Checking the turbo pressure regulator

|

|

Checking the turbo pressure regulator

|

Warning

Warning

|

|

Be careful if the car is warm. The coolant is hot and there is a risk of burns from the intake manifold.

|

|

|

|

|

|

If the basic boost pressure cannot be adjusted, check the pressure regulator as follows:

|

1.

|

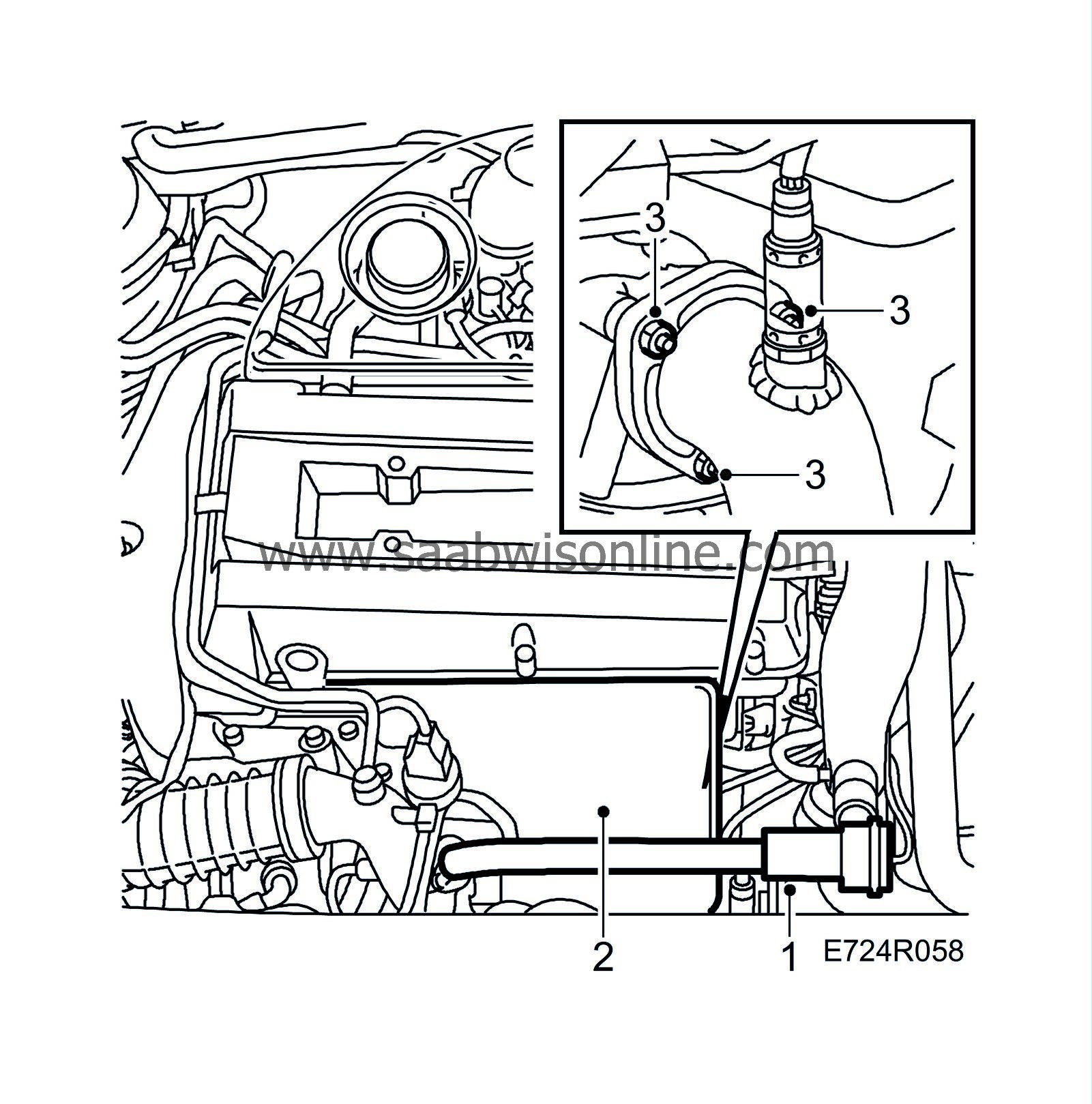

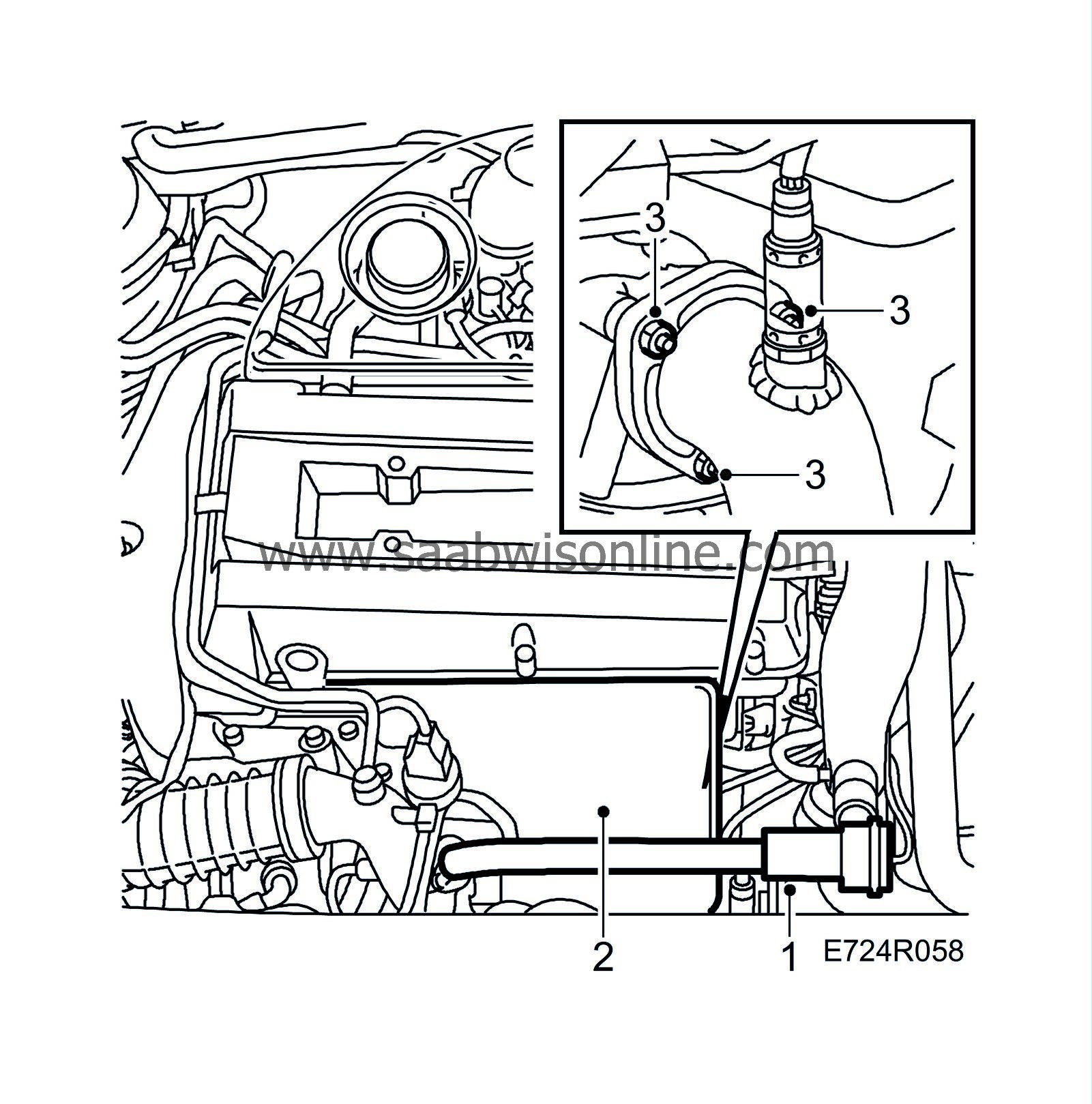

Undo the hose clip on the turbocharger pressure pipe and bend the bypass pipe aside.

|

|

2.

|

Remove the exhaust manifold heat shield. The heat shield is attached with a nut and two clips on the underside.

|

|

3.

|

Undo the three bolts securing the front exhaust system to the turbo.

|

Important

|

|

The flexible bellows on the front section of the exhaust system must not be bent more than 7° from its neutral position. This means that it must not be bent more than is caused by its own weight when the front exhaust system is left hanging.

|

|

If the pipe is strained too much its components can be permanently deformed. This will result in noise, leakage and an eventual breakdown.

|

|

|

|

|

4.

