Gearcase and torque converter shell

|

|

Gearcase and torque converter shell

|

|

Important

|

|

It is very important to observe great cleanliness when working on the gearbox. Dirt particles can seriously damage the function and service life of the gearbox.

|

|

|

|

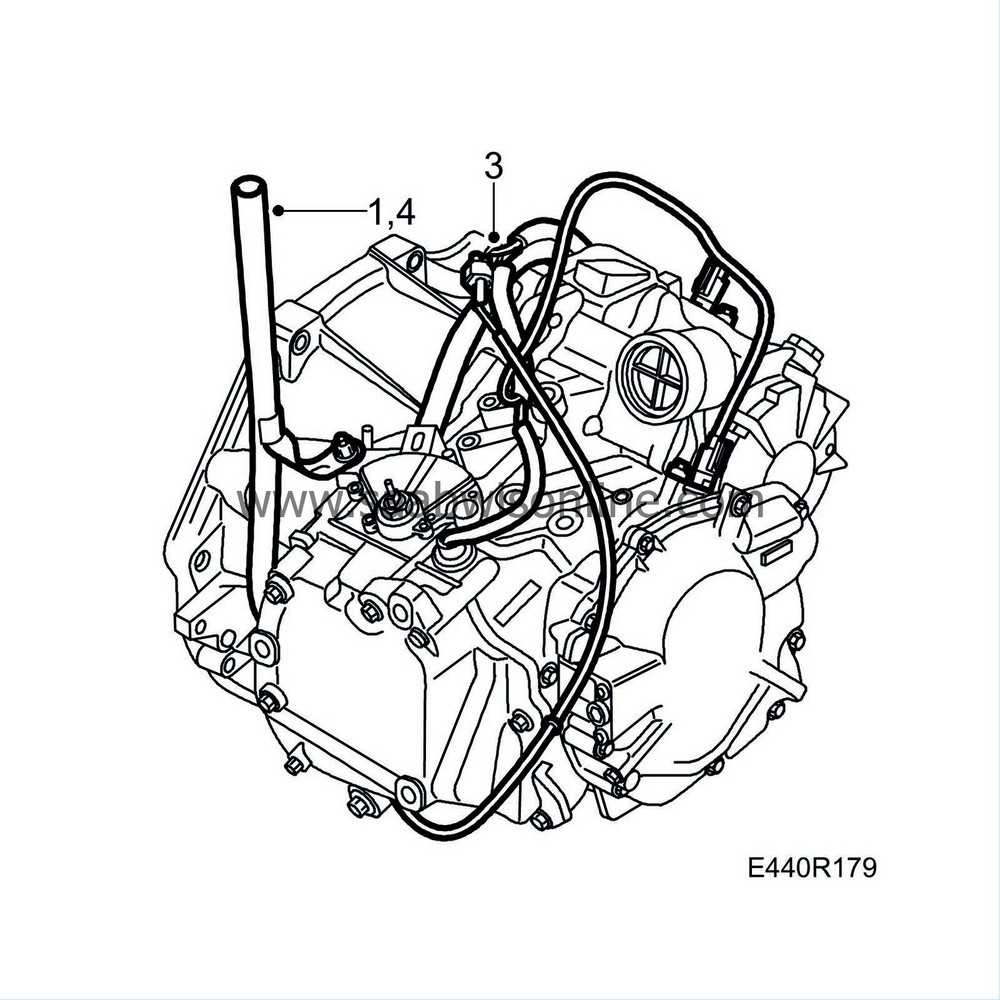

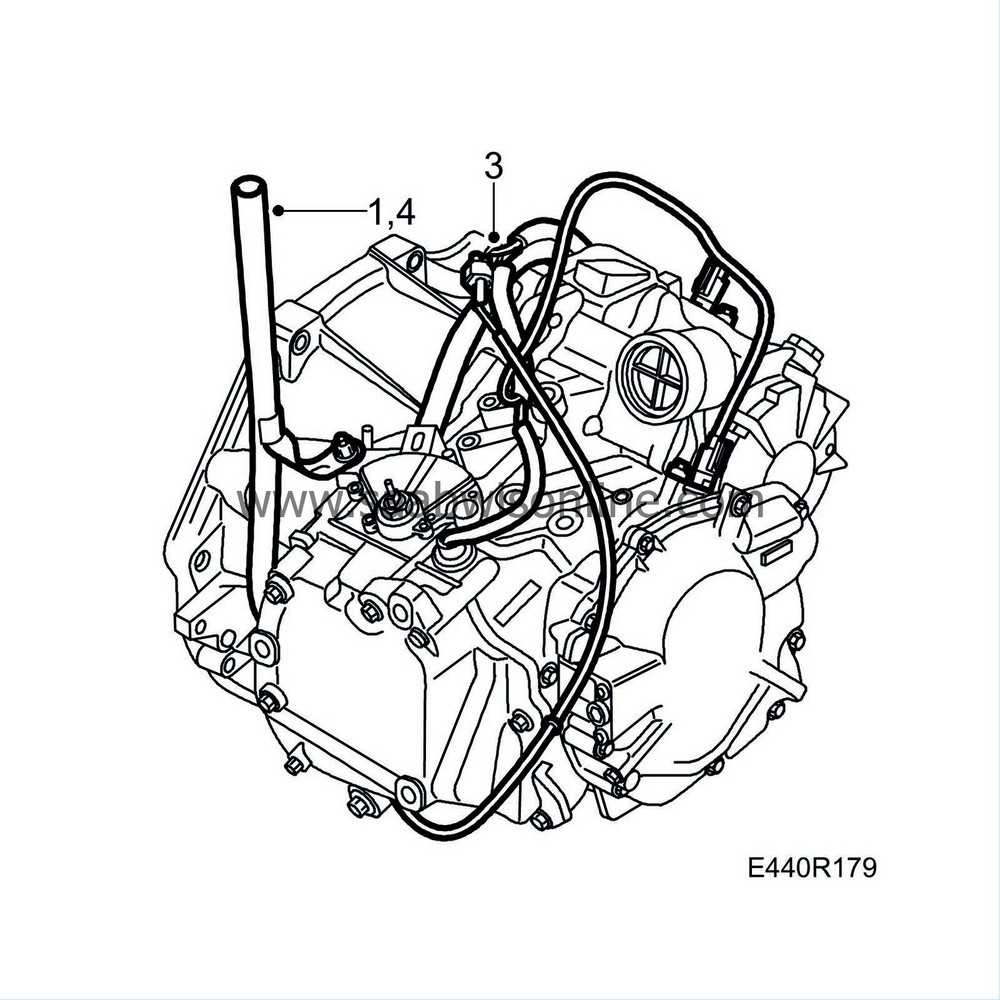

1.

|

Drain the oil from the transmission in the car before starting removal. Remove the gearbox from the car. See removing gearbox assembly. Fit the dipstick pipe.

|

|

2.

|

Plug the shaft openings. Clean the exterior of the gearbox. Use plug 91 32 929, seals 91 32 937 and 87 92 665. Plug the vent pipe.

|

|

3.

|

Unplug the connectors and remove the wiring harness.

|

|

4.

|

Remove the dipstick pipe.

|

|

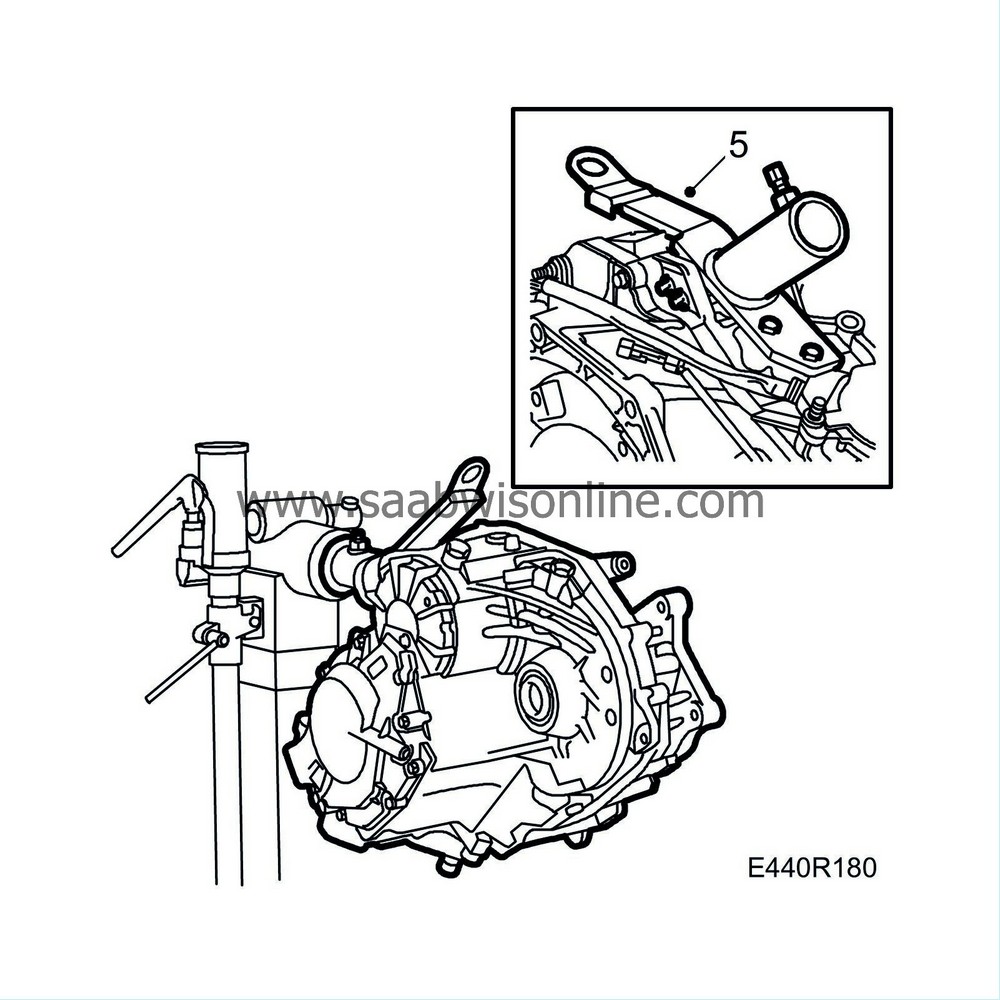

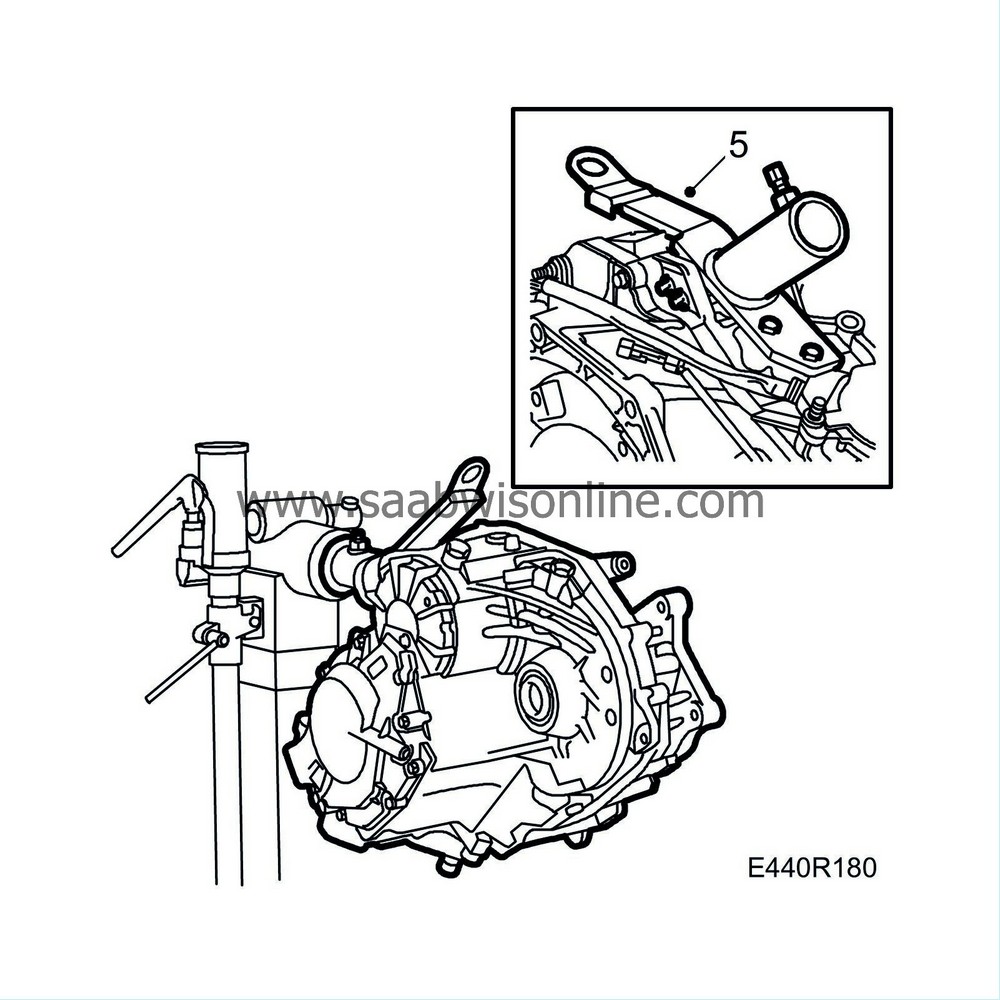

5.

|

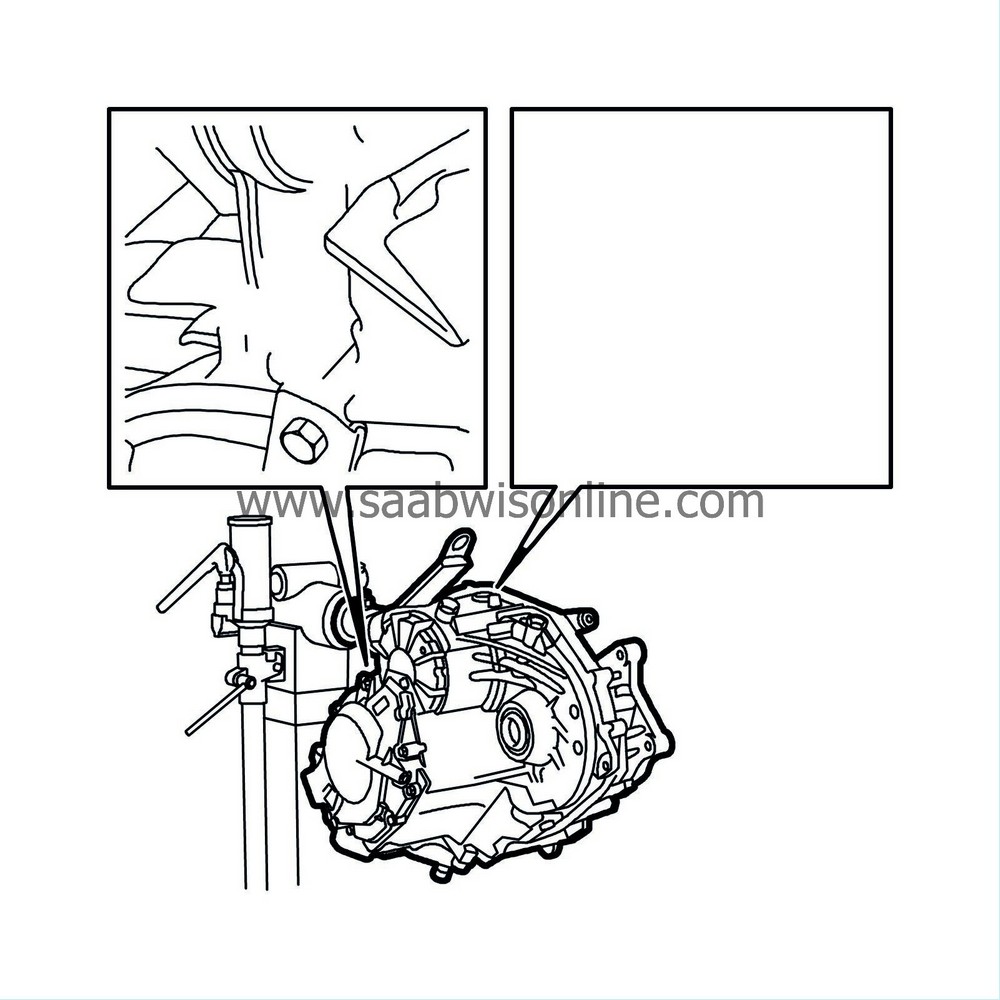

Fit holder 87 92 392 on the gearbox using flange screw M8x25.

|

Note

|

|

Organise the workplace so that groups of associated parts that are dismantled can be kept together to facilitate refitting.

