Fuel pump

| Fuel pump |

|

||||||||||||||||||||||

| To remove |

| Important | ||

|

The car should be parked on a level surface. If the tank is full and the car is jacked up at the rear when the pump is removed, it is very likely that fuel will run out. |

||

|

Place protective paper over the carpeting when the pump is removed as there is a risk of fuel spilling out. |

||

| 1. |

Raise the rear seat cushions and fold the carpeting out of the way.

|

|

| 2. |

Remove the fuel pump cover.

|

|

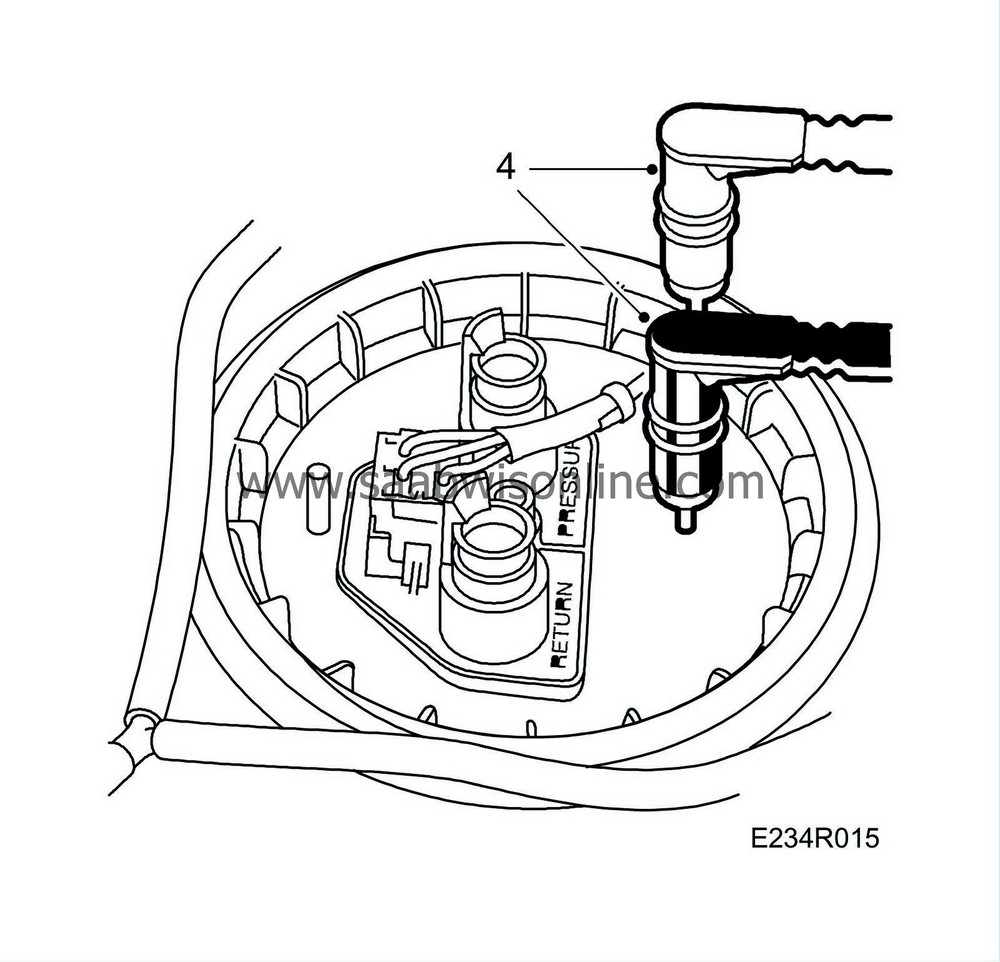

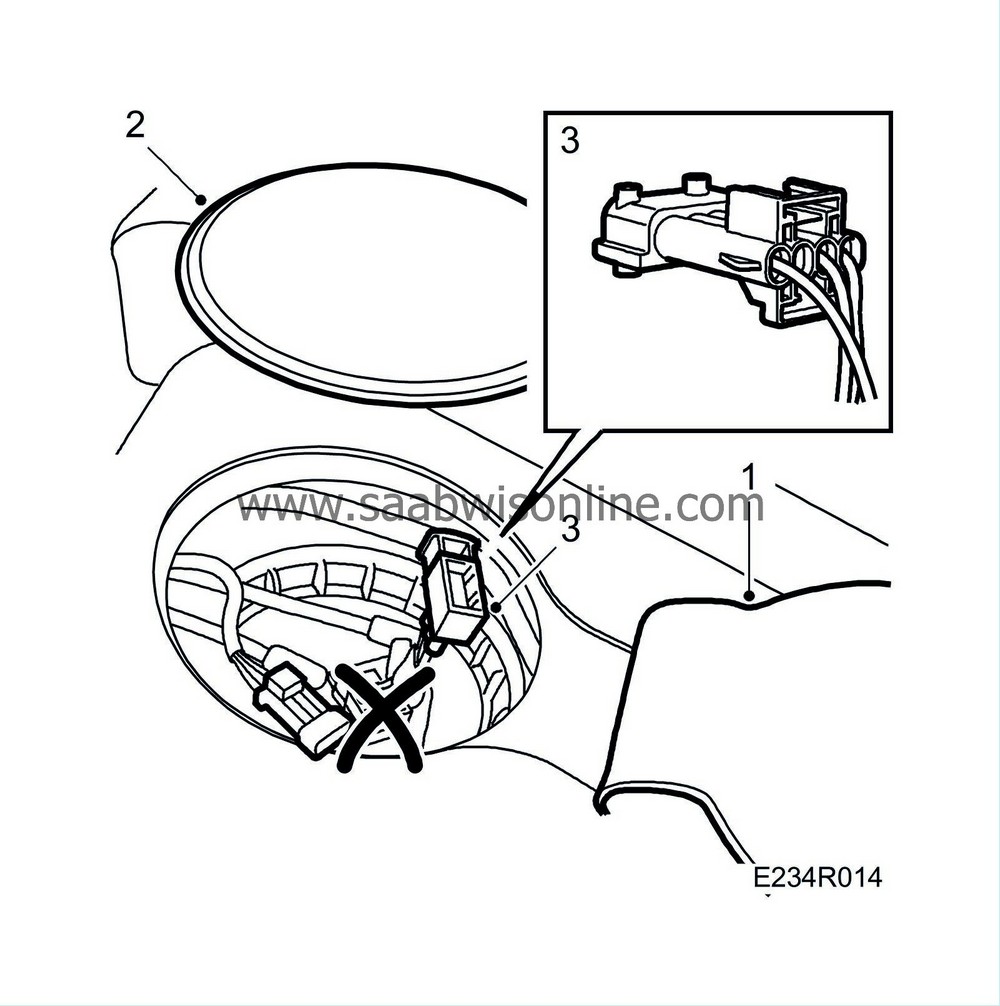

| 3. |

Unplug the upper connector.

