Compensation

| Compensation |

The basic fuel quantity is multiplied by a correction factor which is normally 1.00. If the correction factor is changed, for example to 1.01, the fuel quantity will be increased by 1%. If instead the correction factor is changed to 0.98, the fuel quantity will be reduced by 2%. The closed loop control system is usually disabled if the correction has a value other than 1.00, otherwise the compensation would be corrected by the closed loop system and be ineffective.

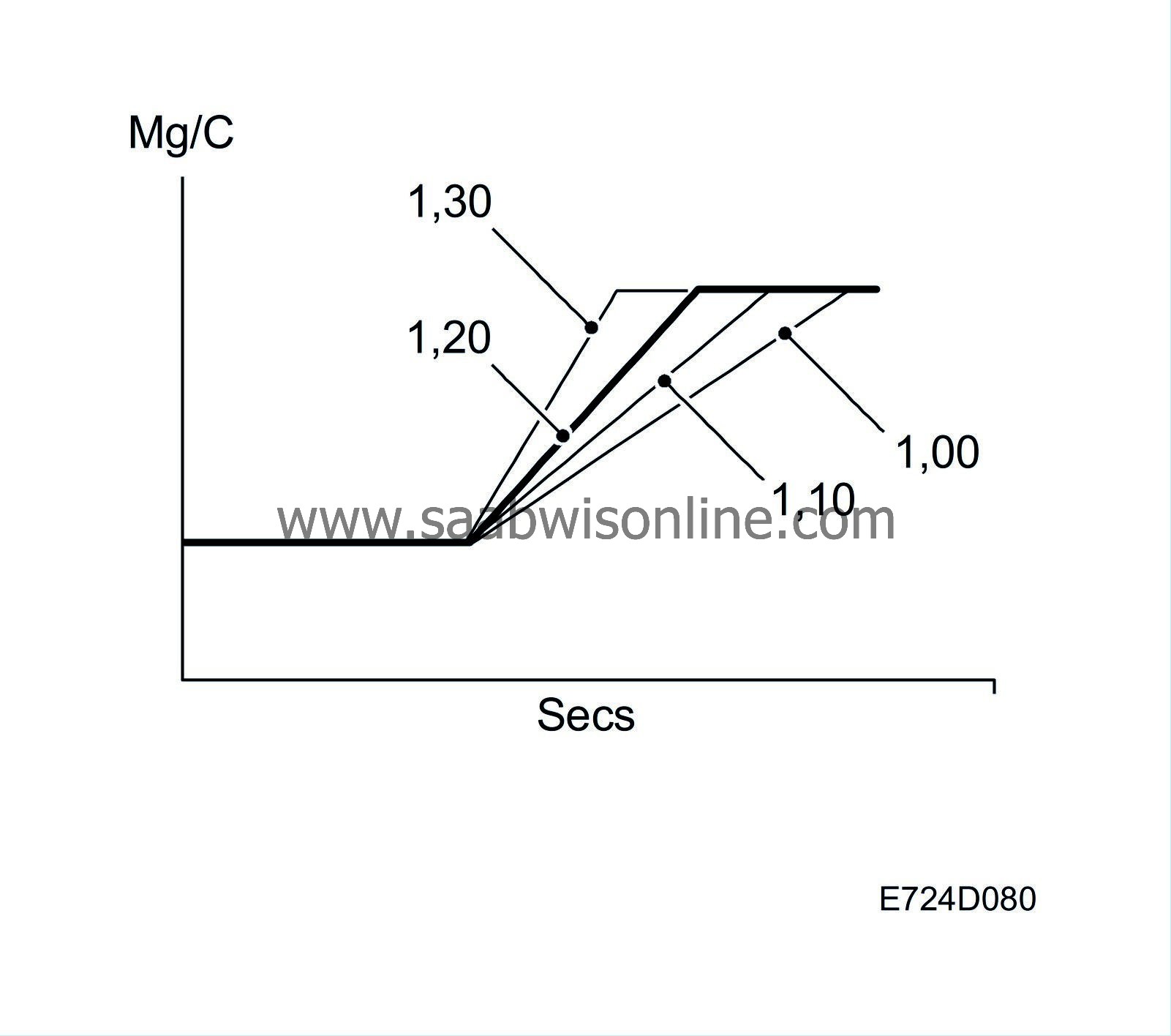

| After starting |

Immediately after starting the engine, the correction factor is slightly over 1 and then falls gradually to 1.00. The extent to which the correction factor exceeds 1 and the time it takes to reach 1.00 again depend on the coolant temperature. On cars with carburettor engines, this function is the choke. The closed loop control system's starting conditions are such that it starts just when fuel enrichment after starting has dropped to 1.00.