|

|

|

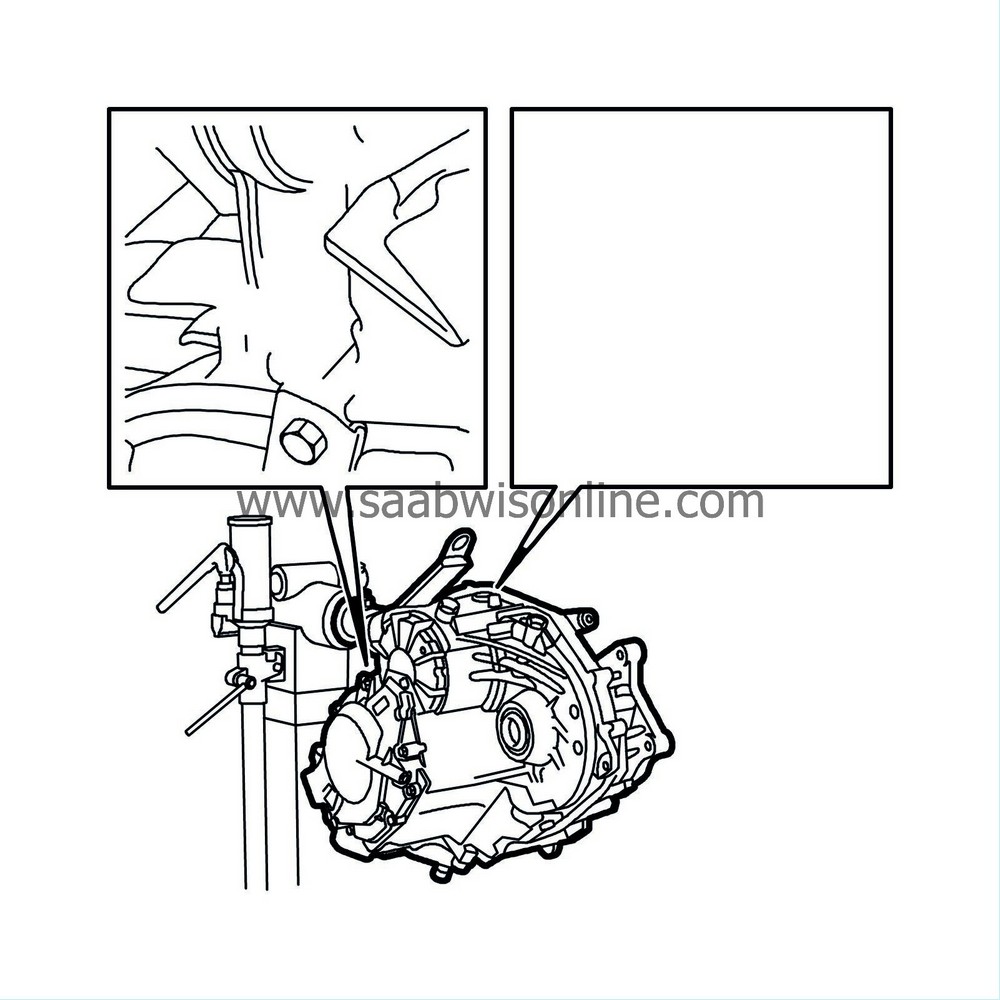

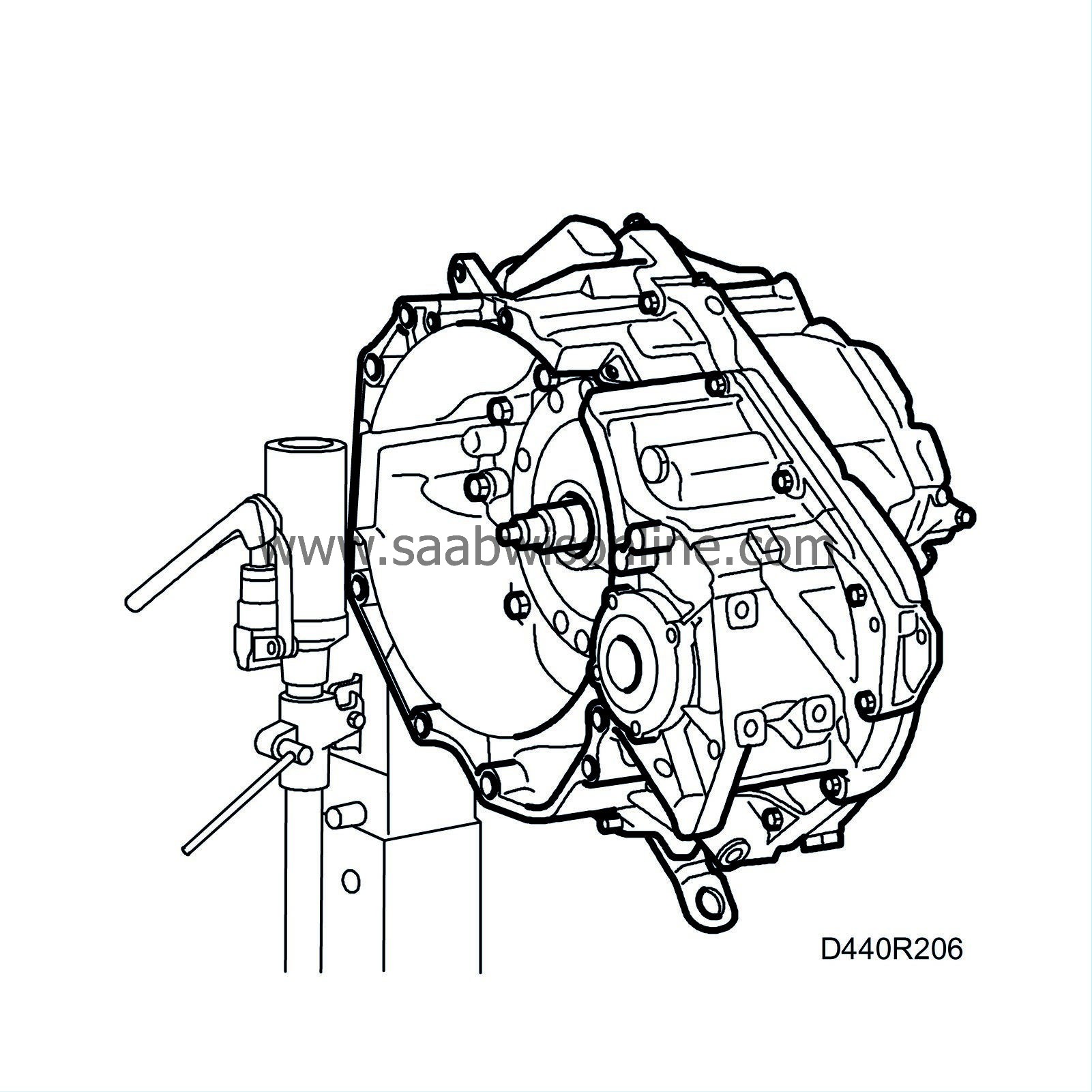

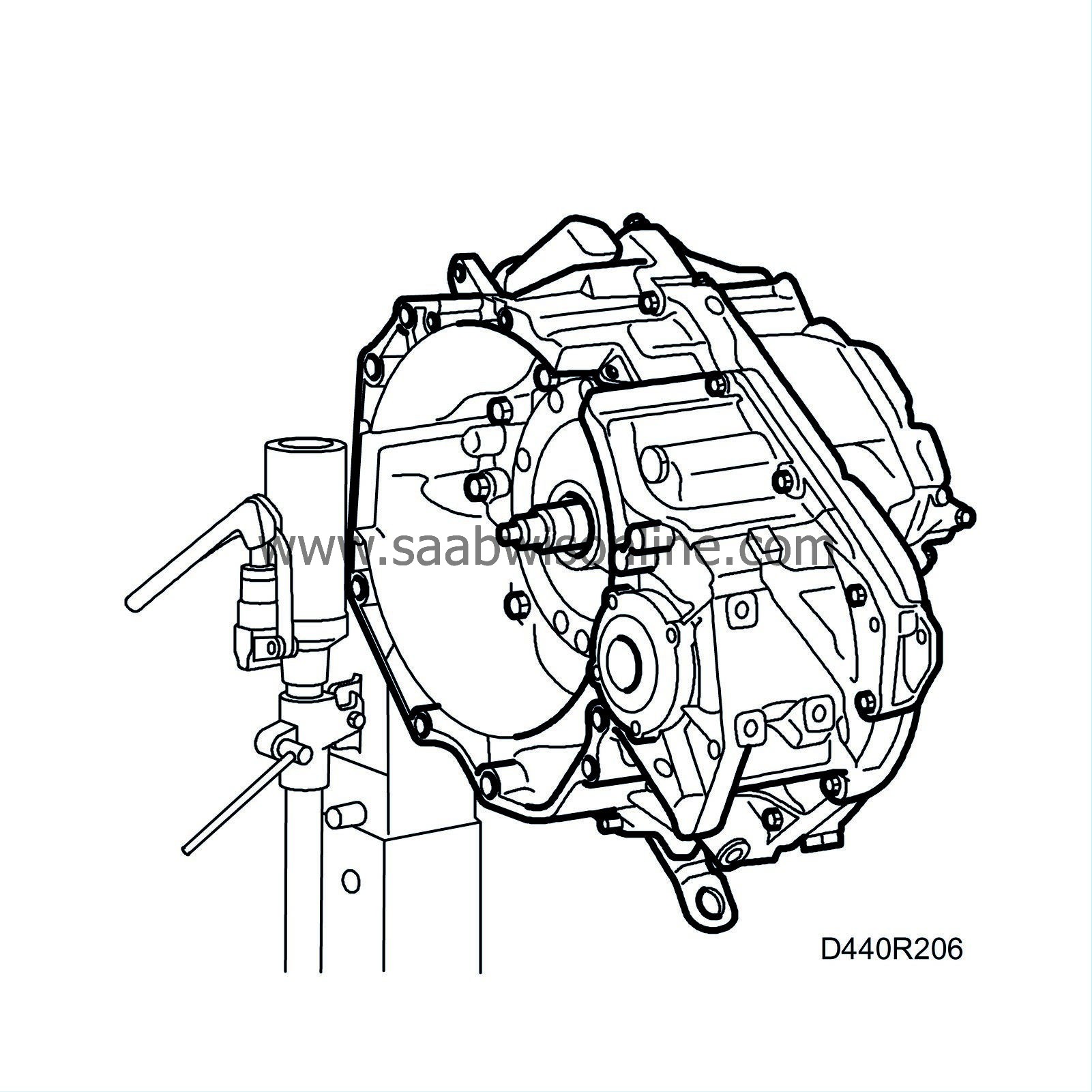

6.

|

Mount the gearbox in stand 78 74 878.

|

|

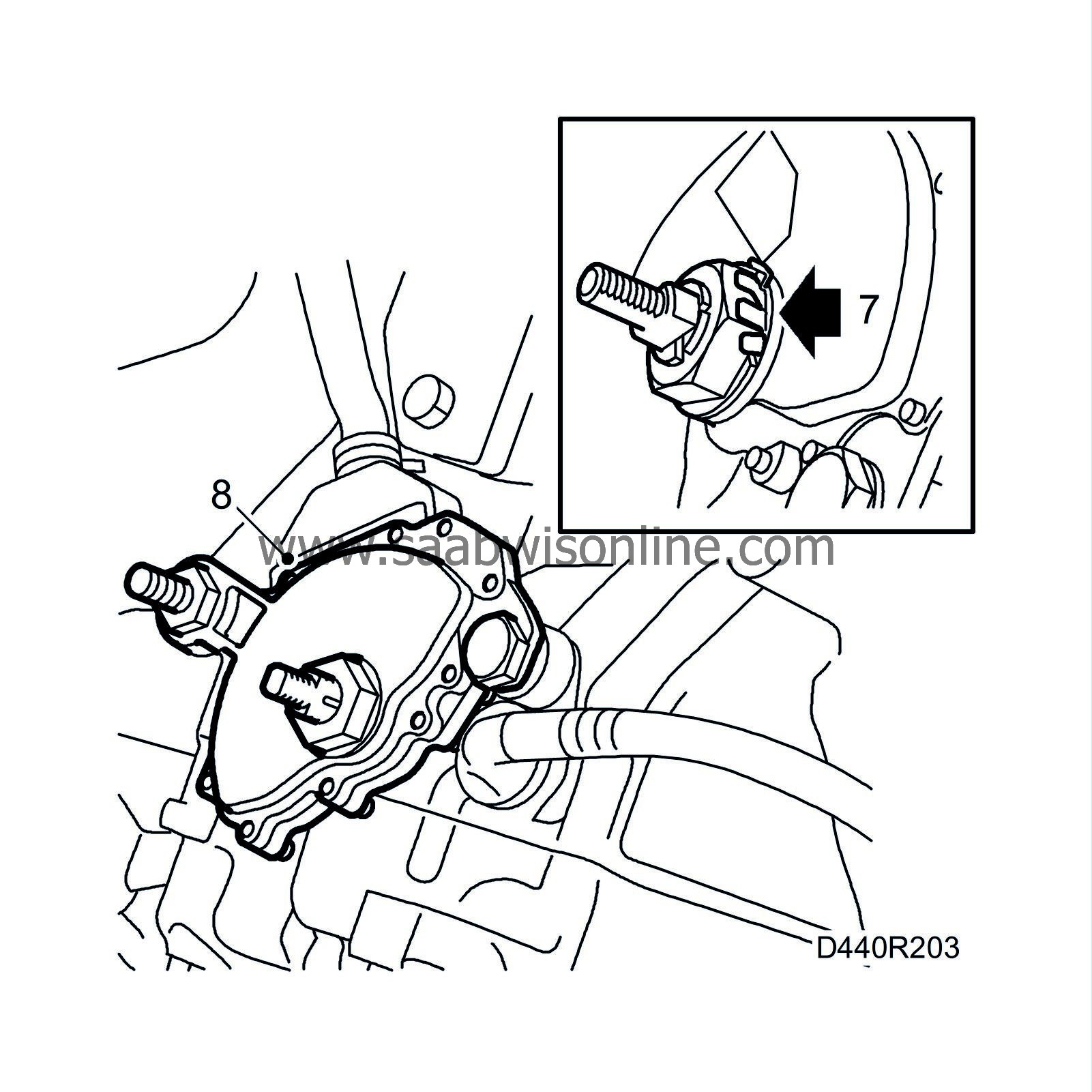

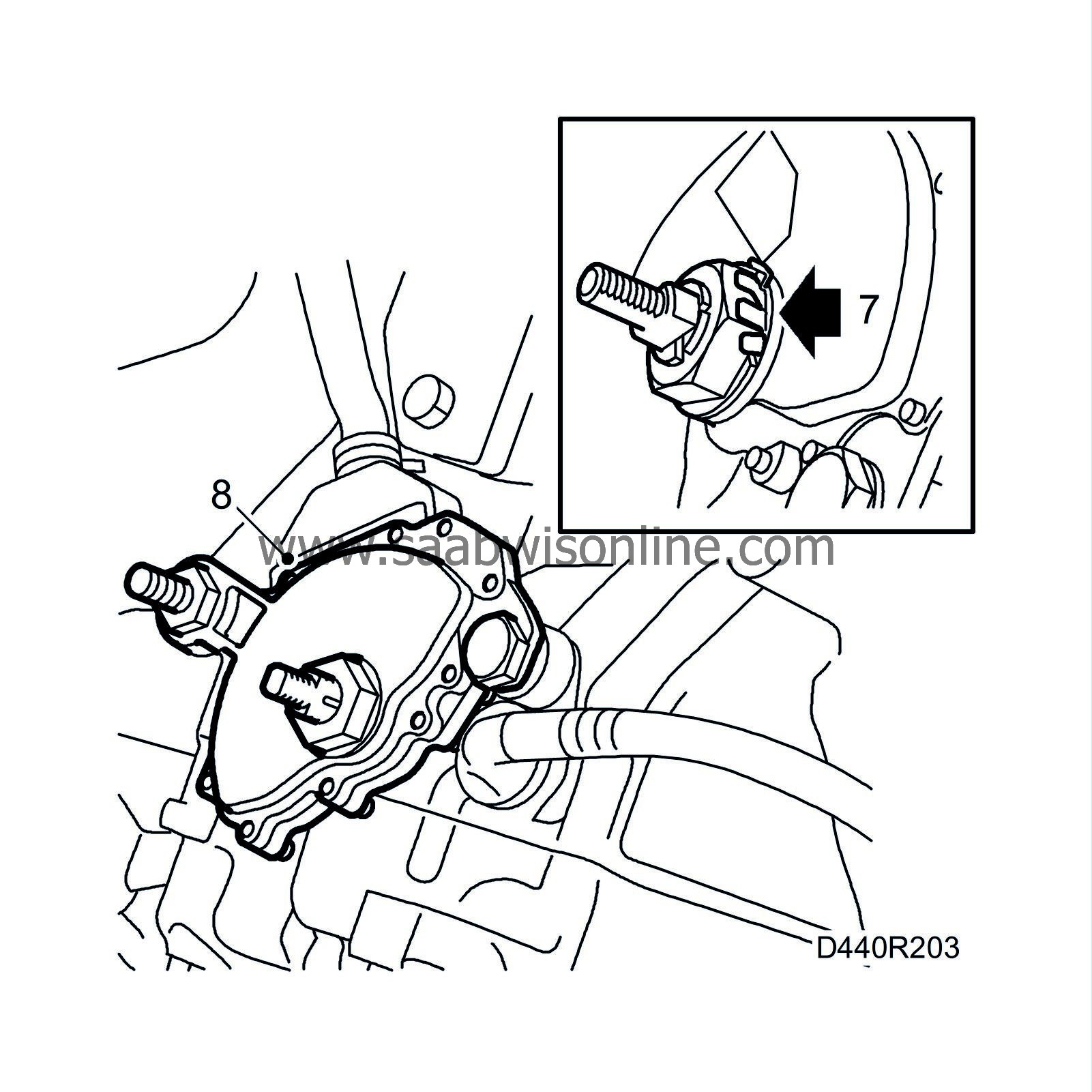

7.

|

Bend out the lock washer for the gear position sensor nut and loosen the nut slightly.

|

|

8.

|

Remove the gear position sensor.

|

|

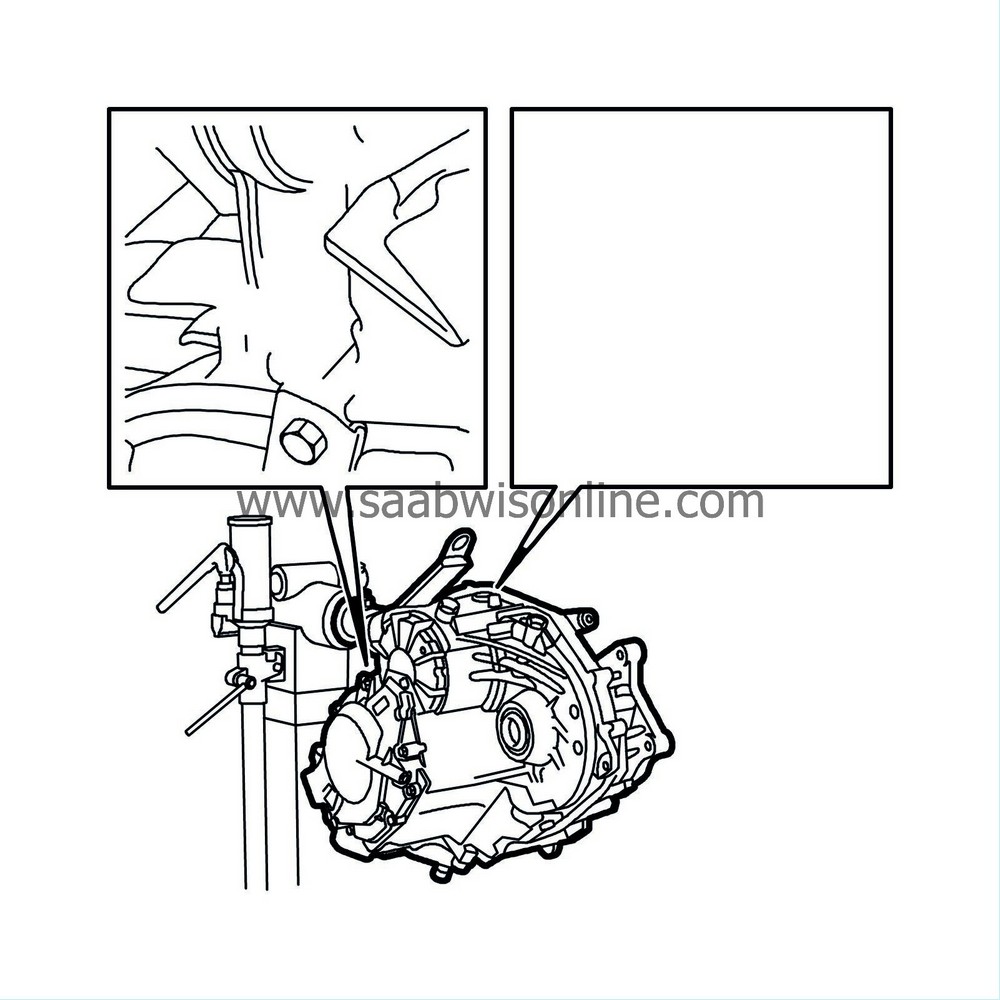

9.

