Torque converter shell

| Torque converter shell |

| To remove |

| Important | ||

|

It is very important to observe great cleanliness when working on the gearbox. Dirt particles can seriously damage the function and service life of the gearbox. |

||

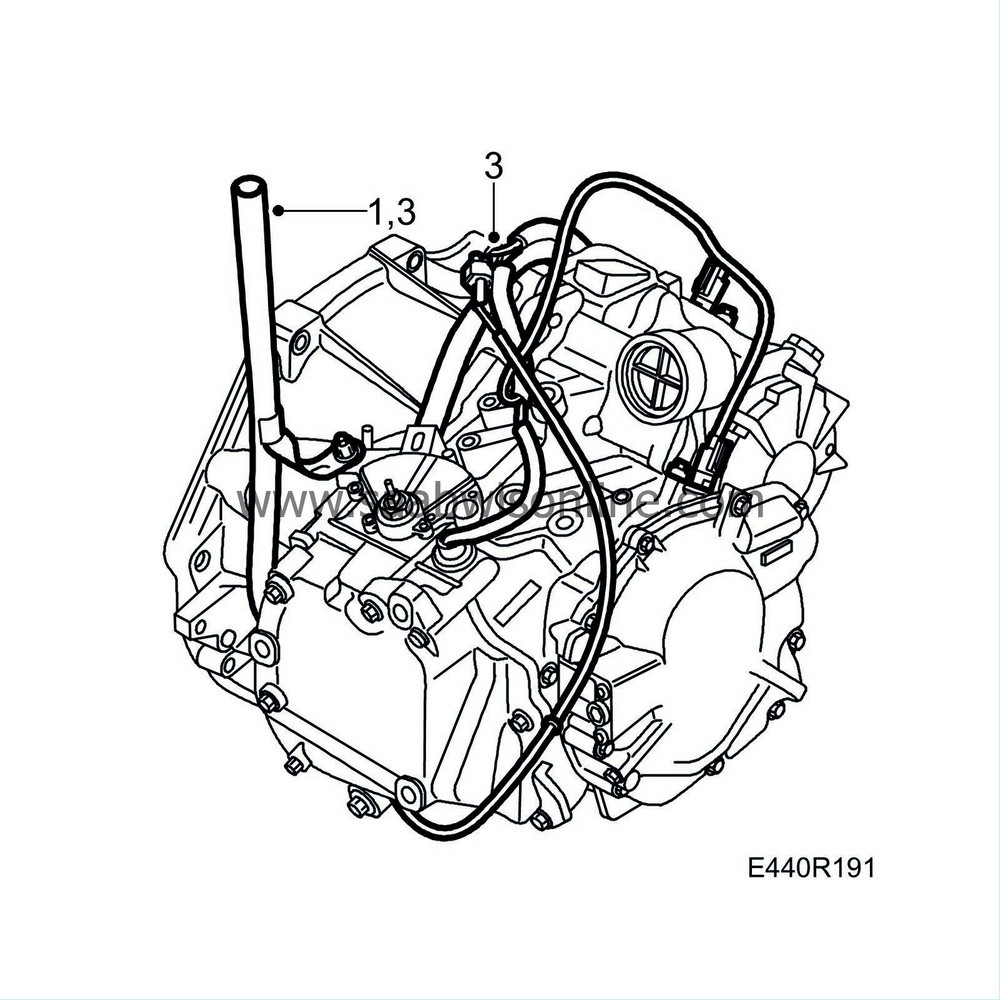

| 1. |

Drain the oil from the transmission in the car before starting removal. Remove the gearbox from the car. See adjustment/replacement, removing gearbox assembly. Fit the dipstick pipe.

|

|

| 2. |

Plug the shaft openings and clean the exterior of the gearbox. Use plug 91 32 929, seals 91 32 937 and 87 92 665. Plug the vent pipe.

|

|

| 3. |

Remove the dipstick pipe.

|

|

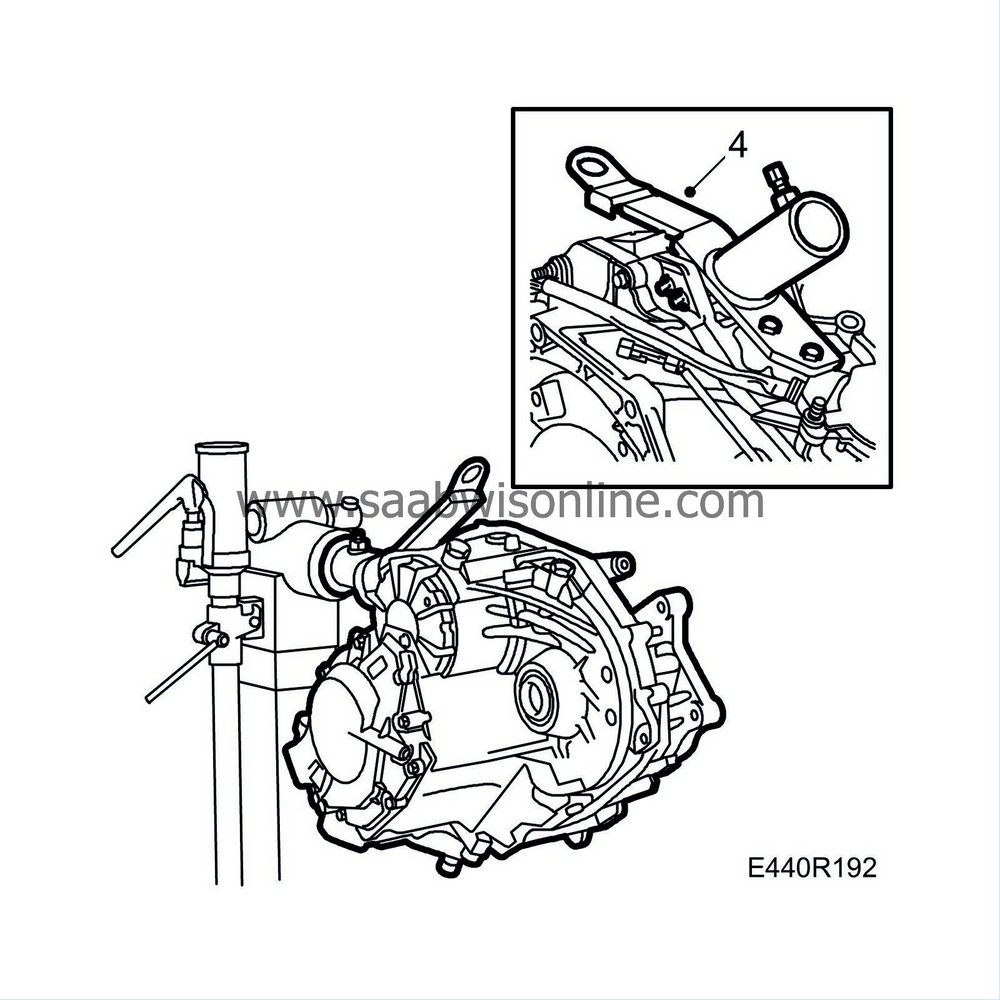

| 5. |

Fit tool 87 91 766 into the torque converter. Remove holder 87 92 574.

|

|

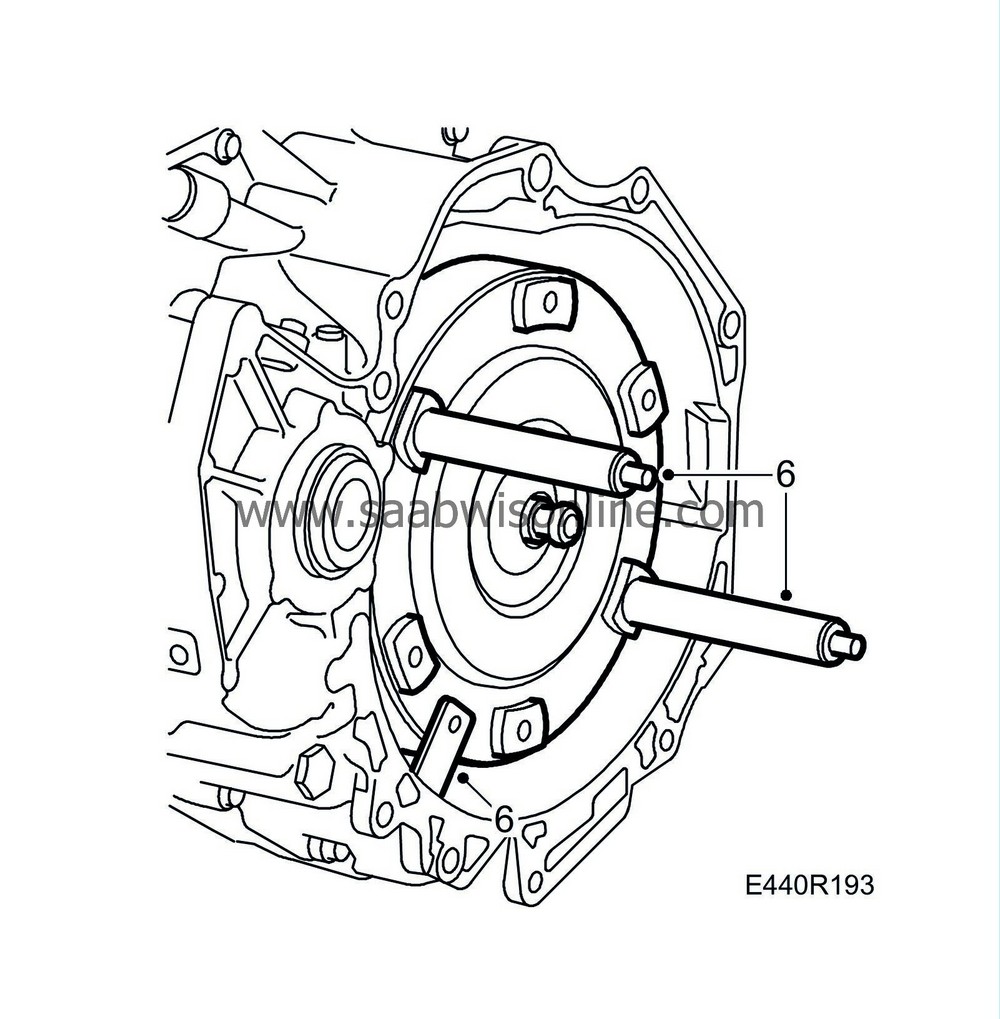

| 6. |

Remove the torque converter.

