Timing cover

| Timing cover |

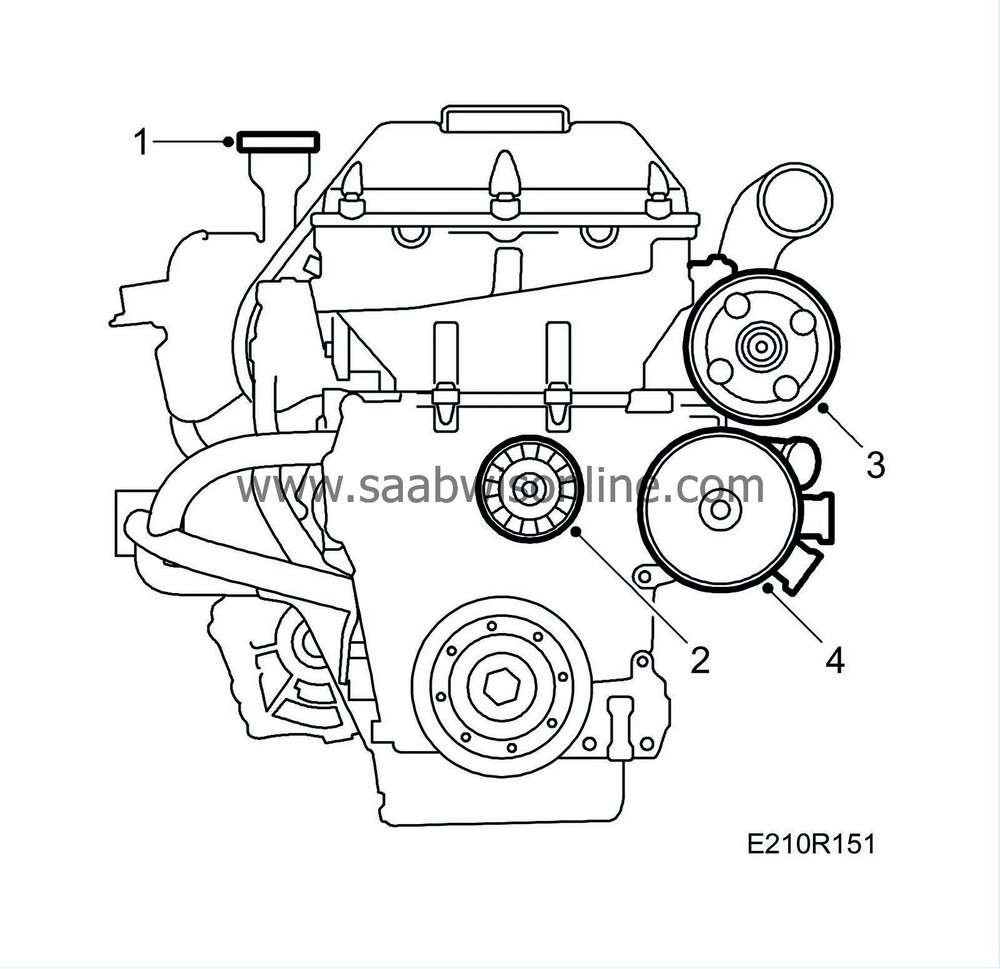

| 1. |

Remove the dipstick.

|

|

| 2. |

Remove the idler pulley.

|

|

| 3. |

Remove the power steering pump and its bracket with the lifting eye.

|

|

| 4. |

Remove the water pump and the sleeve with O-rings.

