(210-2417 utg. 4) Oil leakage from engine

Symptom: Oil leakage from engine.

|

TECHNICAL SERVICE BULLETIN

|

|

Bulletin Nbr:

|

210-2417 utg. 4

|

|

Date:

...........

|

April 2006

|

|

Market:

|

all

|

Saab 9-5 M98 - M03 with engine variants B205 and B235

The flow through the crankcase ventilation may be inadequate in certain operating conditions, and oil leakage may then arise. Most common is leakage at the joint between the timing cover, the cylinder block and the cylinder head as well as leakage at the crankshaft seal. Well functioning crankcase ventilation is also very important for avoiding increased oil consumption. Gasket replacement/resealing must only be carried out if the oil leakage does not cease after the following procedure.

In the case of customer complaint, the following procedure must be carried out.

Symptom description

Oil leakage from engine.

55 561 200 Renovation kit, crankcase ventilation, consisting of:

Nipple

Insulation

Hose kit

Hose kit

Oil filler pipe

Oil trap

Cable tie (x 2)

Bushing

If the hoses and/or check valve must be replaced:

55 560 445 (CA: 30566431) Hose to oil pan

55 560 463 (CA: 30581025) Hose for camshaft cover

93 99 973 (CA: 30585634) Hose with check valve

|

1.

|

Disconnect the battery's negative cable.

|

|

2.

|

Remove the upper engine cover.

|

|

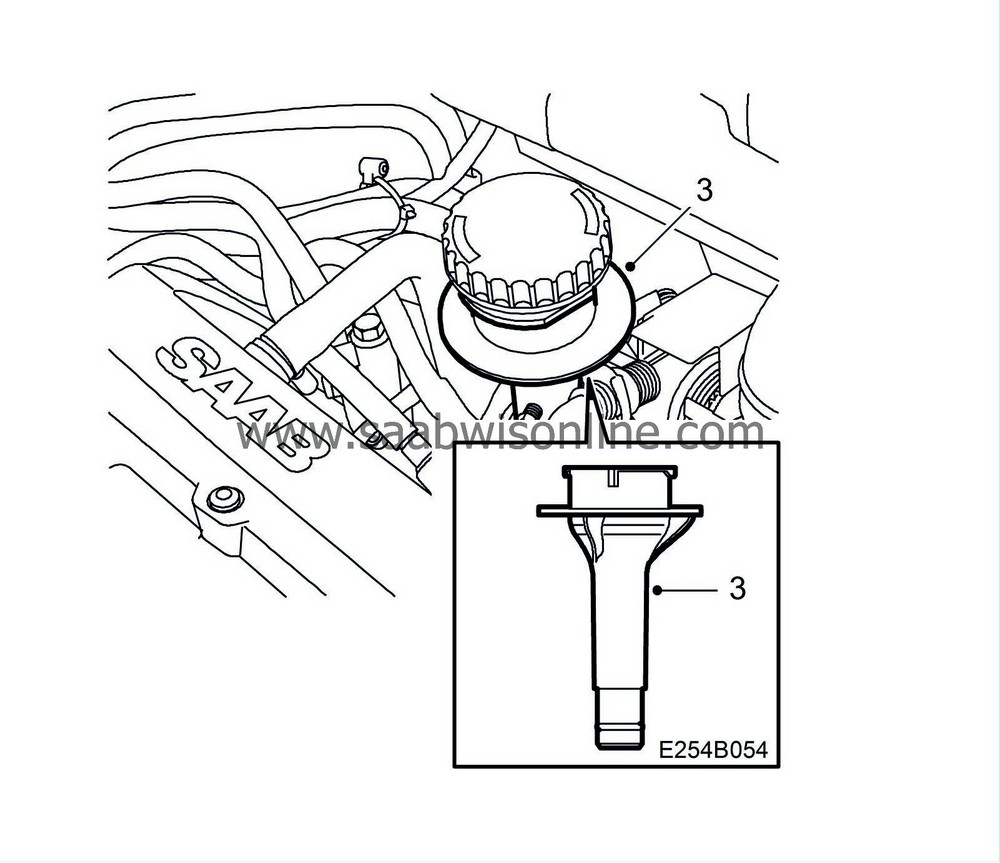

3.