|

|

| 7. |

Turn the gearbox through 180° in the stand.

|

|

| 8. |

Remove the cover plate for the temperature sensor and the cover plate.

|

|

| 9. |

Remove the bolts securing the oil pump to the gearcase

|

|

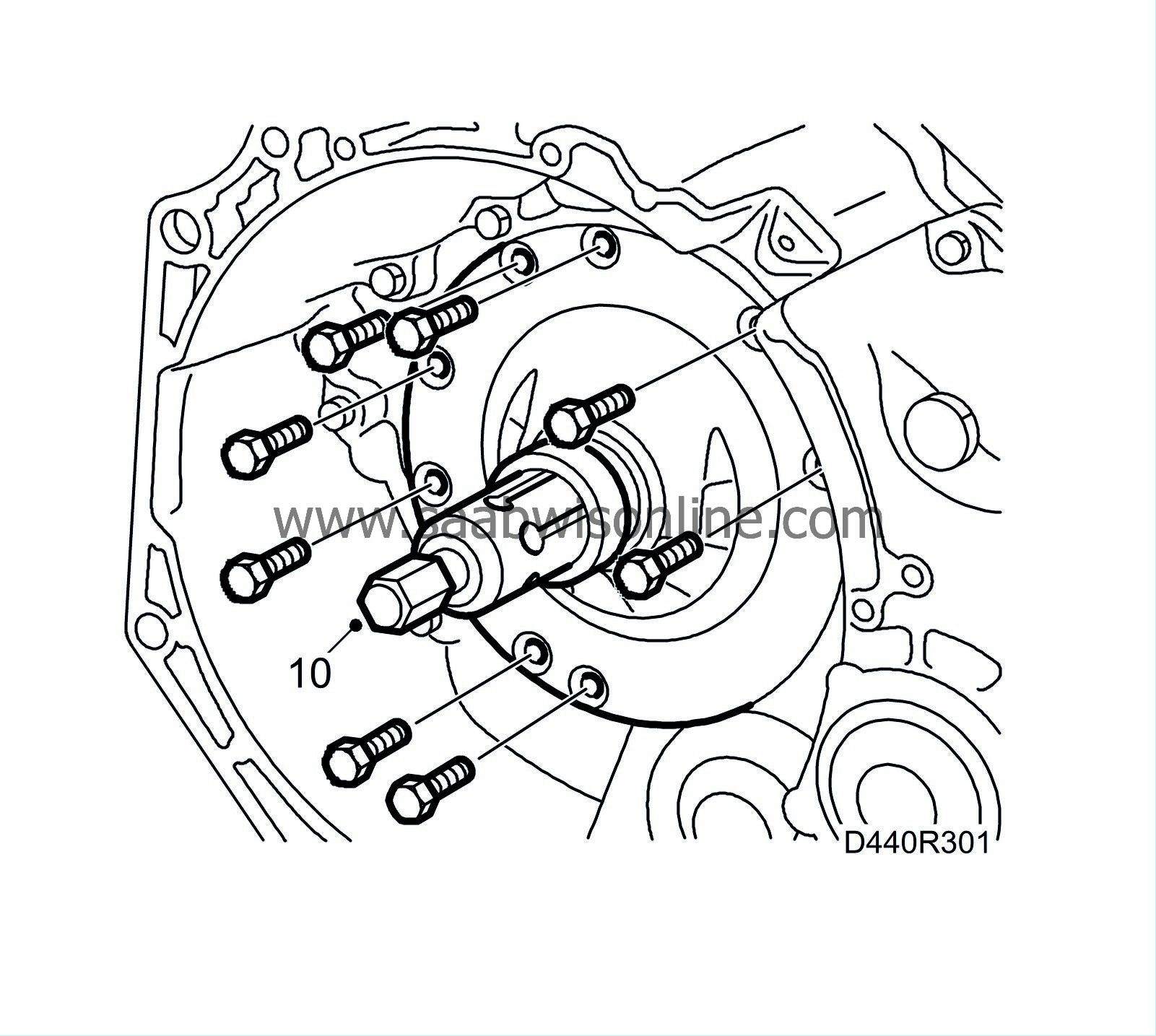

| 10. |

Pull off the oil pump and brake unit B2 from the gearcase using puller 87 92 699.

|

|

| 11. |

Remove the brake hub and freewheel F1.

|

|

| 12. |

Turn the gearbox through 90° in the stand

|

|

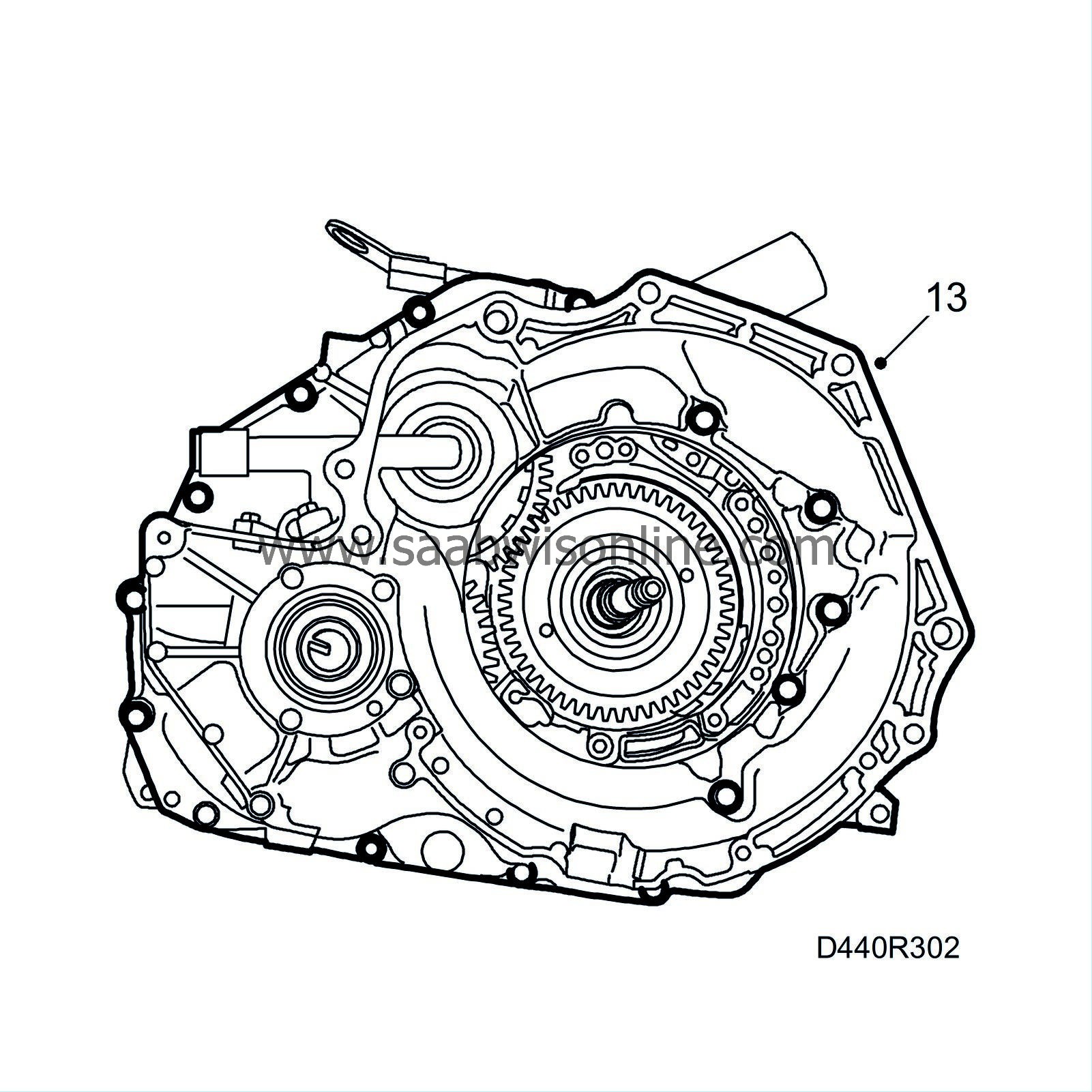

| 13. |

Remove the torque converter shell. Knock loose the housing with a plastic mallet. Remove the small seal.

|

|

| 14. |

Remove the oil channel plate and lift it out. Retain the three magnets.

|

|

| 15. |

Remove the pipe holder and pipe. Use sliding hammer 83 90 270 and hook 87 92 384.

