Subframe

| Subframe |

| 1. |

Raise the car and remove the rear wheels.

|

|

| 2. |

Hook off the exhaust pipe from its rear and centre rubber mounts. Support the exhaust system so that it does not excessively strain the front mounts or the bellows pipe.

|

|

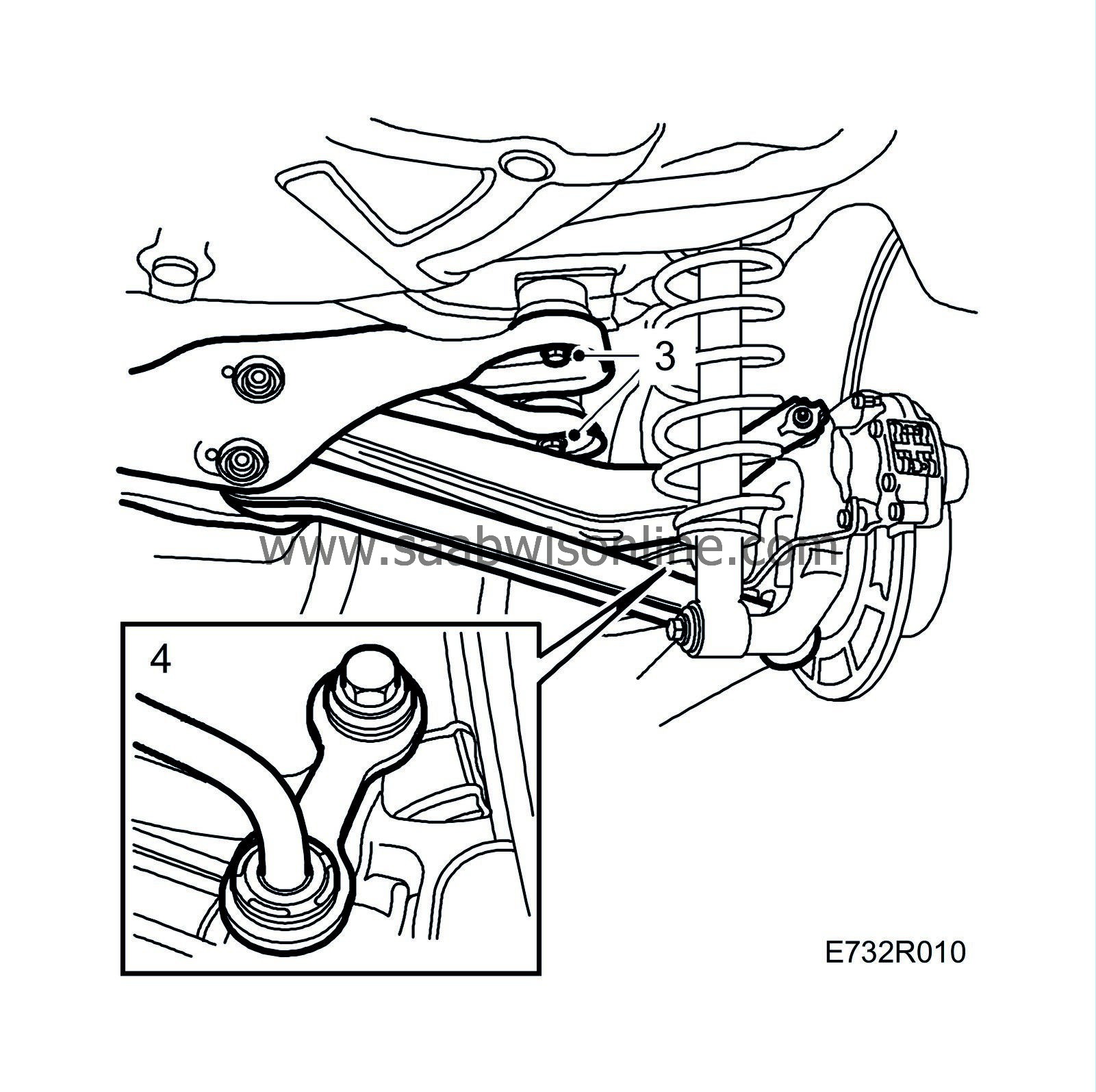

| 3. |

Detach the lower transverse link from the longitudinal link on both sides of the car.

|

|

| 4. |

Detach the upper transverse link from the longitudinal link on both sides of the car.