|

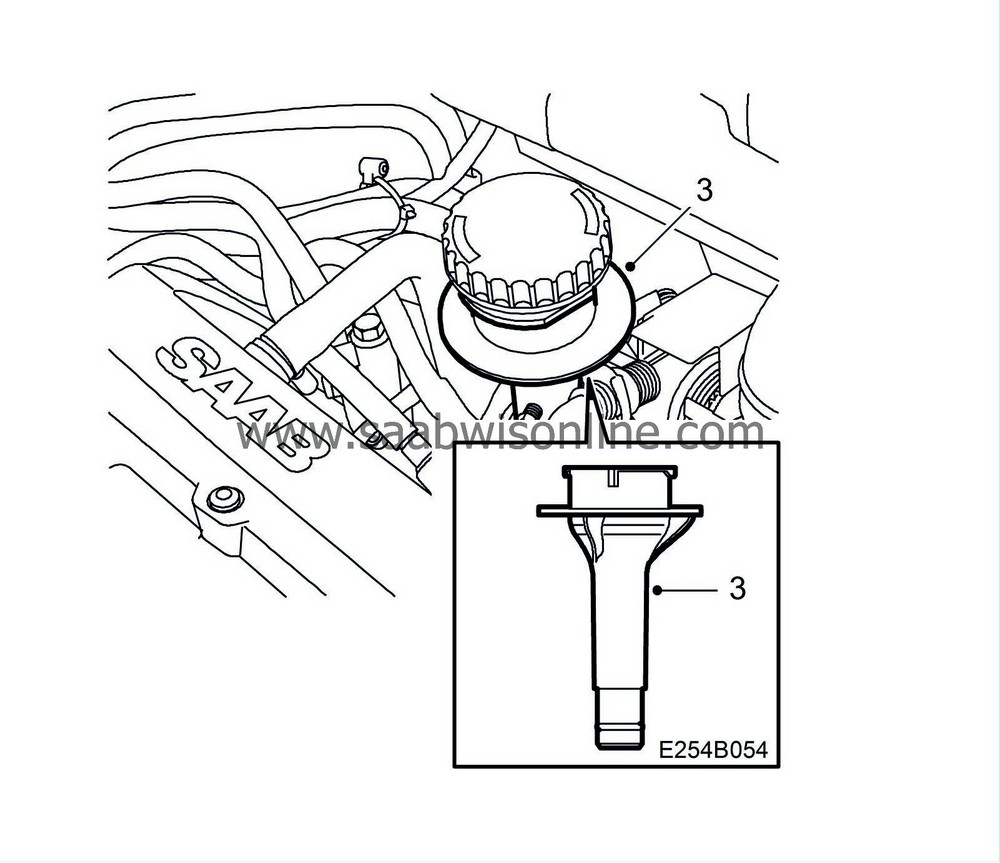

Fit a new oil filler pipe.

|

|

4.

|

Remove the hose from the pipe connection on the turbo's intake manifold.

|

|

5.

|

Remove the hoses from the nipple in the camshaft cover. Check the condition of the hoses, replace if necessary.

|

|

6.

|

Remove the old nipple and bushing from the camshaft cover and fit the new nipple and bushing.

|

|

8.

|

Remove the oil trap's two upper hoses.

|

|

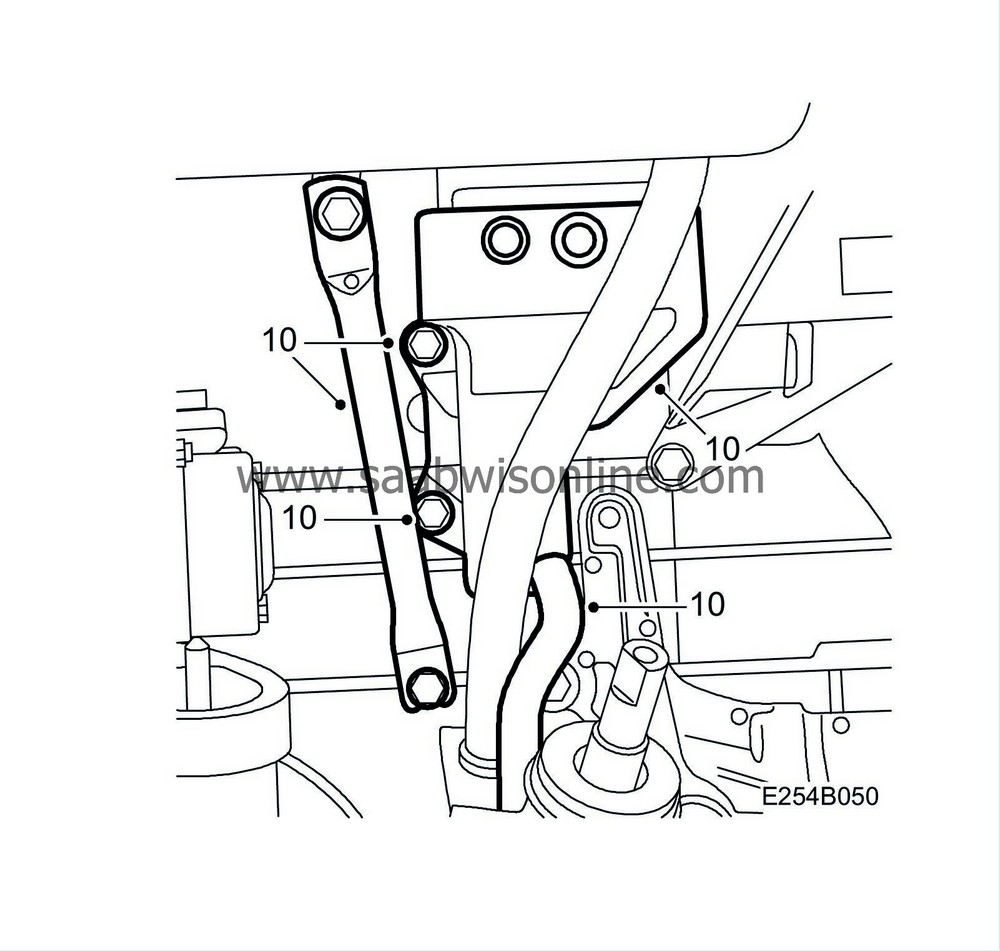

9.

|

Remove the lower hose to the oil trap. Remove the stay to the intake manifold and the oil trap. If necessary, remove the generator positive cable.