|

|

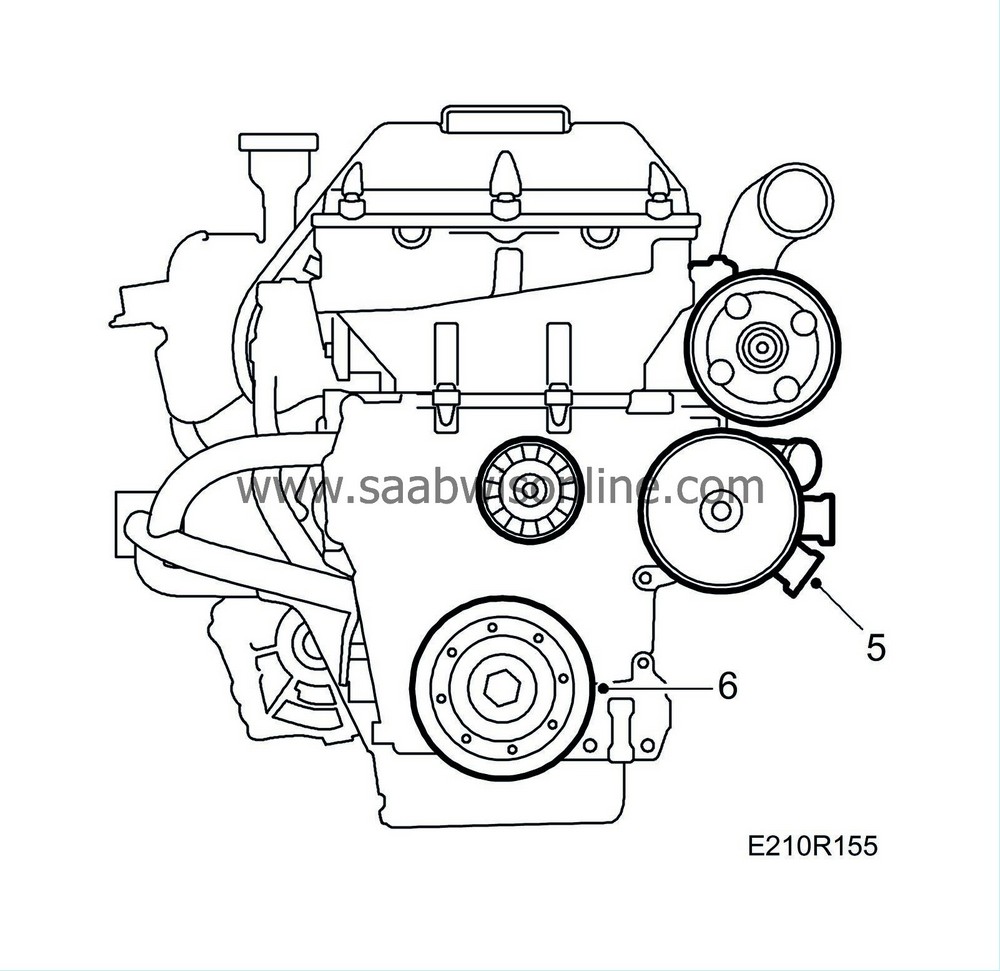

| 5. |

Remove the protective plate and oil sump. Leave the guide sleeve in the cylinder block. Wipe up any oil that has dripped out.