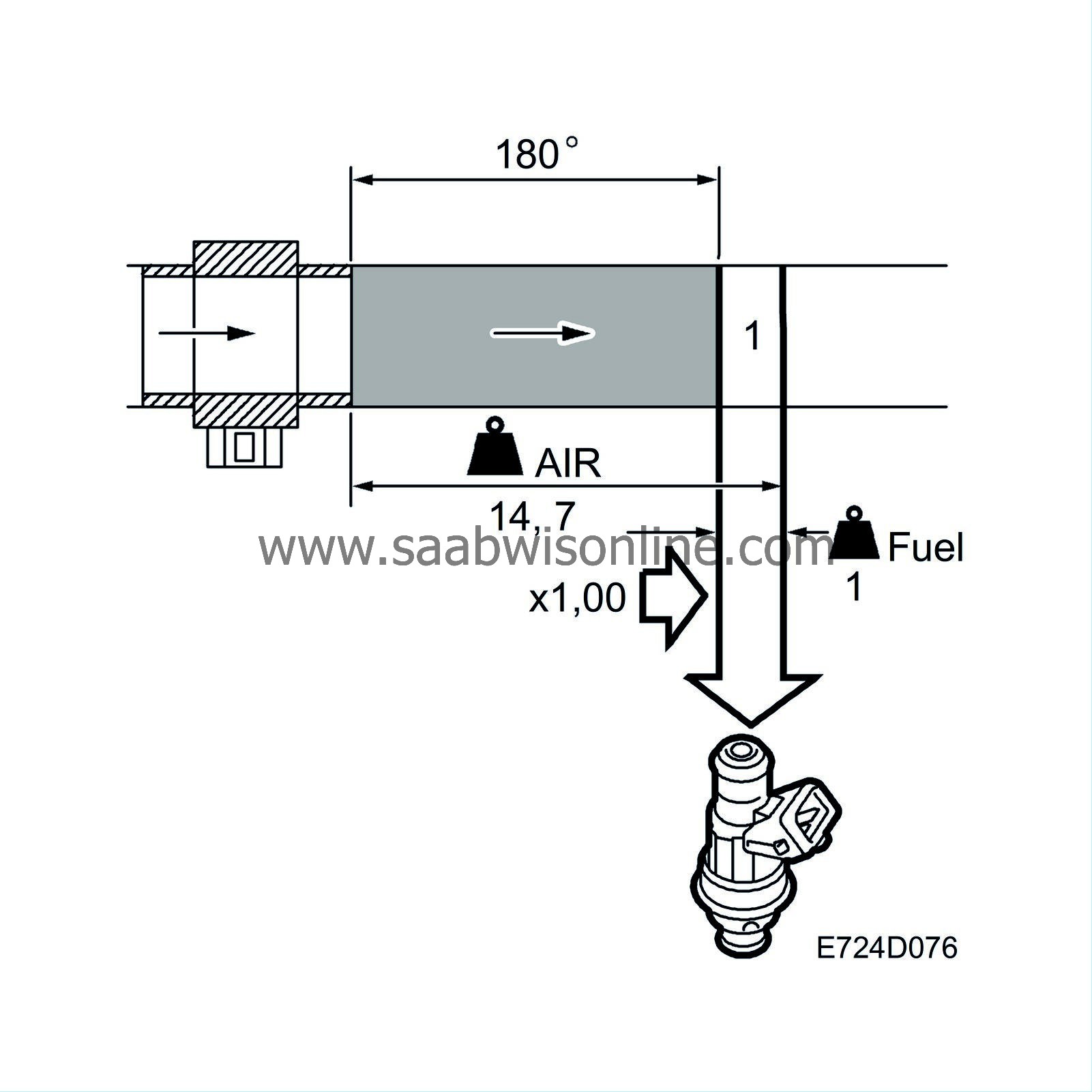

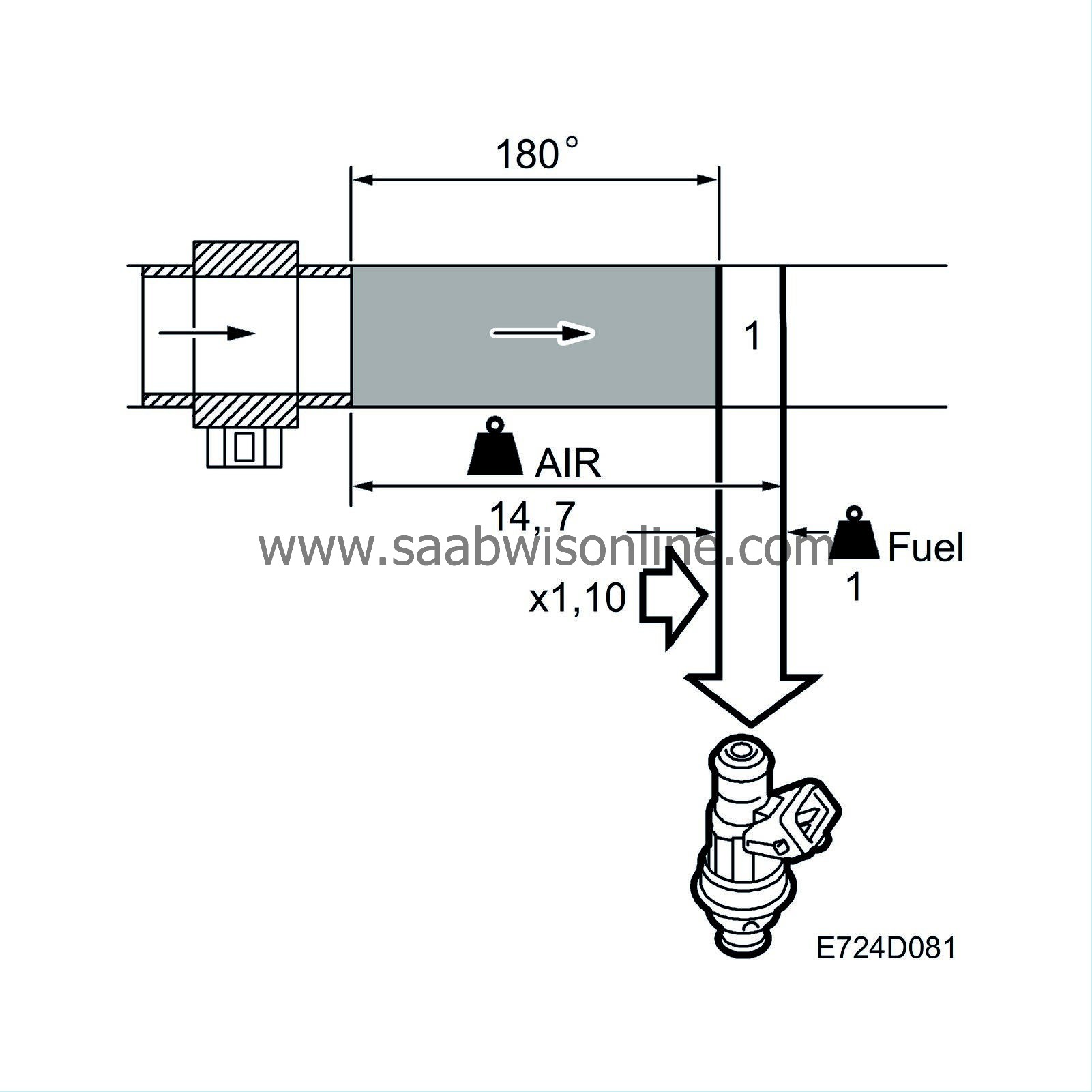

| Load changes |

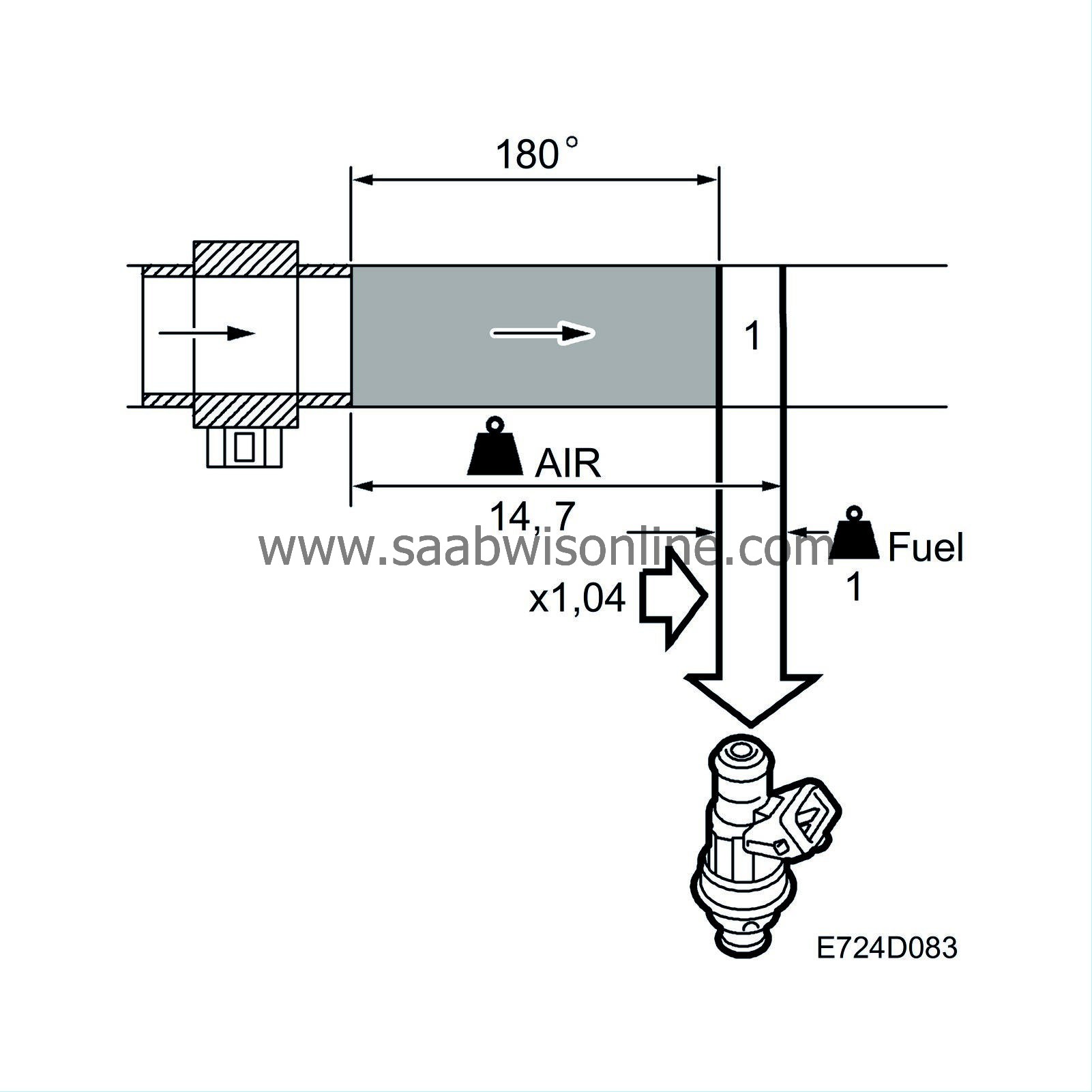

A sudden load increase causes the mg air/combustion to increase rapidly and it is well known that petrol engines then require a richer mixture. This is because fuel is deposited on the walls of the intake manifold due to the increase in pressure there, the so-called wet-film thickness increases. The fuel quantity used here must be replaced by a slightly larger quantity of injected fuel, which is achieved by increasing the correction factor by a few percentage points. For example, the correction factor can be increased from 1.00 to 1.03, which gives 3% more fuel.

As soon as the load increase stops, the correction factor returns to its original value.

In the case of a load reduction, the function is reversed. The wet-film deposited on the walls of the inlet manifold thins quickly as the pressure drops. The quantity of injected fuel must then be reduced to avoid a negative effect on emissions and fuel consumption, so the correction factor is reduced by a few percentage points. For example, the correction factor can be reduced from 1.00 to 0.96, giving a 4% reduction in fuel quantity.