|

Unplug the connectors to the speed sensors and the temperature sensor. Remove the speed sensors.

|

|

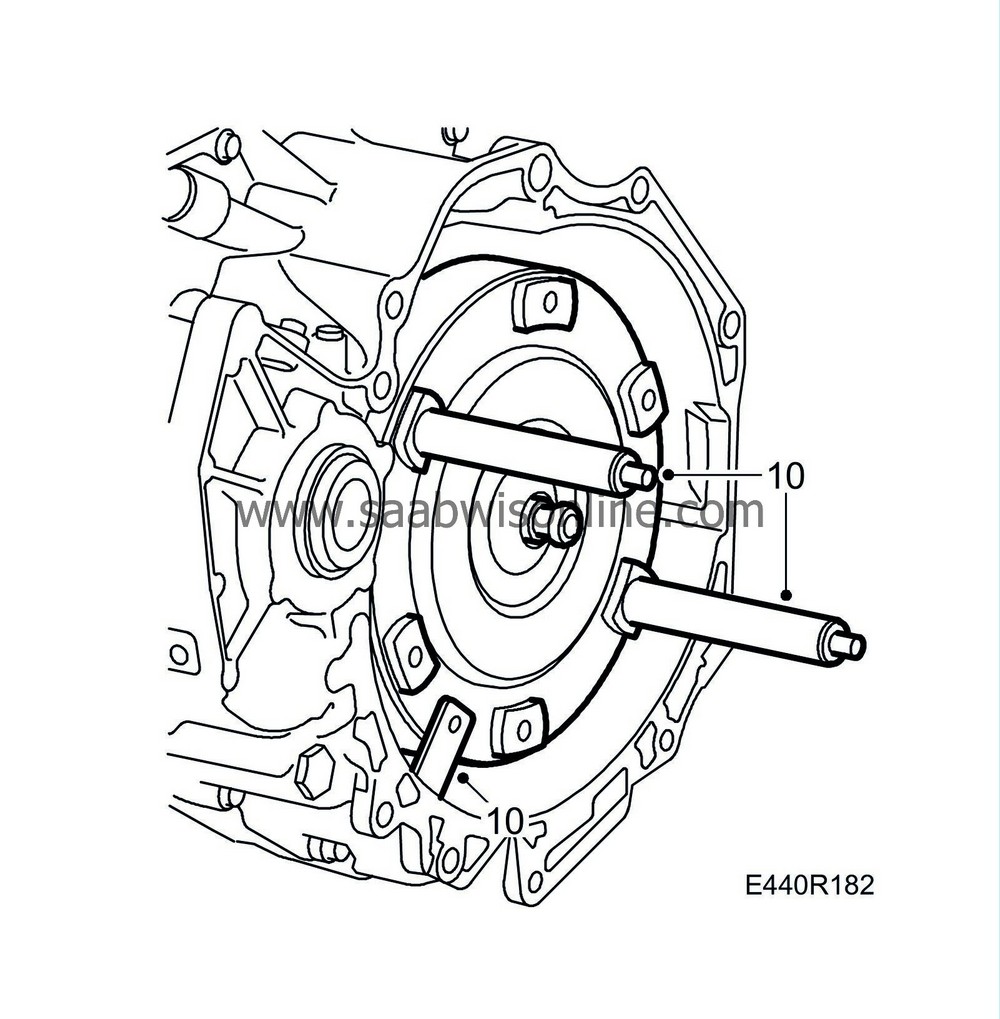

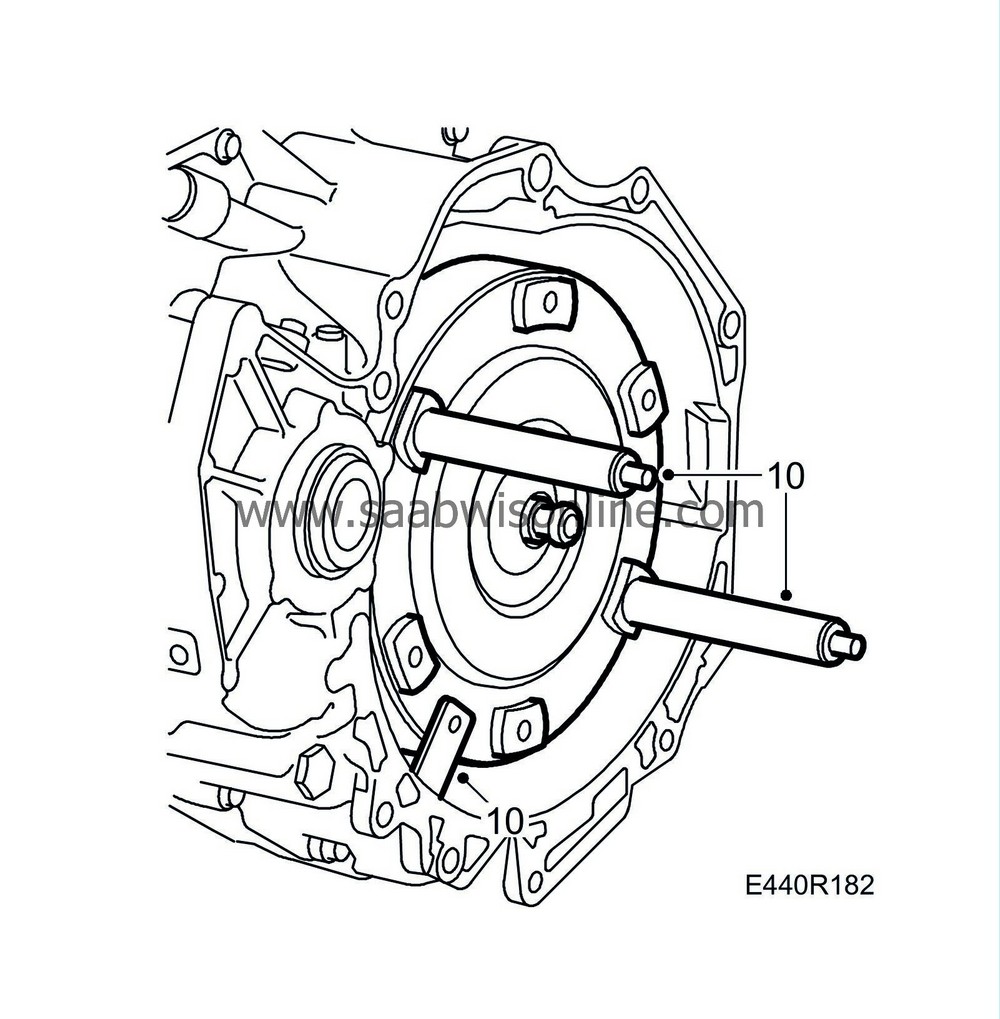

10.

|

Fit tool 87 91 766 into the torque converter. Remove holder 87 92 574. Remove the torque converter.

|

|

11.

|

Turn the gearbox through 180° in the stand.

|

|

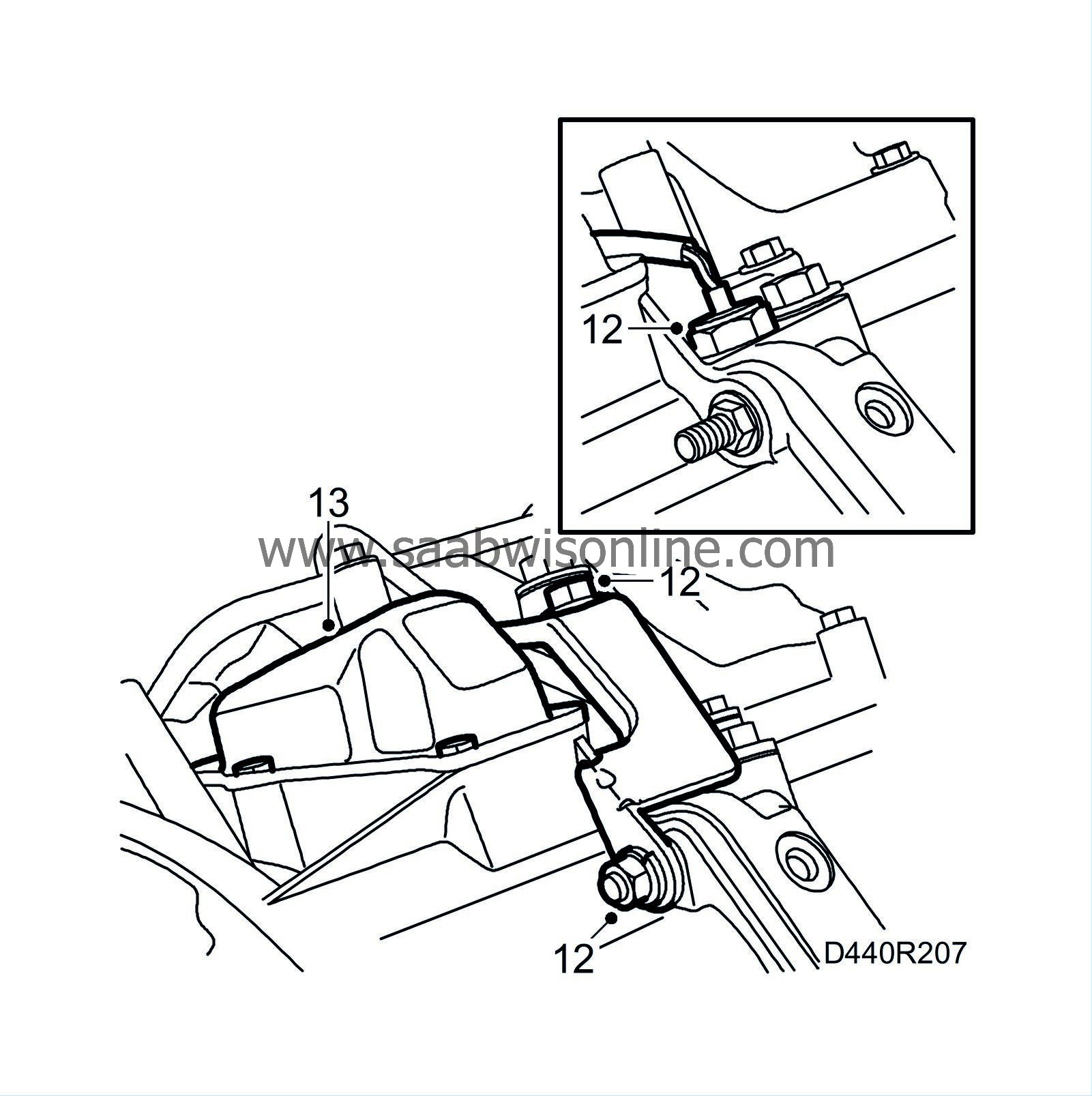

12.

|

Remove the cover plate and the temperature sensor.

|

|

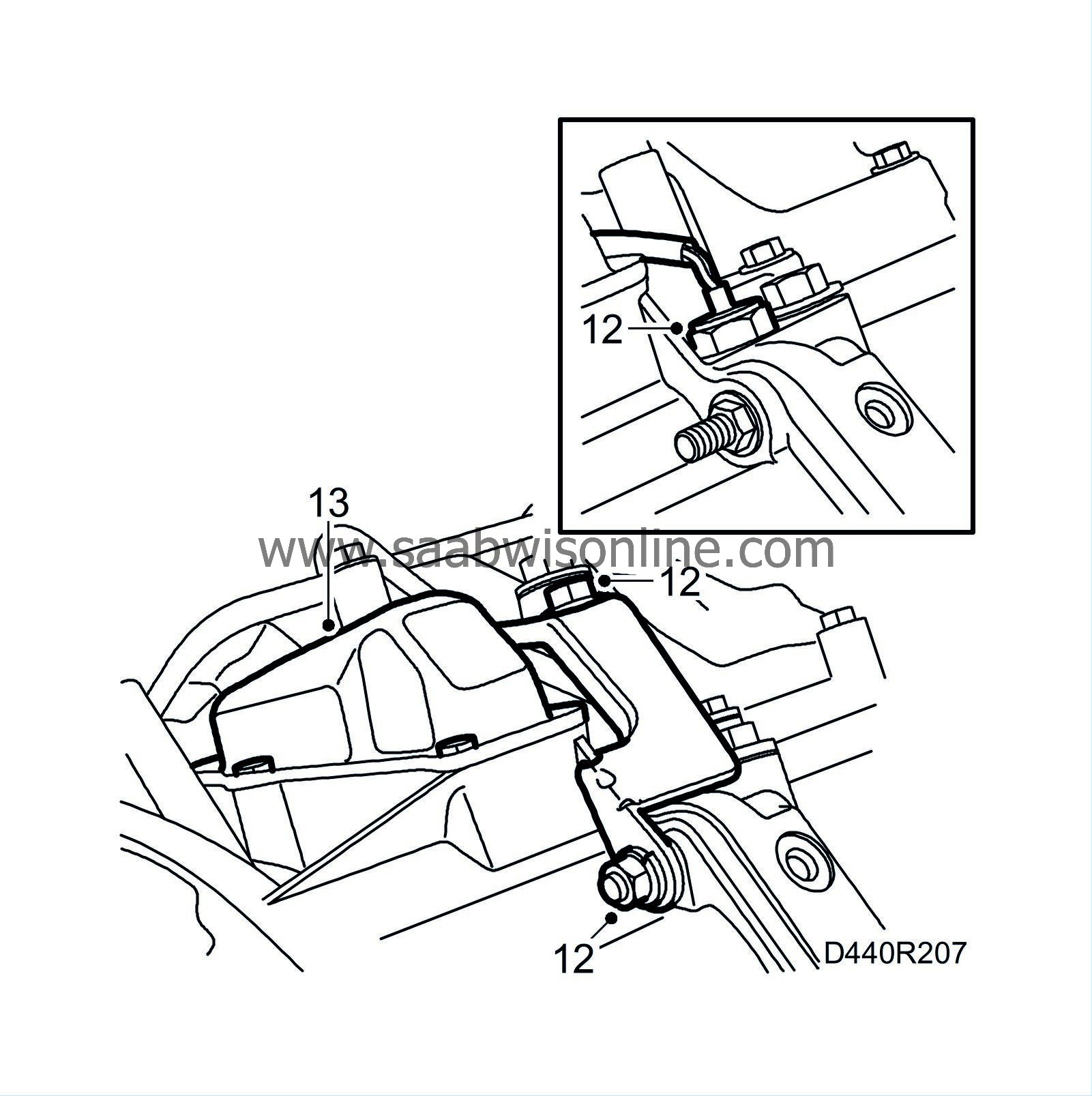

13.

|

Remove the plate cover on the torque converter shell.