|

|

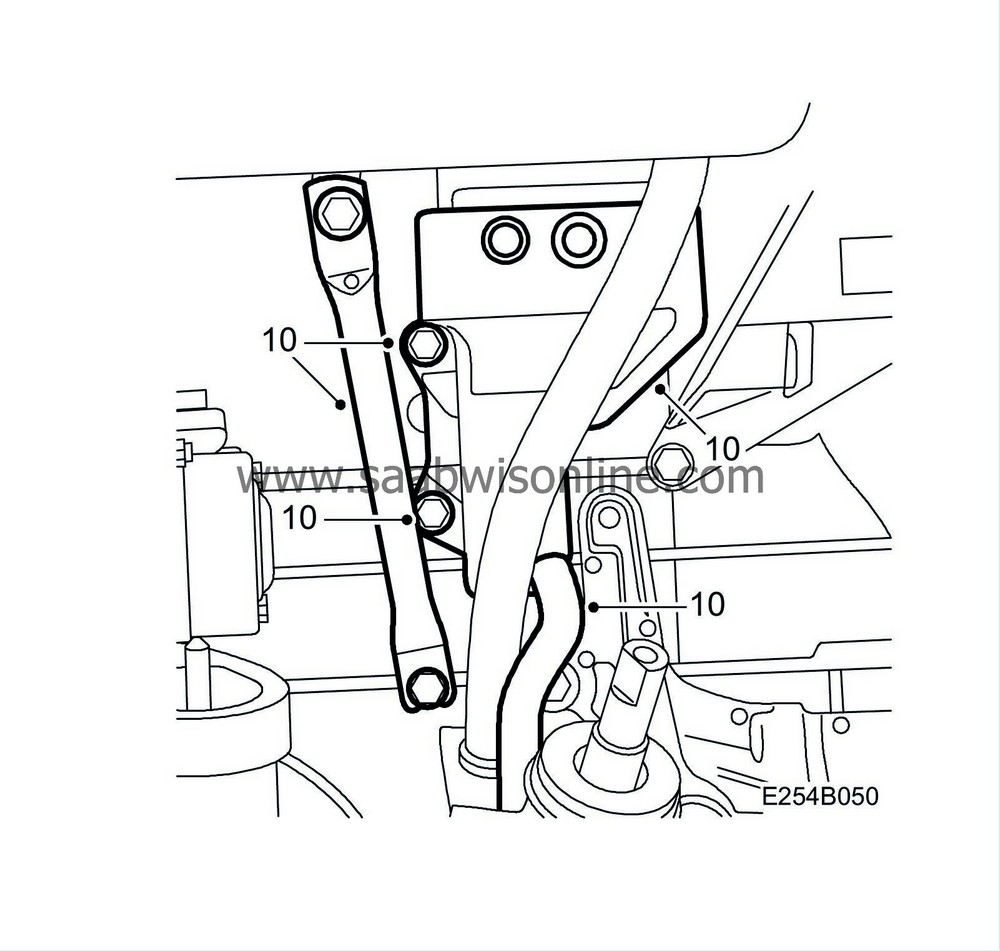

10.

|

Fit the new oil trap, the lower hose to the oil trap (replace hose if necessary) and the stay for the intake manifold. If the positive cable was removed, connect it to the generator.

|

|

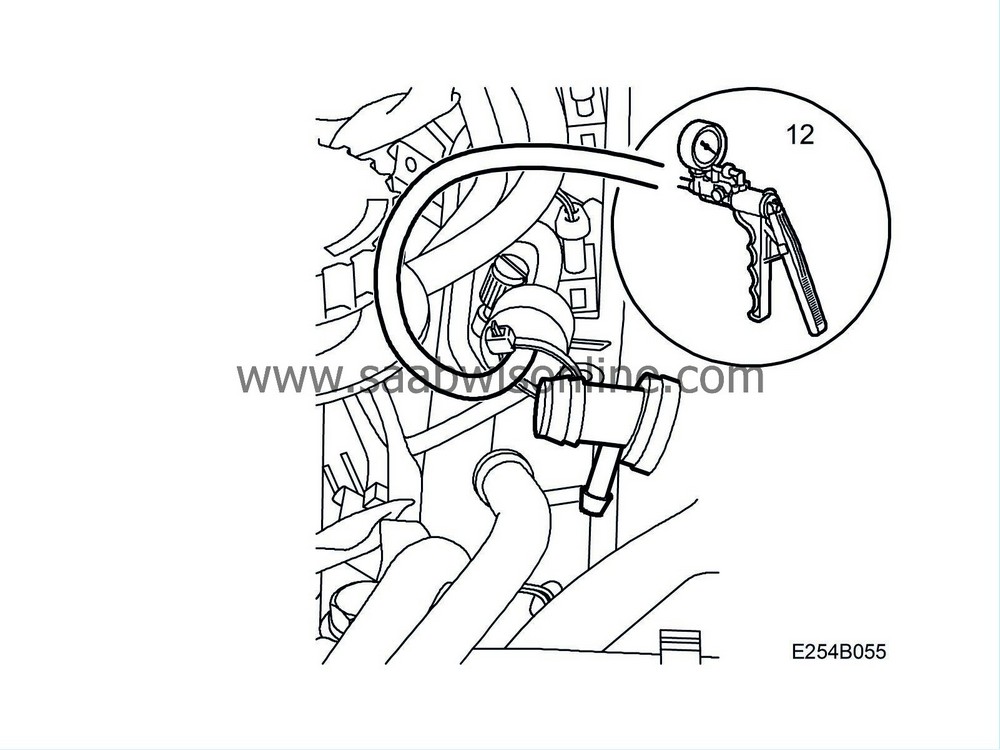

12.