|

|

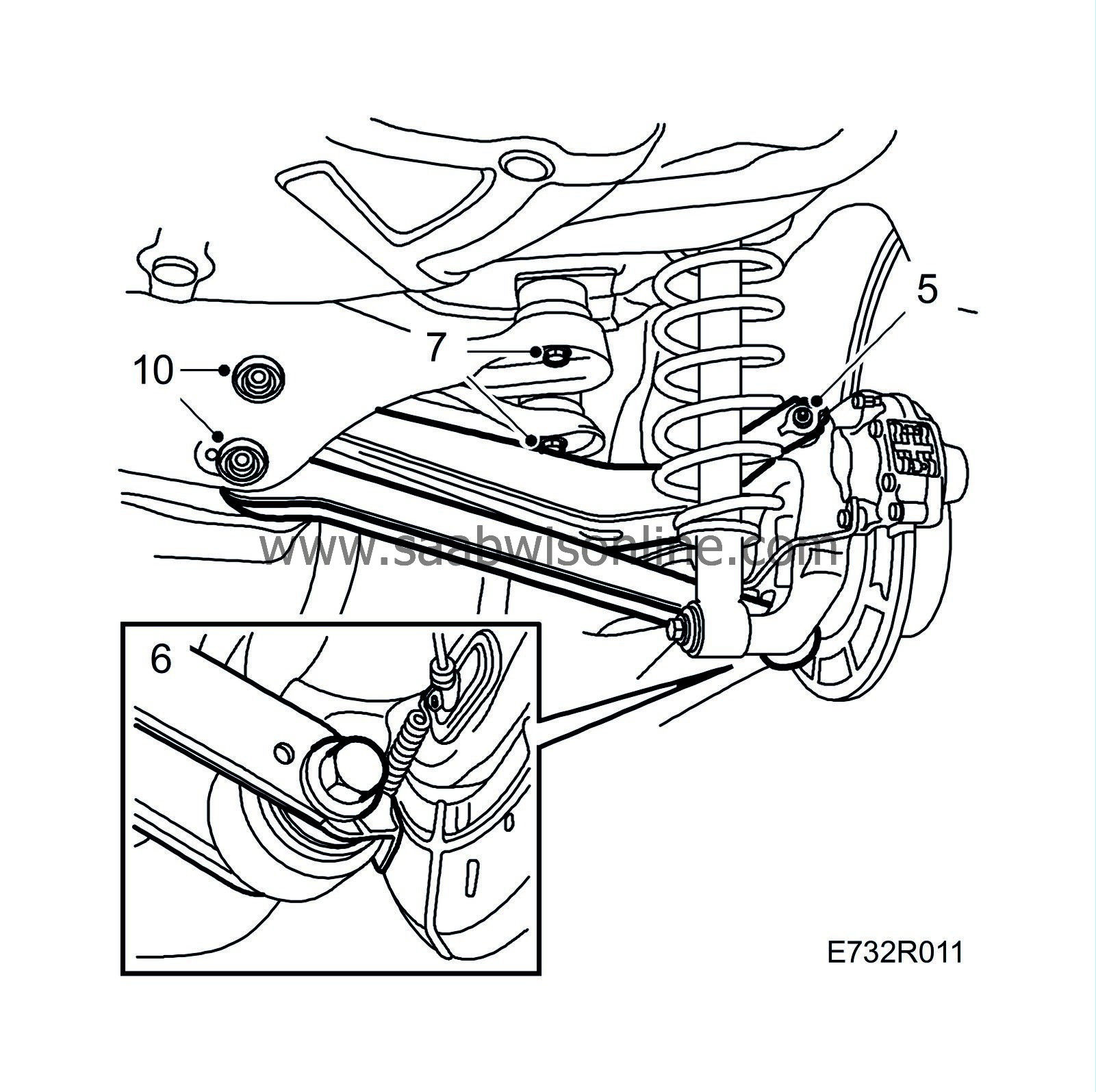

| 5. |

Detach the anti-roll bar from the longitudinal link on both sides of the car.

