Closed loop

| Closed loop |

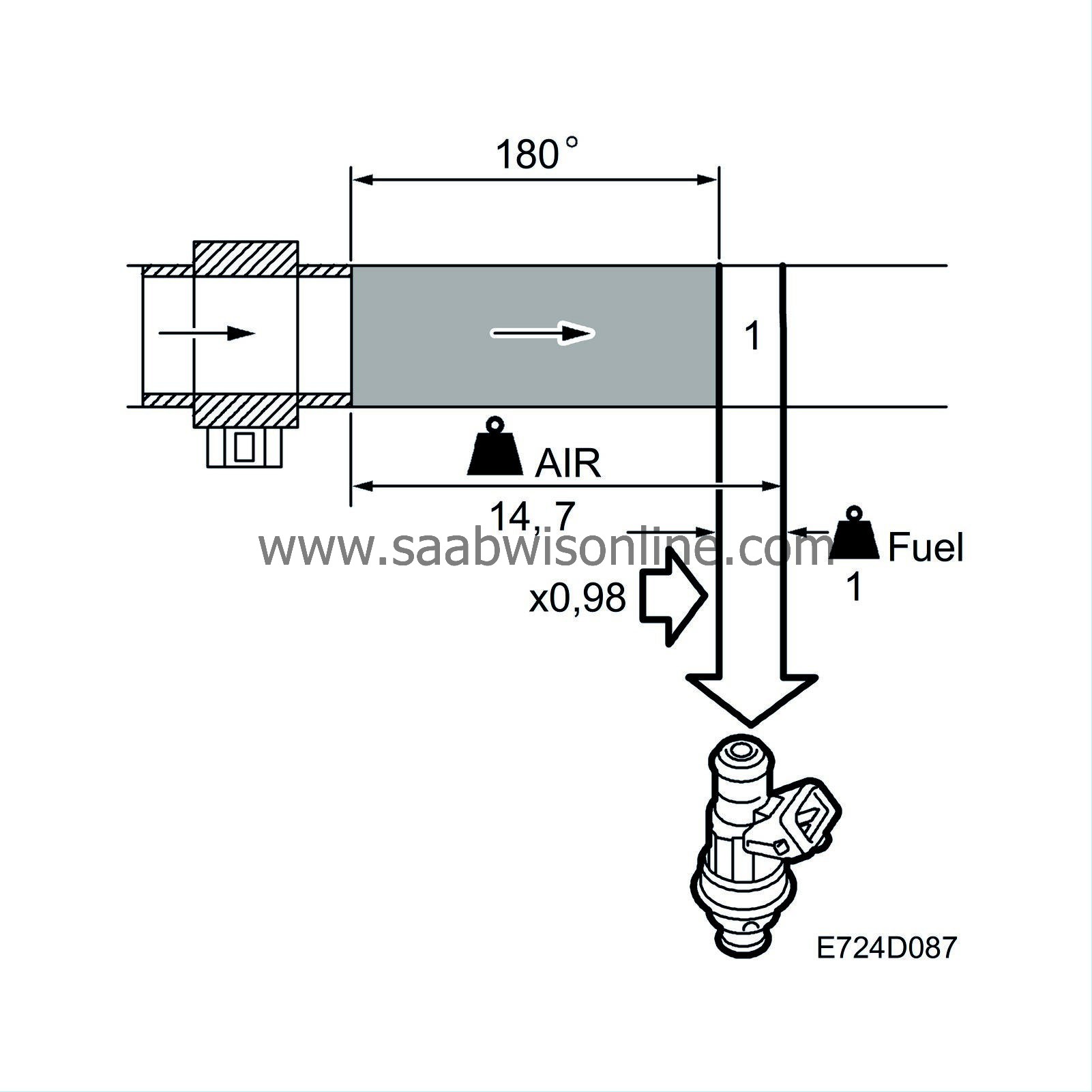

The basic fuel quantity has been calculated to give an air/fuel ratio of 14.7:1. The calculation is based on the reading obtained from the mass air flow sensor. Air leaks and tolerances in the mass air flow sensor can affect this calculation. When the fuel quantity is subsequently converted into injection duration, the control module assumes the flow through the injectors to be functioning faultlessly. Tolerances in the injectors and variations in the fuel pressure can affect this calculation.