|

|

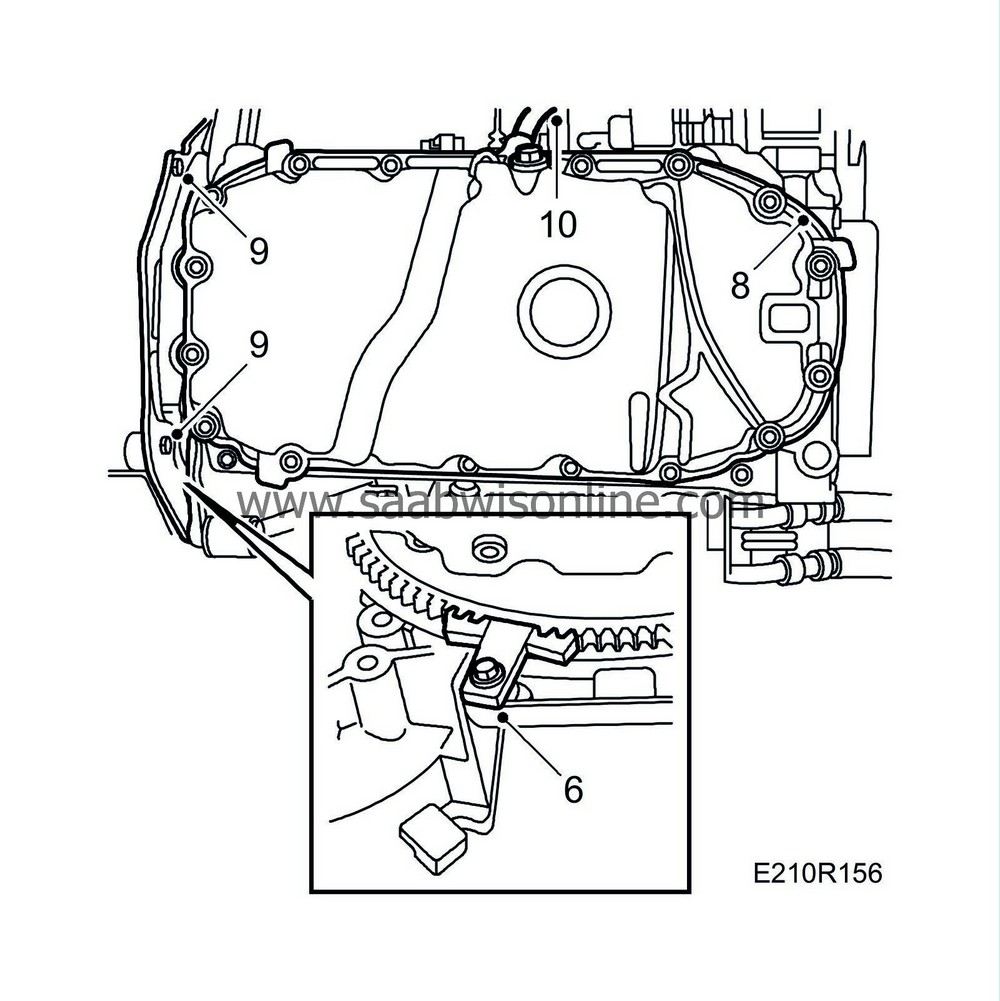

| 6. |

Use flywheel locking segment 83 94 868

. Remove the crankshaft pulley.

. Remove the crankshaft pulley.

|

|

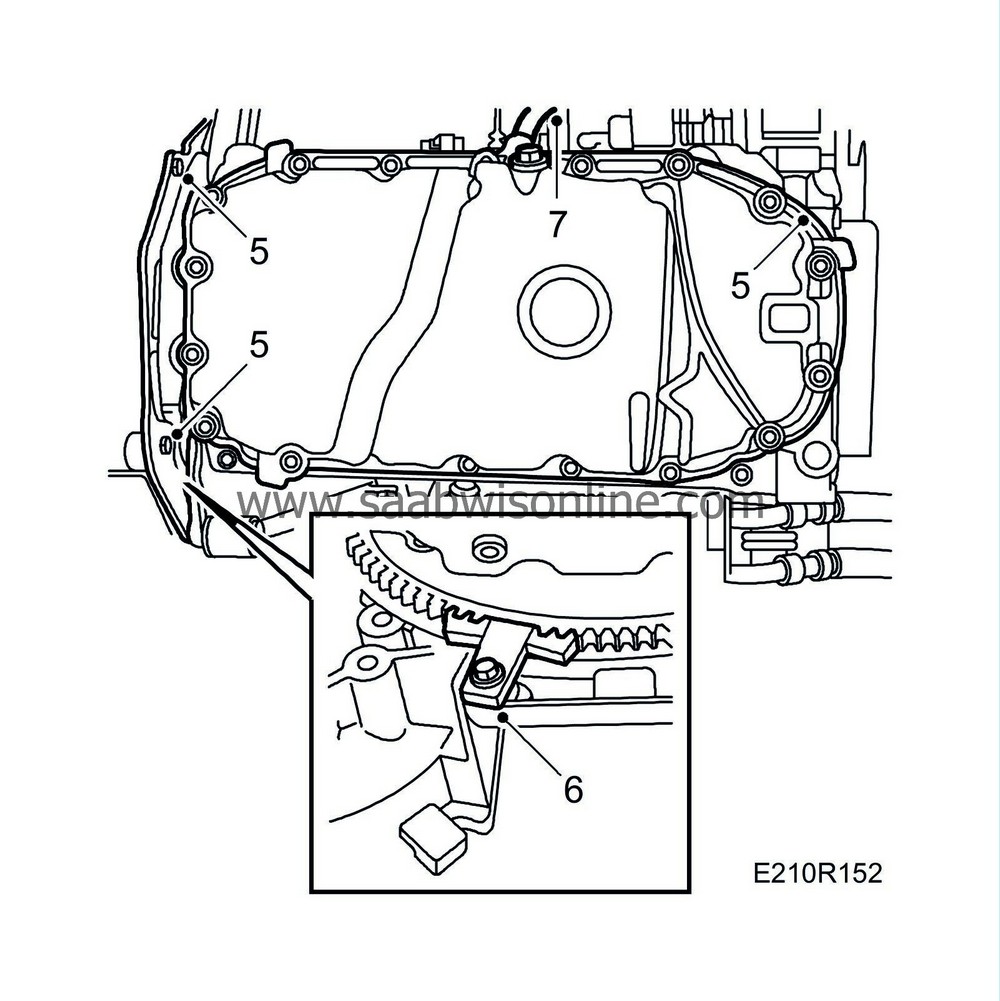

| 7. |

Disconnect the crankcase breather hose from the oil sump.

|

|

| 8. |

Remove the locating pins in the timing cover by cutting an internal thread in them using a 3/8” UNC thread tap and withdraw them with sliding hammer 83 90 270

.

