Oil leakage/oil patches on engine

Symptom: Visible oil leaks on the engine or abnormally high oil consumption.

|

|

Oil leakage/oil patches on engine

|

Fault symptoms

Visible oil leaks on the engine or abnormally high oil consumption.

Conditions

The following conditions apply for the current fault symptom:

|

•

|

Oil patches on the engine due to small leaks that can be hard to localise.

|

|

•

|

The table shown below lists 5 different types of leak that refer to the 5 points in the action list. For some model years, it has been possible to rectify the cause for the leak, making the leak less likely. Example: An MY02 vehicle can have a type 1, 2 and 3 leak, but is unlikely to have a type 4 or 5 leak.

MY

|

-98

|

-99

|

-00

|

-

01

|

-02

|

-03

|

1

|

x

|

x

|

x

|

x

|

x

|

x

|

2

|

x

|

x

|

x

|

x

|

x

|

x

|

3

|

x

|

x

|

x

|

x

|

x

|

|

4

|

x

|

x

|

x

|

x

|

|

|

5

|

x

|

x

|

x

|

x

|

|

|

|

Procedure

When an oil leak is detected, check the areas listed below

|

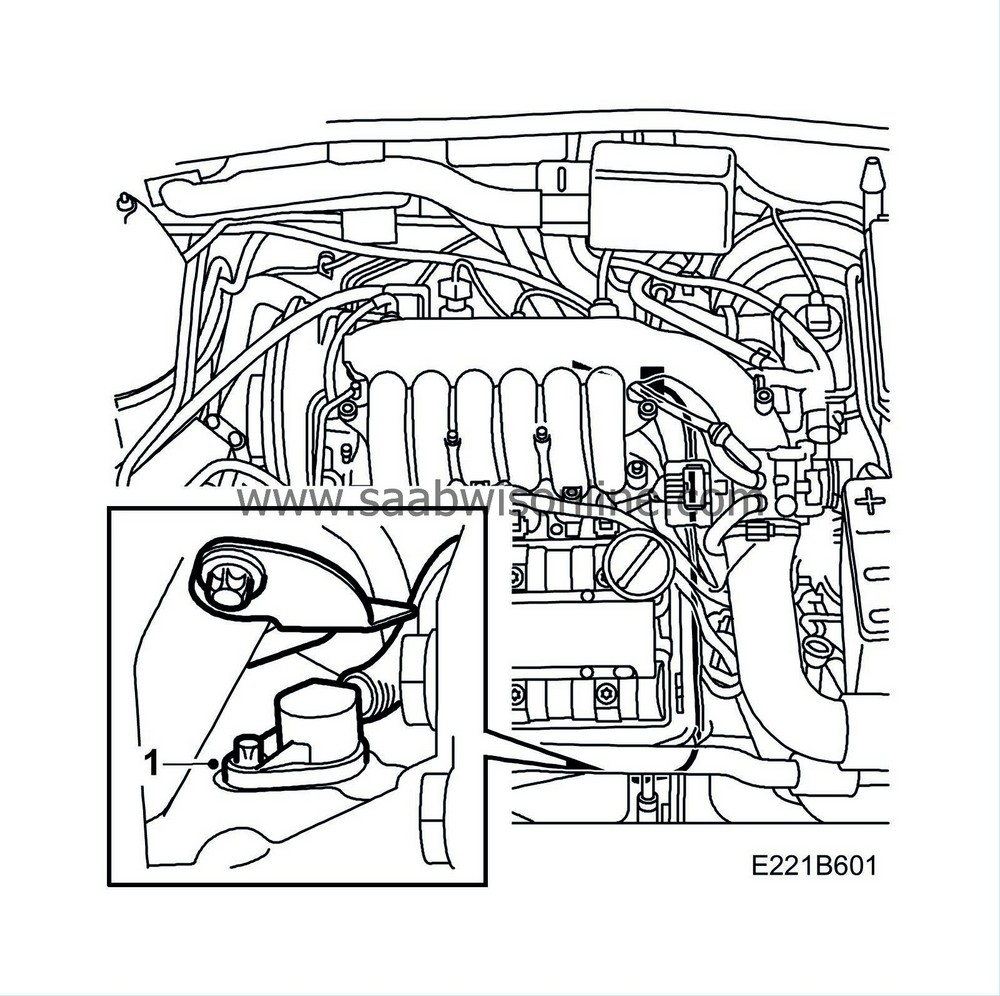

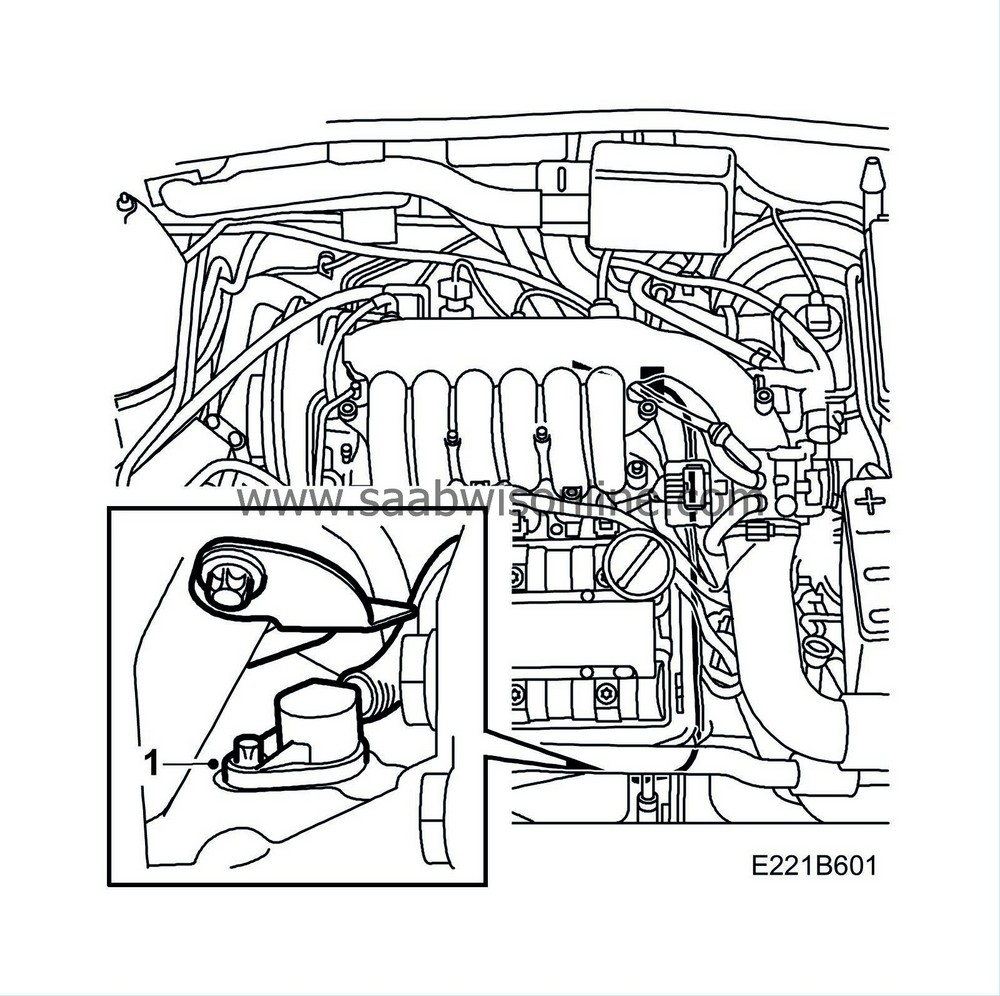

1.

|

Oil patch by crankshaft position sensor.