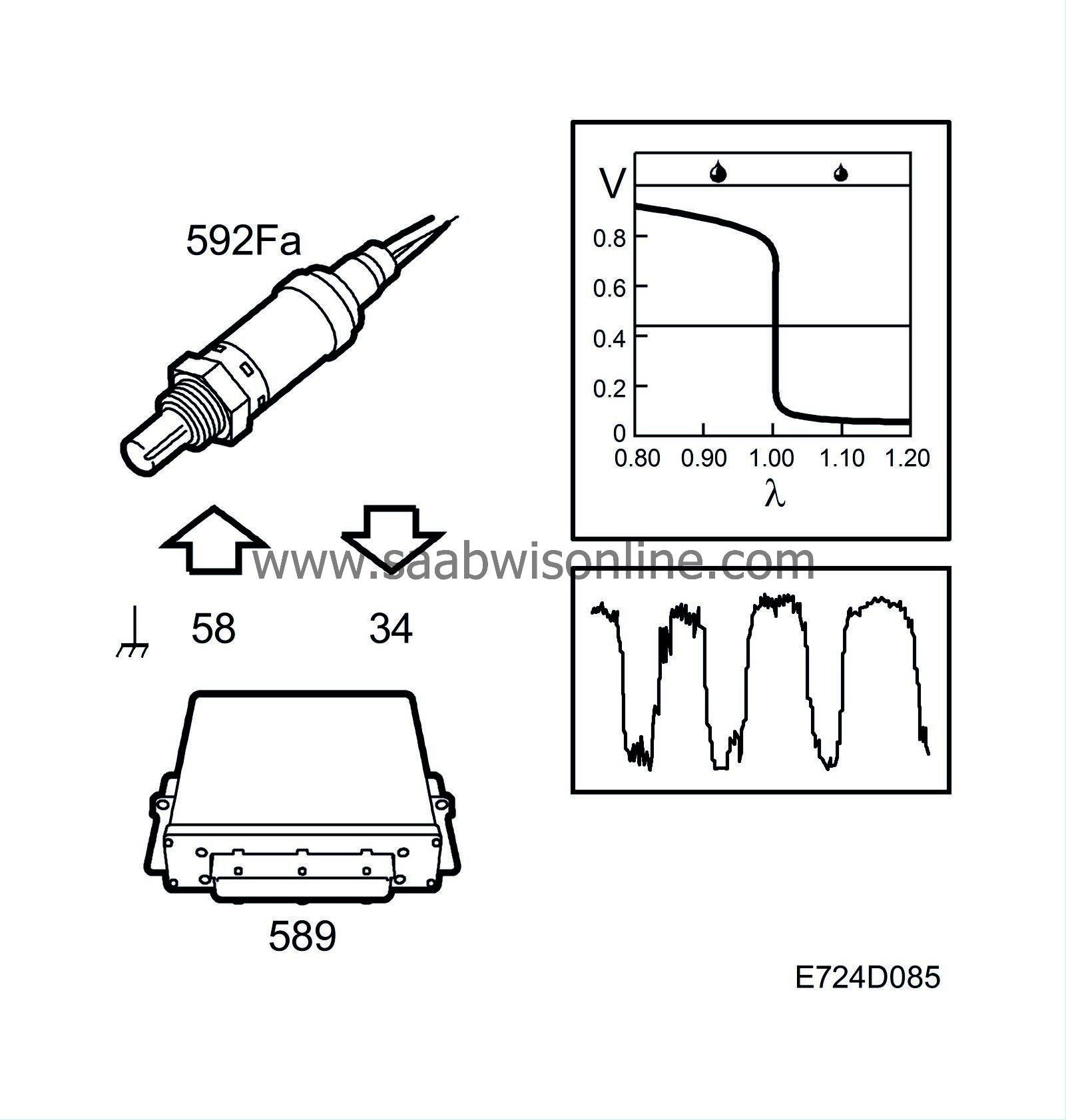

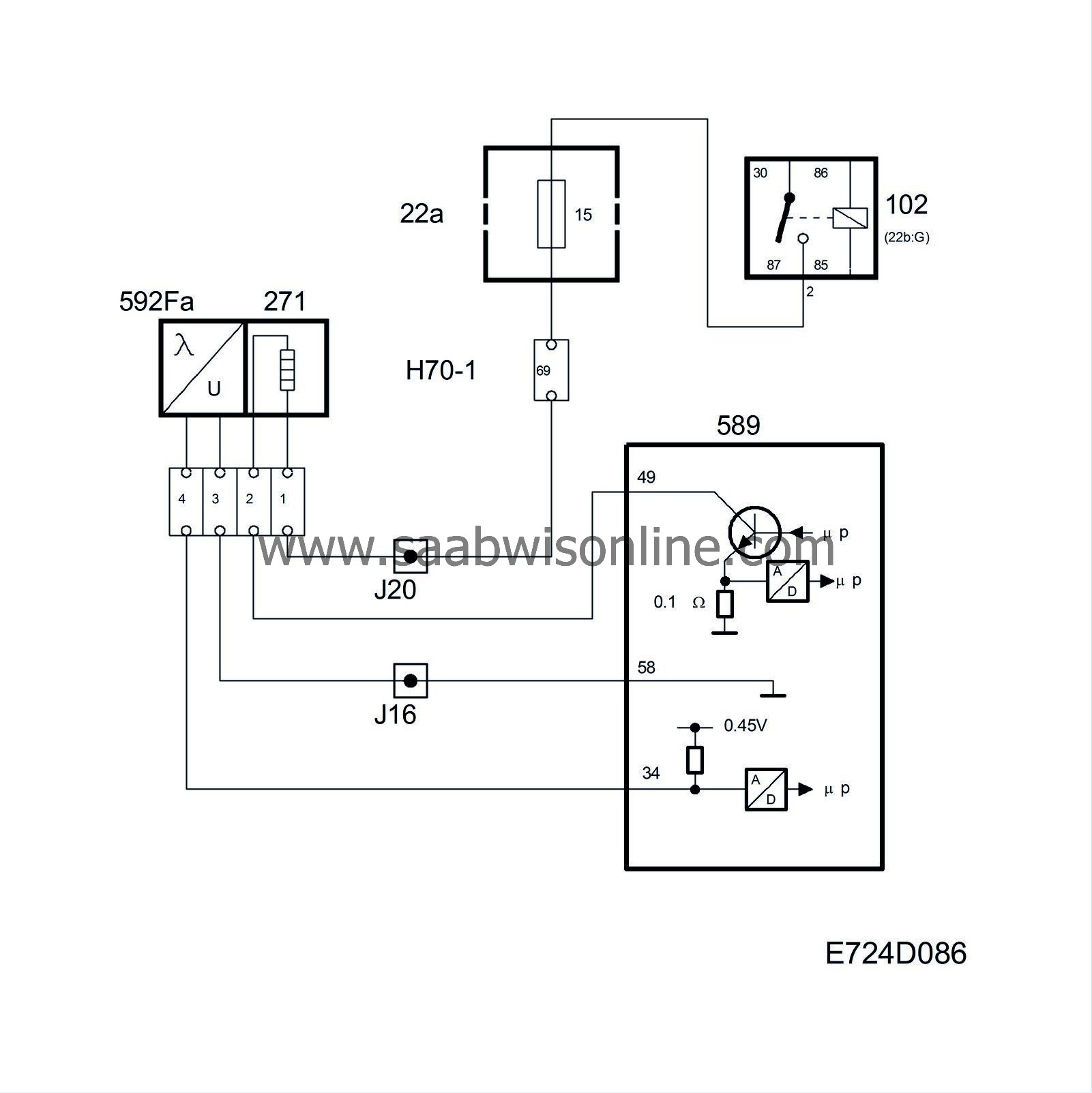

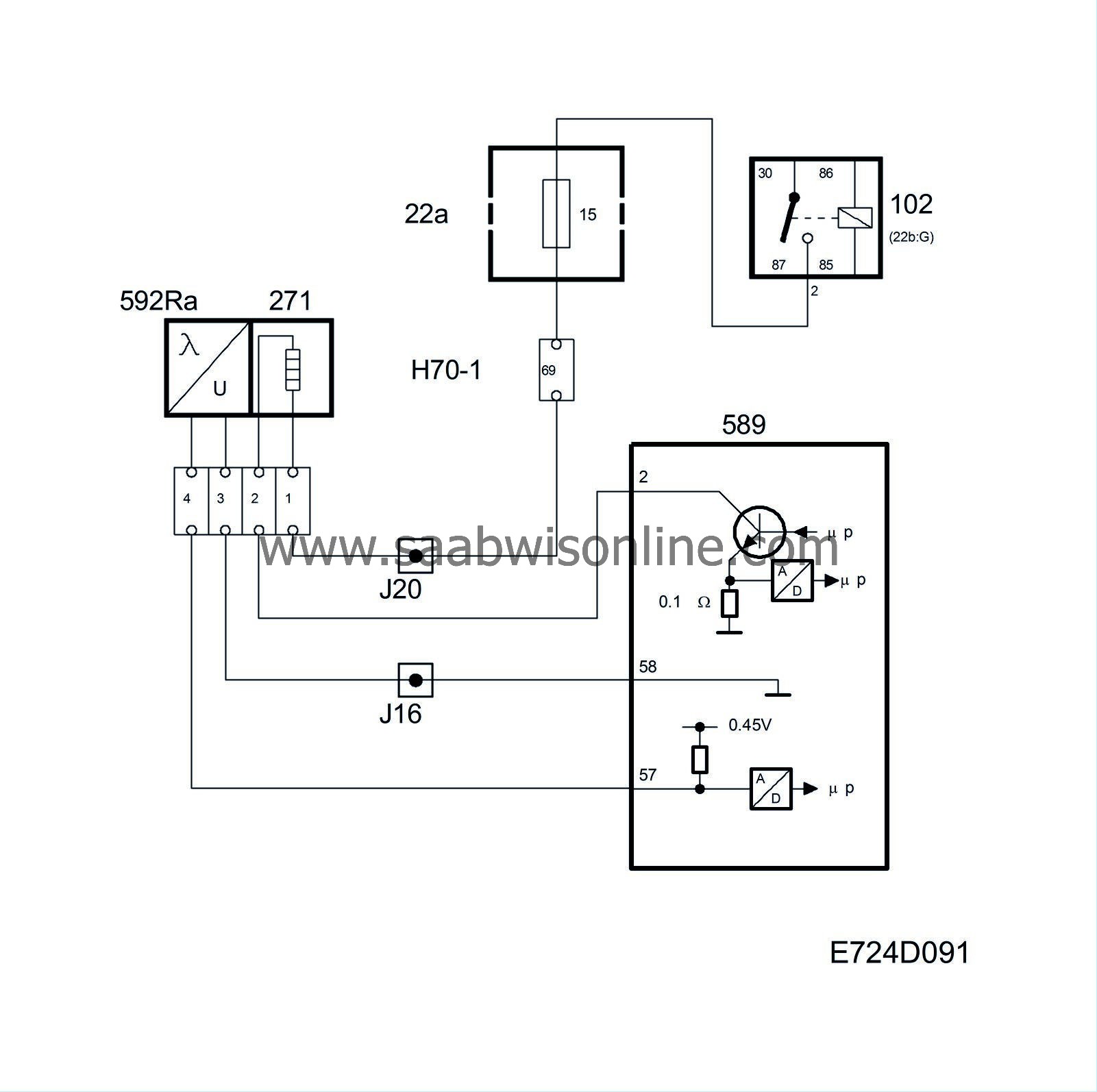

To work well, the catalytic converter requires an air/fuel ratio of precisely 14.7:1. Therefore the system is fitted with an oxygen sensor, called oxygen sensor 1 or O2S 1, mounted before the catalytic converter. The oxygen sensor is connected to control module pin 34 and grounded via control module pin 58.

To produce a voltage signal quickly after starting, the oxygen sensor must be preheated. The preheating element is supplied with B+ current from the fuel pump relay via fuse 15 and grounded via control module pin 49.

The control module estimates the exhaust temperature on the basis of engine load and speed. If the exhaust temperature is high, preheating will be disconnected to prevent damage to the sensor.

When the exhaust gases pass the oxygen sensor, their oxygen content is measured by a chemical reaction. The oxygen sensor's output voltage is proportional to the current oxygen content. The oxygen content describes the composition of the fuel/air mixture. If the engine has a richer mixture than normal (lambda less than 1), the oxygen sensor's output voltage will be about 0.9 V. If the fuel mixture is leaner than normal (lambda over 1), the sensor's output voltage will be about 0.1 V.

The sensor's voltage changes very quickly when lambda passes 1.