|

|

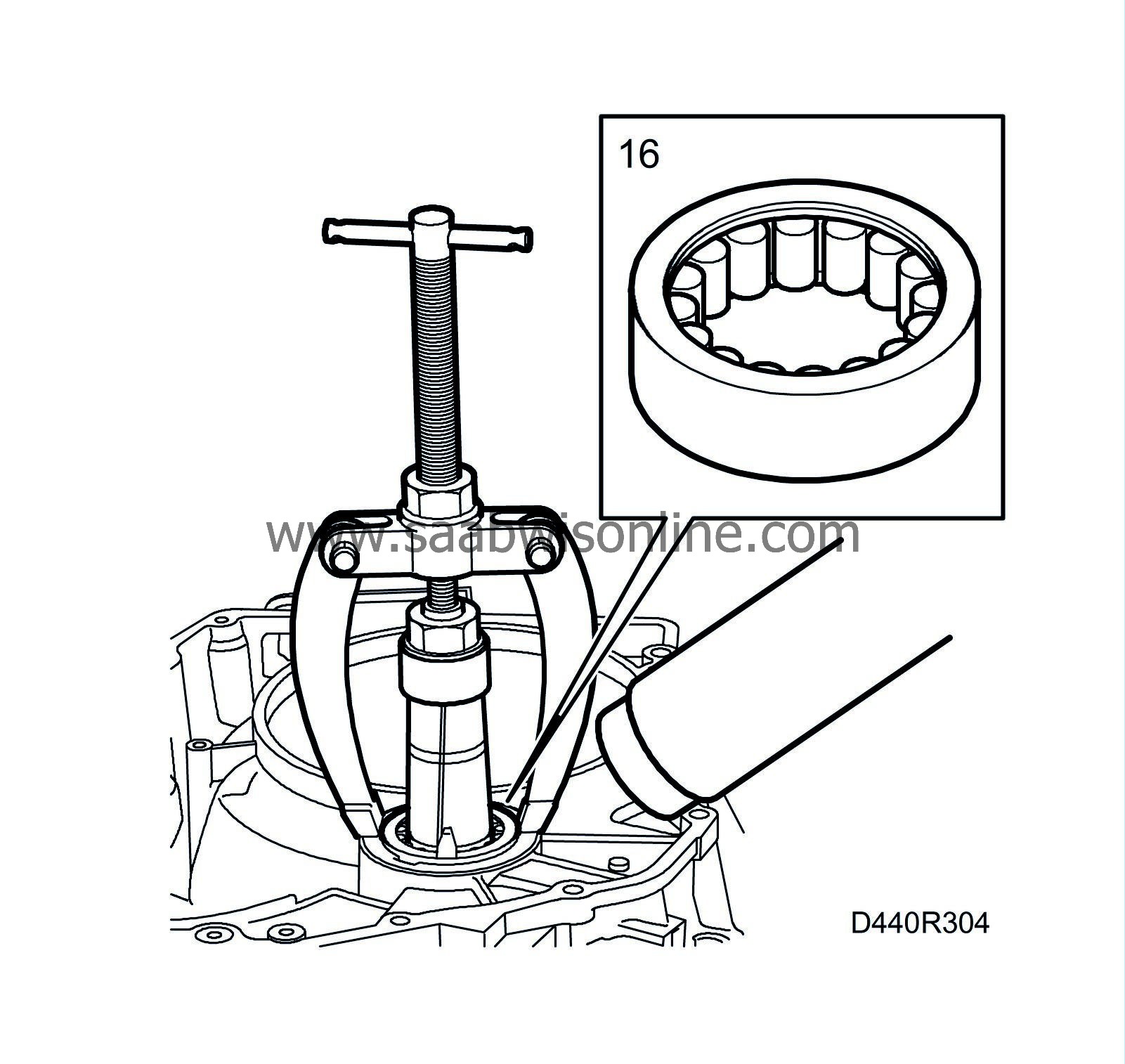

| 16. |

Fit puller 87 91 675 and 87 91 683 and remove the roller bearing by heating the case with a hot-air gun for about 5 minutes. Pull out the bearing.

|

|

| 17. |

Fit puller 87 91 683 and 87 91 675 and remove the bearing race for the taper roller bearing in the torque converter shell by heating around the bearing seat with a hot-air gun for about 5 minutes. Pull out the bearing.

|

|

| 18. |

Remove the cover and the remaining plugs.

|

|

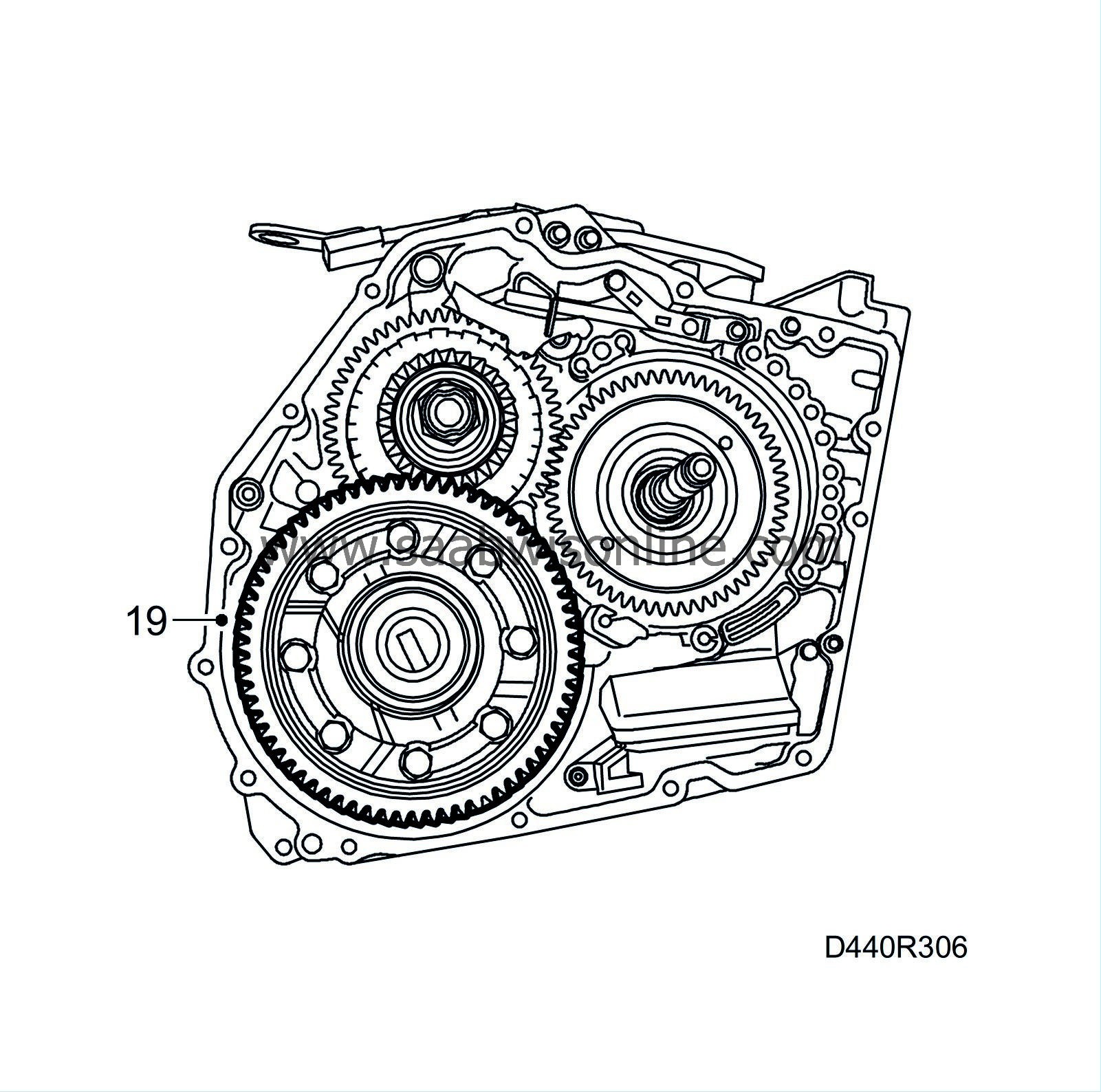

| 19. |

Lift out the differential unit.

|

|

| 20. |

Remove any gasket remains from the gearcase sealing surfaces. Use the gasket scraper with great care.

|

||||||||||

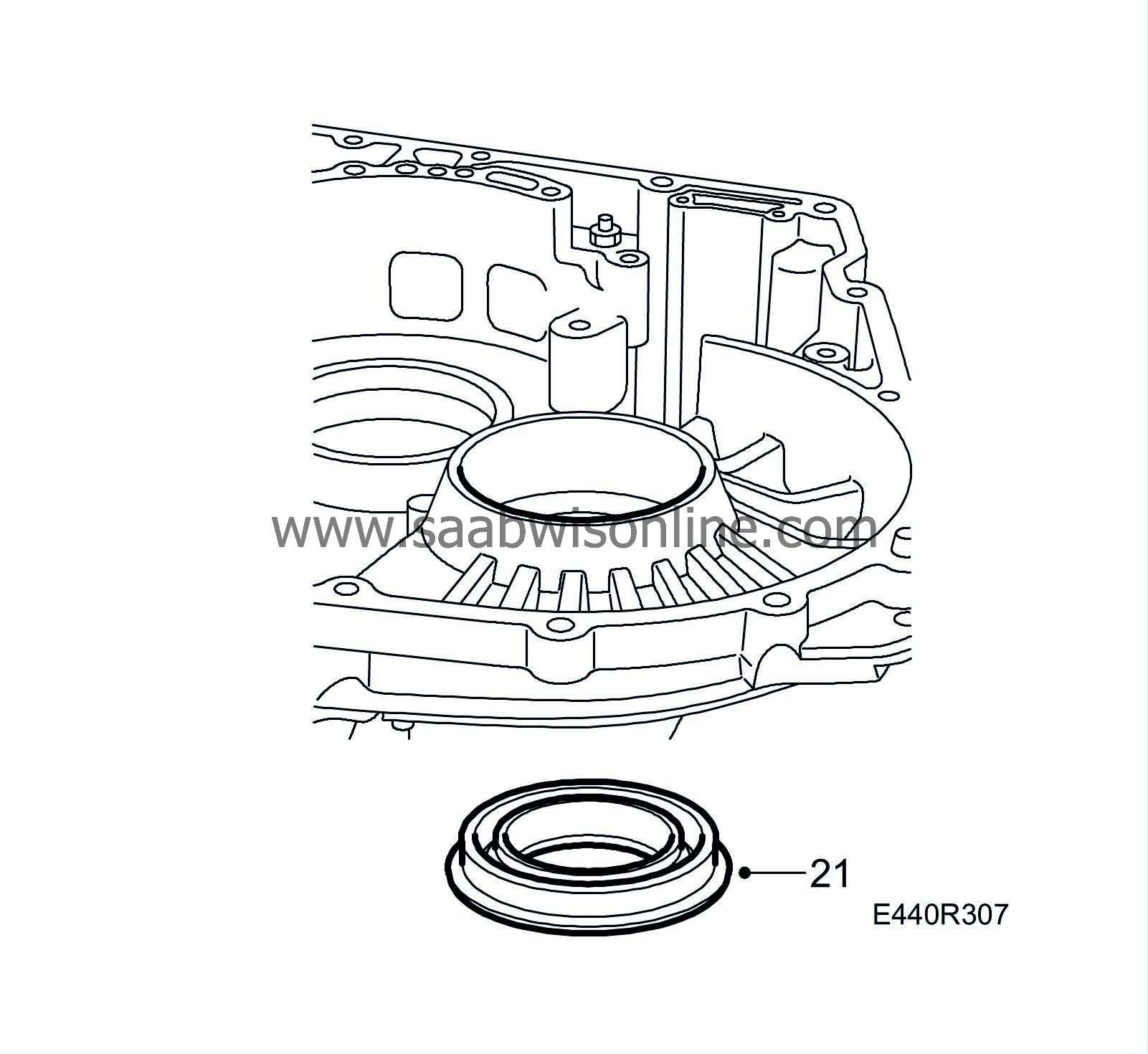

| 21. |

Knock out the shaft seal.