|

||||||||||

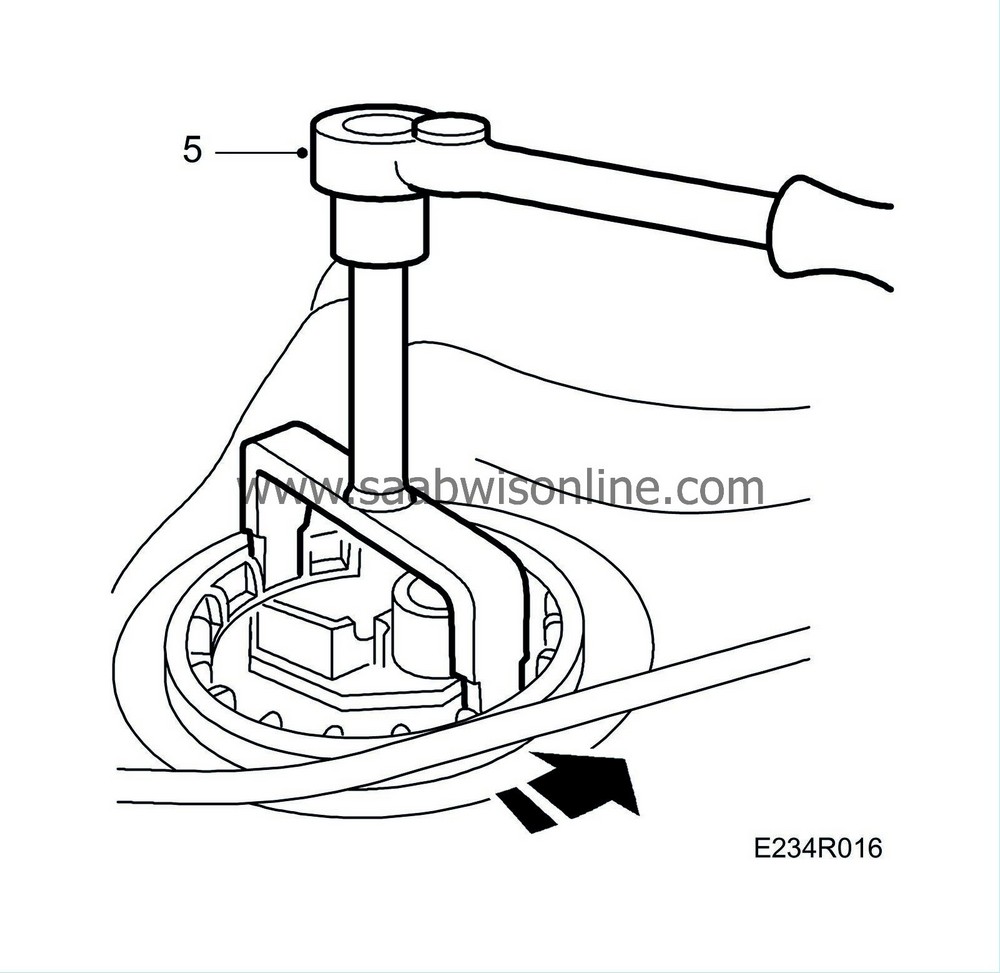

| 5. |

Remove the screw ring. Use the key, part no. 83 94 462.

|

|

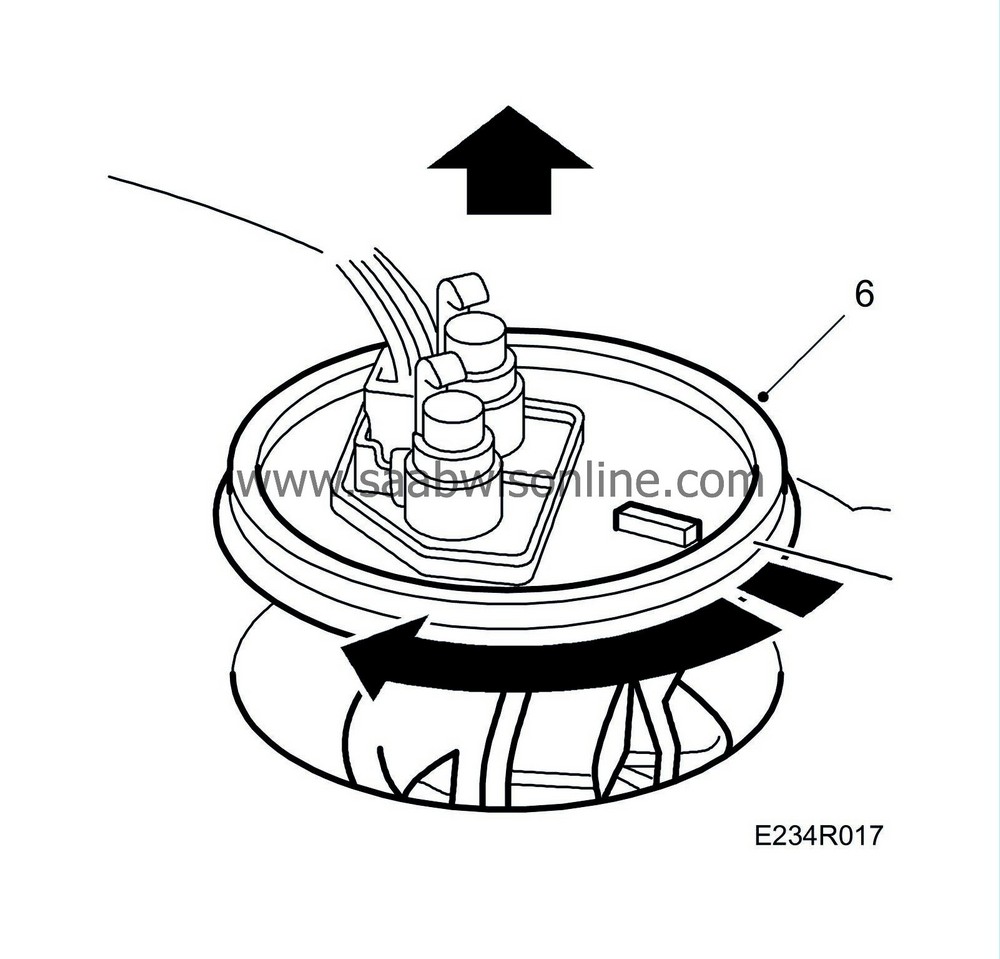

| 7. |

Transfer the pump to a suitable receptacle and pour off the fuel.