|

|

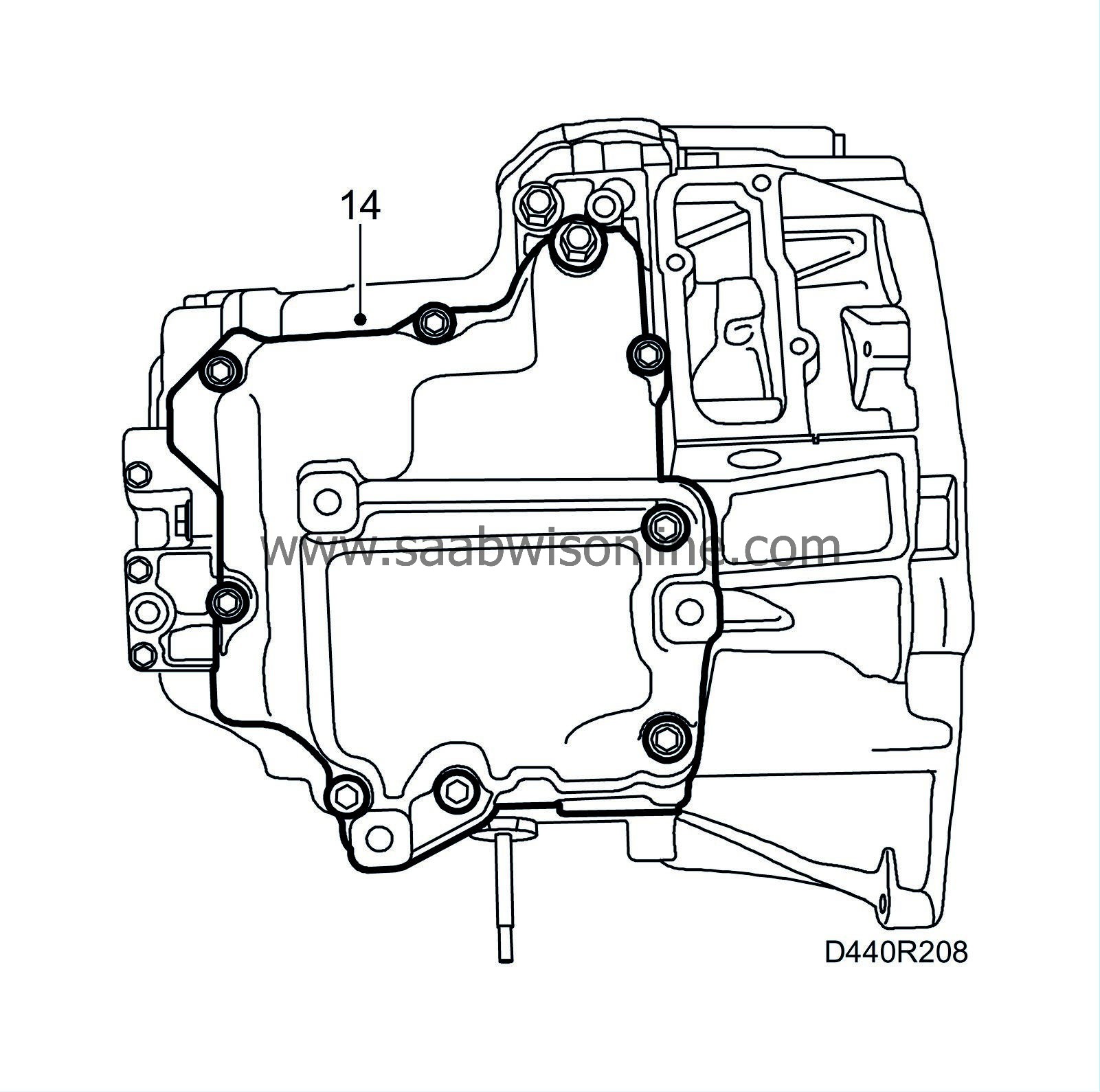

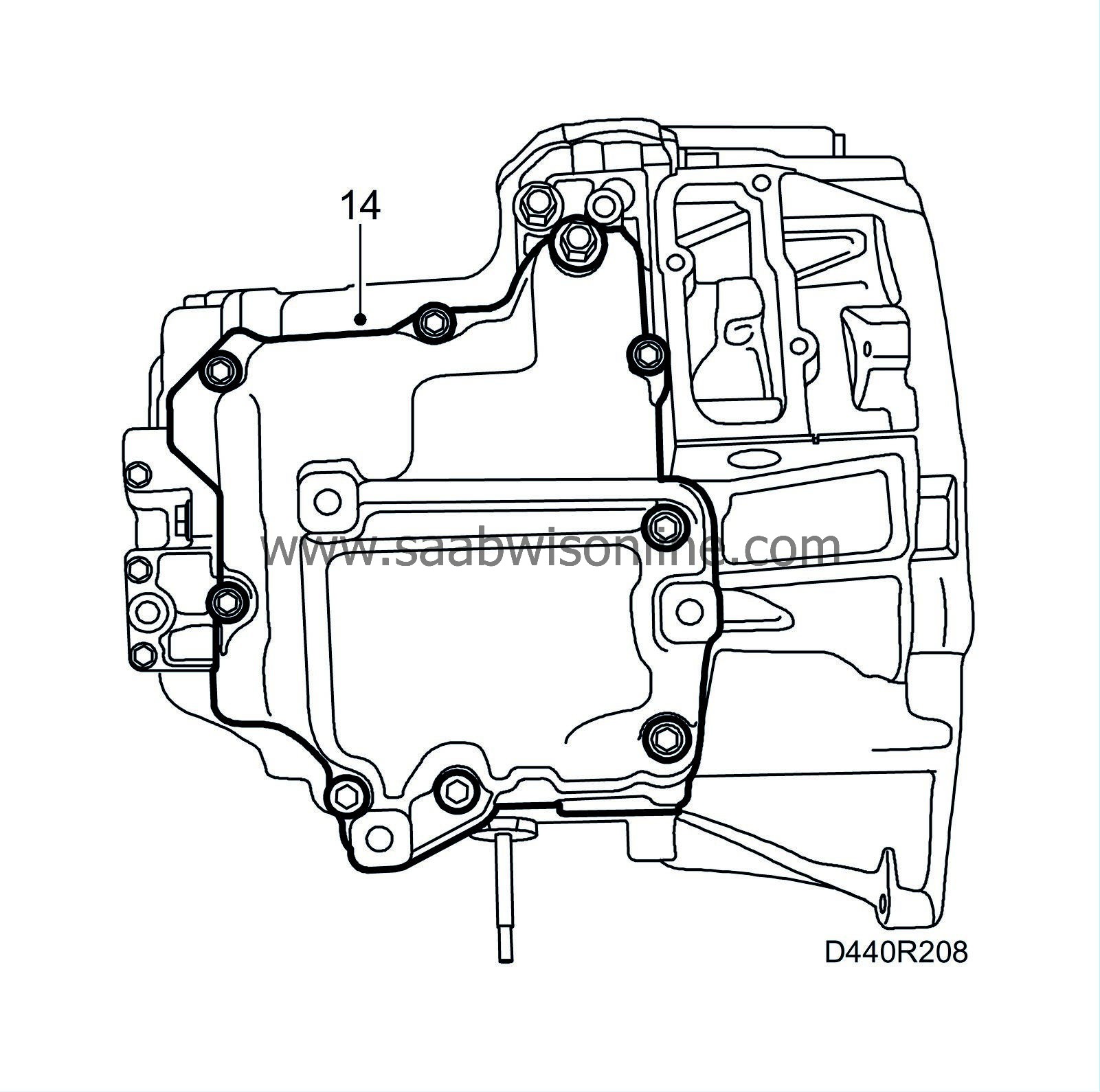

14.

|

Remove the bolts securing the valve body cover and knock loose the cover using a splinter-free plastic mallet.

|

Important

|

|

Take care that the sealing surfaces are not damaged.

|

|

|

|

|

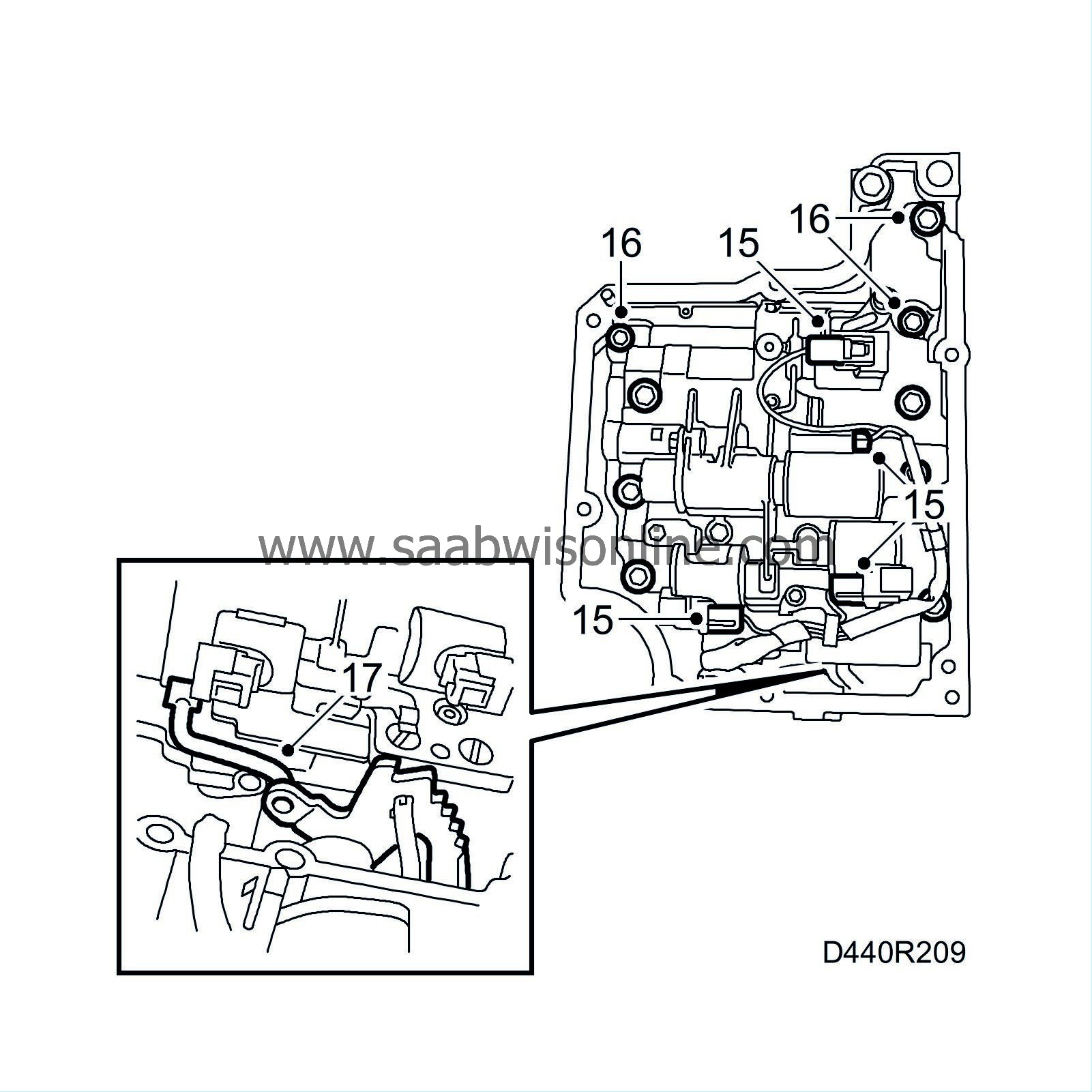

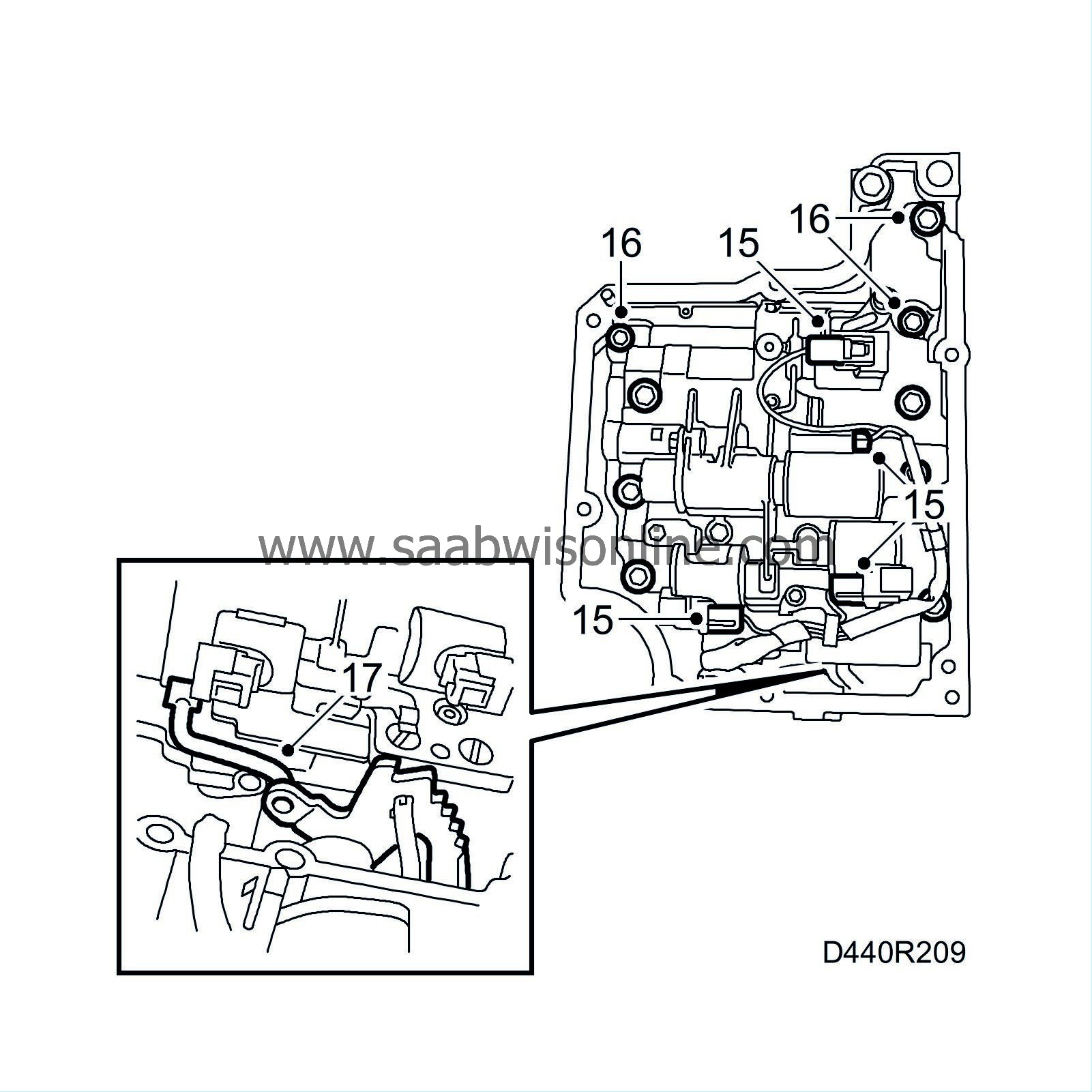

15.

|

Disconnect the solenoid electric connections. Lift the system pressure solenoid shell slightly using a small screwdriver to access the catch. Unhook the cable. Pull out the cable and grommet from the gearcase. Retain the holder.

|

|

16.

|

Remove the valve body bolts (only bolts with 10 mm head). Retain the small cover.

|

|

17.

|

Unhook the manual valve connecting rod from the valve control and remove the valve body.