When the coolant temperature is below 40°C, the closed loop control system is disabled during load changes (if it is active). This is to prevent the closed loop system from compensating. When the coolant temperature exceeds 70 °C, the closed loop system is active during load changes, as fuel correction is then so small that compensation will not affect the running of the engine. How far from 1.00 the correction factor is moved in connection with a load change depends on how quickly the air mass/combustion is modified and also on the temperature of the coolant.

On a car with a carburettor engine, the function described above corresponds to the accelerator pump or damper piston.

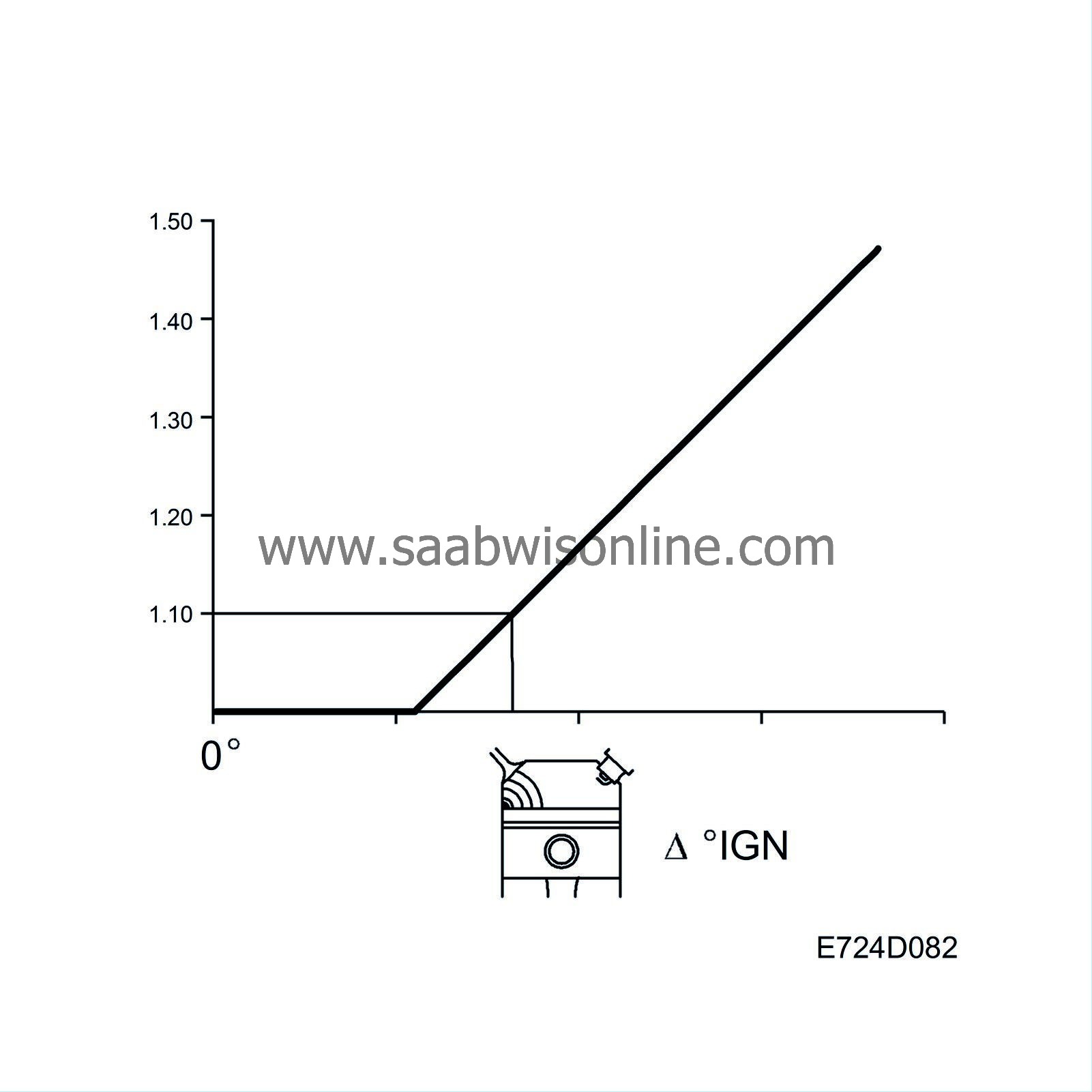

| Knocking |

If knocking occurs in the engine it is corrected by retarding the ignition for the cylinder concerned. If knocking continues despite the ignition being retarded, the correction factor will be increased. In connection with this, the closed loop system will be disabled (if active) to prevent it from compensating.