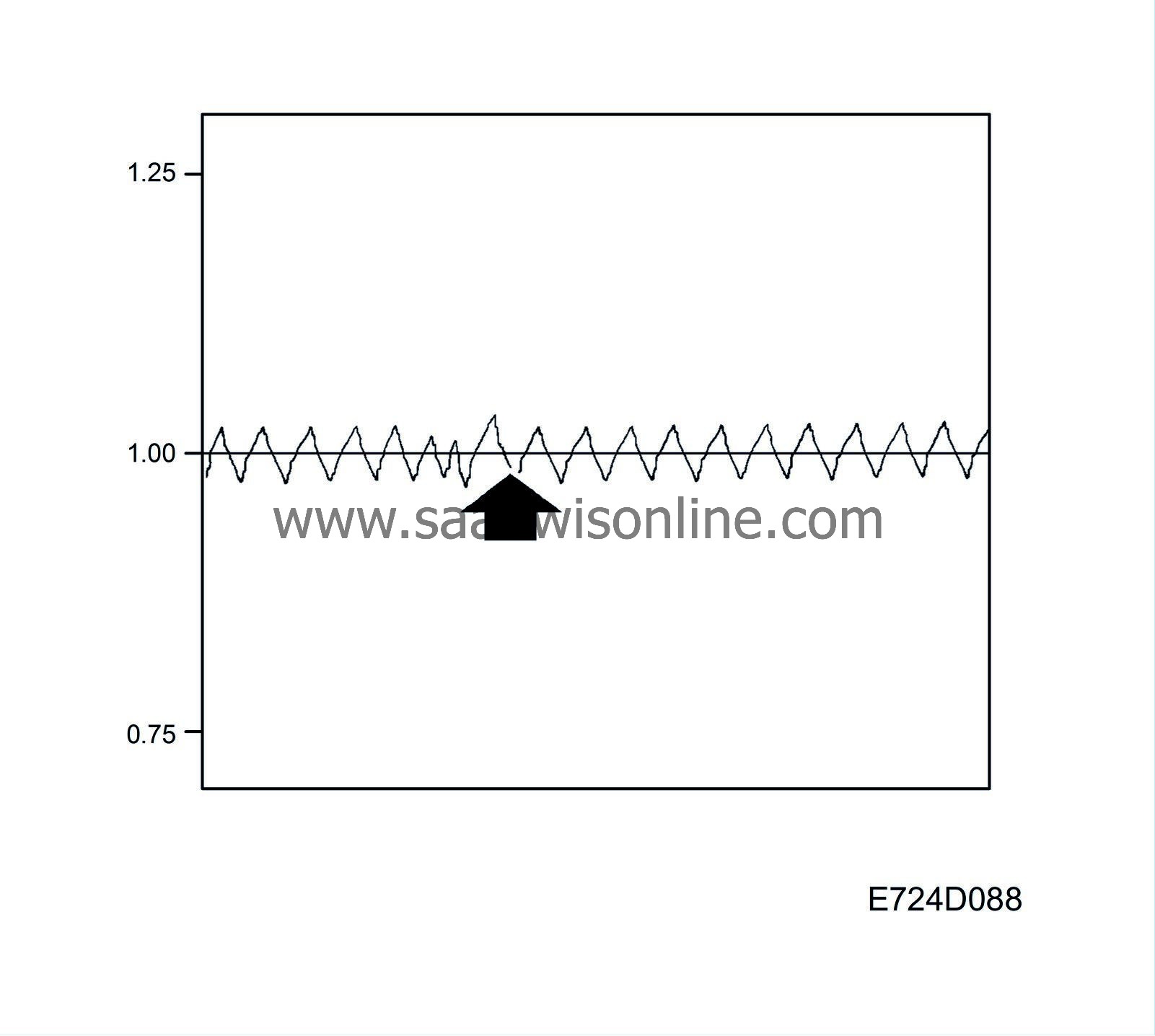

The closed loop control system's correction factor is 1.00 when the system is not active. As soon as the closed loop system is activated, the oxygen sensor's voltage is allowed to influence its correction factor. If the oxygen sensor produces a voltage of less than 0.50 V, the correction factor will be slowly increased. Conversely, the correction factor will be slowly decreased if the oxygen sensor's output voltage exceeds 0.50 V.

The correction factor limits are 0.75 and 1.25.