|

|

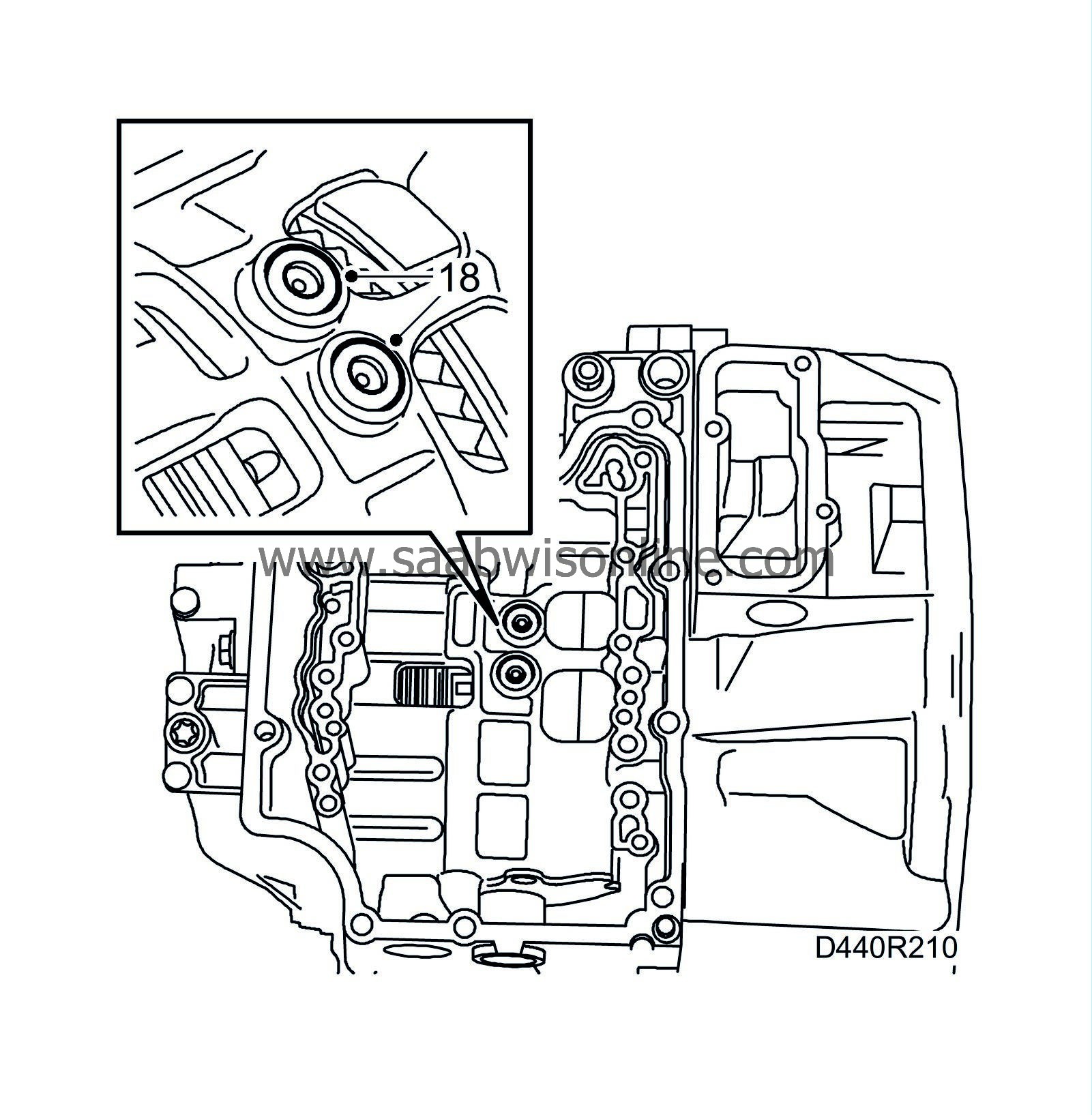

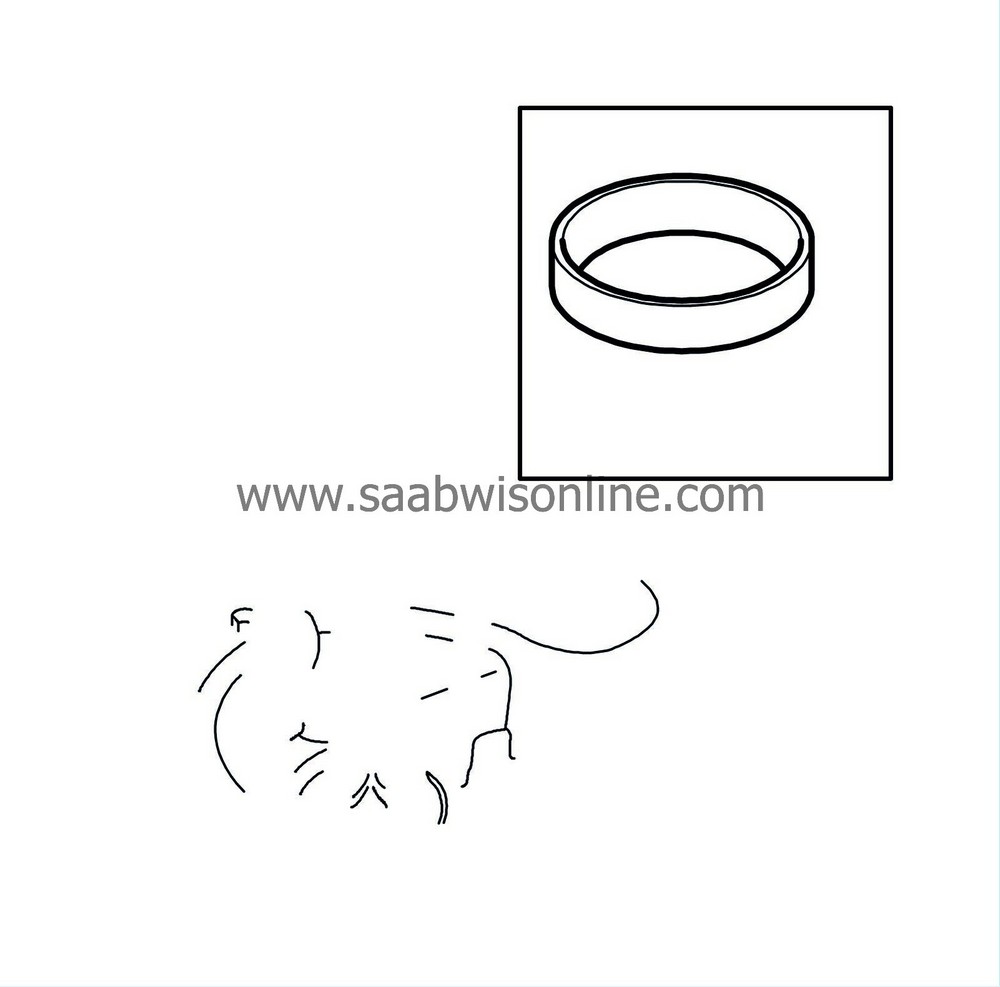

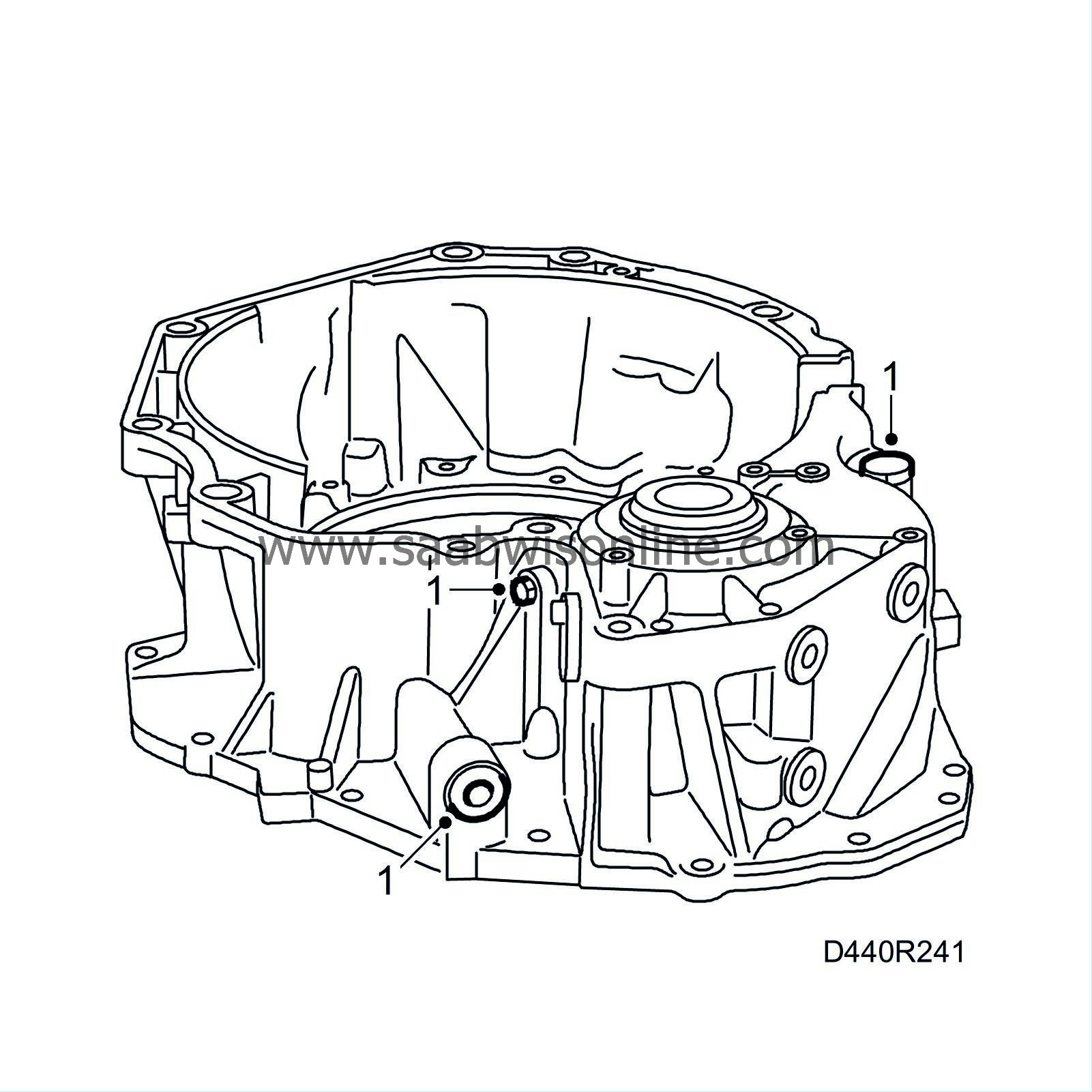

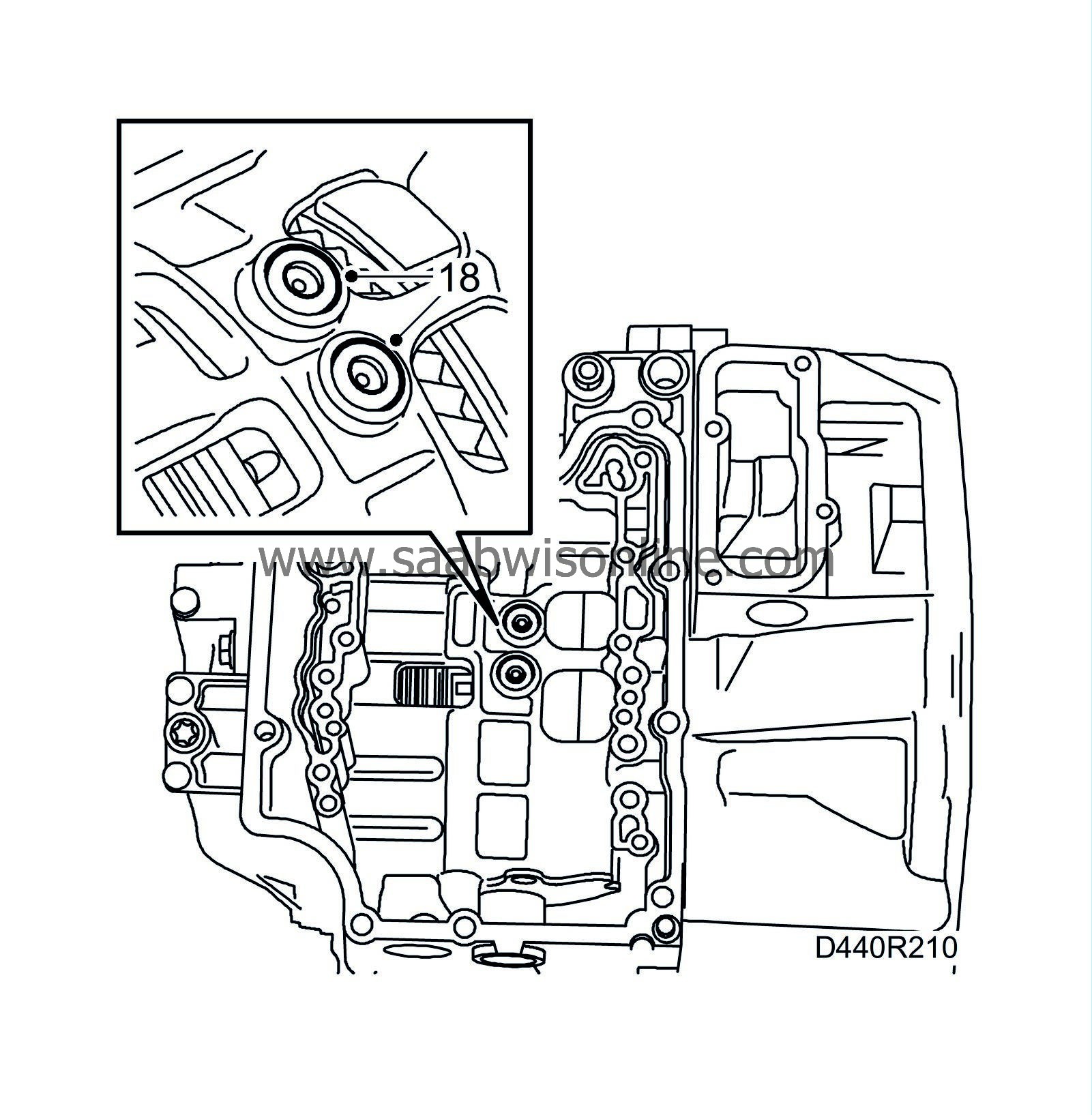

18.

|

Remove the two seals.

|

|

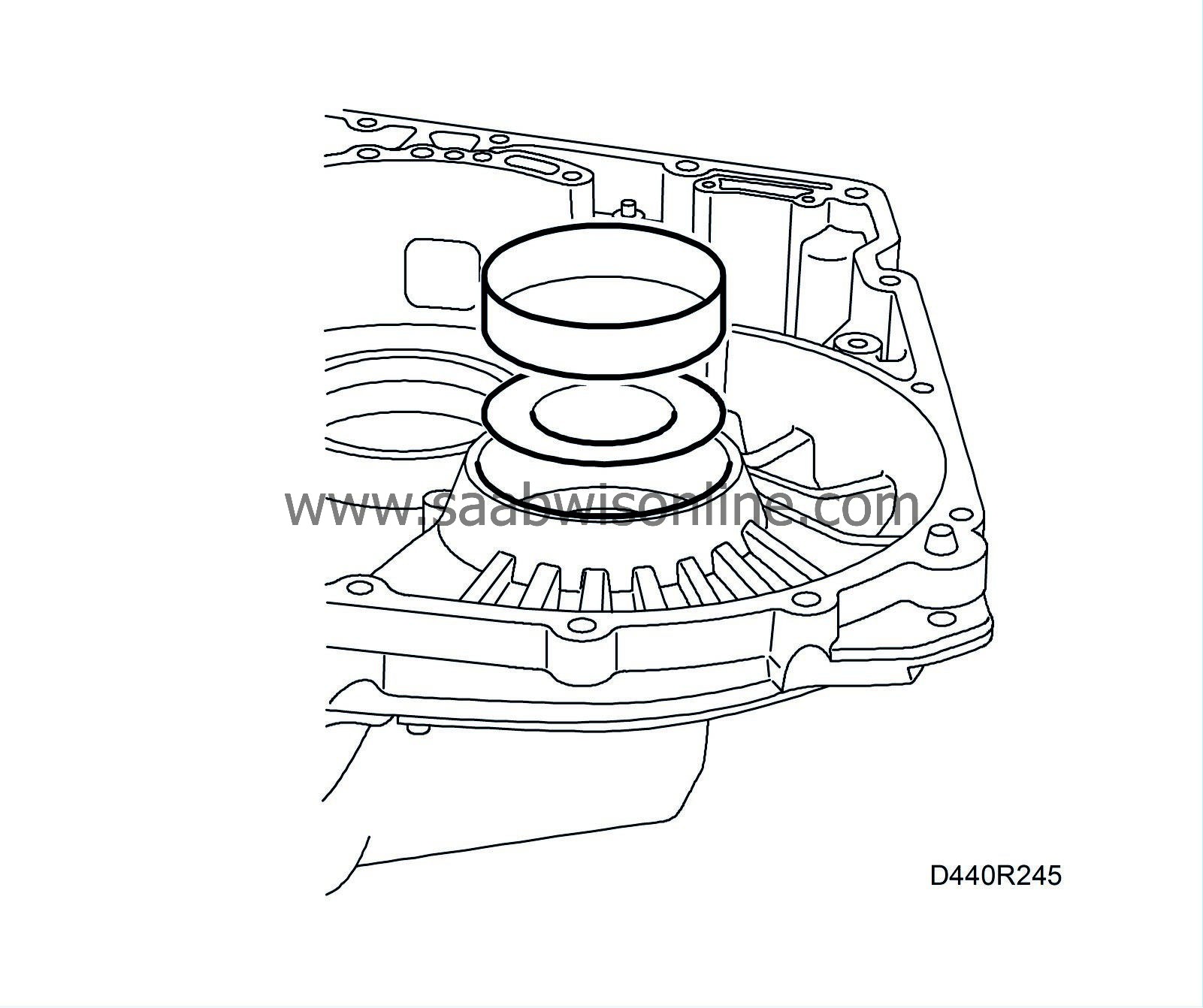

19.

|

Remove the bolts securing the oil pump to the gearcase.

|

|

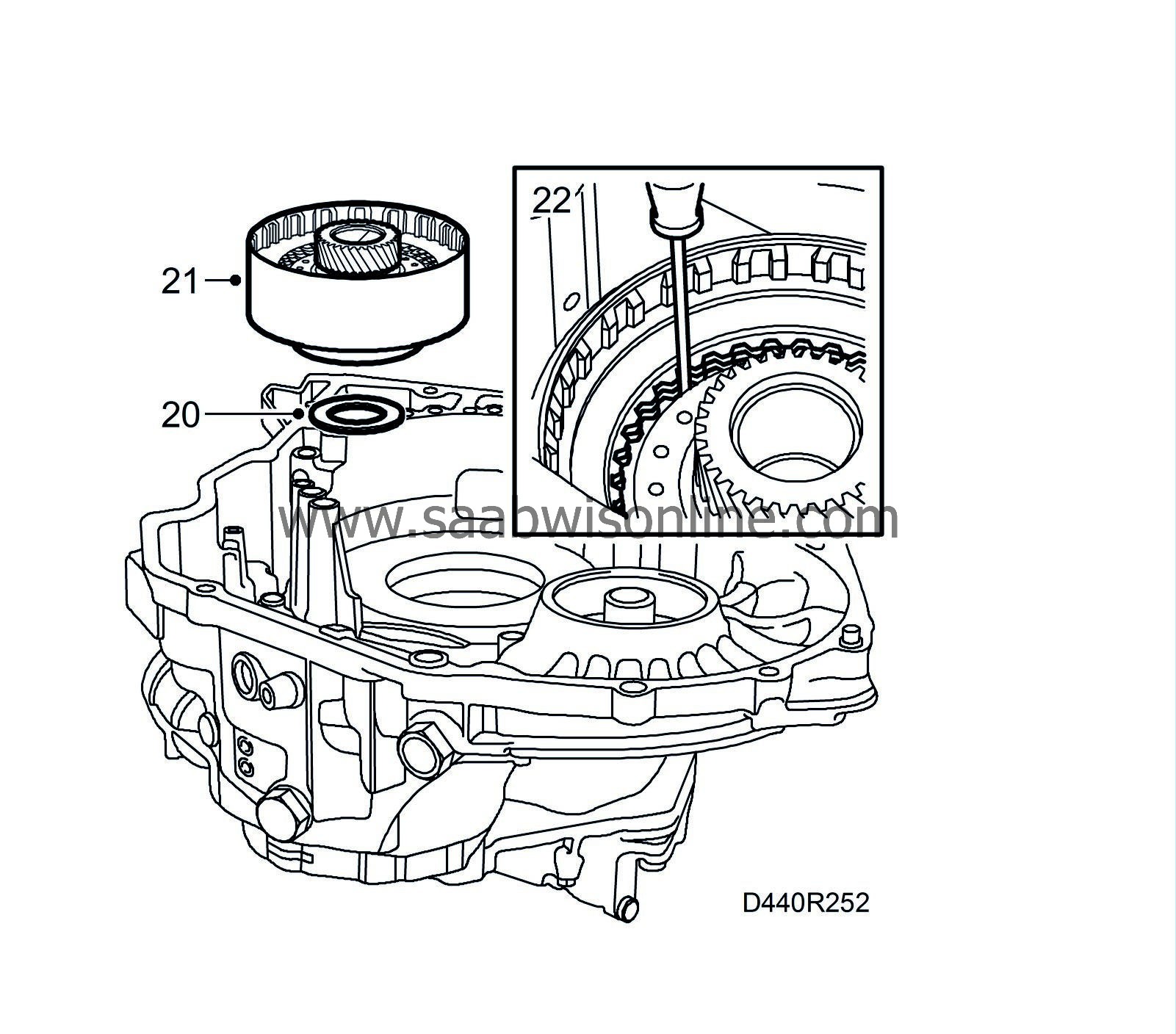

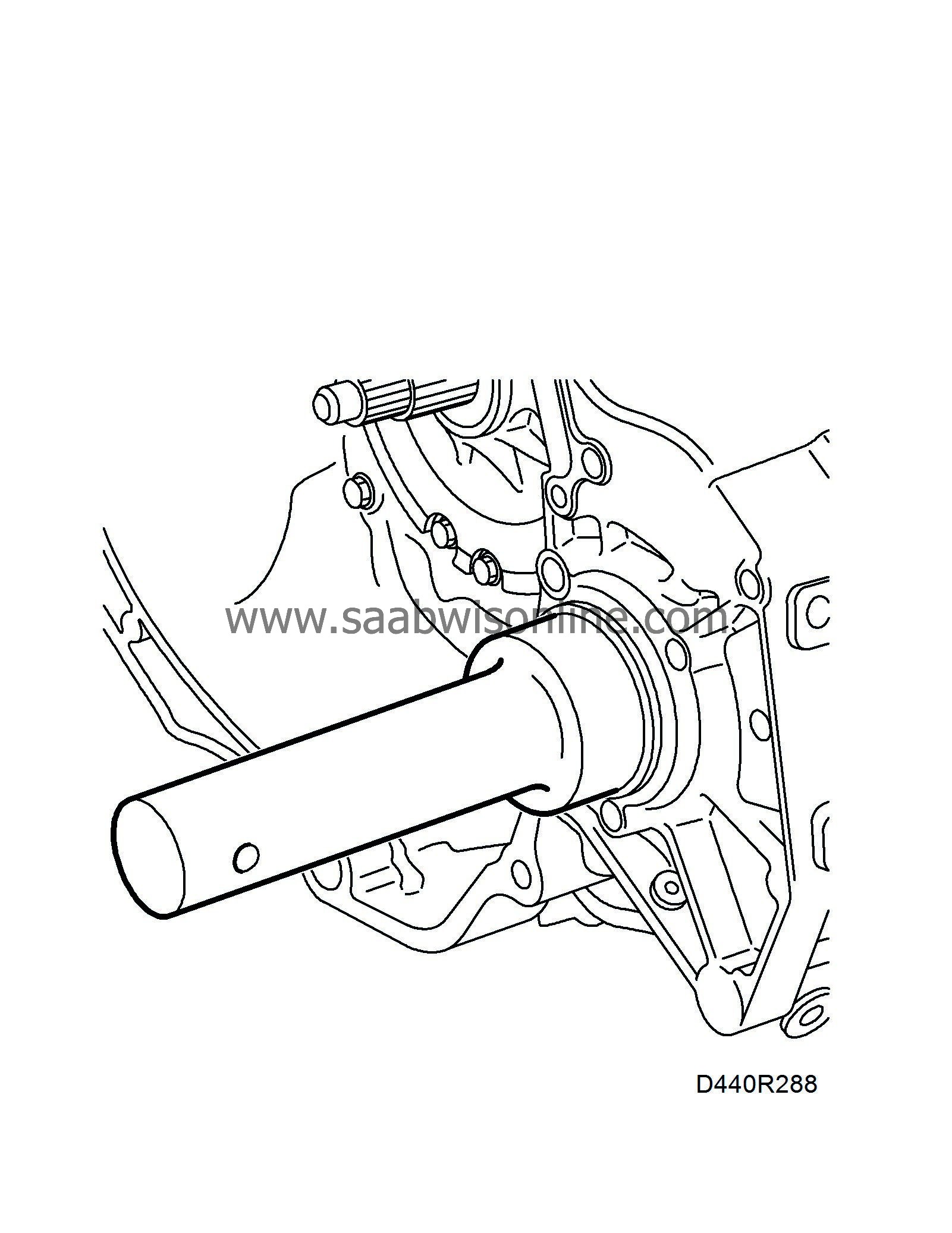

20.