|

|

| 22. |

Bend out the locking washers on the crown wheel and remove the bolts. Knock away the crown wheel using a splinter-free plastic mallet.

|

|

| Fitting |

| 1. |

Heat the bearing seat for the differential bearing race in the torque converter shell. Fit the bearing race. Make sure the bearing race is all the way home.

|

|

| 2. |

Heat the bearing seat using a hot-air gun and fit the roller bearing into the torque converter shell with the text face down until it bottoms in the torque converter shell. The side of the roller bearing will be the bearing race for the thrust bearing on the output shaft.

|

|

| 3. |

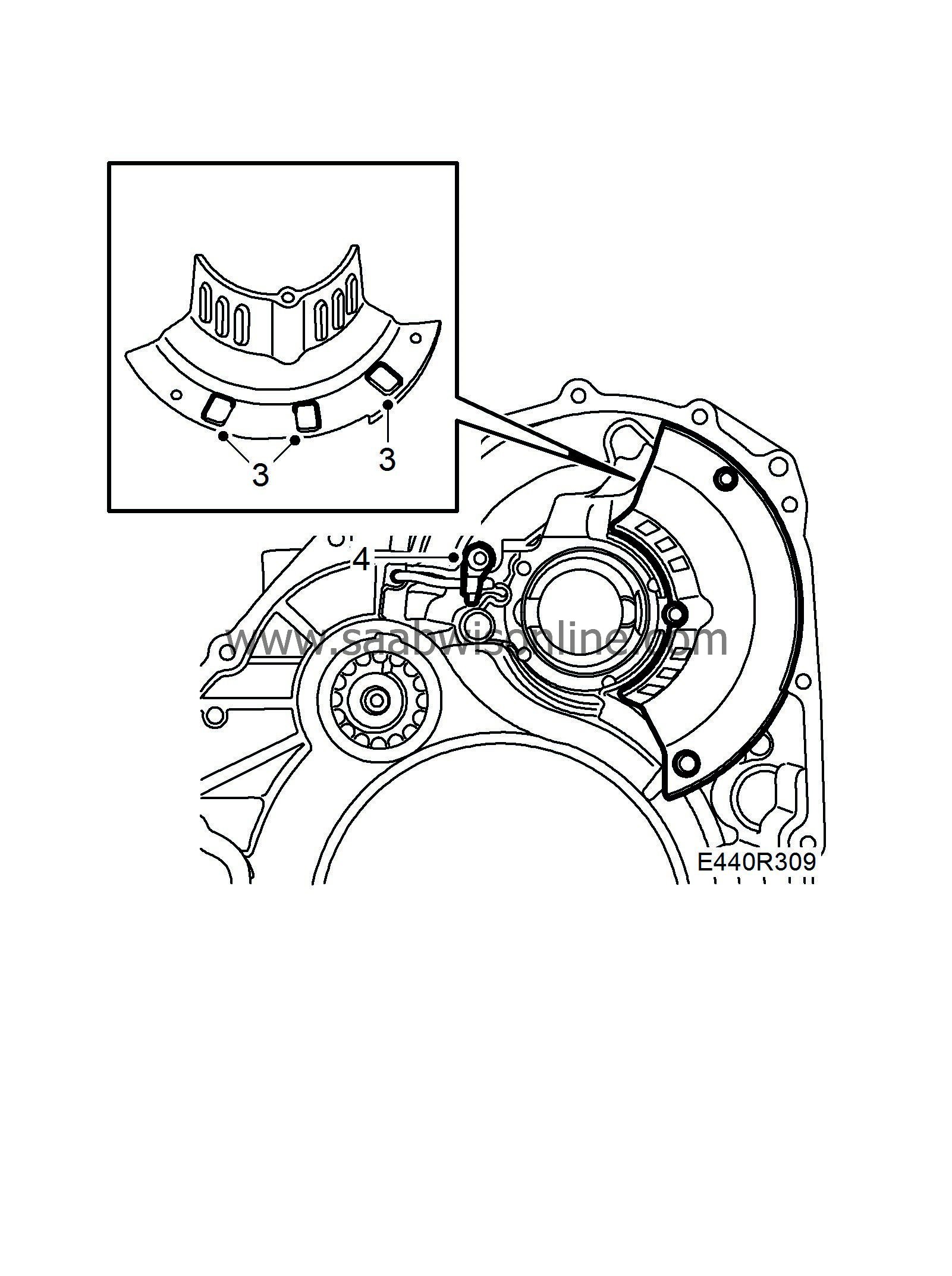

Place the three cleaned magnets on the oil channel plate. Apply thread locking compound 74 96 268 to the bolts and fit the oil channel plate.

Tightening torque 5.5 Nm (4 lbf ft)

|

|

| 4. |

Fit the pipe using a splinter-free plastic mallet. Take care not to bend or damage the pipe. Fit the pipe clamp.

|

|

| 5. |

Lubricate the bearings with automatic transmission fluid and fit the differential into the gearcase without the crown wheel.

|

|

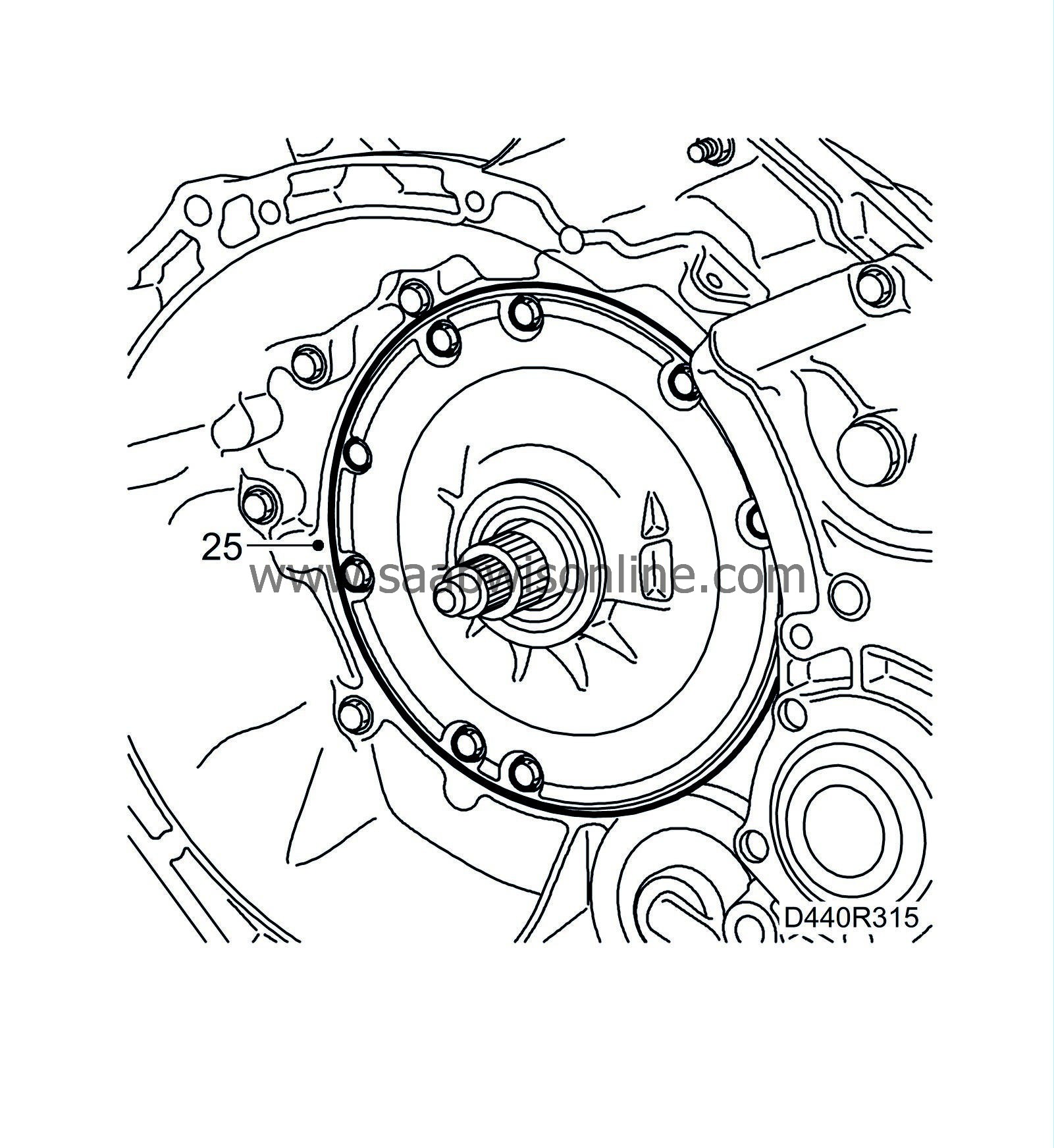

| 6. |

Fit the torque converter shell. Fit only every other bolt.

