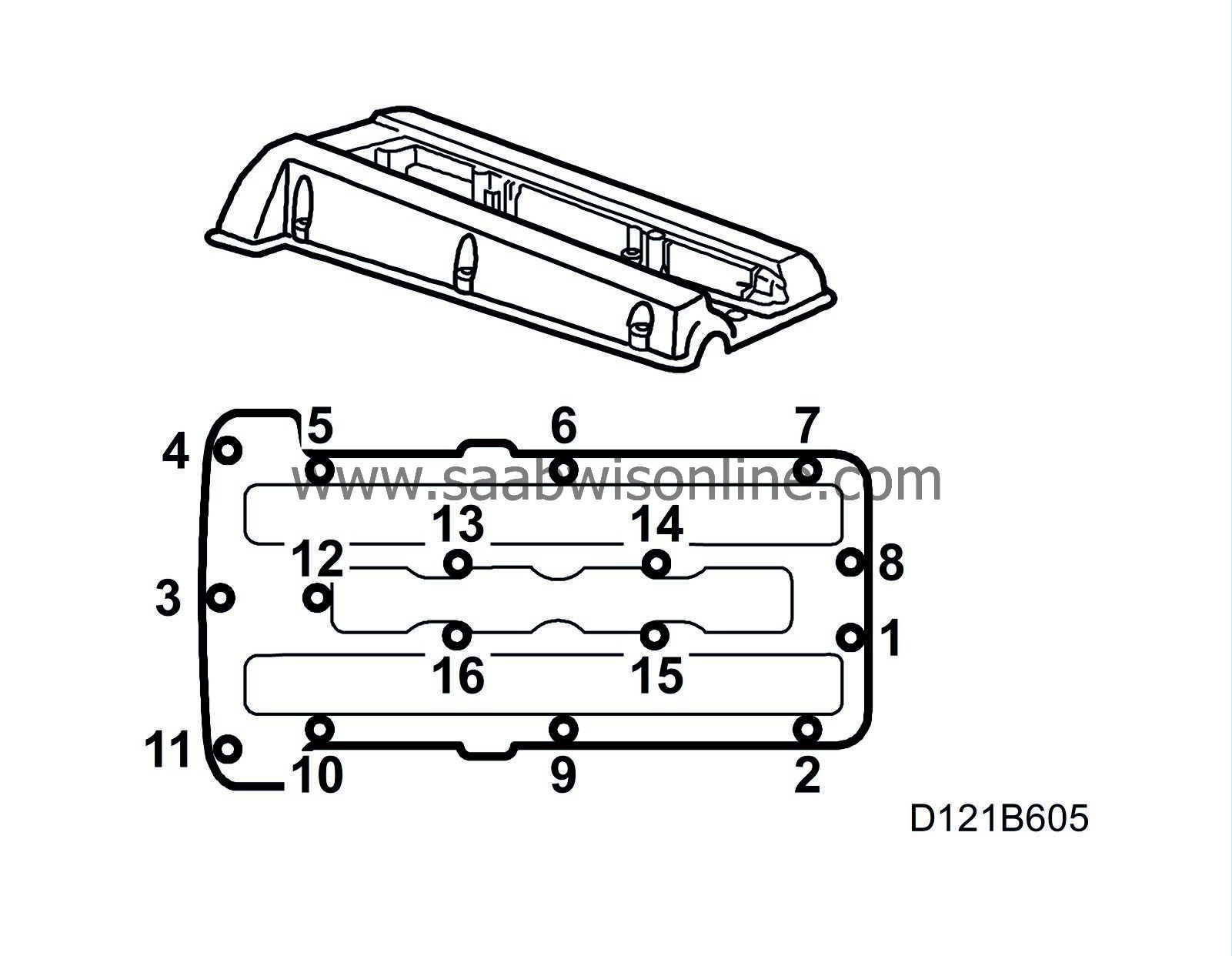

Smear oil in the recess on the camshaft cover and fit the cover starting at the recess. Following which, tighten the bolts in the order shown in the illustration.