|

|

| To fit |

| Note | ||

|

Spray the connectors with Kontakt 61, part no. 30 04 520, before connecting them. |

| 1. |

Clean sealing surfaces.

|

|

| 2. |

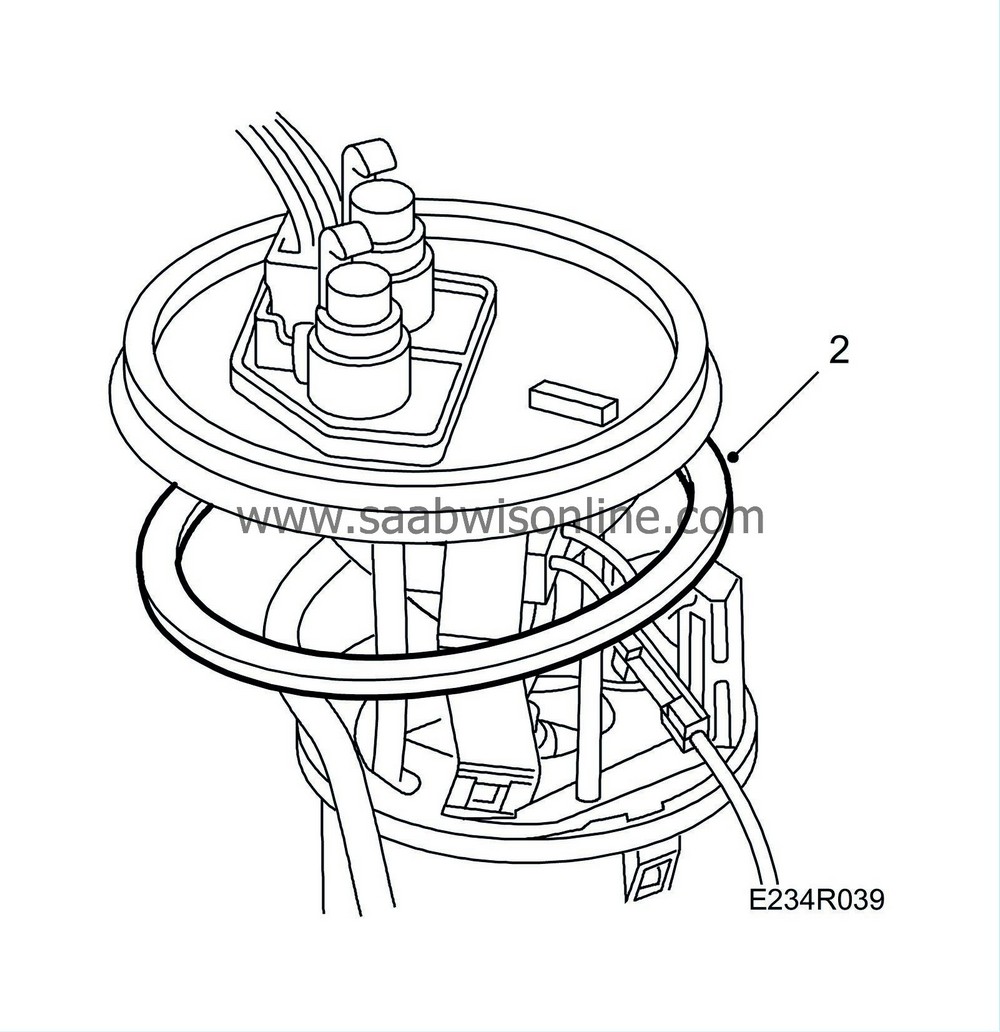

Fit a new O-ring in the groove in the tank.

|

|

| 4. |

Lubricate the screw threads on the pump cover and the upper edge of the pump with acid-free vaseline to prevent the pump turning when the screw ring is tightened.

|

|

| 5. |

Fit the screw ring and tighten it with the tool, part no. 83 94 462.