The diagnostic tool always shows 0% when the closed loop control system is not active, 25% when the correction factor is 1.25 and -25% when the correction factor is 0.75.

The following conditions must be fulfilled for the closed loop system to be engaged:

| • |

Engine speed over 500 rpm.

|

|

| • |

The engine must have performed 200-700 revolutions since starting. The value is dependent on coolant temperature.

|

|

| • |

The engine must have been running for at least 10 seconds.

|

|

| • |

The oxygen sensor's voltage must have dropped below 0.4 V or exceeded 0.6 V at some time since starting.

|

|

| • |

At idling speed, the coolant temperature must exceed approx. 28 °C, depending on the starting temperature.

|

|

| • |

Under partial load, the coolant temperature must exceed approx. 18 °C, depending on the starting temperature.

|

|

| • |

Fuel compensation for knocking or high load must not take place at the same time.

|

|

| • |

Engine load above 50 mg/c.

|

|

| • |

No fuel compensation for load changes when the coolant temperature is below 40 °C.

|

|

| Diagnostics, oxygen sensor 1 |

| • |

If the current in the oxygen sensor preheating circuit is too low, diagnostic trouble code P1135 will be generated.

|

|

| • |

If the current in the oxygen sensor preheating circuit is too high, diagnostic trouble code P1136 will be generated.

|

|

| • |

If the sensor lead is short-circuited to ground, diagnostic trouble code P0131 will be generated.

|

|

| • |

If the sensor lead is short-circuited to B+, diagnostic trouble code P0132 will be generated.

|

|

| • |

If the reaction of the sensor to changes in the fuel/air mixture is too slow or if its voltage transition is too far from lambda 1, diagnostic trouble code P0133 will be generated.

|

|

| • |

If there is a break in any of the sensor ground leads or sensor voltage leads, the control module will continuously read 0.45 V and diagnostic trouble code P0134 will be generated.

|

|

System reaction to a fault

| • |

Closed loop control system blocked.