|

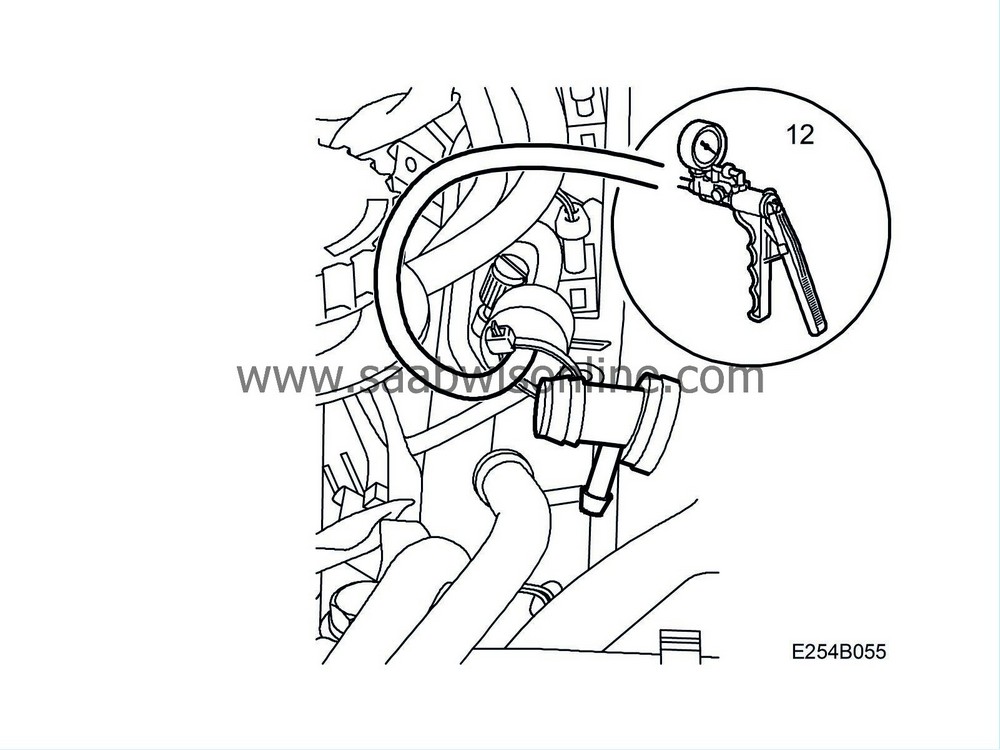

Check the function of the check valve on the small circuit with 30 14 883 Pressure/Vacuum pump, replace if necessary. The arrow must point toward the throttle body.

|

Note

|

|

Arrow's direction on the check valve.

|

|

|

13.

|

Connect the new hose kit (with T-connection) between the nipple on the oil filler pipe and the connection on the turbo's intake manifold.

