Closed loop fuel injection system

| Closed loop fuel injection system |

The catalytic converter has a high conversion efficiency within a very narrow range. If the fuel-air mixture is not kept within this range, one or more gases will inevitably exceed the permitted limits. A closed loop fuel injection system ensures that the fuel-air mixture is completely correct.

Provided that the closed loop fuel injection system gives an optimal fuel-air mixture ratio, the catalytic converter reduces the nitrous oxides (NO x ) and oxidizes the carbon monoxide (CO) and hydrocarbons (HC). The end products are carbon dioxide (CO 2 ), water (H 2 O) and nitrogen (N 2 ).

In order for the catalytic converter to reduce the emissions, the car must be run on unleaded petrol only. This is because lead destroys the active components of the three-way catalytic converter.

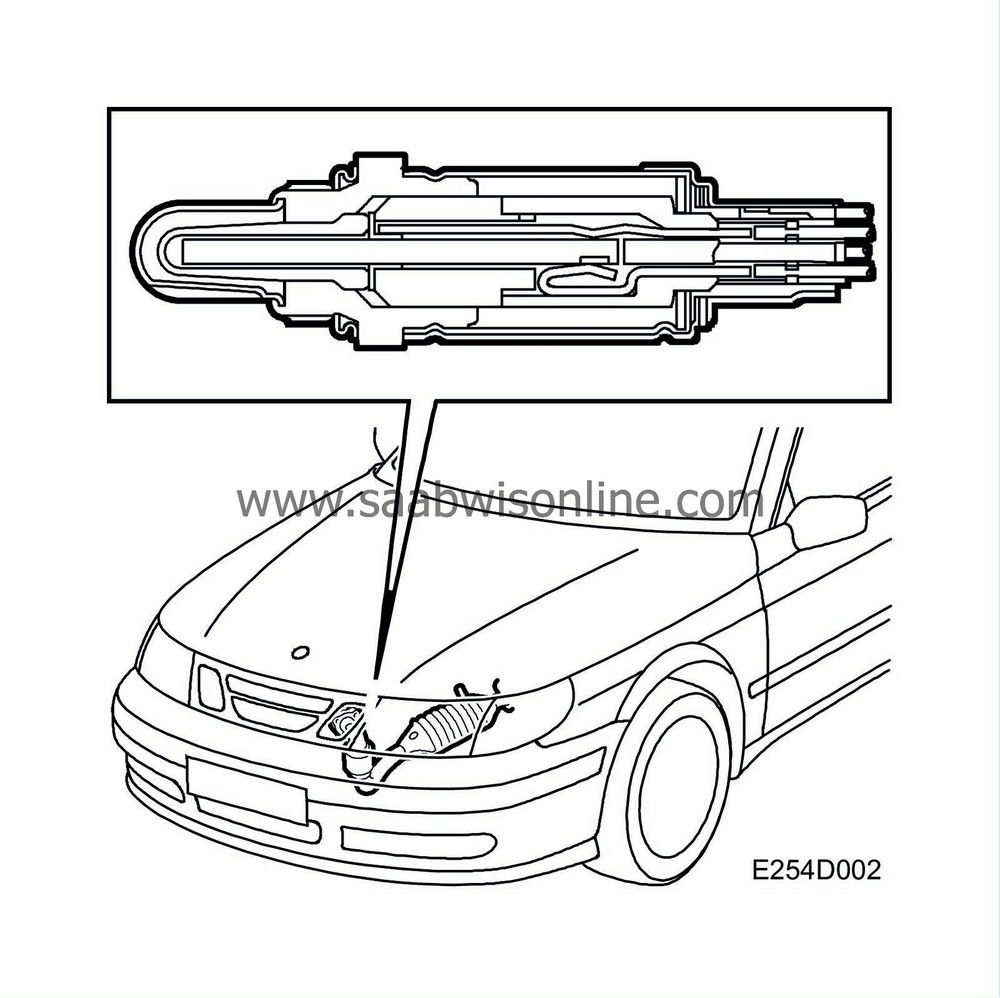

| Oxygen sensor |

The oxygen sensor consists of a primary cell with a fixed electrolyte. The electrolyte is ceramic (zirconium dioxide) and temperature-stabilized by the addition of a small quantity of yttrium oxide. The electrolyte is tubular and hollowed out at one end.

To function properly, the catalytic converter requires an air/fuel ratio of precisely 14.7:1.

If the mixture is too weak, the oxygen content in the exhaust gases will increase. The oxygen sensor output voltage will then be about 0.1 V (lambda over 1). The engine control module reacts by extending the injection times.

If the mixture is too rich, the oxygen sensor output voltage will be about 0.9 V (lambda under 1) and the injection pulses are shortened.

Since the working range of the oxygen sensor is between 200°C-850°C (392°F-1562°F), it is fitted with an electric preheater. Preheating is controlled by the system's control module. At high load and high rpm, the exhaust temperature is high and the preheating circuit is shut off.

For further information about the closed loop control see Group 2 “Engine control system”

.

.