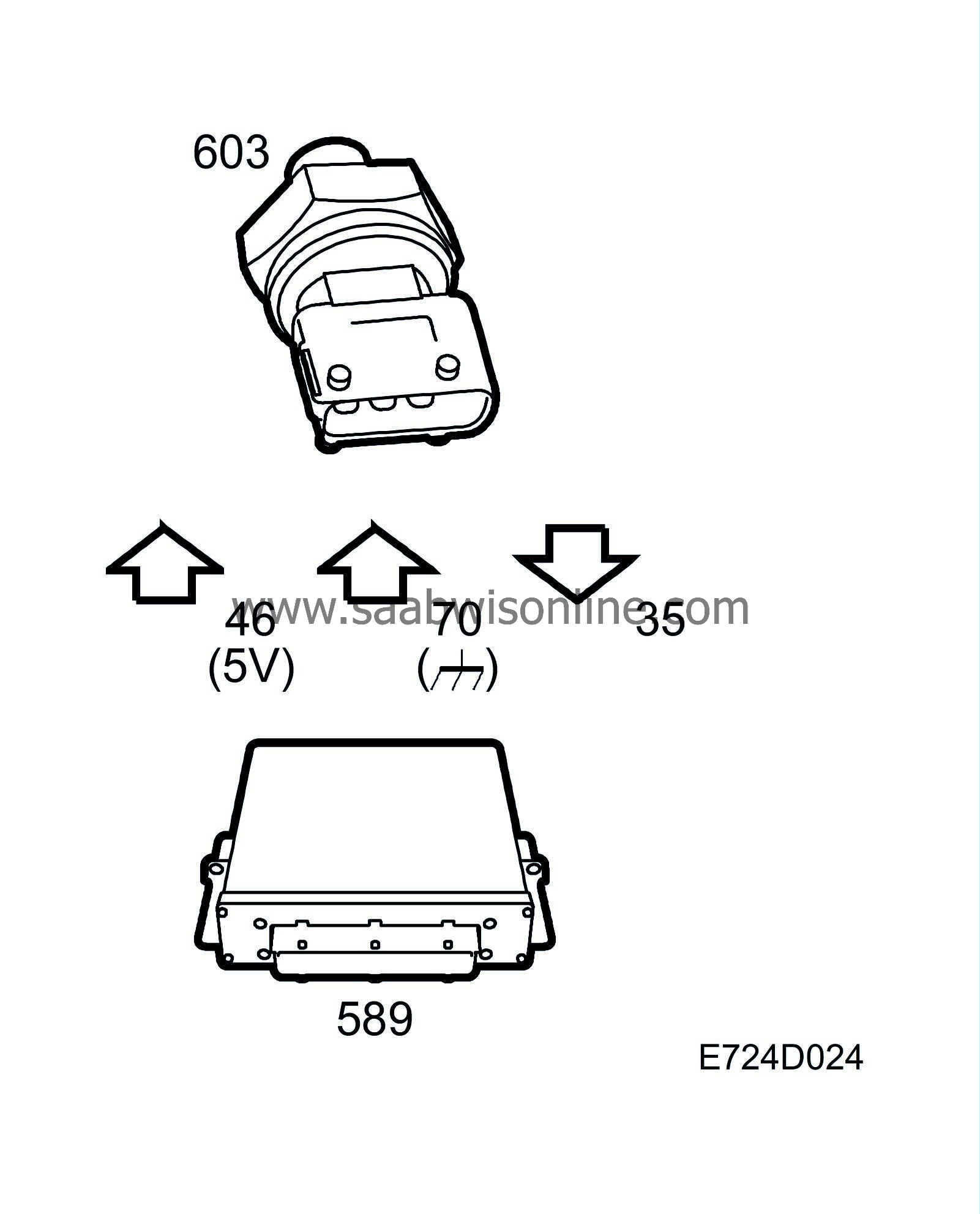

Charge air absolute pressure sensor

| Charge air absolute pressure sensor |

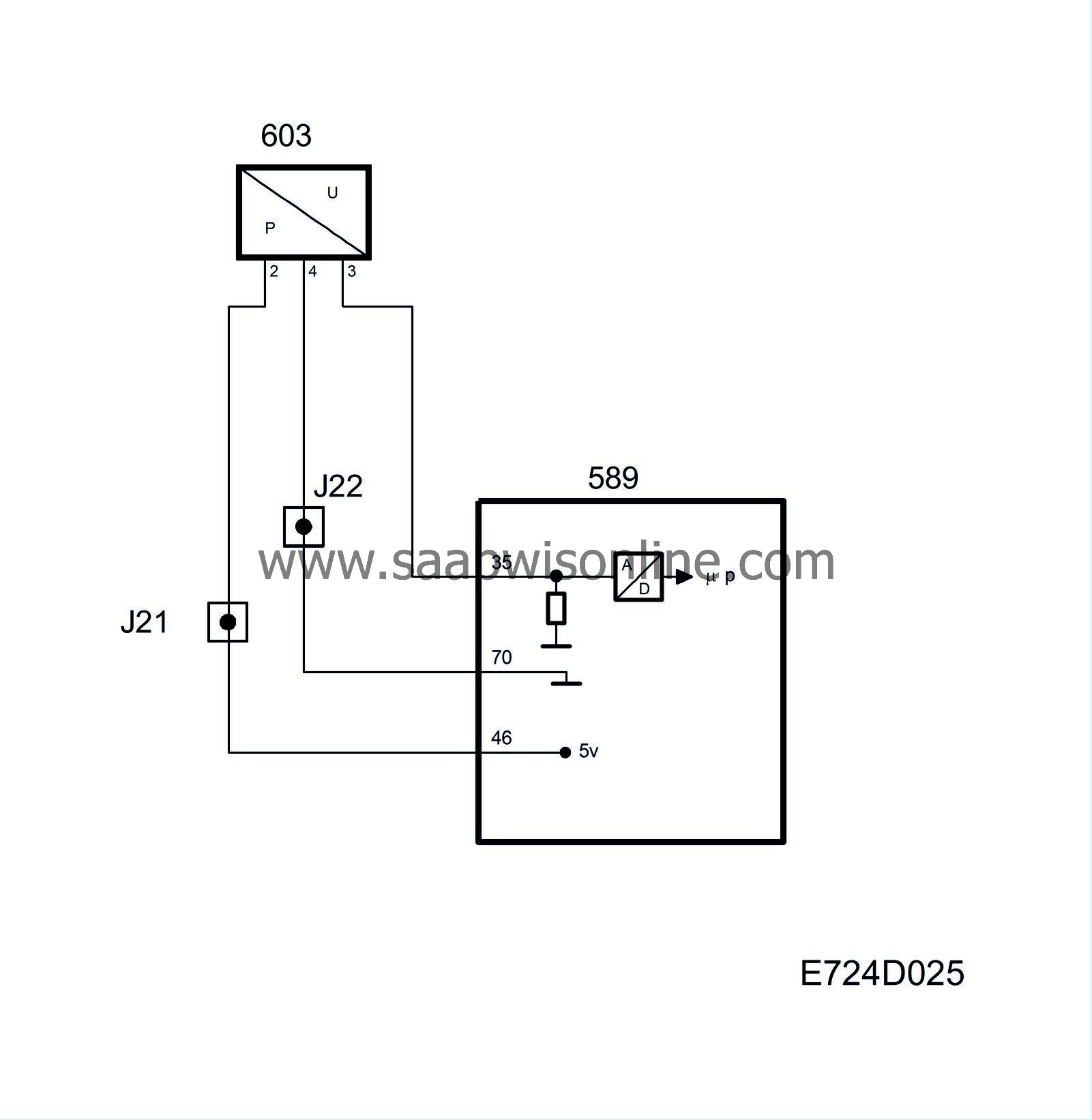

Inside the pressure sensor there are two metal-plated ceramic discs mounted close together. The disc situated closest to the pressure connection is thinner and bends when exposed to pressure. This changes the capacitance between the metal-plated discs depending on the pressure. Integrated in the sensor is a circuit that converts capacitance to analogue voltage. The pressure sensor is connected with a hose to the intake manifold on the engine after the throttle and is powered with 5V from control module pin 46 and grounded from control module pin 70.

Depending on the pressure in the charge air pipe, the pressure sensor delivers a proportional voltage to control module pin 35.

The air mass control determines which air mass/combustion is to be drawn in during the cylinder's induction stroke. The value corresponds to the engine torque.

Throttle control adjusts the throttle so that the current air mass/combustion is the same as the requested.

If the air in front of the throttle has a high density, a smaller throttle angle will be required than if the air density is low. The density of the air is therefore calculated by the control module using the charge air pressure and the intake air temperature.

At normal atmospheric pressure, 100 kPa, the pressure from the sensor is approx. 2.1 V.

| Diagnostics |

| • |

If the sensor voltage is too low, diagnostic trouble code P1107 will be generated.

|

|

| • |

If the sensor voltage is too high, diagnostic trouble code P1108 will be generated.

|

|

| • |

If the pressure value is implausible, diagnostic trouble code P1106 will be generated.

|

|

| • |

If the hose to the sensor breaks, diagnostic trouble code P1105 will be generated.

|

|

System reaction to a fault

| • |

Density compensation of the throttle angle is blocked.

|

|