|

|

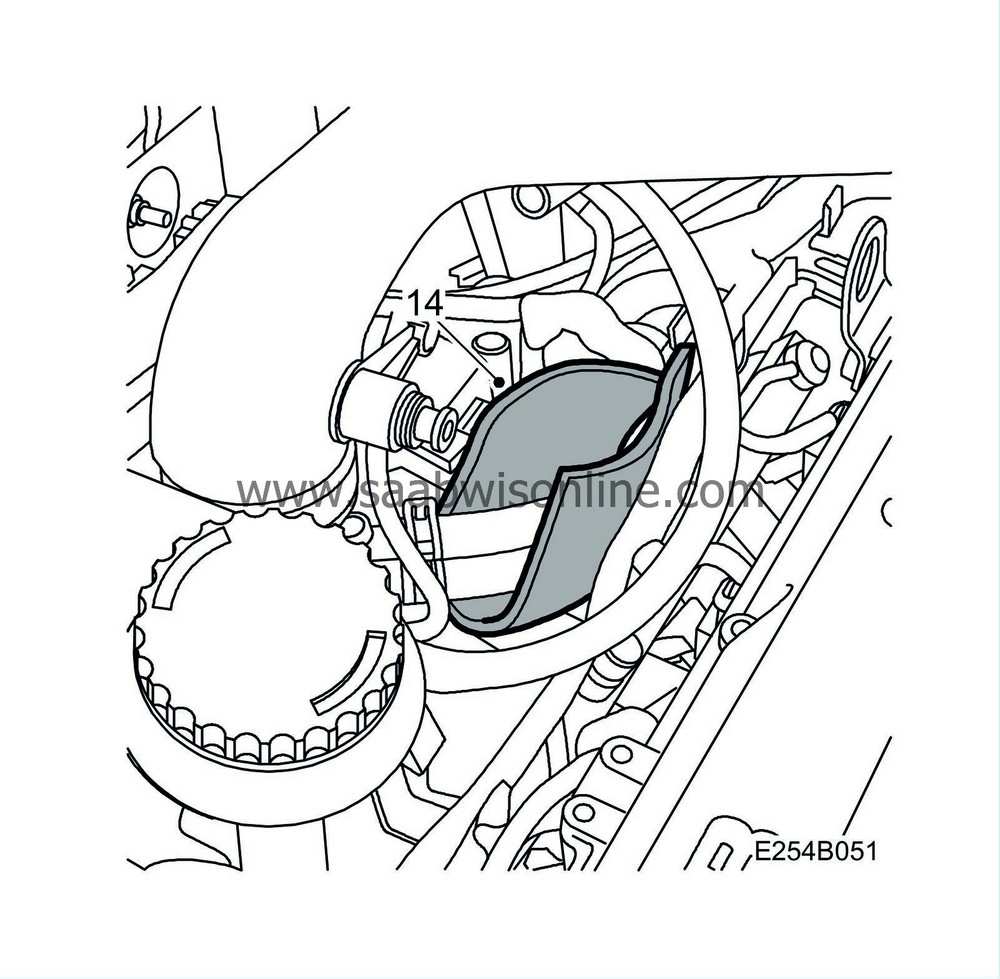

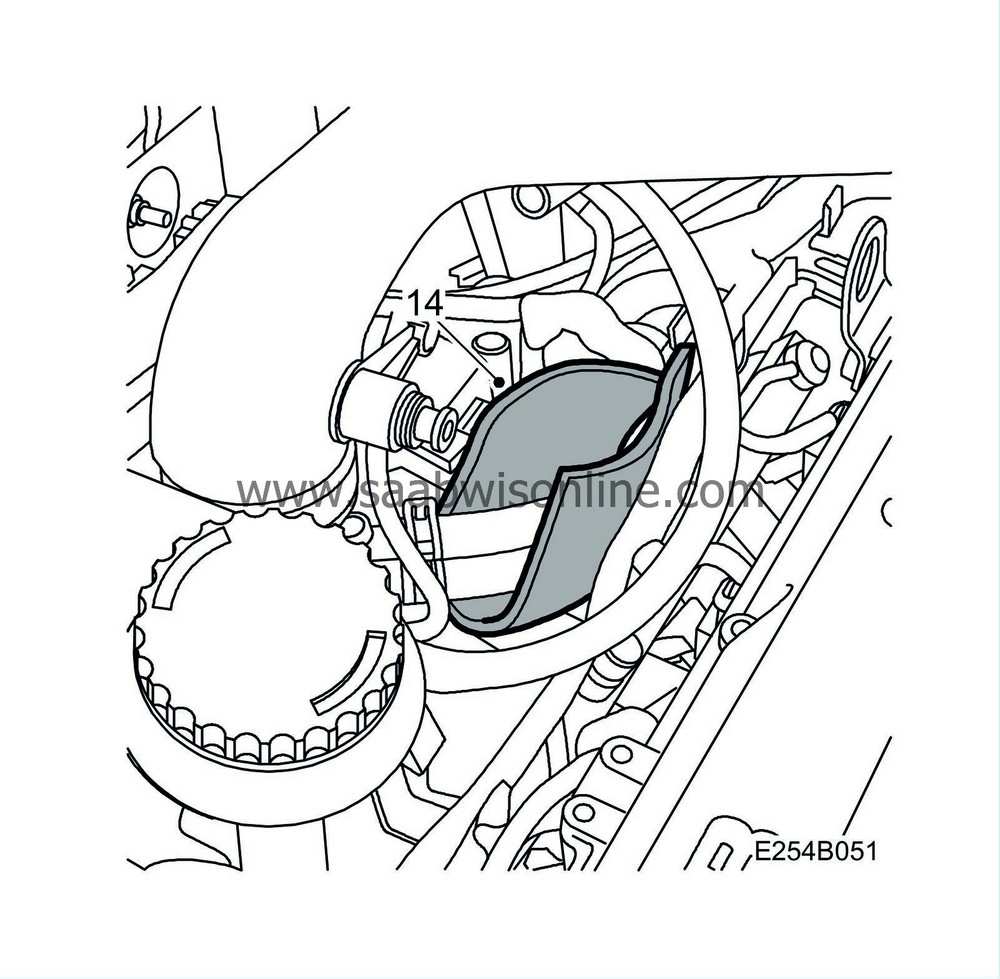

14.

|

Fit the insulation under the throttle body's coolant hoses so that the insulation's short sides point upward.