|

|||||||

| Diagnostics, closed loop |

| • |

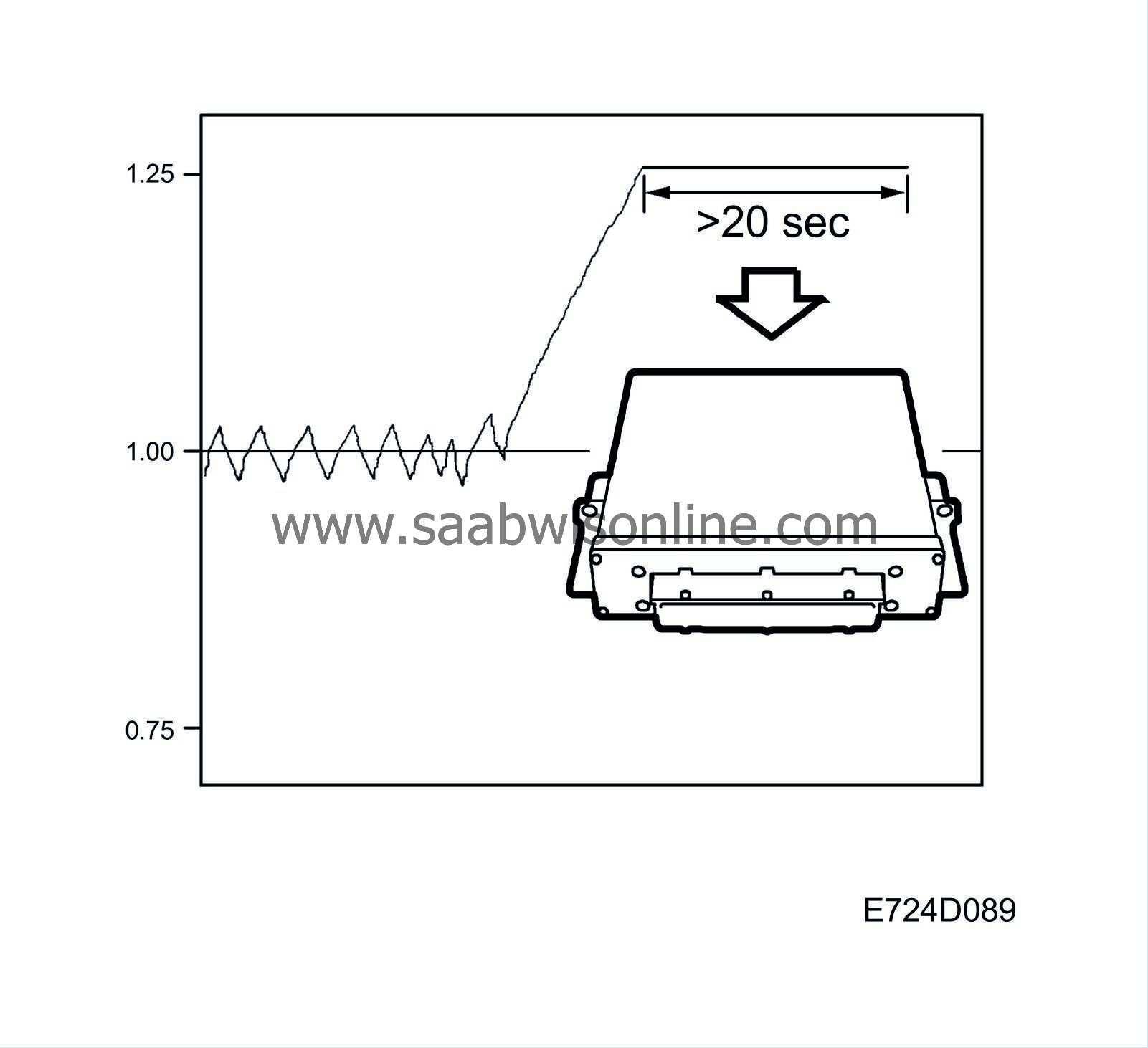

If the correction factor is 0.75, the system will read a rich fuel/air mixture and the fuel quantity is reduced as much as possible. If the condition persists for more than 20 seconds, diagnostic trouble code P1172 will be generated. The fault may have been caused by:

|

|

| - |

Air leakage between compressor and throttle.

|

| - |

The purge valve has seized in the open position.

|

| - |

Faulty mass air flow sensor.

|

| - |

Fuel pressure too high.

|

| • |

Similarly, if the correction factor is 1.25, the system will read a lean air/fuel mixture and the fuel quantity is increased as much as possible. If this condition persists for longer than 20 seconds, diagnostic trouble code P1171 will be generated. The fault may be caused by:

|

|

| - |

Air leakage after the throttle.

|

| - |

Low fuel pressure.

|

| - |

Faulty mass air flow sensor.

|

| - |

Blocked injectors.

|

| • |

If closed loop does not start within a reasonable time after starting, diagnostic trouble code P0125 will be generated.

|

|

| Oxygen sensor 2 |

To enable diagnosis of the catalytic converter, there is an oxygen sensor fitted after it in the exhaust system. The sensor is called oxygen sensor 2 or O2S 2. The oxygen sensor is connected to control module pin 57 and grounded from control module pin 58.

To produce a voltage signal quickly after starting, the oxygen sensor must be preheated. The preheating element is supplied with B+ current from the fuel pump relay via fuse 15 and grounded via control module pin 2.

Preheating is activated as soon as the coolant temperature exceeds 50 °C.

The control module estimates the exhaust temperature on the basis of engine load and speed. If the exhaust temperature is high, preheating will be disconnected to prevent damage to the sensor.