|

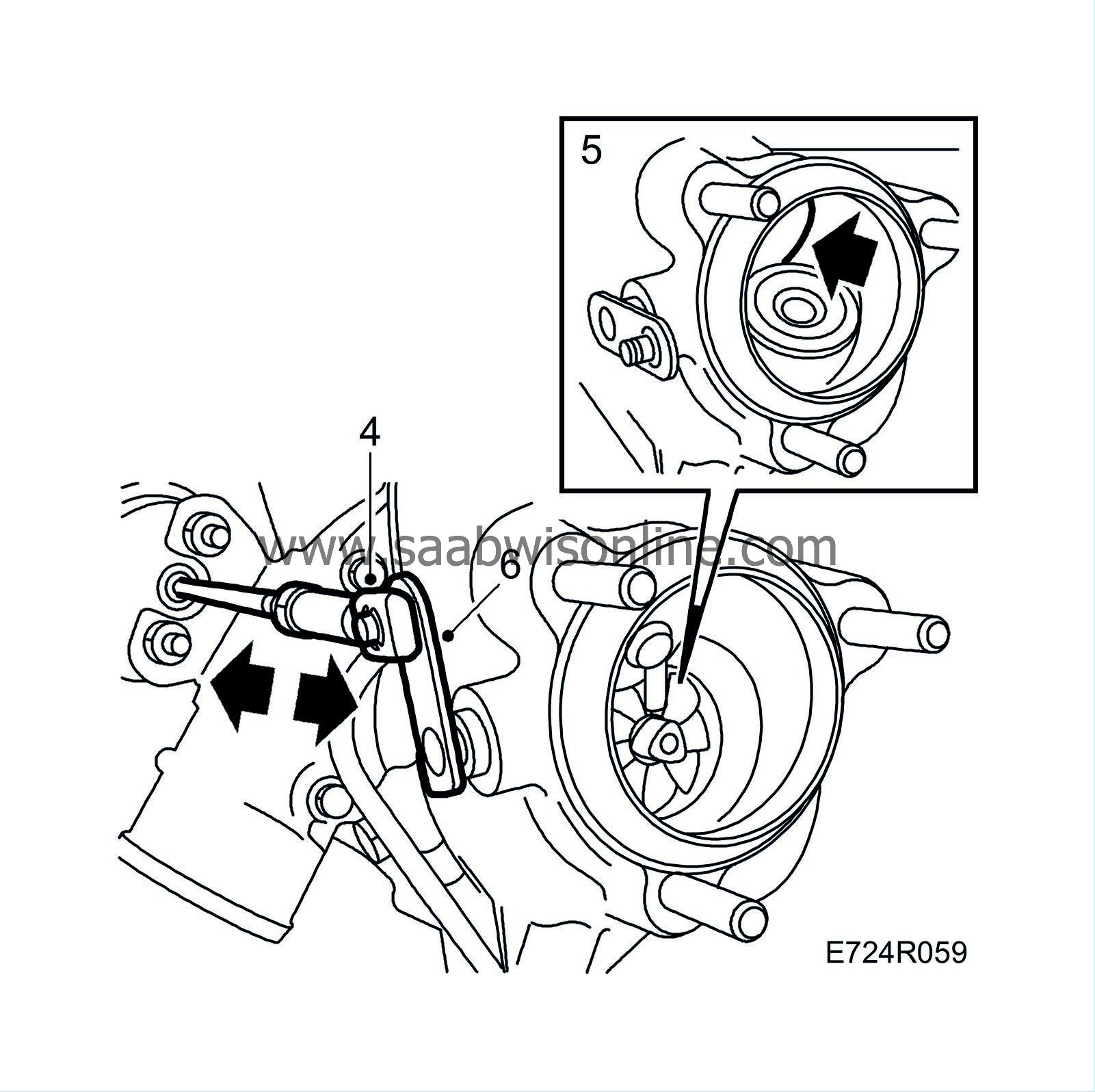

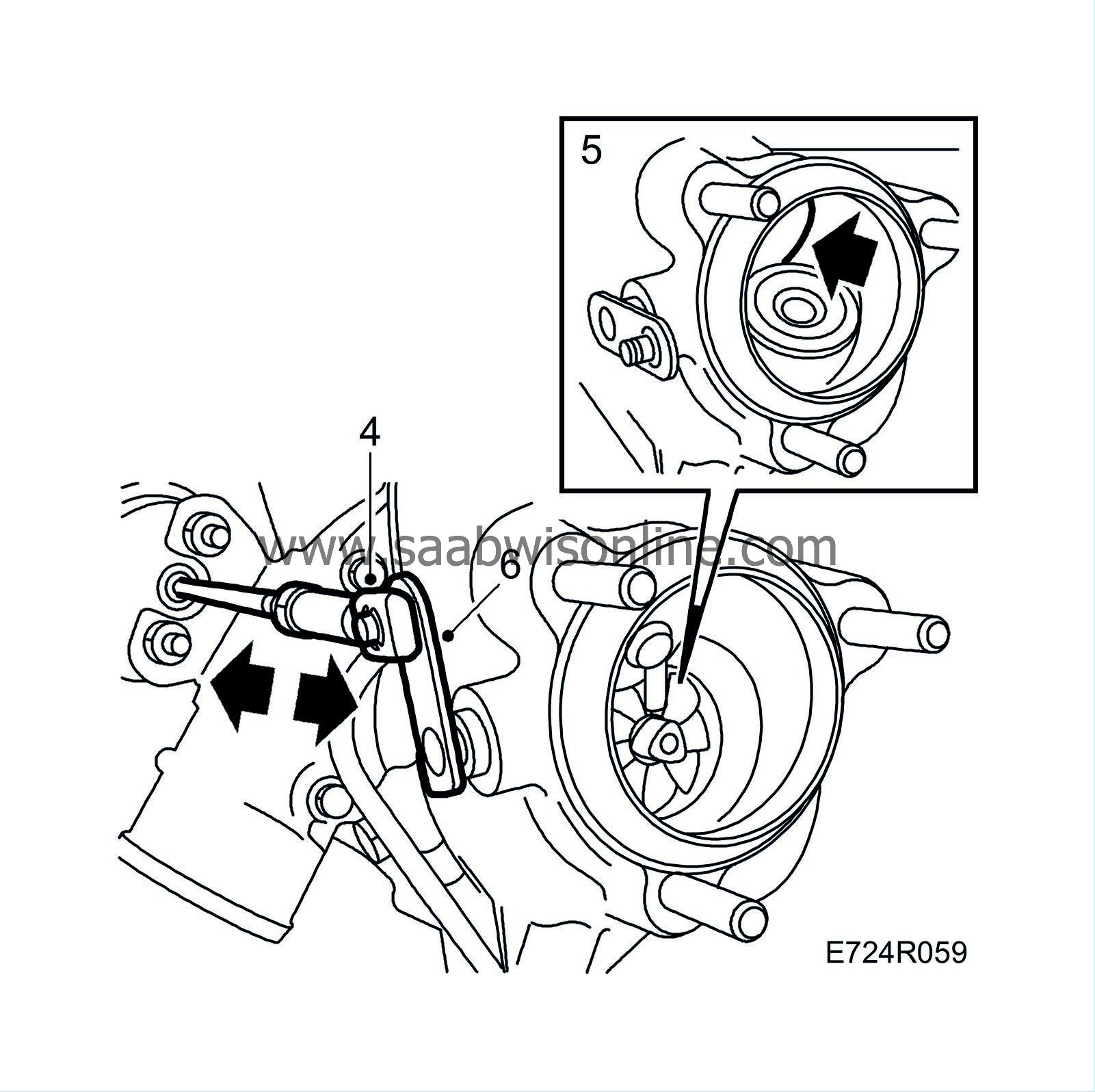

Remove the retaining ring and unhook the pushrod from the valve control arm.

|

|

5.

|

Observe whether the flap valve abuts firmly against the turbine housing. Check for carbon deposits, etc.

|

|

6.

|

Check that the arm moves easily.

|

|

7.

|

Refit the retaining ring and hook on the pushrod.

|

|

8.

|

Fit the front exhaust system to the turbo. Lubricate the studs with Molykote 1000 (part no. 30 20 271).

Tightening torque: 25 Nm (18.4 lbf ft)

|

Important

|

|

When fitting the front exhaust system to the turbo, the nuts should be tightened alternately to avoid distorting the flange. The flange must not abut against the turbo connection flange.

|

|

|

|

|

9.

|

Mount the heat shield. Press on the left-hand clamp first. Coat the stud with Molycote 1000 (part no. 30 20 971).

|

|

10.

|

Mount the bypass valve with pipe. Fit a new O-ring, greased with non-acidic vaseline.

Tightening torque: 8 Nm (5.9 lbf ft)

|

Warning

Warning