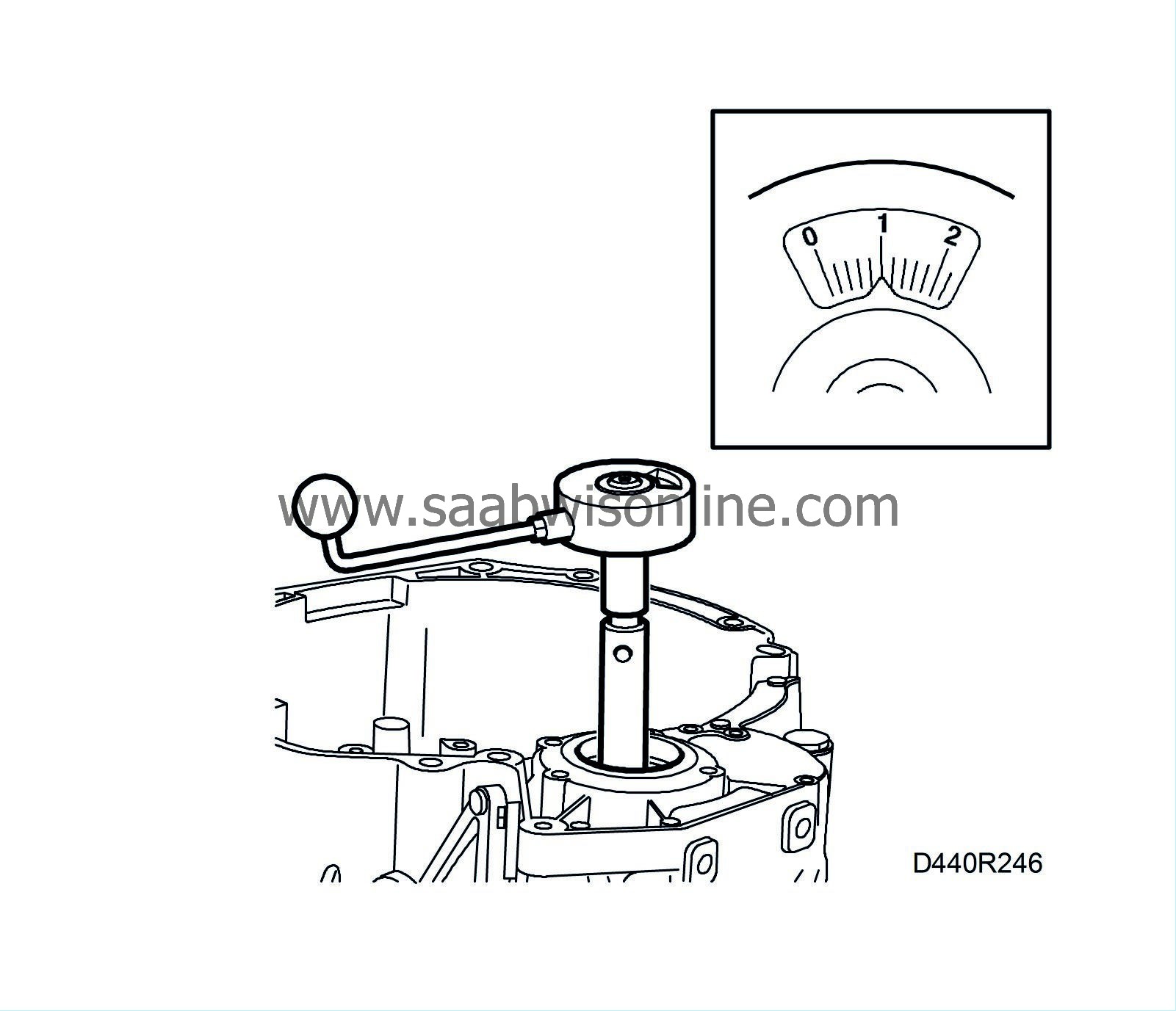

Tightening torque 25 Nm (18 lbf ft) Measure the prestress on the differential with a dynamometer 87 92 483 and drift 87 91 337. Rotate until the value has stabilised. Start value:

|

|||||

| 7. |

If the prestress is not within specified limits, remove the differential and bearing race from the gearcase and change shim. If the reading exceeds the specified value, change to a thinner shim. If the reading is lower than the specified value, change to a thicker shim. Shims are available between 1.0 - 1.90 mm in small intervals.

|

|

| 8. |

Remove the torque converter shell and lift out the differential.

|

|

| 9. |

Heat the crown wheel with a hot-air gun for about 5 minutes.

|

|

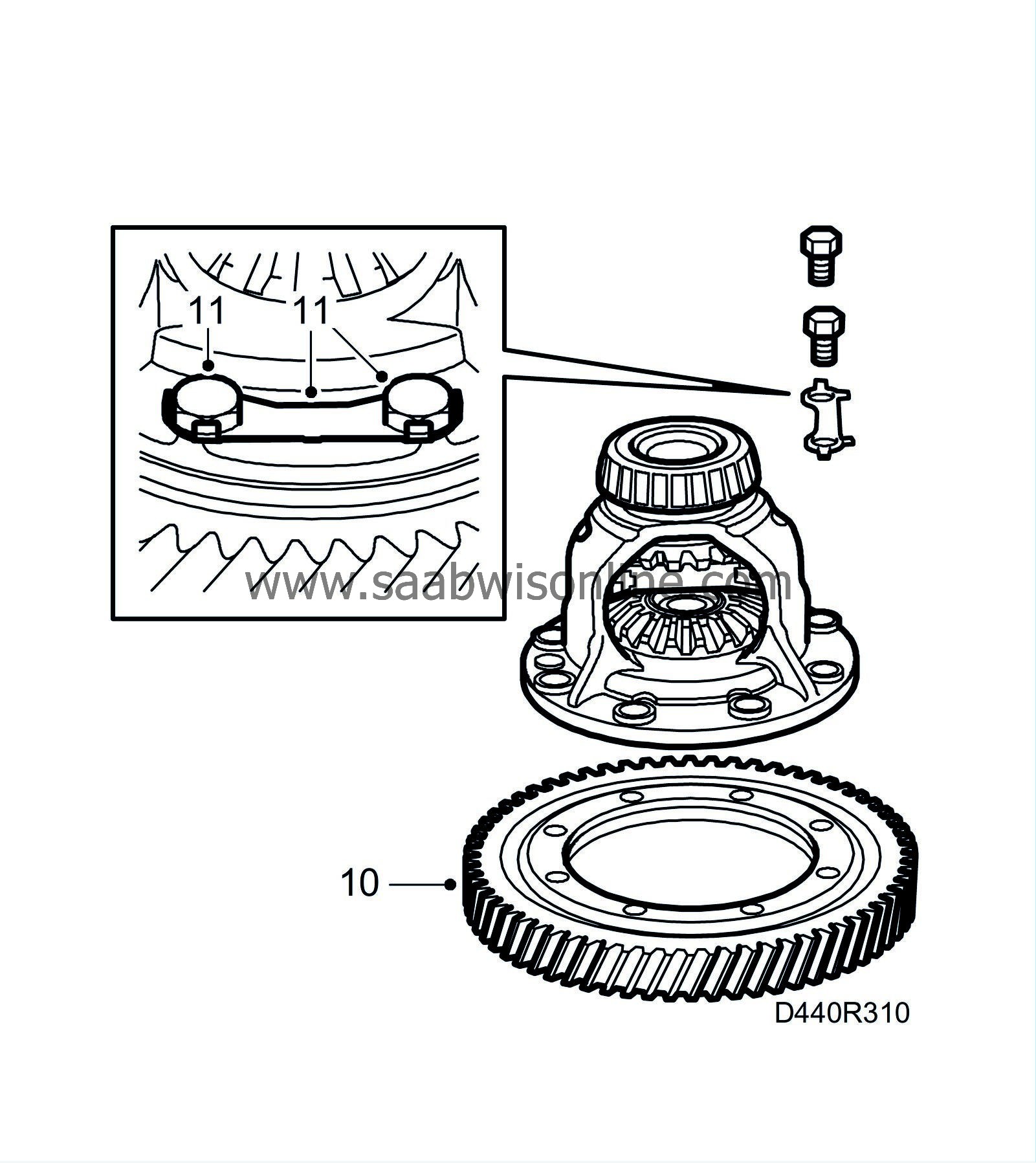

| 10. |

Fit the crown wheel on the new differential.

|

|

| 11. |

Fit new locking washers and fit the bolts.

Tightening torque 100 Nm (74 lbf ft) |

|

| 12. |

Bend up the locking washer against the flat surface on the bolt head.

|

|

| 13. |

Fit the differential unit.

|

|

| 14. |

Clean the sealing surfaces on the gearcase and torque converter shell. Use cleaner 30 02 599. Keep the surfaces free from grease.