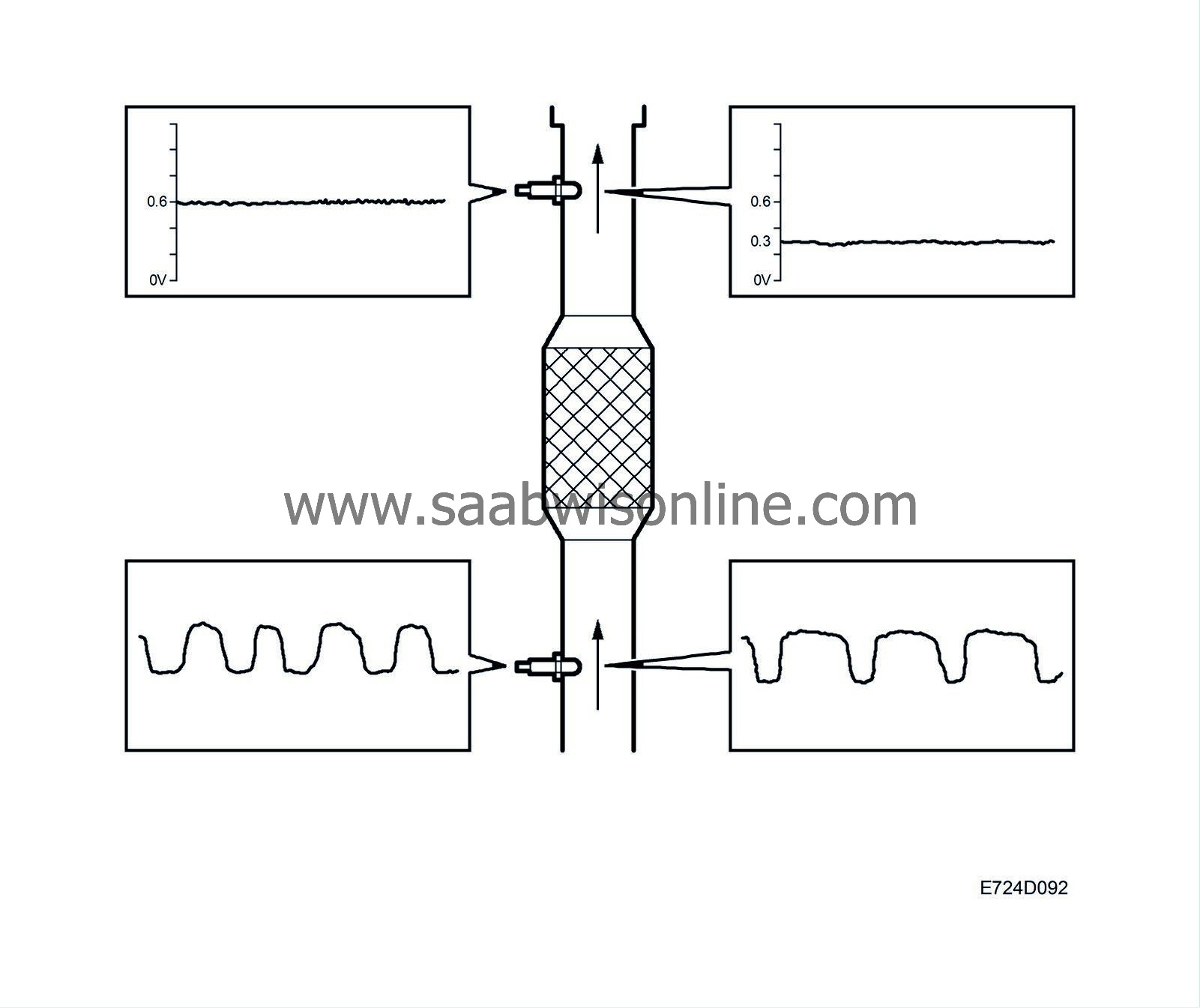

If the catalytic converter is damaged, its ability to absorb oxygen will decrease. The normal closed loop fluctuations will then be noticed on the voltage from oxygen sensor 2 and a diagnostic trouble code will be generated. The diagnosis is performed one per driving cycle.

Besides being used for the catalytic converter diagnostics, the value from the oxygen sensor is also used to correct the closed loop system for minor faults in oxygen sensor 1.

The best emission values are obtained when the voltage from oxygen sensor 2 is 0.6 V.

If the voltage is 0.3 V, for example, the engine is running lean. The closed loop correction factor will then be locked in rich position for a certain number of combustions before the voltage from oxygen sensor 1 is again allowed to affect it.

| Diagnostics |

Oxygen sensor 2

| • |

If the current in the oxygen sensor preheating circuit is too low, diagnostic trouble code P1141 will be generated.

|

|

| • |

If the current in the oxygen sensor preheating circuit is too high, diagnostic trouble code P1142 will be generated.

|

|

| • |

If the sensor lead is short-circuited to B+, diagnostic trouble code P0138 will be generated.

|

|

| • |

If an open circuit occurs in any of the sensor ground or sensor voltage leads, or if the sensor voltage is shorted to ground, diagnostic trouble code P0140 will be generated.

|

|

System reaction to a fault

| • |

Transition adaptation of closed loop is blocked.

|

|||||||

Three way catalytic converter

| • |

A damaged catalytic converter will generate diagnostic trouble code P0420.

|

|