|

|

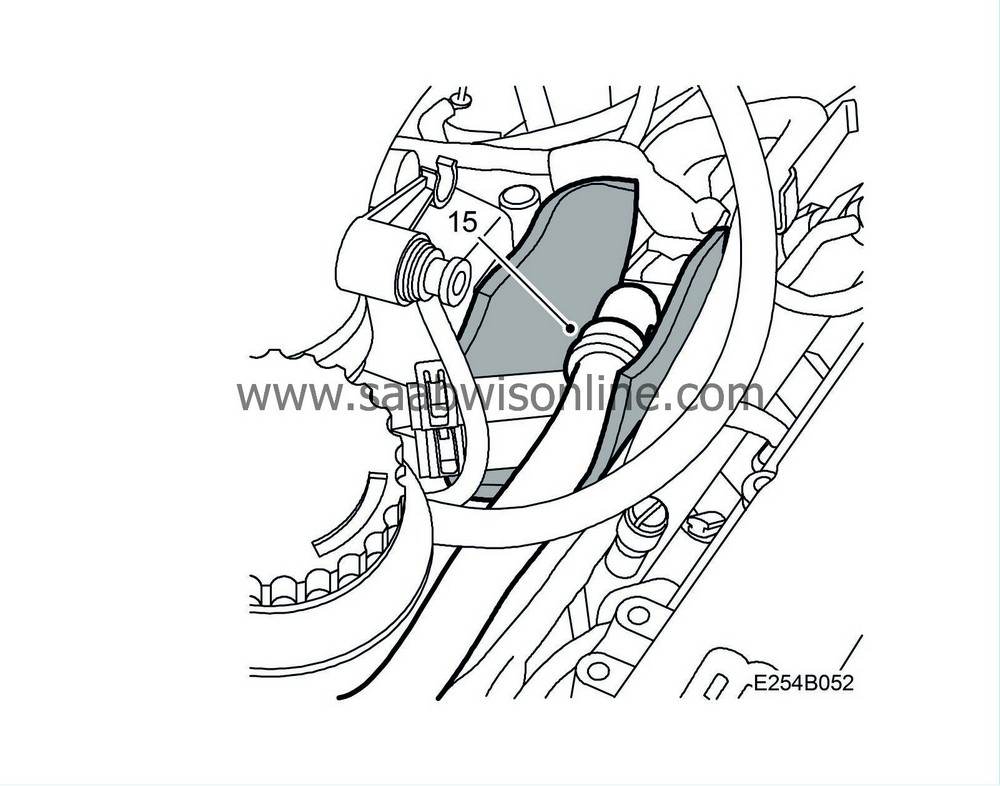

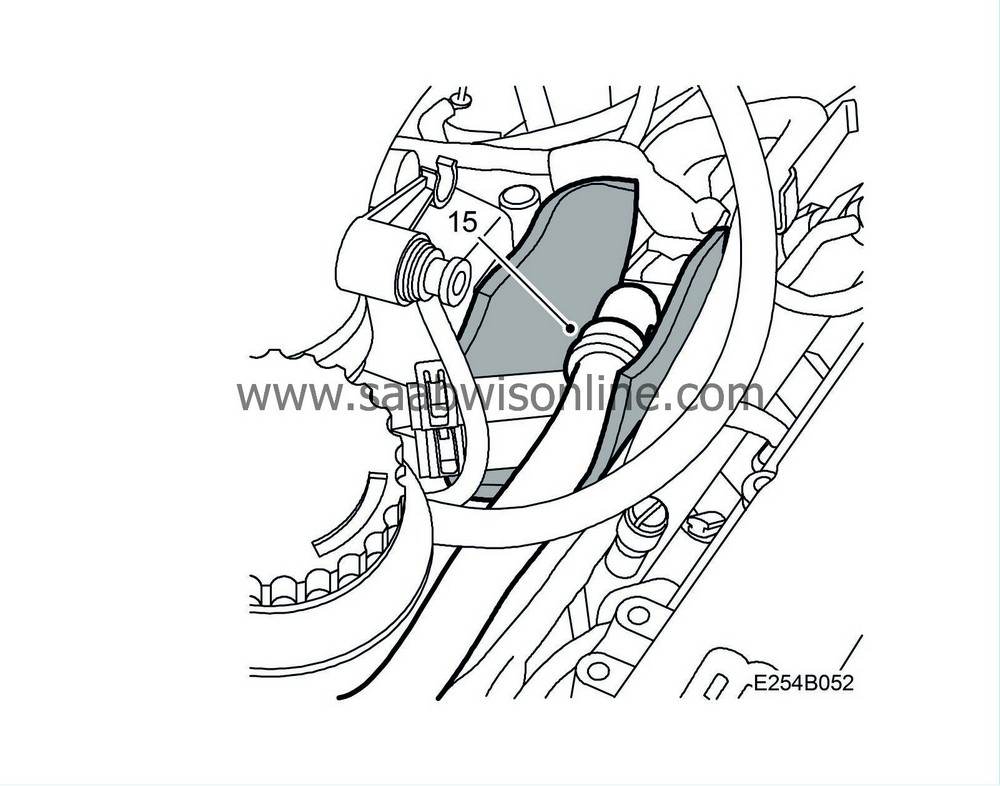

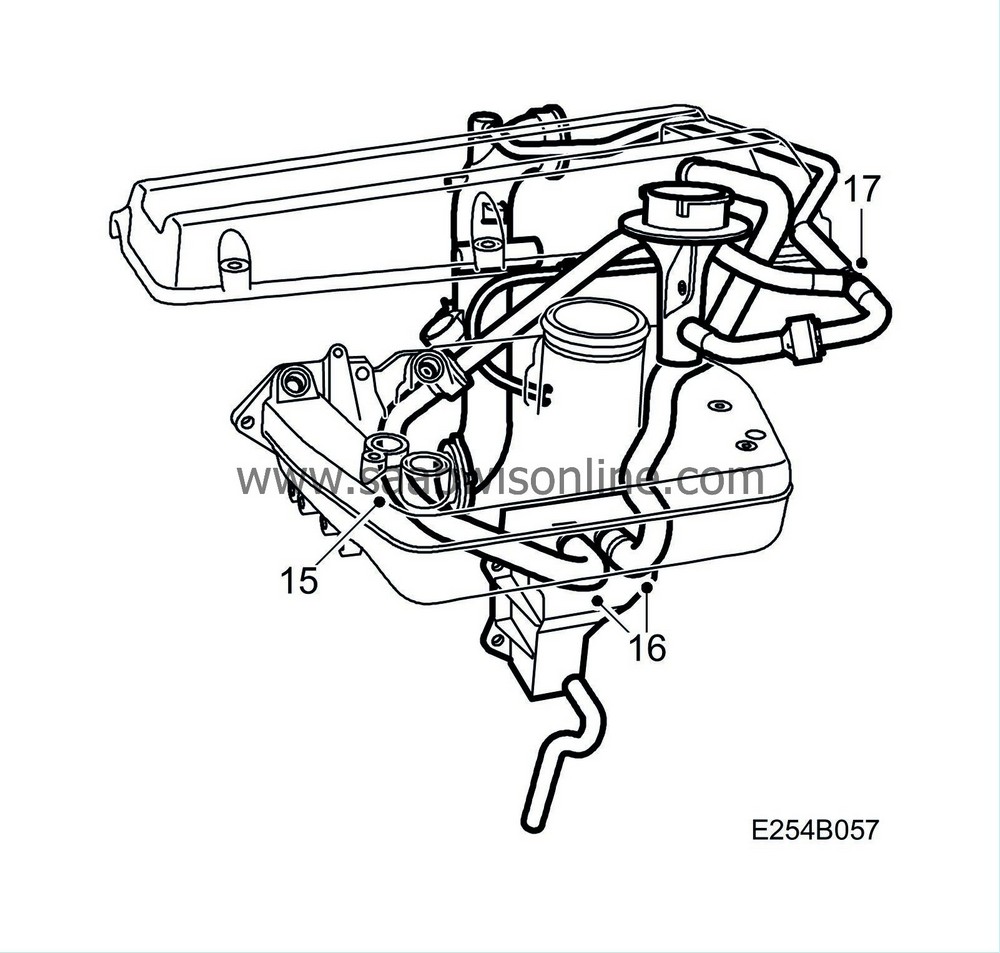

15.

|

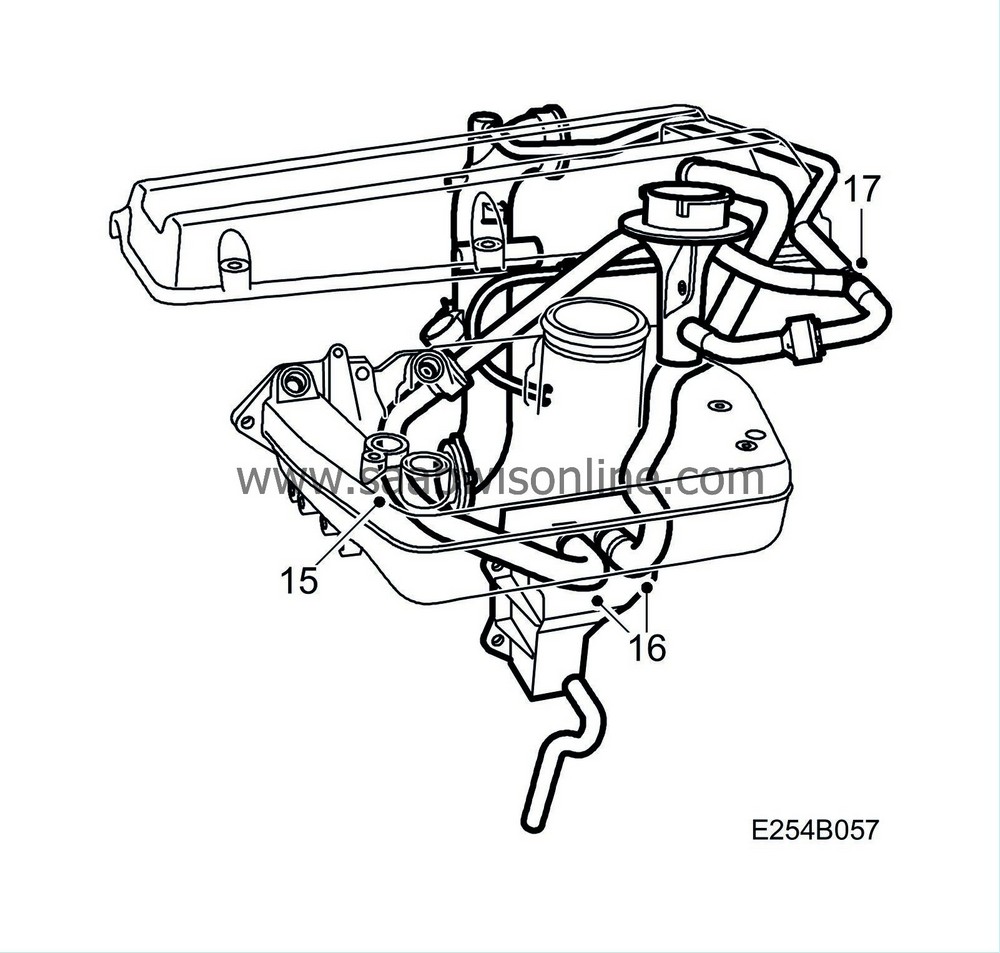

Fit the crankcase ventilation hose in place so that the check valve is located above the coolant hoses. The crankcase ventilation hose must follow the route of the lower coolant hose through the intake manifold and then on to the oil trap.

|

|

16.

|

Connect the oil trap's upper hoses. If the hose with part no. 91 88 806 is replaced then the nipple enclosed with the hose must not be used. Use the nipple enclosed with the spare parts kit.

|

|

17.

|

Connect the new hose kit together at the T-connection.