|

|

| 15. |

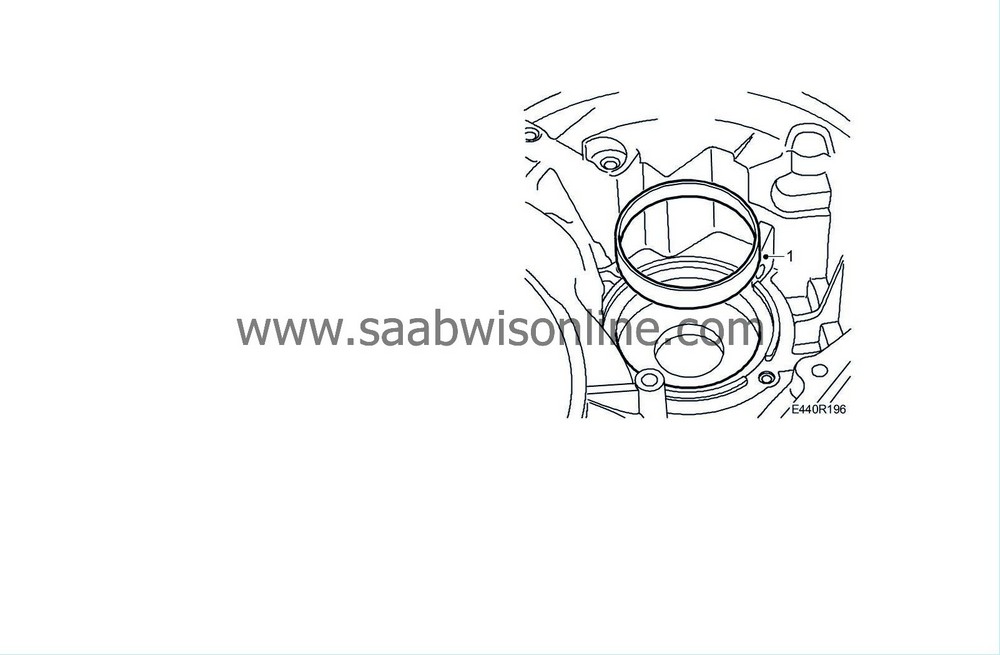

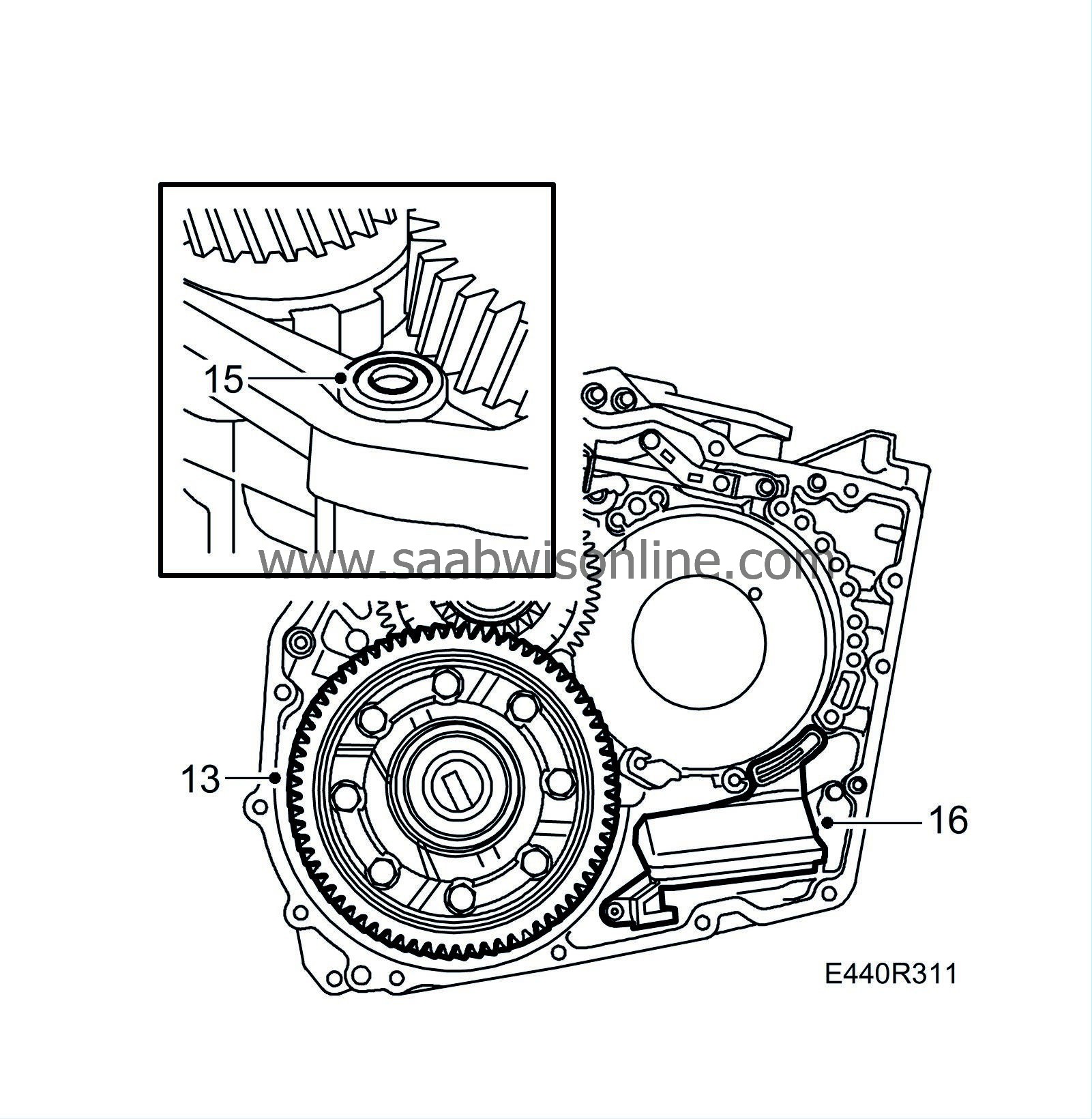

Fit a new seal in the gearcase.

|

|

| 16. |

Change the oil strainer in the gearcase

|

|

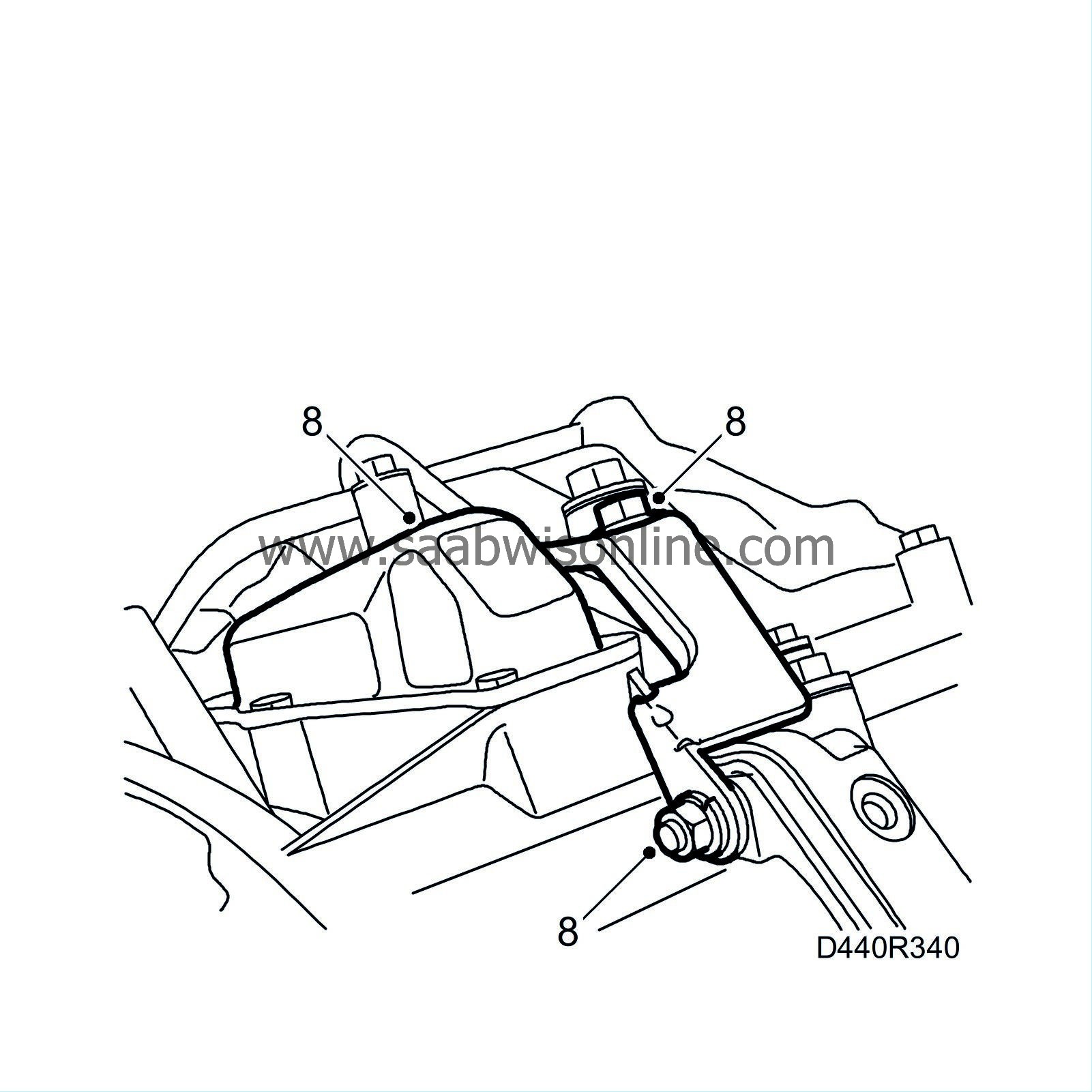

| 17. |

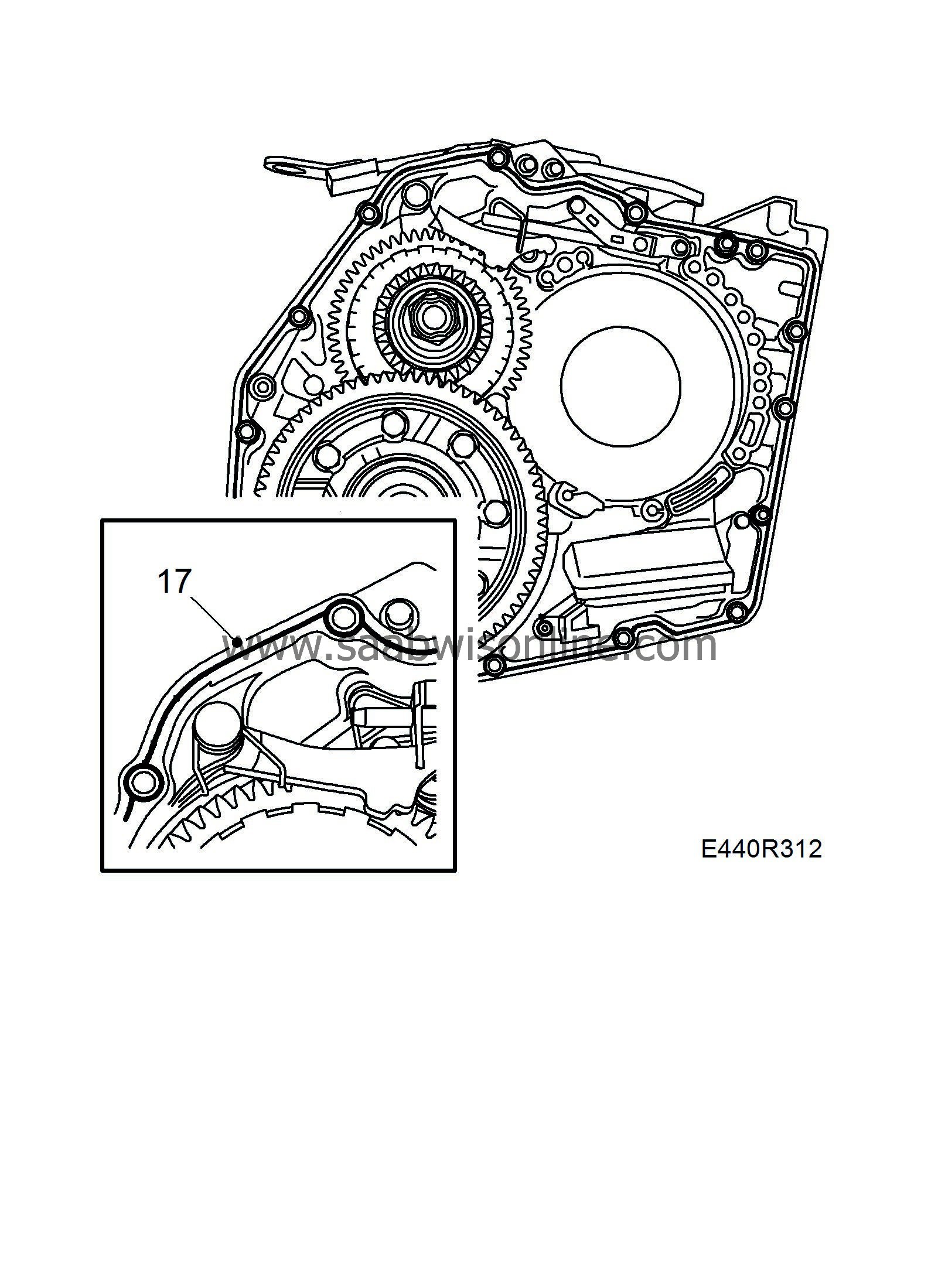

Apply a bead of flange sealant 93 21 795 approximately 1 mm wide to the gearcase as illustrated and fit the torque converter shell.

