Engine torque

| Engine torque |

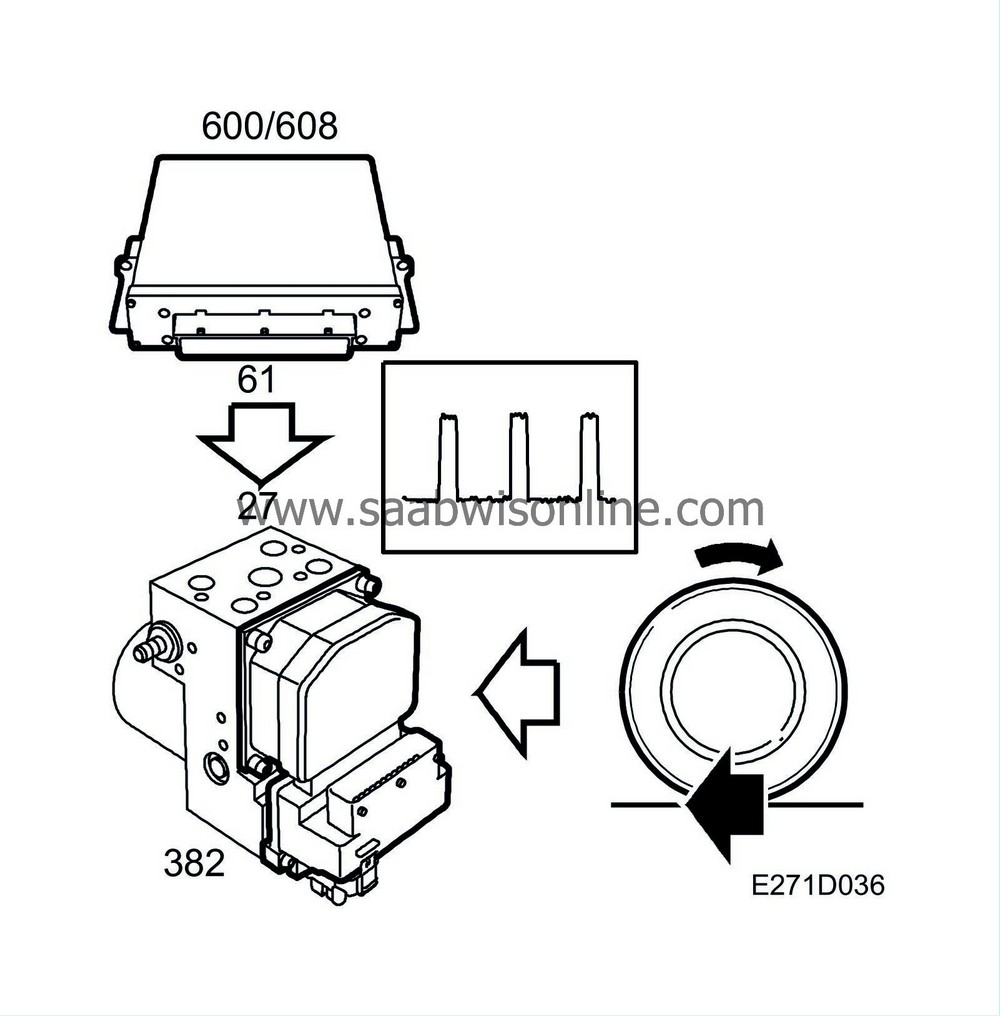

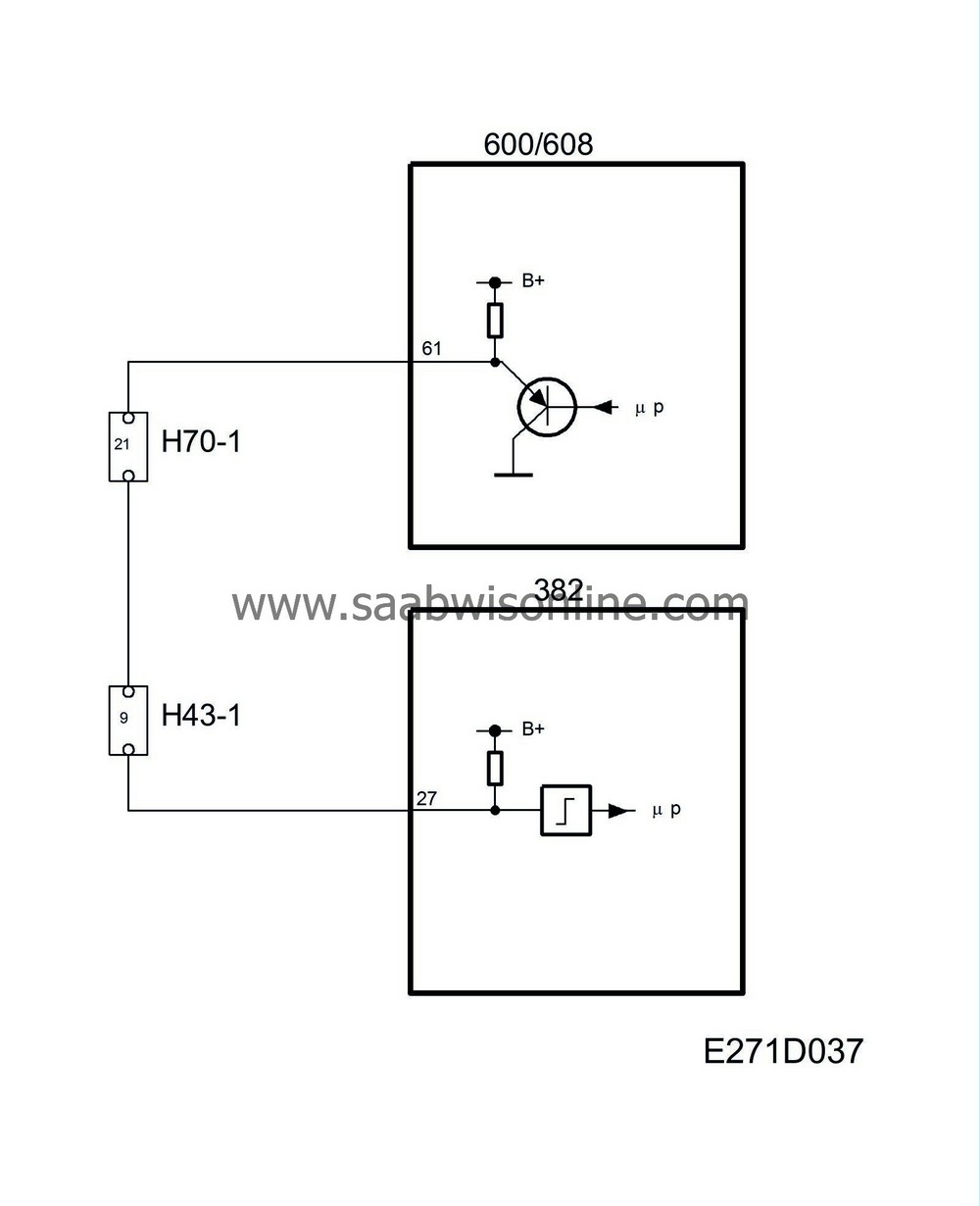

The Trionic converts the current air mass/combustion to engine torque. The signal is a 100 Hz PWM which is sent by the Trionic to pin 27 of the TC/ABS control module.

The pulse ratio is 5-96% and the different pulse ratios have different meanings:

|

5%

|

Engine stationary.

|

|

9-92%

|

Engine running and torque between 0 and 410 Nm.

|

|

96%

|

Trionic has detected a fault affecting the TCS function.

|

The TC/ABS control module uses engine torque information for:

| • |

Calculating the current drive wheel torque. Engine rpm and car speed are used to calculate the current ratio. When engine torque and the current ratio are known, the control module can calculate the drive wheel torque. Drive wheel torque is used to calculate the magnitude of brake/engine torque limitation during TCS modulation.

|

|

| • |

Detecting faults in the system.

|

|

Diagnostics

Diagnostic trouble code C0244 will be set in the event of a break/short circuit in the lead for engine torque. The TCS function is disabled and the TCS OFF lamp lights up.The Trionic can detect three different faults which affect the TCS function. It then sends a pulse ratio of 96% as an engine torque signal, causing the TC/ABS control module to set diagnostic trouble code C0241. The TCS function is disabled and the TCS OFF lamp comes on.

The three faults are:

| • |

Break/short circuit in the lead for torque limitation.

|

|

| • |

TC/ABS programmed for wrong engine variant.

|

|

| • |

Fault in Trionic throttle control (Limphome). This fault also causes the CHECK ENGINE (MIL) lamp to come on and the cause of the fault is in the Trionic.

|

|