Tightening torque: 75 Nm (55 lbf ft). |

|

| 6. |

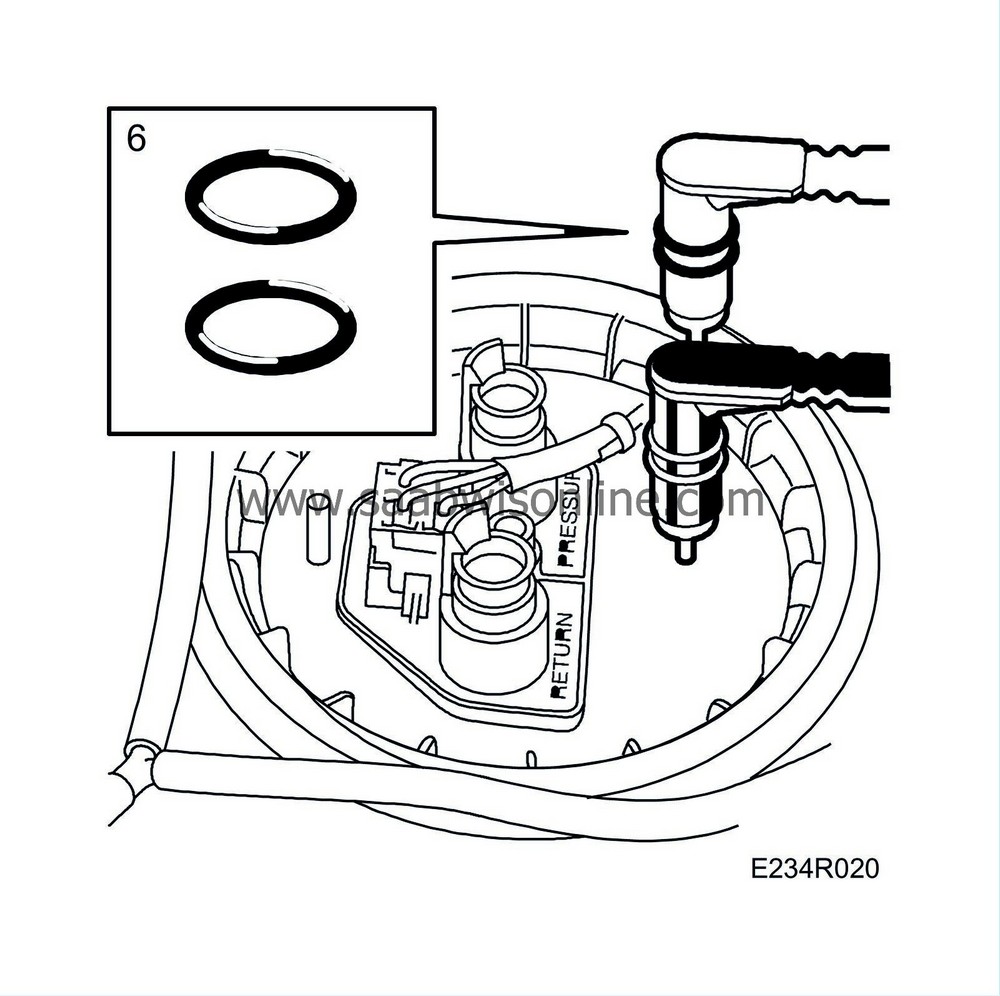

Inspect the O-rings on the fuel line connections, lubricate them with acid-free vaseline and connect the fuel lines to the pump.

|

|

| 7. |

Make sure that the yellow hooks have snapped in place over the connections.

|

|

| 8. |

Plug in the connector.

|

|

| 9. |

Check that the pump works properly and that it does not leak.

|

|

| 10. |

Fit the fuel pump cover, return the rear seat cushions to their places and fold back the carpeting.

|

|

| Checking the fuel gauge float arm position |

With the pump placed on a level surface, the distance between the surface and the bottom of the float should be 0-3 mm.

The sensor resistance should be:

Tank empty, float in bottom position: 50 ± 1.5 ohms.

Tank full, float in top position: 425 ± 6.5 ohms.

Warning

Warning