|

|

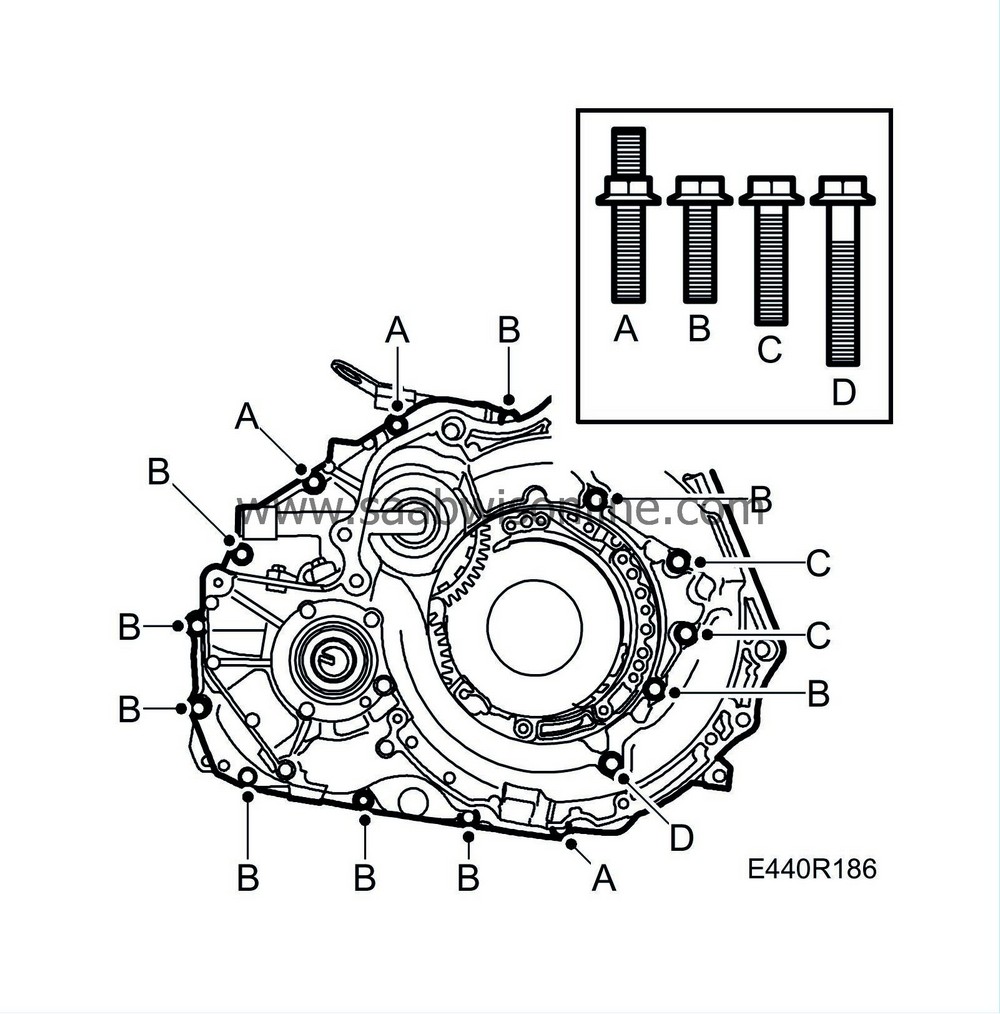

| 18. |

Apply thread locking compound 74 96 284 to the internal bolts. Fit the bolts (different lengths). Tighten the bolts.

Tightening torque: 25 Nm (18 lbf ft)

|

|

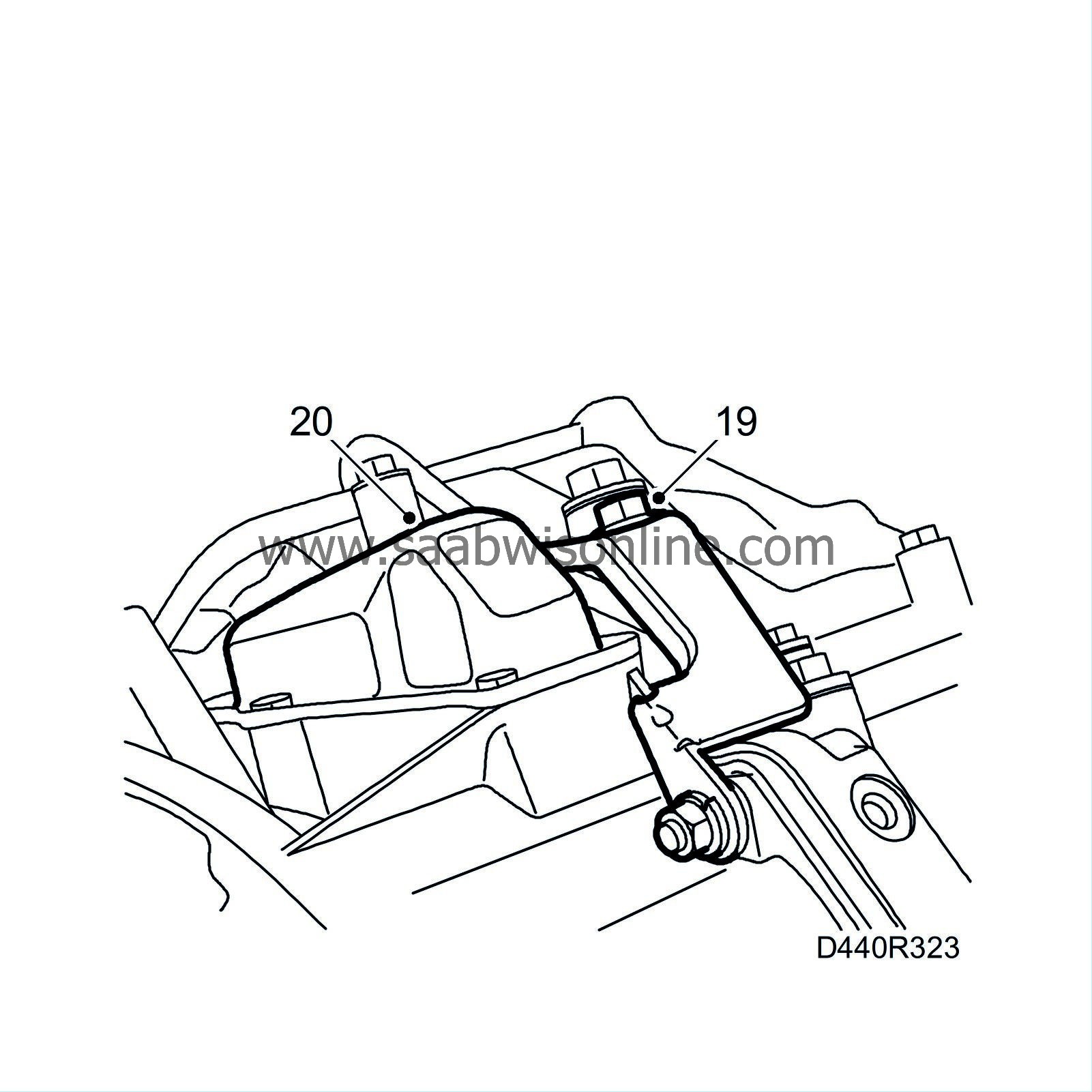

| 19. |

Fit the oil temperature sensor cover plate with nut, washer and bolt.

Tightening torque, bolt 25 Nm (18 lbf ft) Tightening torque, nut 10 Nm (7 lbf ft)

|

|

| 20. |

Fit the cover plate

|

|

| 21. |

Clean the magnetic surface on the drain plug and fit it with a new gasket. Fit the remaining outer plugs.

|

|

| 22. |

Turn the gearbox with turbine shaft 45° downward.