Remove the crankshaft position sensor. Clean the sealing surface and fit a new O-ring greased with

Petrolatum, Klüber Syntheso Pro AA2

. Fit the crankshaft position sensor

|

|

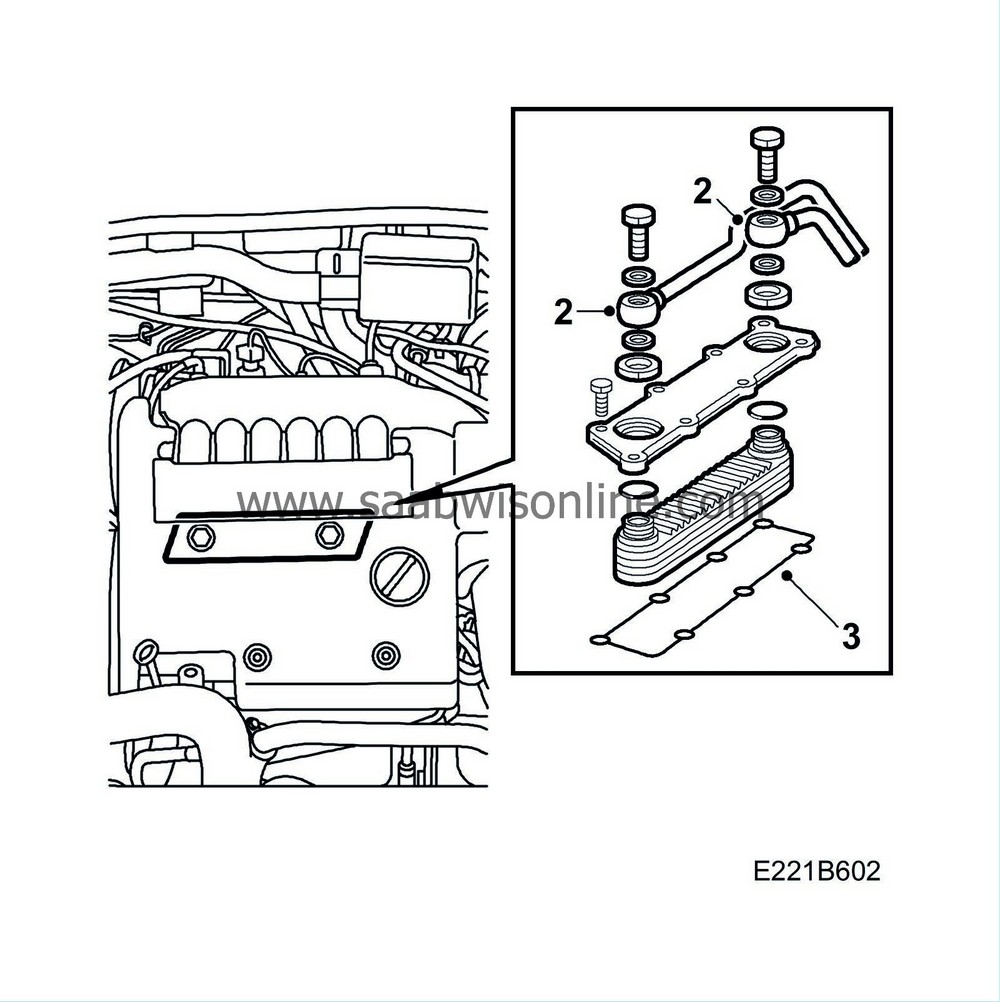

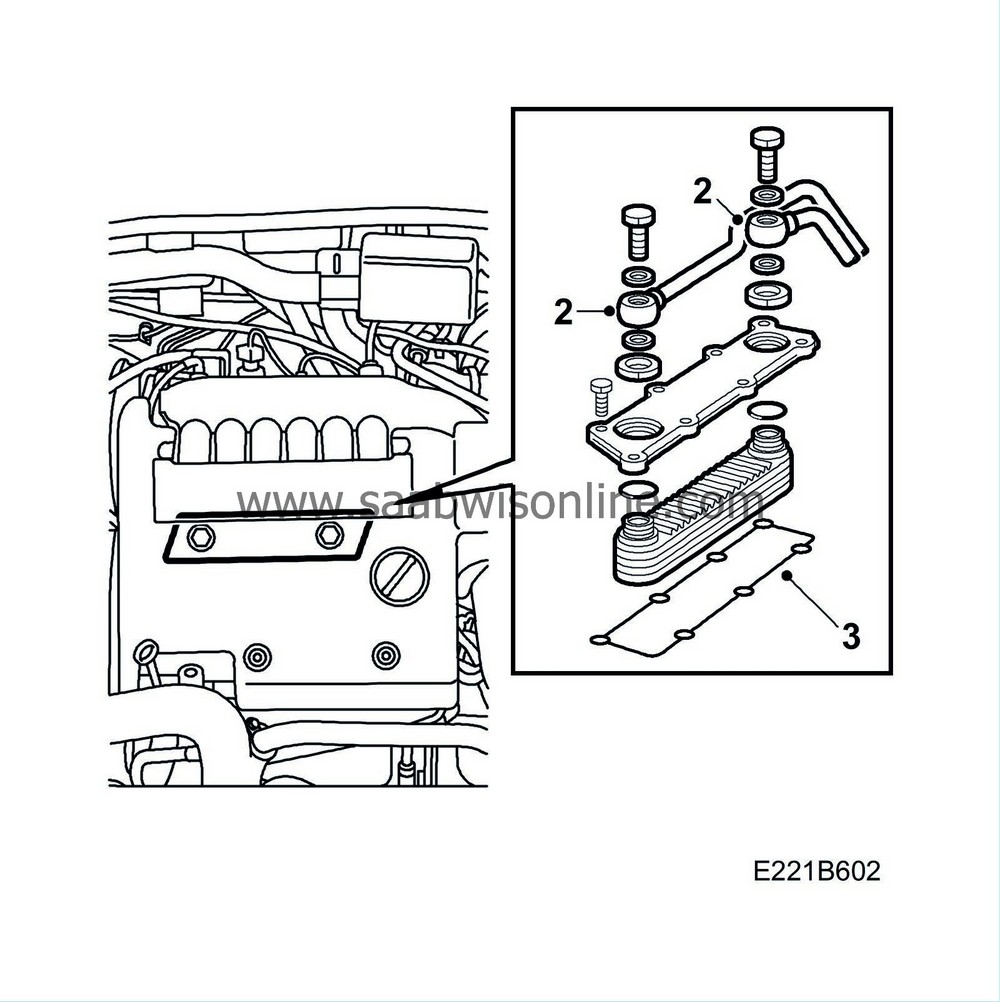

2.

|

Oil patch by the oil cooler intake and outlet.

A banjo screw (part no. 59 58 095) has been developed. This should be used with an aluminium washer (part no. 46 21 413). The new screw is fitted to all engines from engine number B308EE003723200.

|

|

3.

|

Oil patch by the oil cooler seal with the cylinder block.

Remove the oil cooler. Clean the sealing surfaces on the cylinder block and cooler cover and apply TB 1217F (part no. 47 73 594) to the sealing surfaces. This new seal was introduced into production from engine number B308EE003685986. It is difficult to detect the origin of leaks 2 and 3 without using an endoscope, using a tracing agent added to the oil or removing the intake manifold.

|

|

4.

|

Oil patch by the cover on the cylinder block.

Clean the sealing surface, fit a new O-ring (part no. 91 98 615). Use

Vaseline, non-acidic

to secure the O-ring and ensure it remains in its groove. The new O-ring was introduced as from B308EE002577279. Tighten the cover.

Tightening torque 15 Nm (11 lbf ft)

Check also that the tightening torque of the threaded pipe is correct.

Tightening torque: 20 Nm (15 lbf ft)

|

|

5.

|

Oil patch by the oil return pipe from the turbo to the oil pan.

Two possible areas: The flange at the turbo outlet and the O-ring seal at the oil pan. If there is a leak, the entire oil return pipe must be changed along with the gasket and O-ring (part no. 91 85 455, 91 07 582 and 79 85 708). Check that the oil return pipe mates well with the oil pan. If not, slacken the hose clip, adjust the pipe and tighten the clip. The oil return pipe has been rectified for all cars since MY02.

|

After remedial action, clean the engine from oil and dirt and test drive to check that the leak has been rectified.