|

|

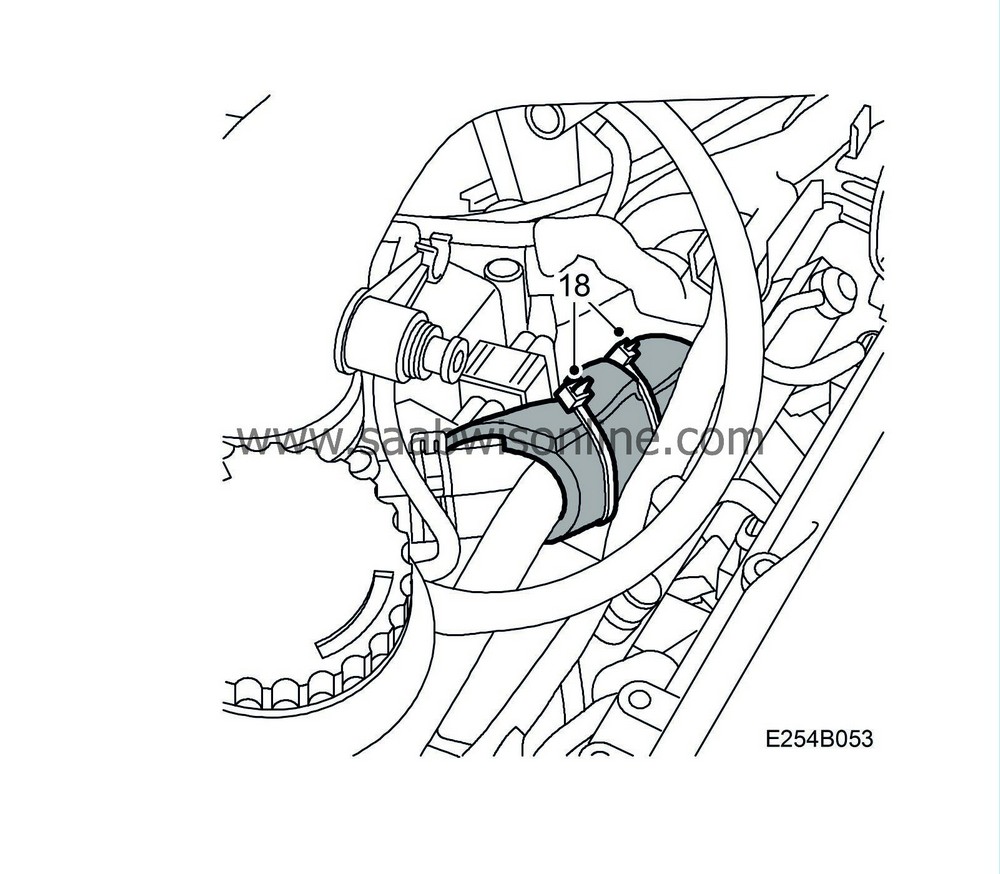

18.

|

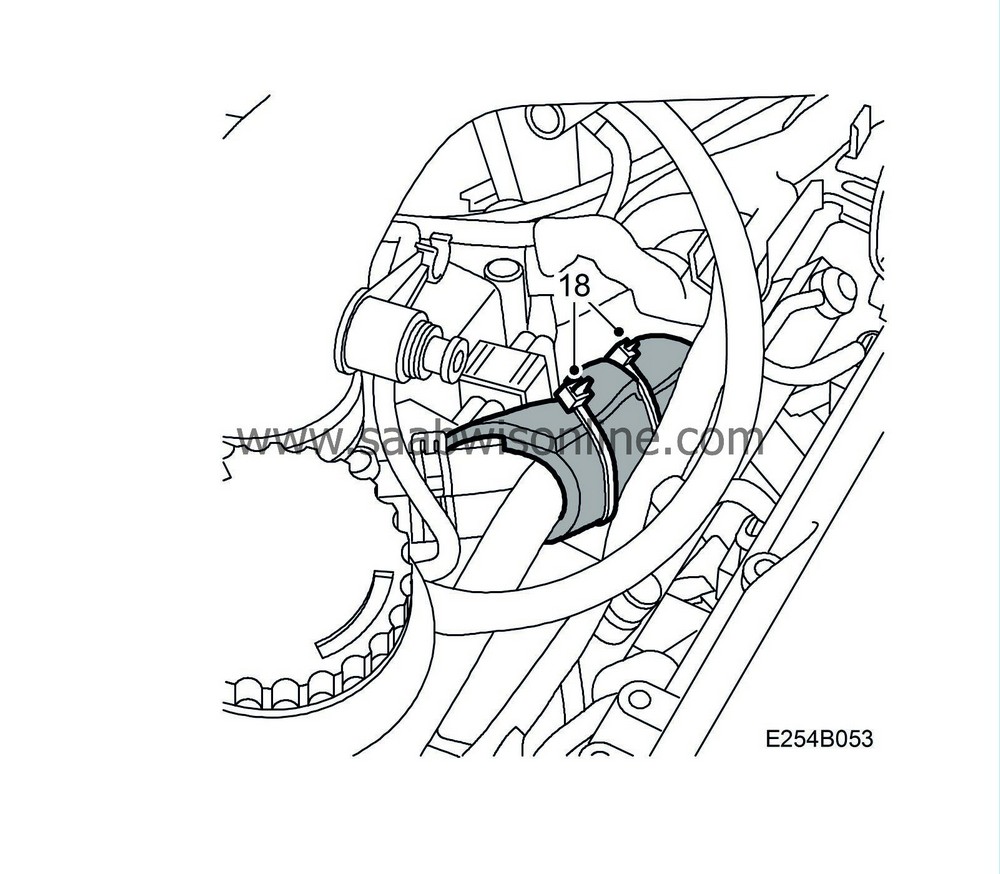

Make sure that the check valve has good contact with both coolant hoses. Affix a cable tie around the insulation on each side of the check valve.

|

|

19.

|

Fit the hoses to the nipple on the camshaft cover.

|

|

20.

|

Fit the upper engine cover.

|

|

21.

|

Connect the cable to the battery's negative terminal.

|

|

22.

|

Set the correct time and date in SID.

|

|

Warranty/Time Information

|

In the case of customer complaint and if the car is

within the warranty period

, use the following information to fill out the claim:

Failed Object: 21216

Fault/Reason code: 57

Location code: 09 (US=9)

Warranty Type (US): 01

Repair/Action code: 05

Labour Operation (US): 2121602

Labour Operation (CA): J6025

Time: 0.6 hr