.

|

|

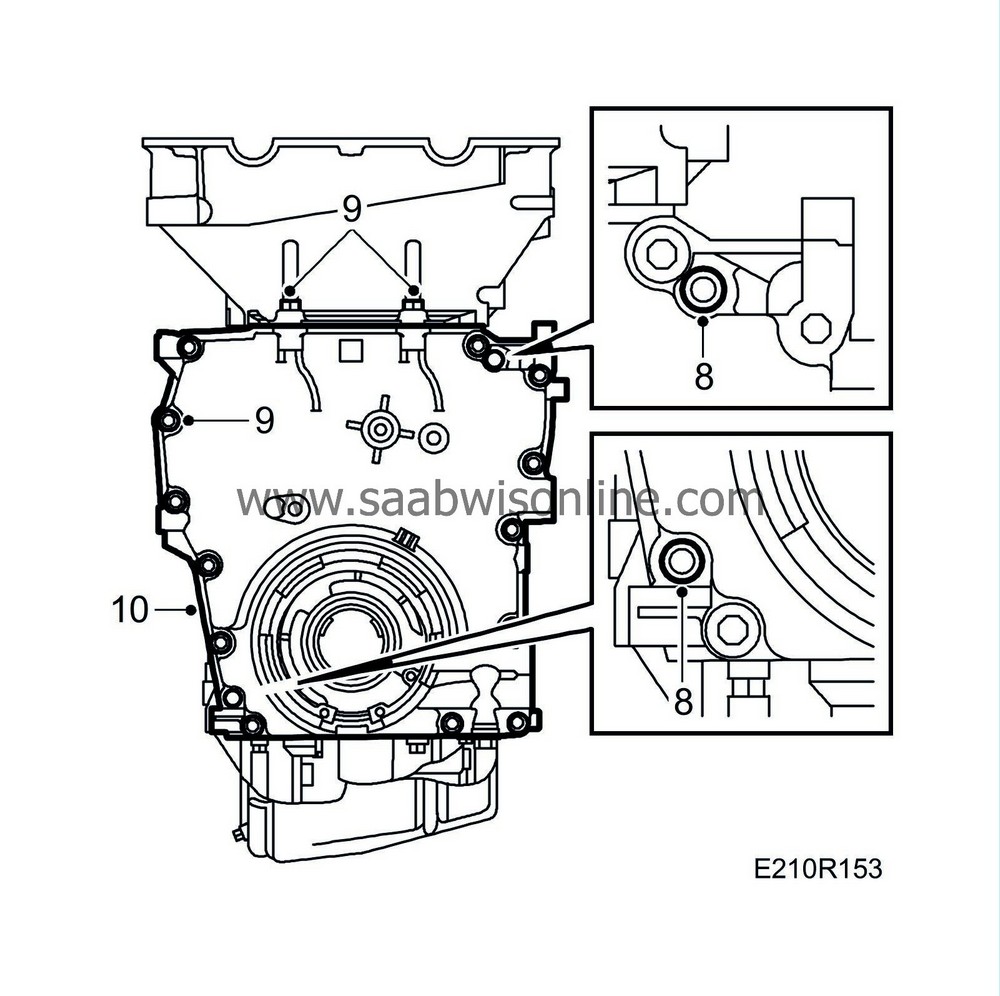

| 9. |

Remove all timing cover retaining bolts.

|

|

| 10. |

Pull the timing cover away, starting at the bottom.

|

|

| 11. |

Then lift the cover outwards/downwards to avoid damaging the gasket at the cylinder head.

|

|

| To fit |

| 1. |

Thoroughly remove all remains of sealant on all surfaces. Wash clean with benzine.

|

|

| 2. |

Apply a bead of Loctite 518 about 1 mm thick along the middle of the sealing surfaces.

|

|

| 3. |

Fit the timing cover, carefully turning it into position. Fit the retaining bolts but do not tighten them. Tap the locating pins in place.

|

|

| 4. |

Tighten the timing cover, using a torque wrench.

Tightening torque 22 Nm (16 lbf ft). |

|

| 6. |

Fit the crankshaft pulley. Use flywheel locking segment 83 94 868.

Tightening torque 175 Nm (130 lbf ft). |

|

| 7. |

Make sure that there are no impurities or other foreign matter in the oil sump and clean its sealing surface.

|

|

| 8. |

Apply an even bead of Loctite 518 on the oil sump's sealing surface and fit the oil sump in place.

Tightening torque 22 Nm (16 lbf ft). |

|

| 9. |

Fit the protective plate, plug in the oil level sensor connector and press the cable back into its clamps.

|

|

| 10. |

Check that the oil plug is properly tightened and connect the cables to the oil pressure sensor, generator and starter motor.

Tightening torque 25 Nm (19 lbf ft). |

|