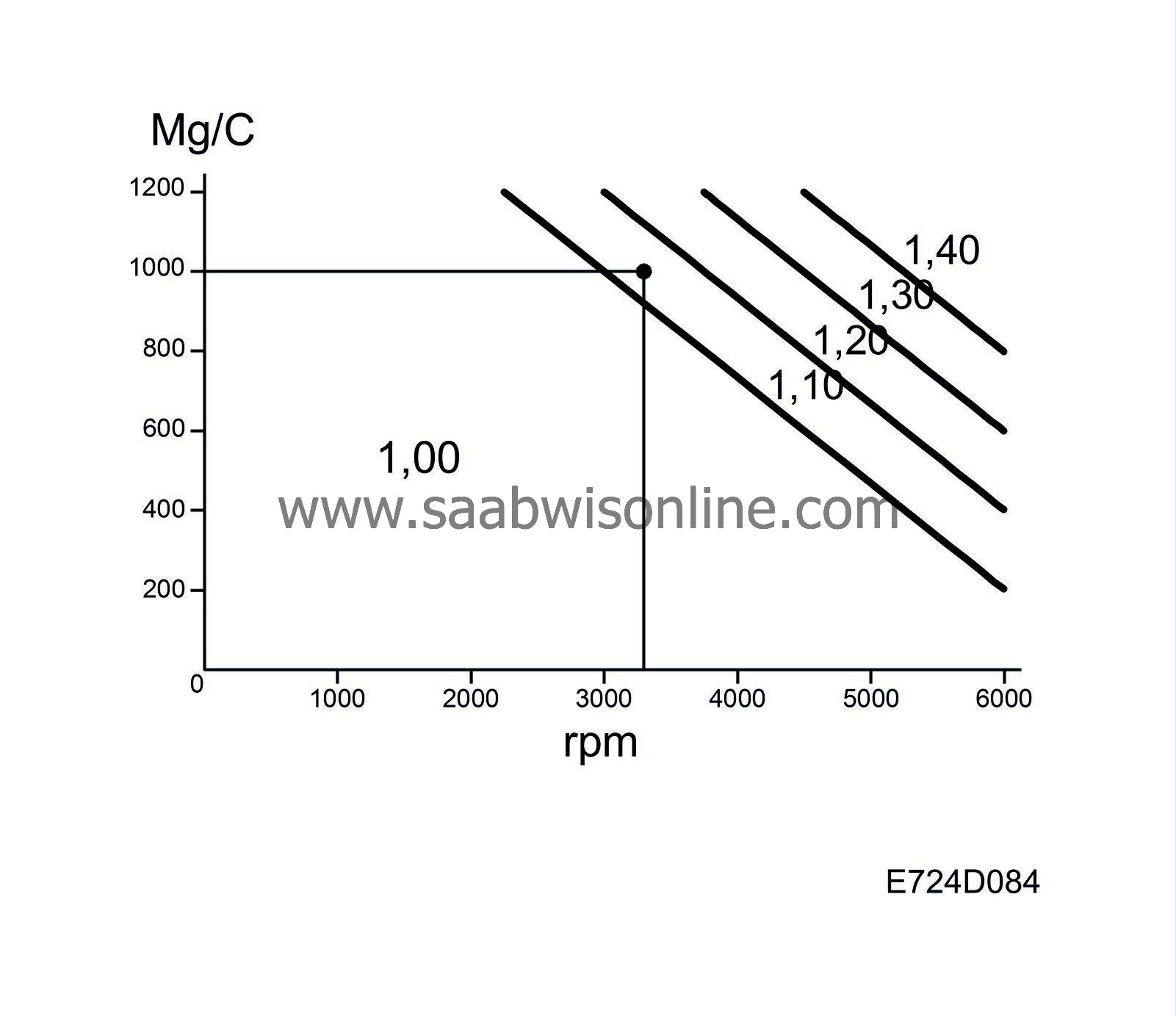

| Full load enrichment |

When engine load and engine speed have reached a certain limit, the correction factor will increase in steps as the load or speed further increases. At the same time, the closed loop system will be turned off (if it was active) to prevent it from compensating. This is to ensure that all the air is consumed during combustion and to keep the combustion temperature under control. The result is increased torque and reduced thermal load.