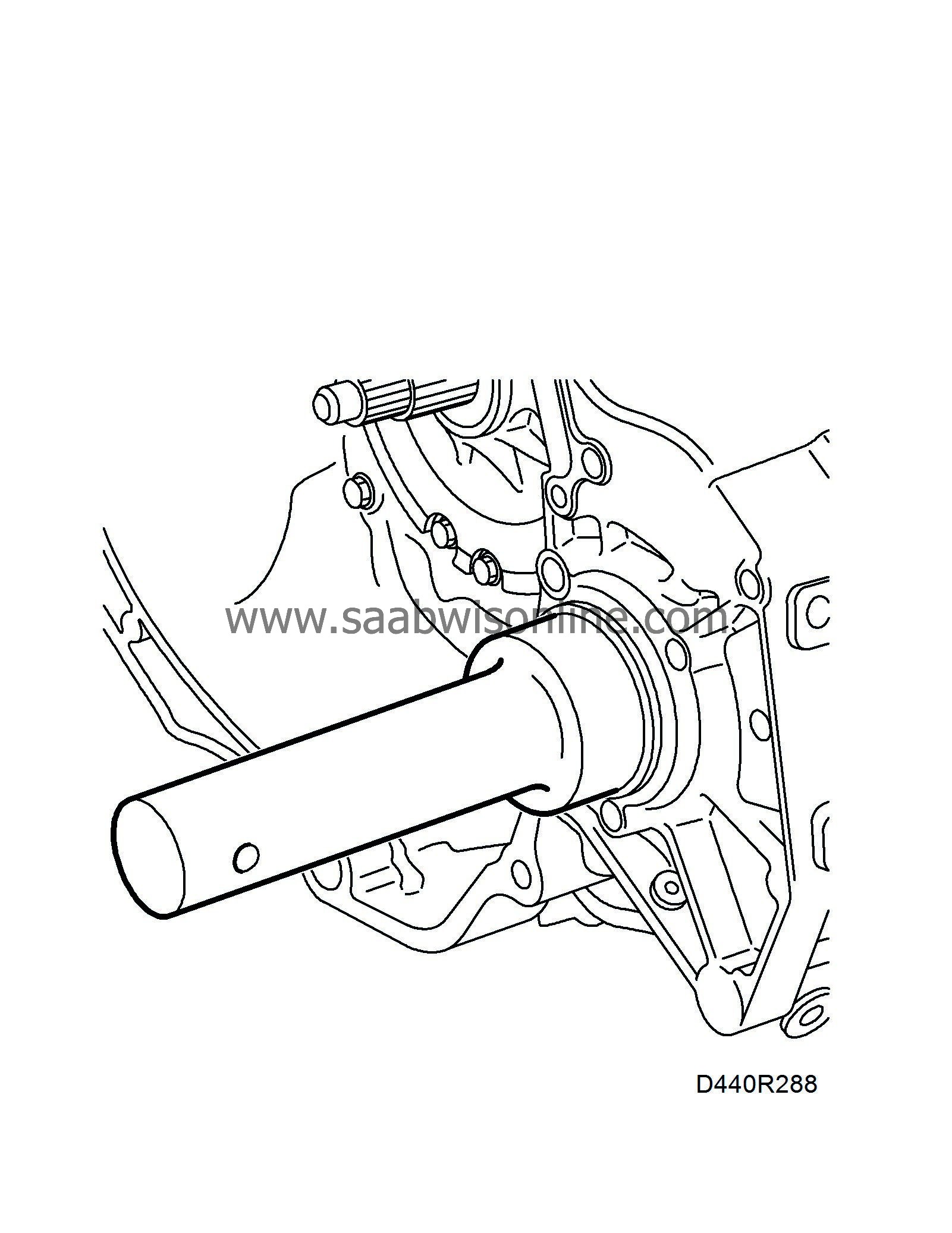

|

Pull off the oil pump and brake unit B2 from the gearcase using puller 87 92 699.

|

|

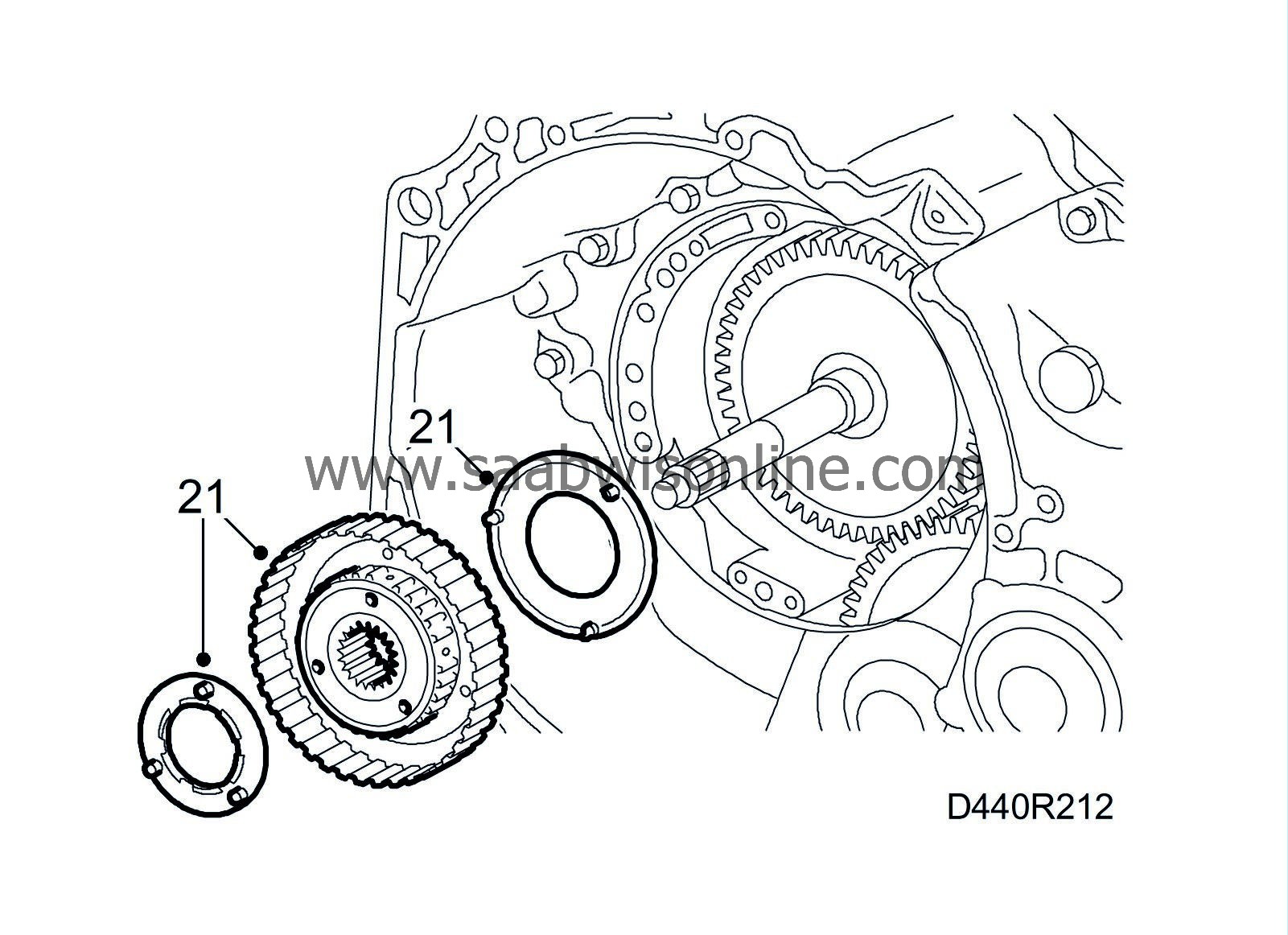

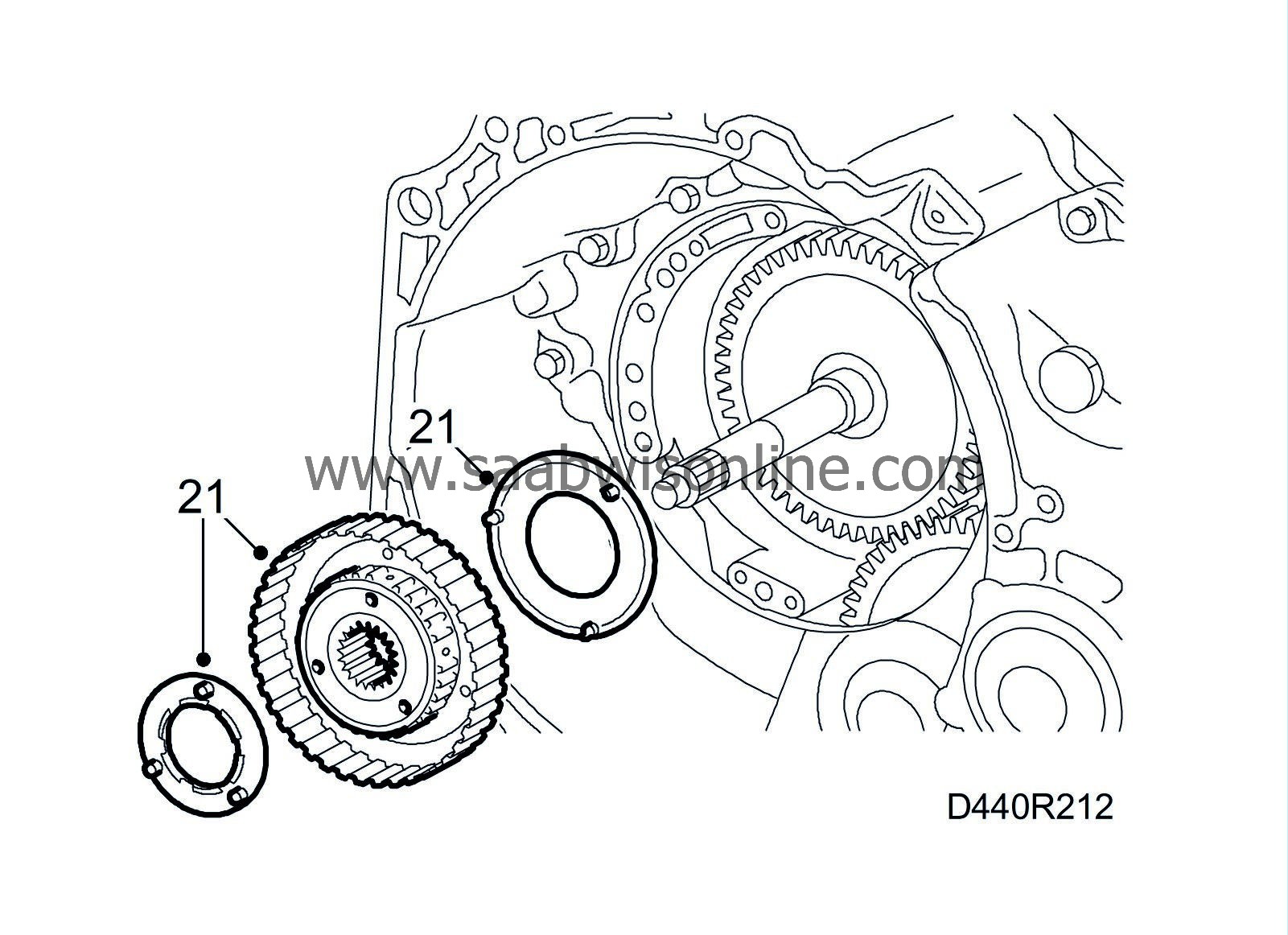

21.

|

Remove the brake hub and freewheel F1.

|

|

22.

|

Turn the gearbox through 90° in the stand.