|

|

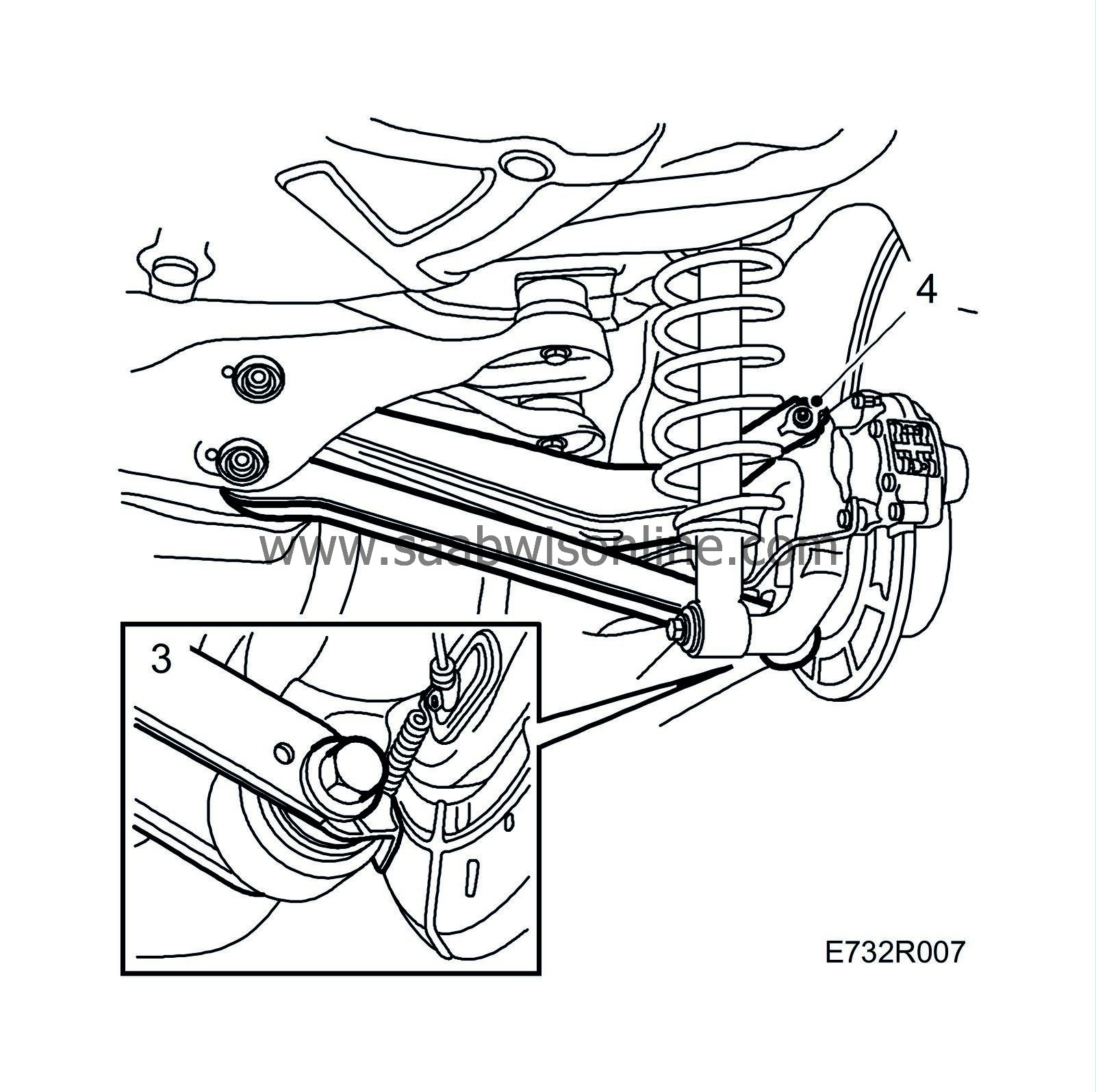

| 6. |

Remove the subframe mounting bolts and lower the subframe together with the anti-roll bar and the transverse links.

|

|

| 7. |

Remove the anti-roll bar and the transverse links.

|

|||||||||

| Assembly |

| 1. |

Fit the anti-roll bar to the subframe.

Tightening torque 50 Nm (40 lbf ft). |

|

| 2. |

Using new nuts, assemble the transverse links to the subframe, but do not tighten the bolts.

|

|||||||||

| 3. |

Lift up the subframe, together with the anti-roll bar and transverse links. Fit but do not tighten the subframe mounting bolts.

|

|

| 4. |

Attach and tighten the anti-roll bar to the longitudinal link on both sides of the car.

Tightening torque 50 Nm (40 lbf ft). |

|

| 5. |

Attach and tighten the upper transverse link to the longitudinal link on both sides of the car.

Tightening torque 90 Nm +60° (70 lbf ft +60°) |

|

| 6. |

Attach and tighten the lower transverse link to the longitudinal link on both sides of the car.

Tightening torque 90 Nm +60° (70 lbf ft +60°) |

|

| 7. |

Tighten the subframe mounting bolts.

Tightening torque 90 Nm +60° (70 lbf ft +60°) |

|

| 8. |

Hook the exhaust pipe onto the centre and rear rubber mounts.

|

|

| 9. |

Fit the wheels, see

Wheels

.

Tightening torque aluminium rim 110 Nm (81 lbf ft). pressed steel rim 50 Nm +2x90°, max 110 Nm (37 lbf ft +2x90°, max 81 lbf ft) Lower the car. |

|

| 10. |

Tighten the bolts attaching the transverse links to the subframe.

Tightening torque 90 Nm (70 lbf ft) +60˚. |

||||||||||

| 11. |

Check the toe-in angle and adjust if necessary, see

Wheel alignment

.

|

|

Warning

Warning