Tightening torque 15 Nm (11 lbf ft). |

|

| 12. |

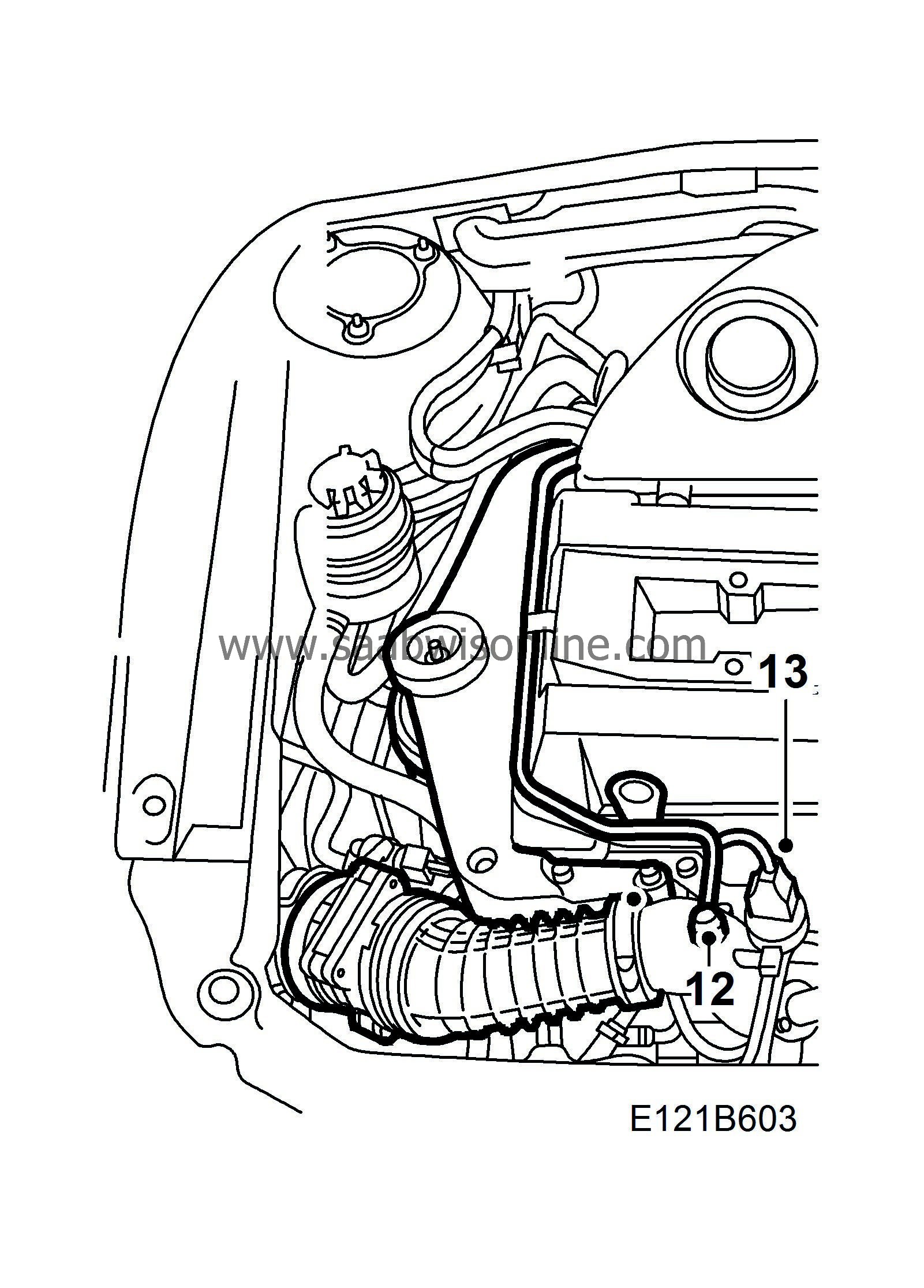

Fit the banjo screw to the crankcase ventilation pipe. Use new gaskets.

|

|

| 13. |

Connect the solenoid valve connector.

|

|

| 14. |

Fit the nipple for the crankcase ventilation to the camshaft cover and a new cable tie to the non-return valve.

|

|

| 15. |

Fit the screw for the crankcase ventilation pipe on the camshaft cover.

|

|

| 16. |

Fit the ignition discharge module and connect its connector.

Tightening torque 11 Nm (8 lbf ft). |

|

| 17. |

Clean the surfaces of oil/coolant leakage.

|

|

| 18. |

Fit the upper engine cover.

|

|

| 19. |

Check/adjust the coolant and oil levels.

|

|

| 20. |

Connect the exhaust evacuator, start the engine and check that the leakage has ceased.

|

|

| Standard times-/Warranty information |

In the case of customer complaint and if the car is within the warranty period , use the following information to fill out the claim:

Failed Object: 21119

Fault/Reason code: 56/57

Location code: 09 (US: 9)

Warranty Type (US): 01

Repair/Action code: 05

Labour Operation (US): 21119-02

(CA): J0135