|

|

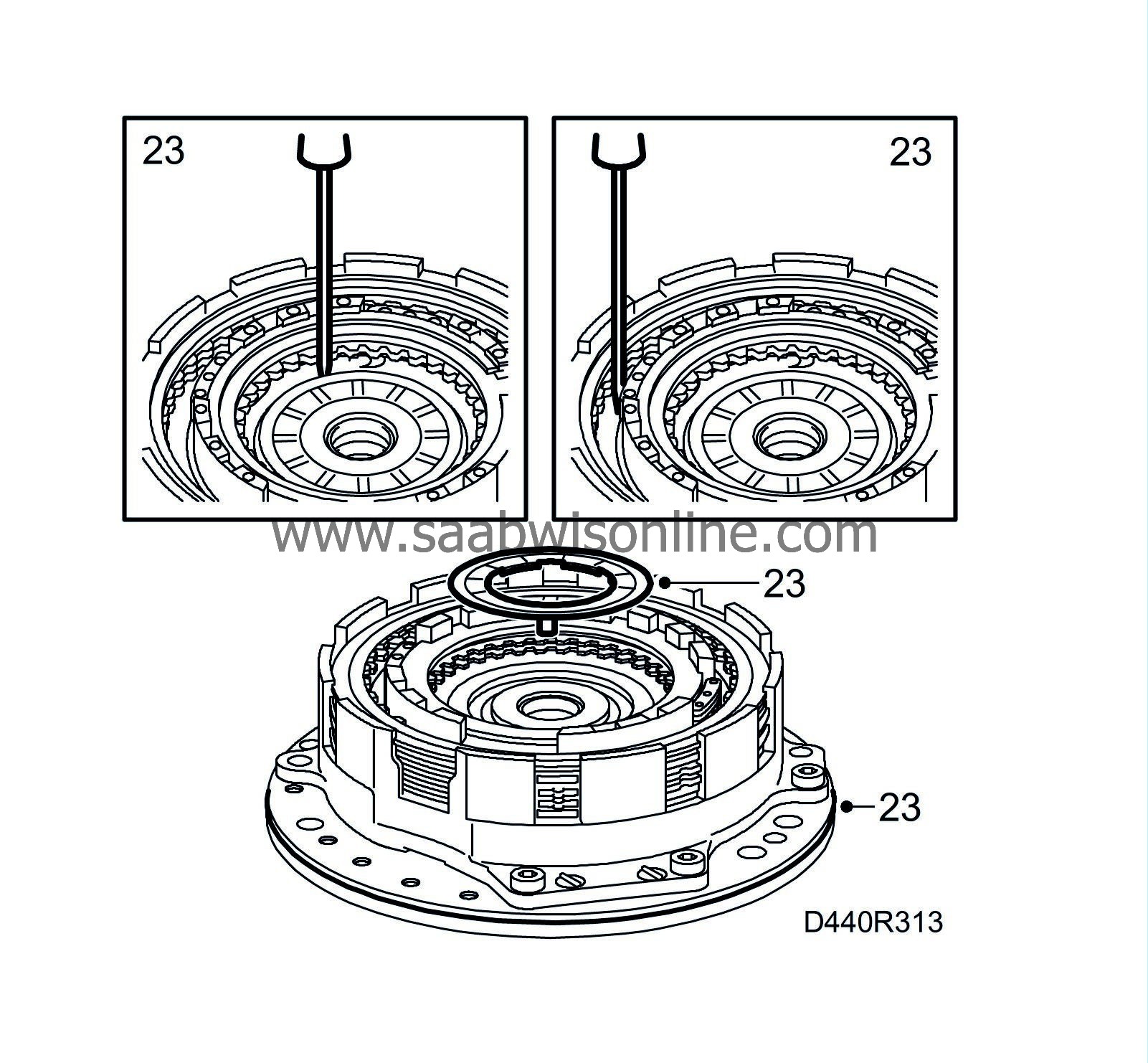

| 23. |

Apply petroleum jelly to the O-rings for the oil pump unit. Align the disc package with a small screwdriver. Fit thrust washers lubricated with petroleum jelly on brake B1/B2.

|

|

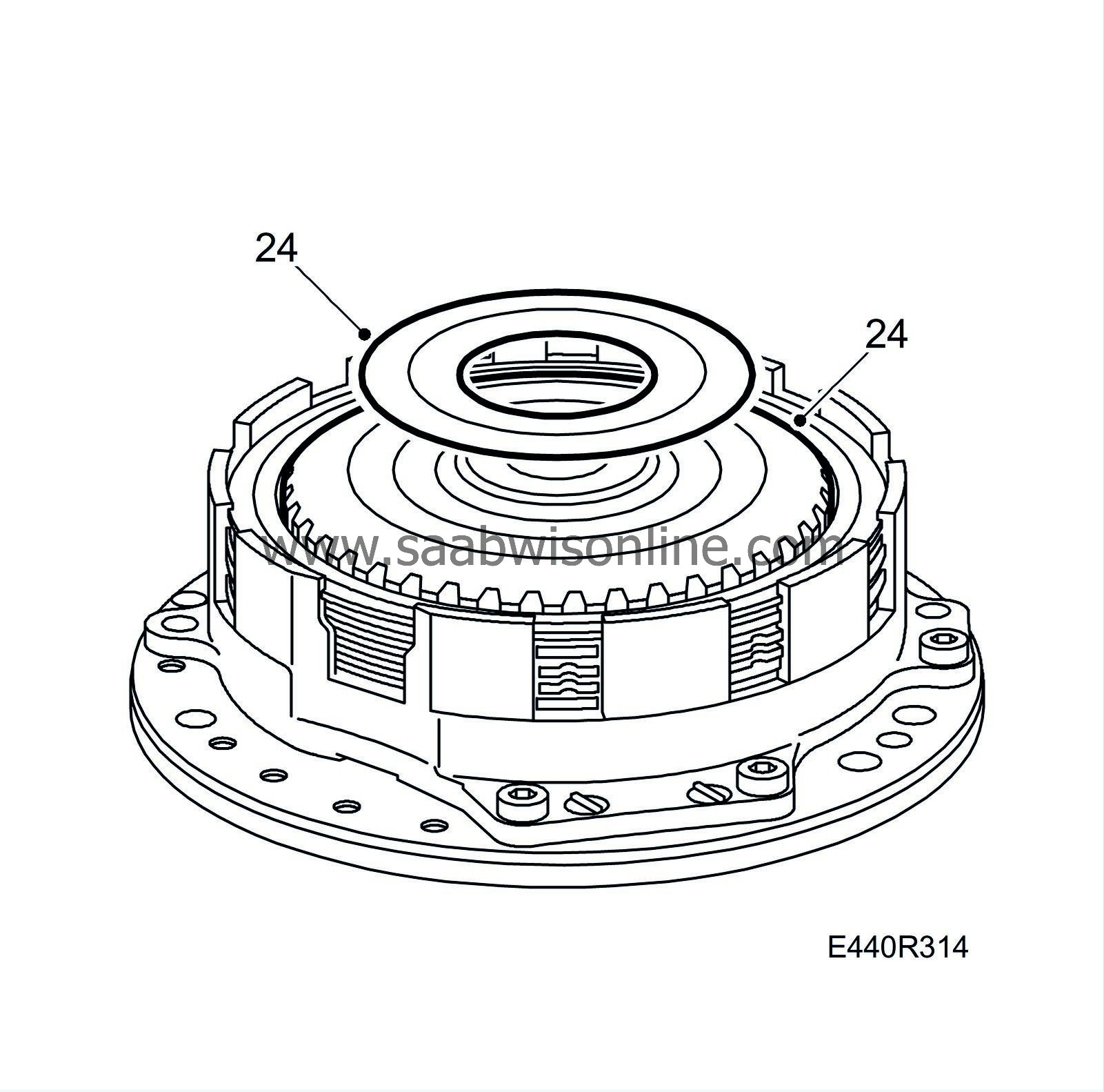

| 24. |

Fit freewheel F1 and the bearing race for brake B1 and B2 on the oil pump unit. Lubricate the bearing race for F1 with petroleum jelly and fit it.

|

|

| 25. |

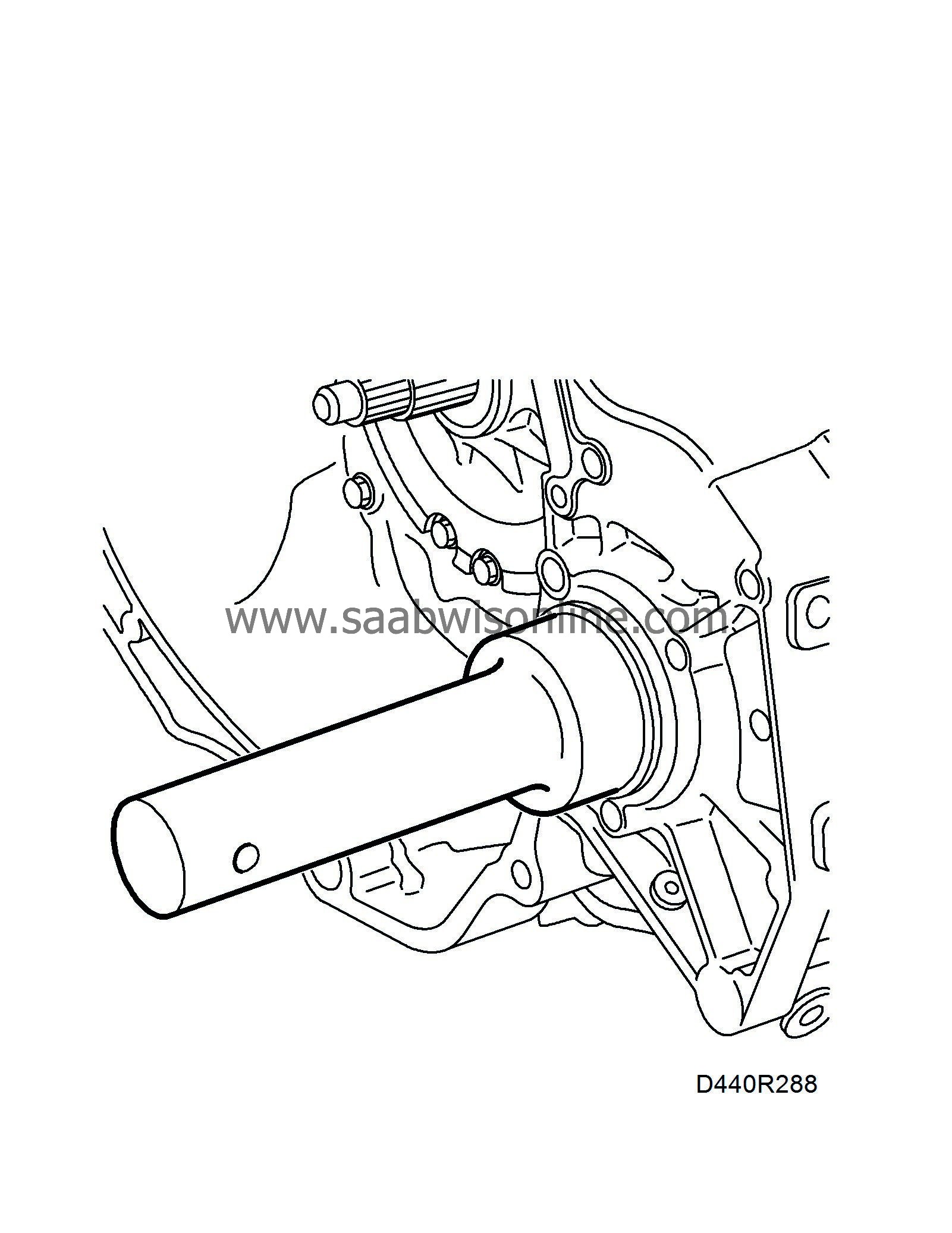

Place the oil pump unit so its bolt holes are aligned with those in the gearcase. Press the pump unit in place carefully. Tighten the bolts carefully and alternately. Make sure the turbine shaft has an axial clearance of 0.37 - 0.9 mm.

Tightening torque 25 Nm (19 lbf ft)

|

|

| 26. |

Turn back the gearcase 45°.

|

|

| 27. |

Change the torque converter seal. See adjustment/replacement, torque converter seal.

|

|

| 28. |

Fit the torque converter. Use holder 87 91 766. Fit locking device 87 92 574.

|

|

| 29. |

Fit new drive shaft seals. Use drift 83 90 122.

|

|

| 30. |

Lift down the gearbox from the stand and remove the holder.

|

|

| 31. |

Fit the gearbox in the car. See adjustment/replacement, fitting gearbox assembly.

|

|