Knock control

| Knock control |

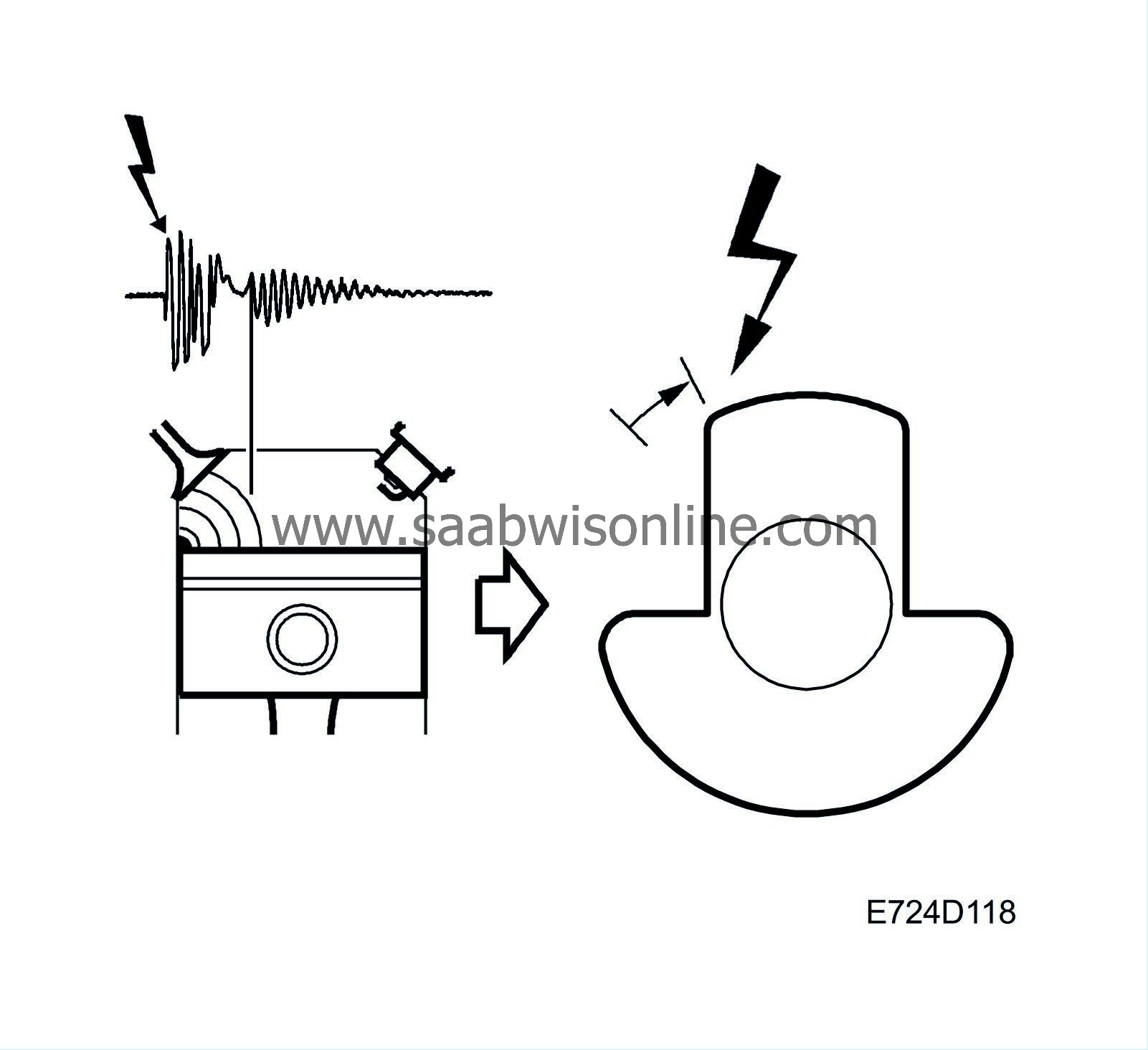

Trionic T7 does not have a conventional knock sensor. Instead, the ignition discharge module analyses the ionization currents across the spark plug gaps in all the cylinders and sends a knock signal from each cylinder to control module pin 38.

From the combustion signals, the control module knows which cylinder has fired and if at the same time a knock signal above a certain level is registered by the control module, the control module retards the ignition in steps for the cylinder concerned until the knocking stops. Timing correction then gradually returns to zero.

If the mean value of ignition retardation on all cylinders exceeds a certain level, fuel enrichment takes place. If the mean value of ignition retardation on all cylinders rises further despite fuel enrichment, the maximum permitted air mass/combustion will be limited.

Since the control module expects the knock signal to have a certain level when the spark is produced, the actual knock detection in the cylinder concerned begins only after a spark has been produced.

| Diagnostics |

| • |

If an open circuit or short circuit occurs on the knock lead between the ignition discharge module and the control module, diagnostic trouble code P0327 will be generated.

|

|