|

|

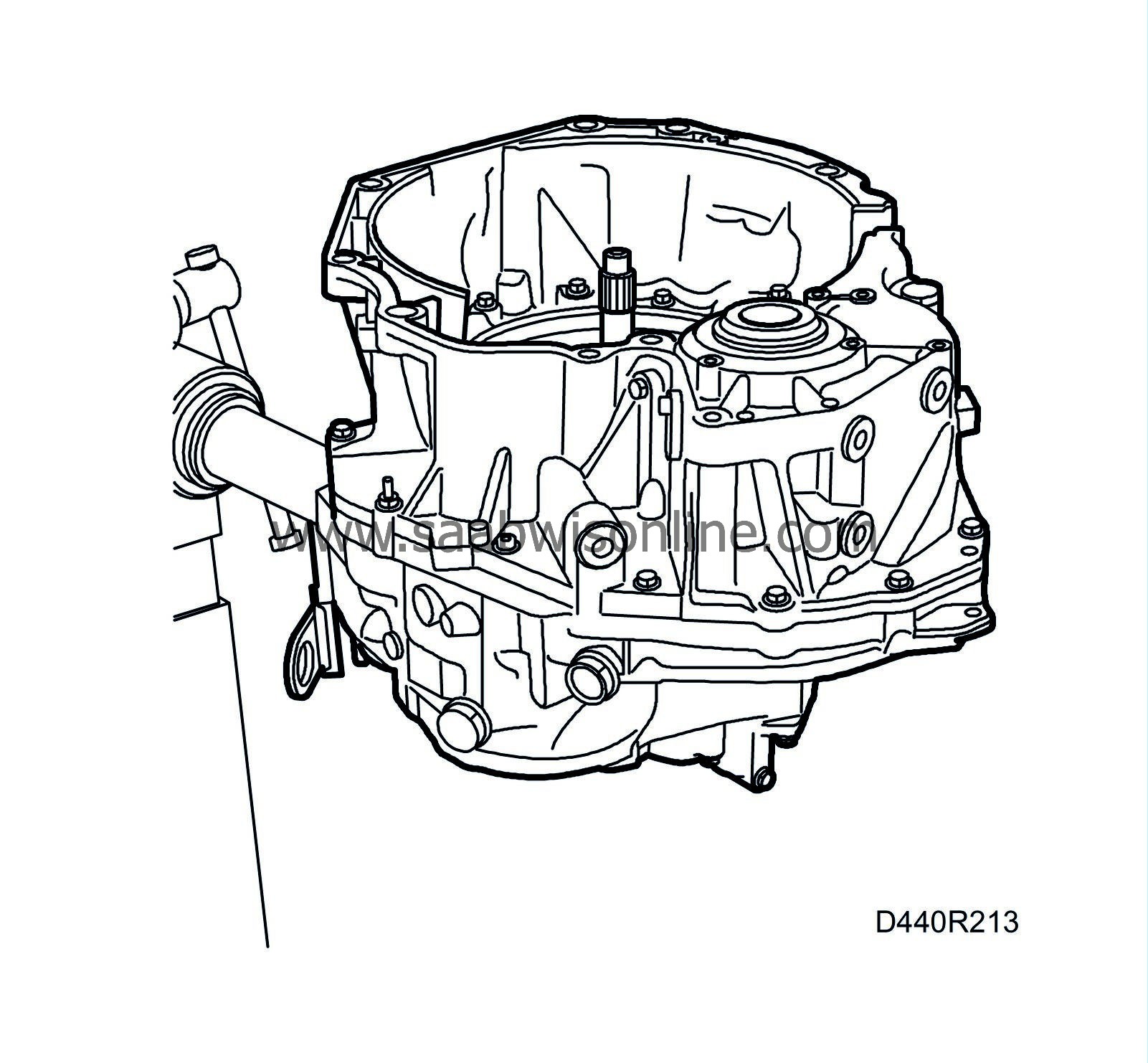

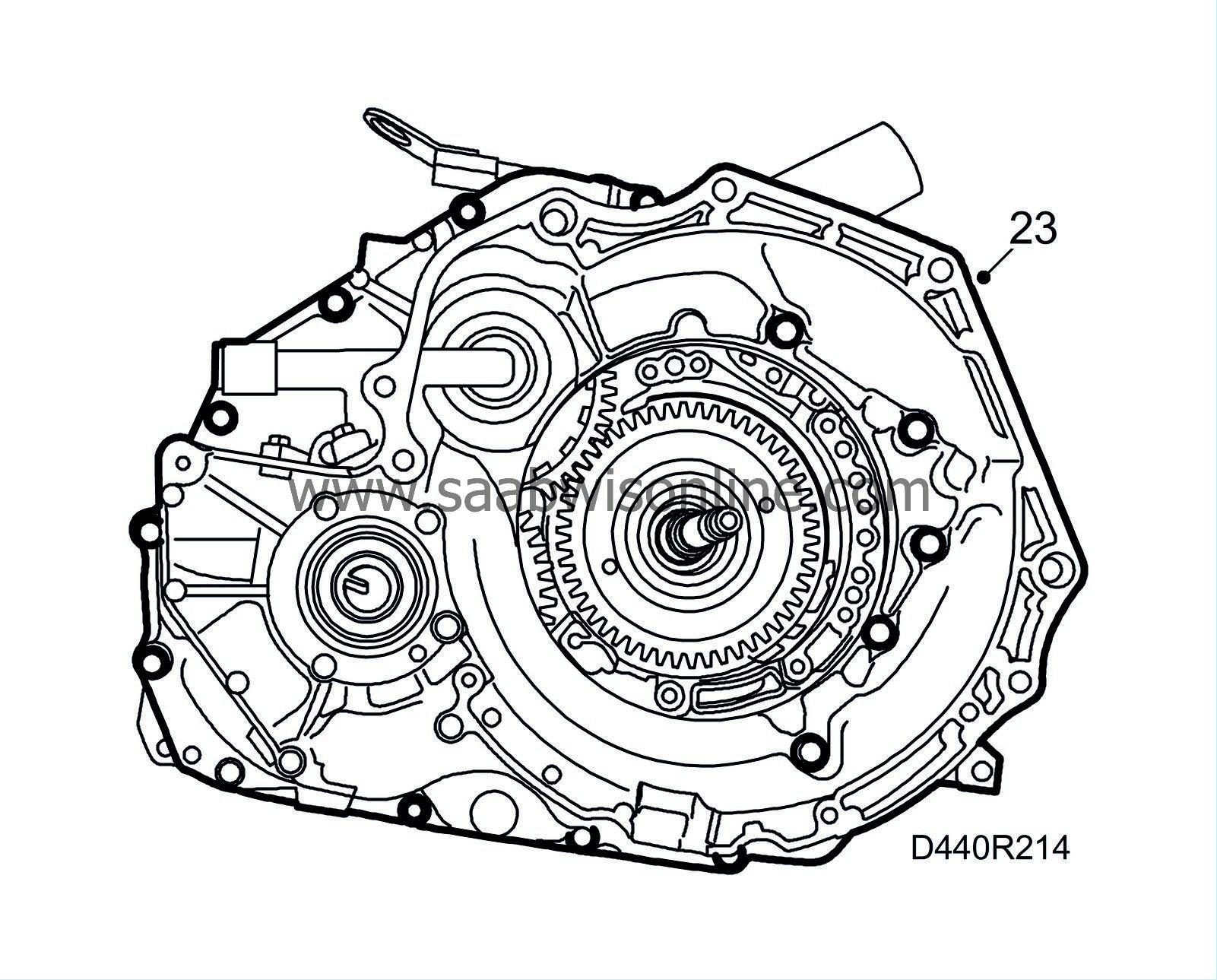

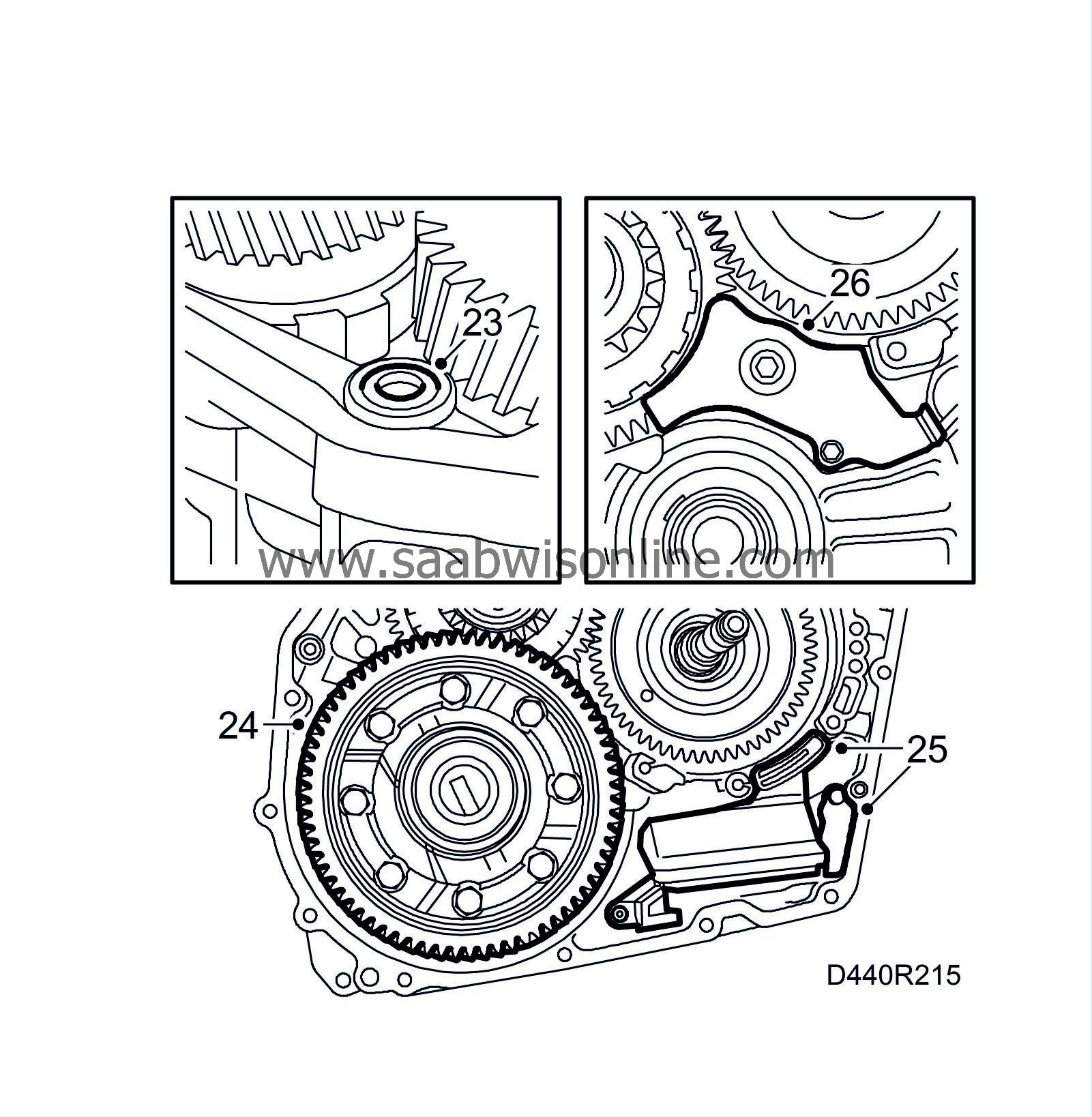

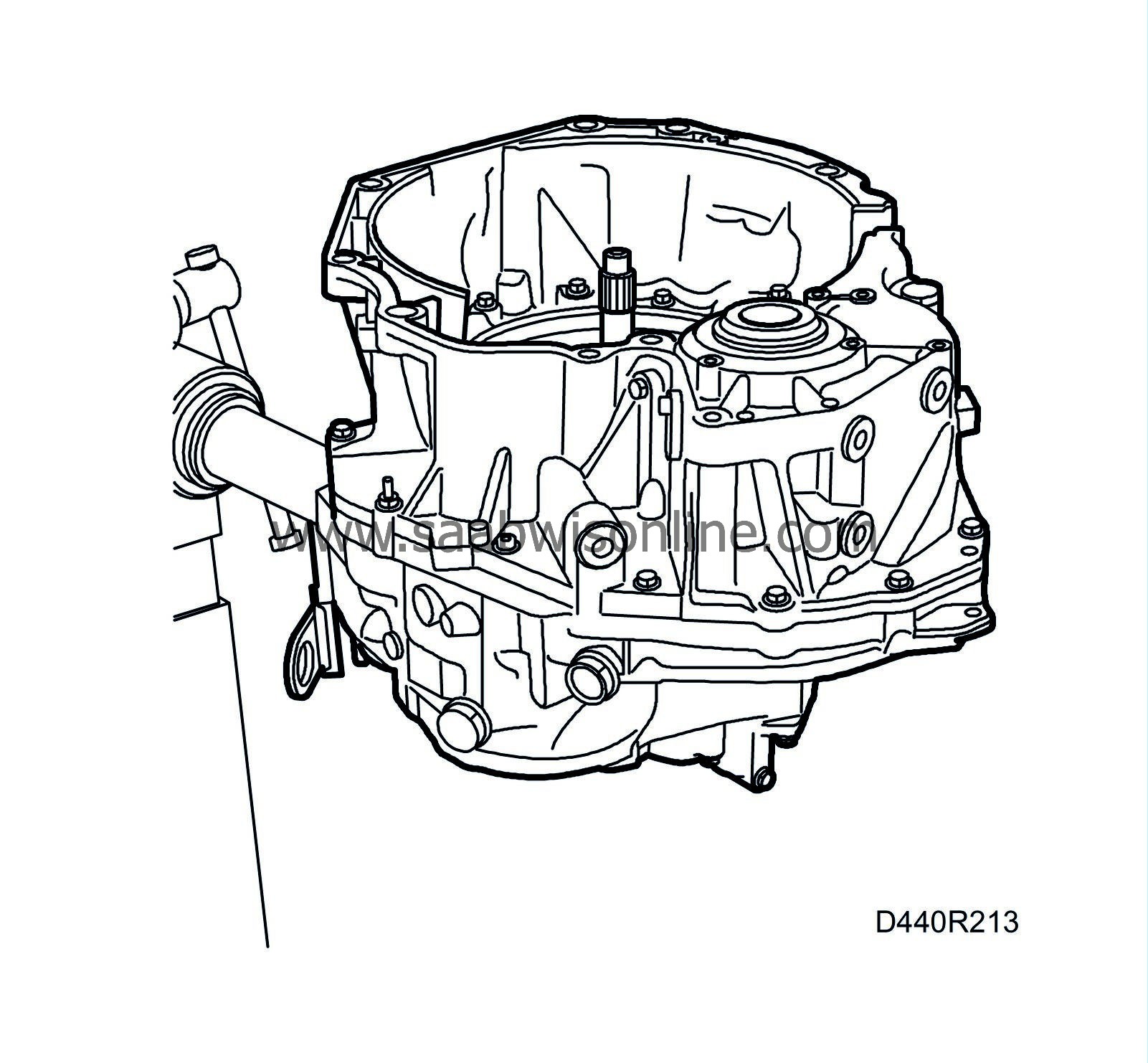

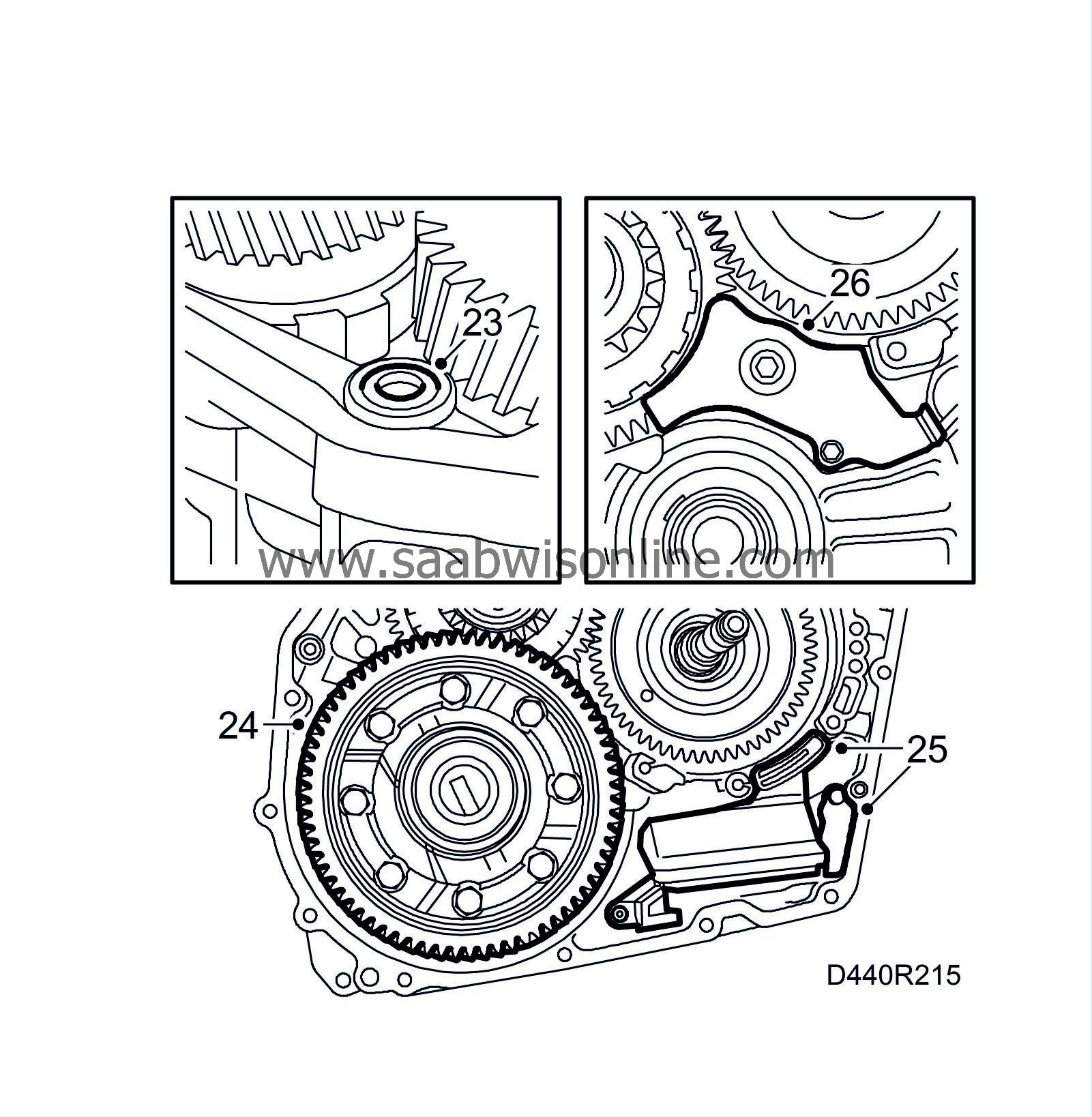

23.

|

Remove the torque converter shell. Knock loose the housing with a plastic mallet. Remove the small seal.

|

|

24.

|

Lift out the differential unit.

|

|

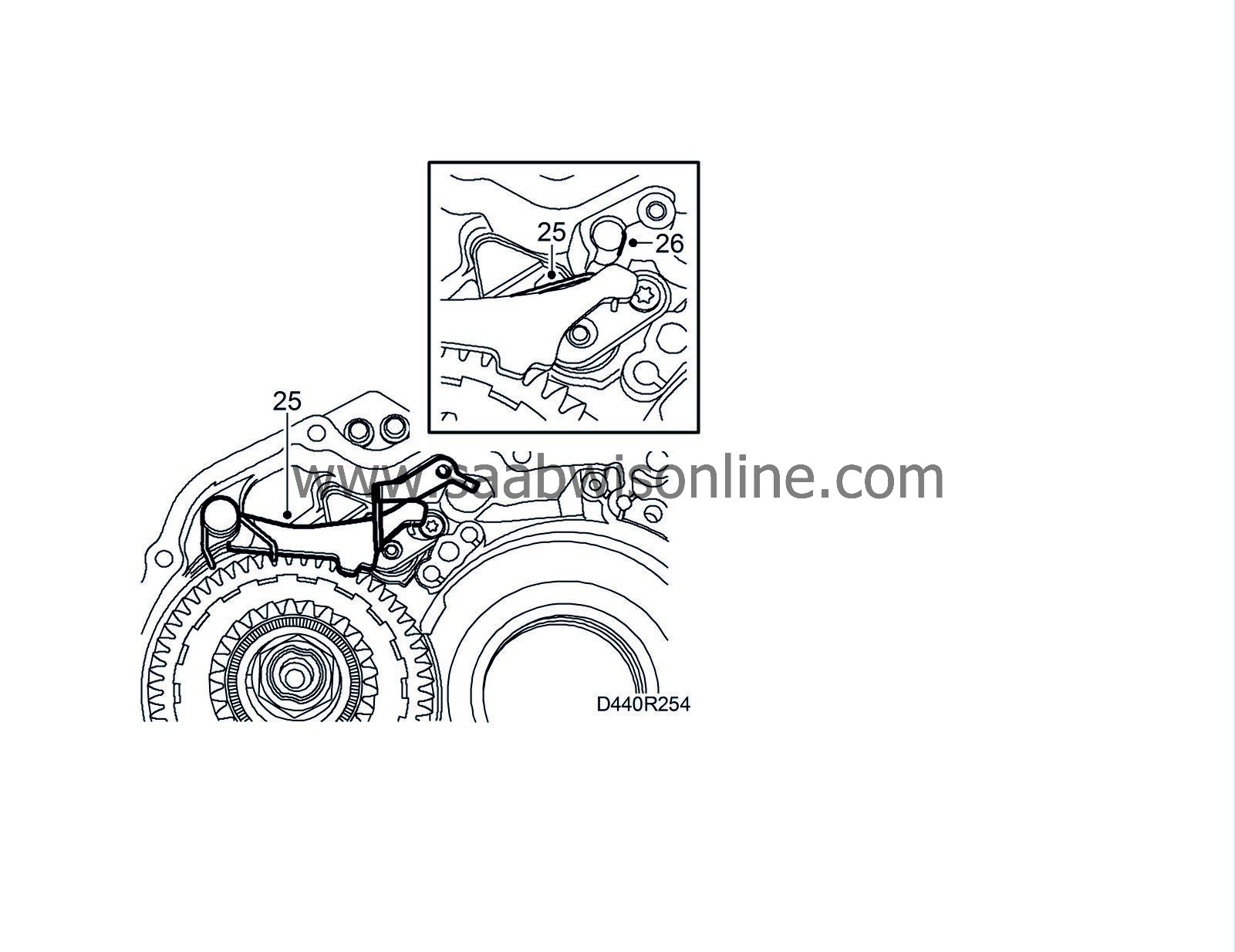

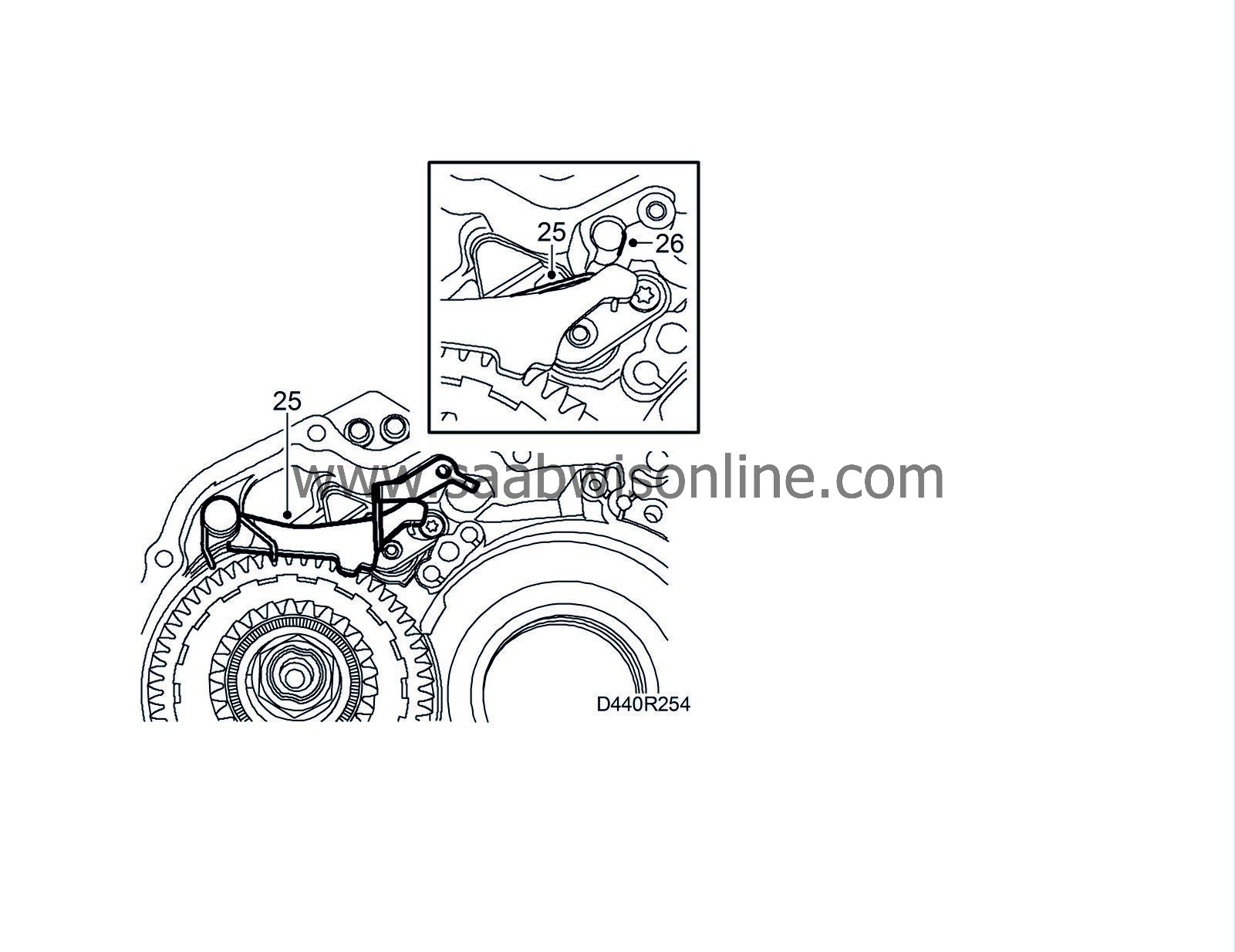

25.

|

Remove the oil strainer and the cover plate.

|

|

26.

|

Remove the oil channel plate from the gearcase.

