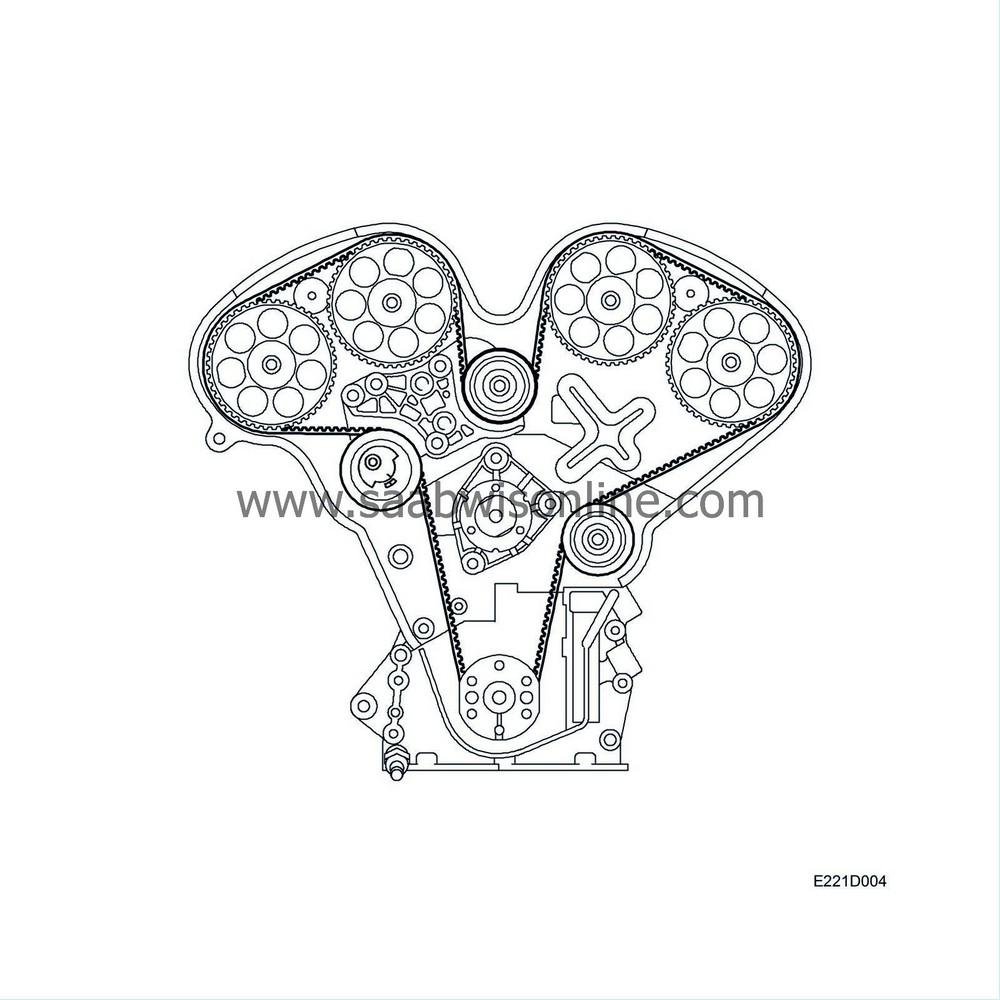

Camshaft drive

| Camshaft drive |

| Camshafts and tappets |

Each cylinder head has twin overhead camshafts with a large-diameter base circle, providing a large amount of lift with little stress. All four camshafts are driven by an internally-cogged belt with self-adjusting belt tensioner. The belt assembly also includes two adjuster rollers.

The camshafts are direct-acting on the valves via hydraulic tappets. The hydraulic tappets adjust automatically to the change in length of the valves at different temperatures. They operate in an oil bath and are supplied with oil via an oilway in the cylinder head. The chief advantages of hydraulic tappets are their quiet operation and their reliability. In addition, each cylinder head has two air purging nozzles to eliminate tappet noise after starting.

The valves have chromium-plated stems and the exhaust valves are sodium-cooled. The camshaft sprockets on the rear cylinder head are interchangeable as also are the camshaft sprockets on the front cylinder head.

| Belt tensioner |

The belt tensioner mounted on the slack side of the internally-cogged belt is of dynamic and adjustable type. Once the belt tension has been adjusted, it tensions the belt continuously and compensates for belt wear.

The belt assembly also includes two adjuster rollers.