|

|

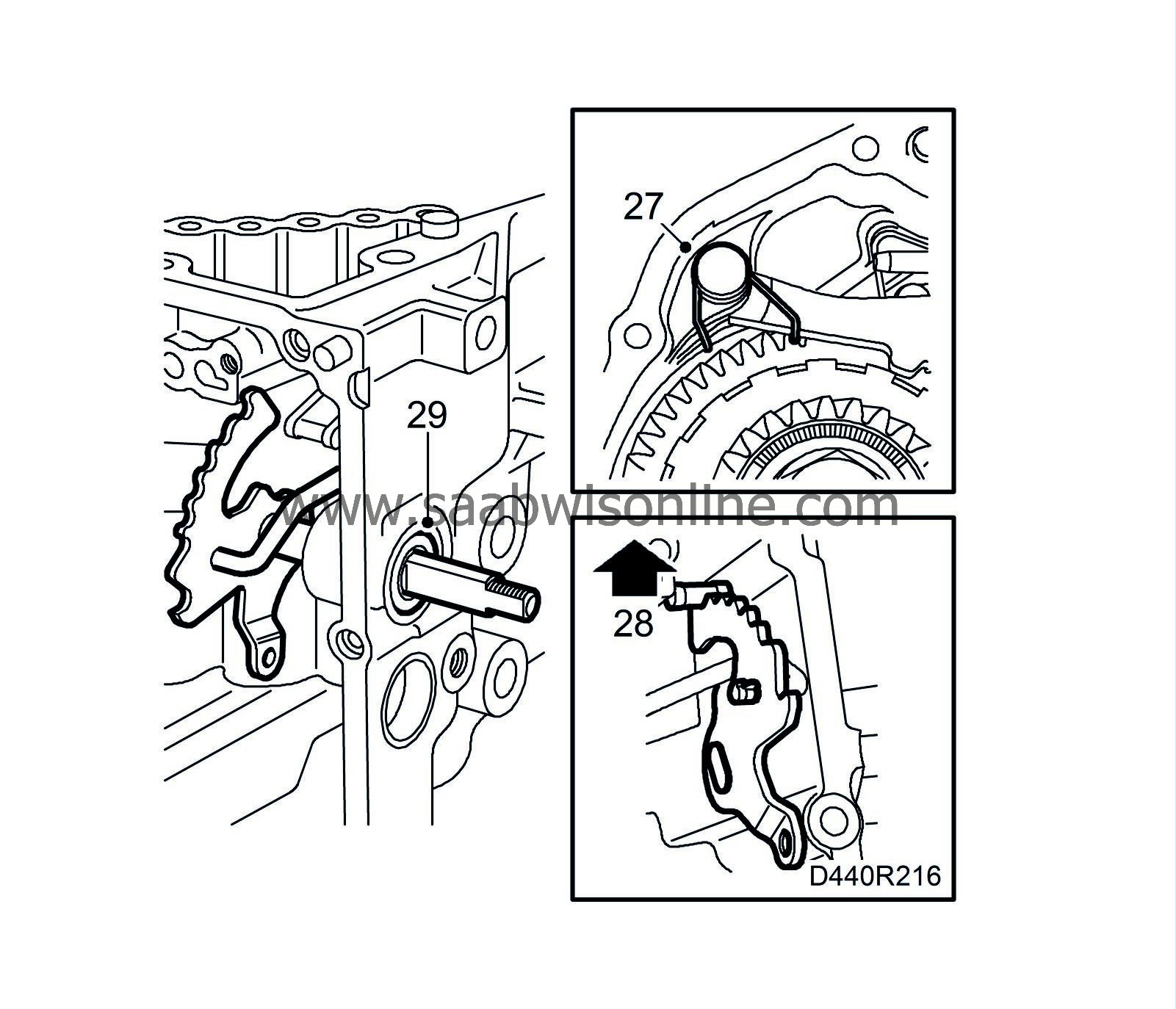

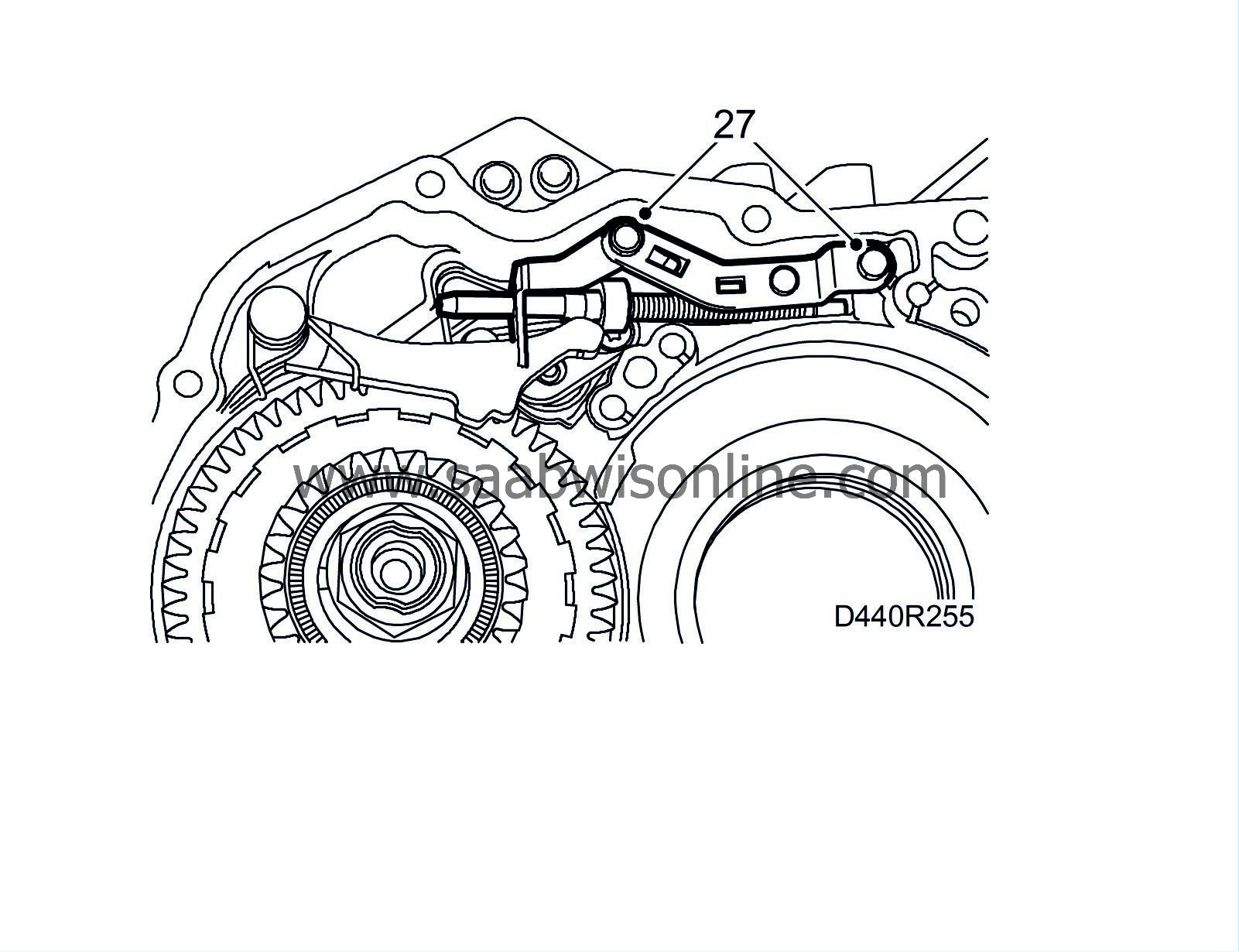

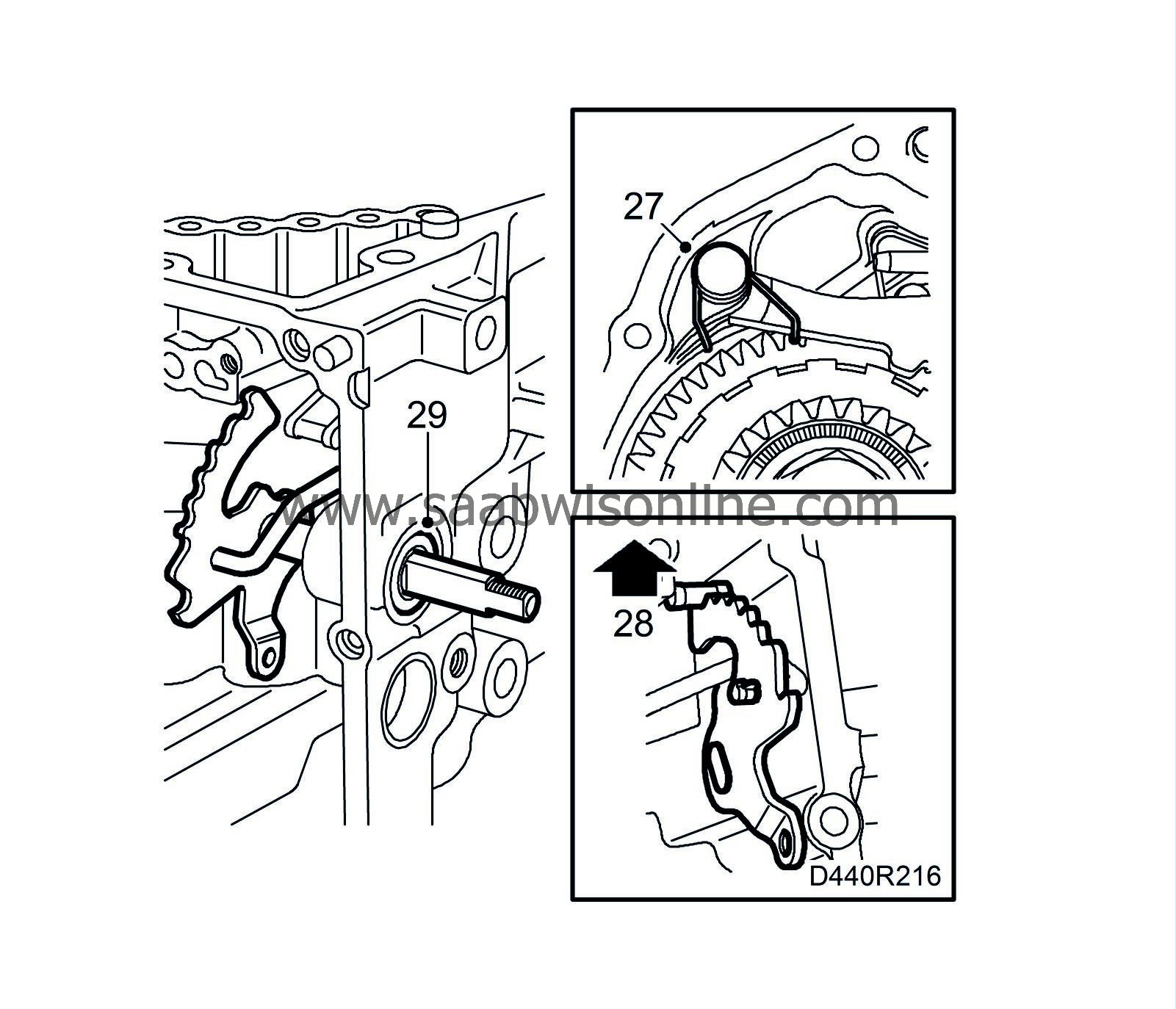

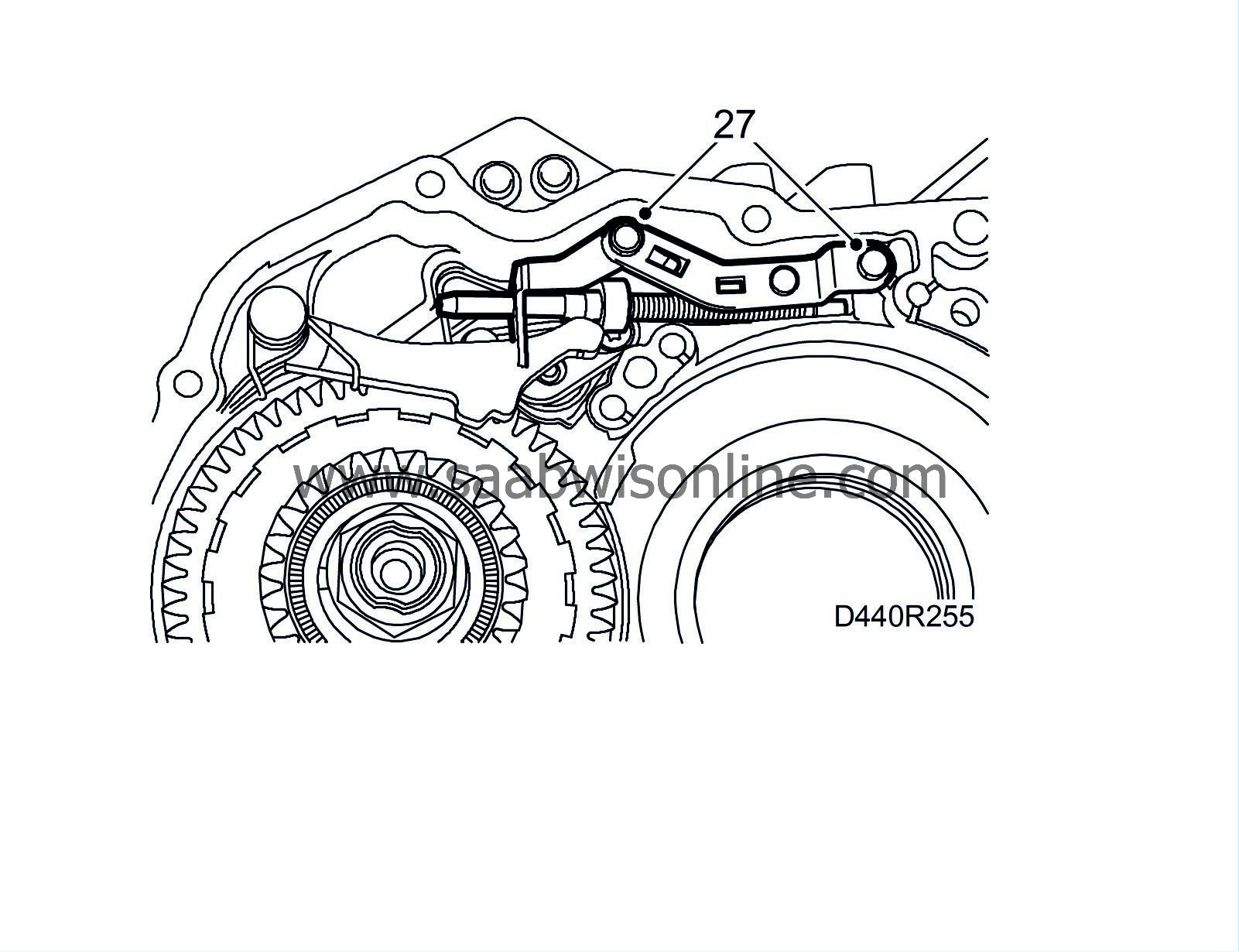

27.

|

Remove the torsion spring and the ratchet spindle for the handbrake.

|

|

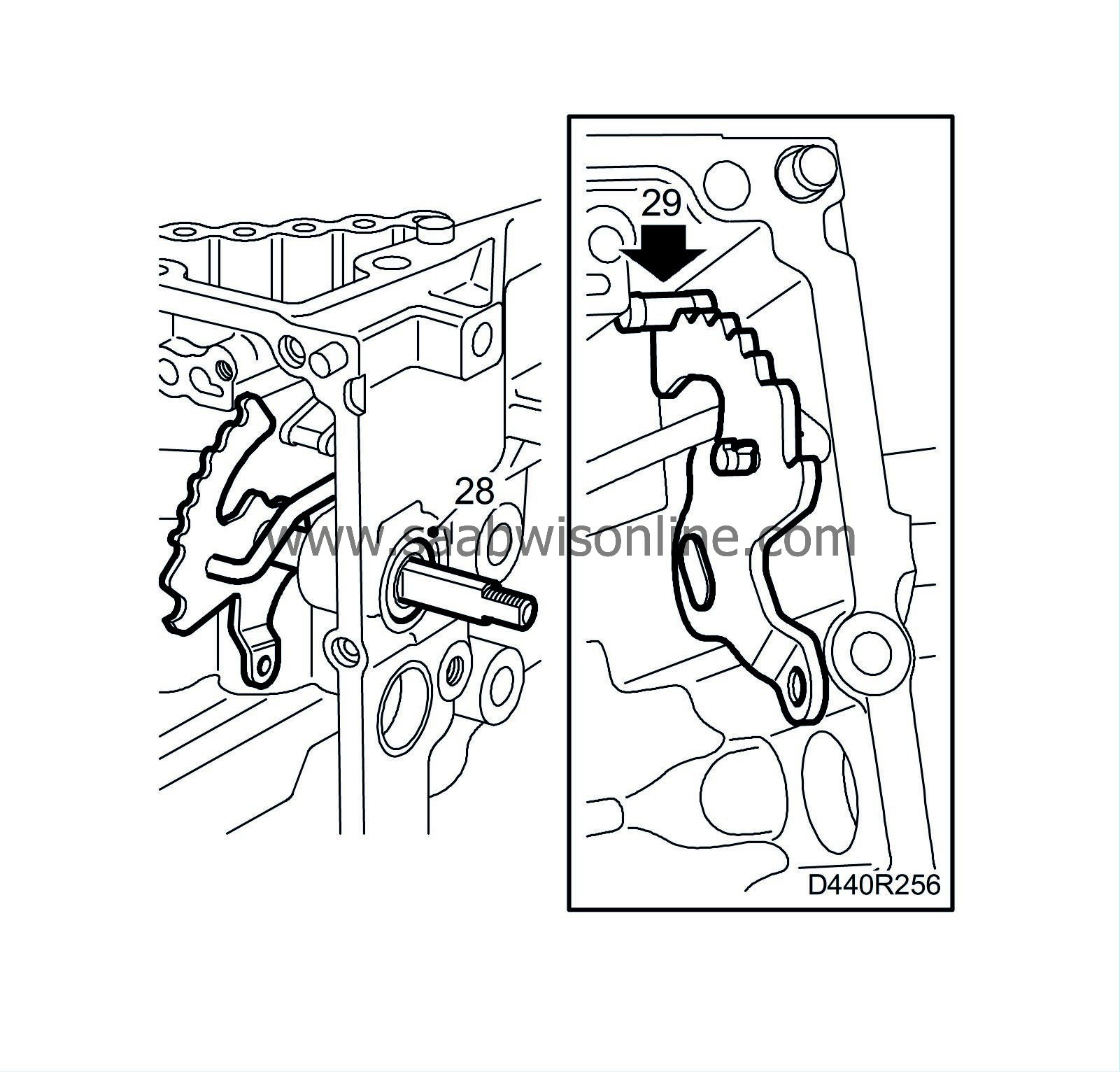

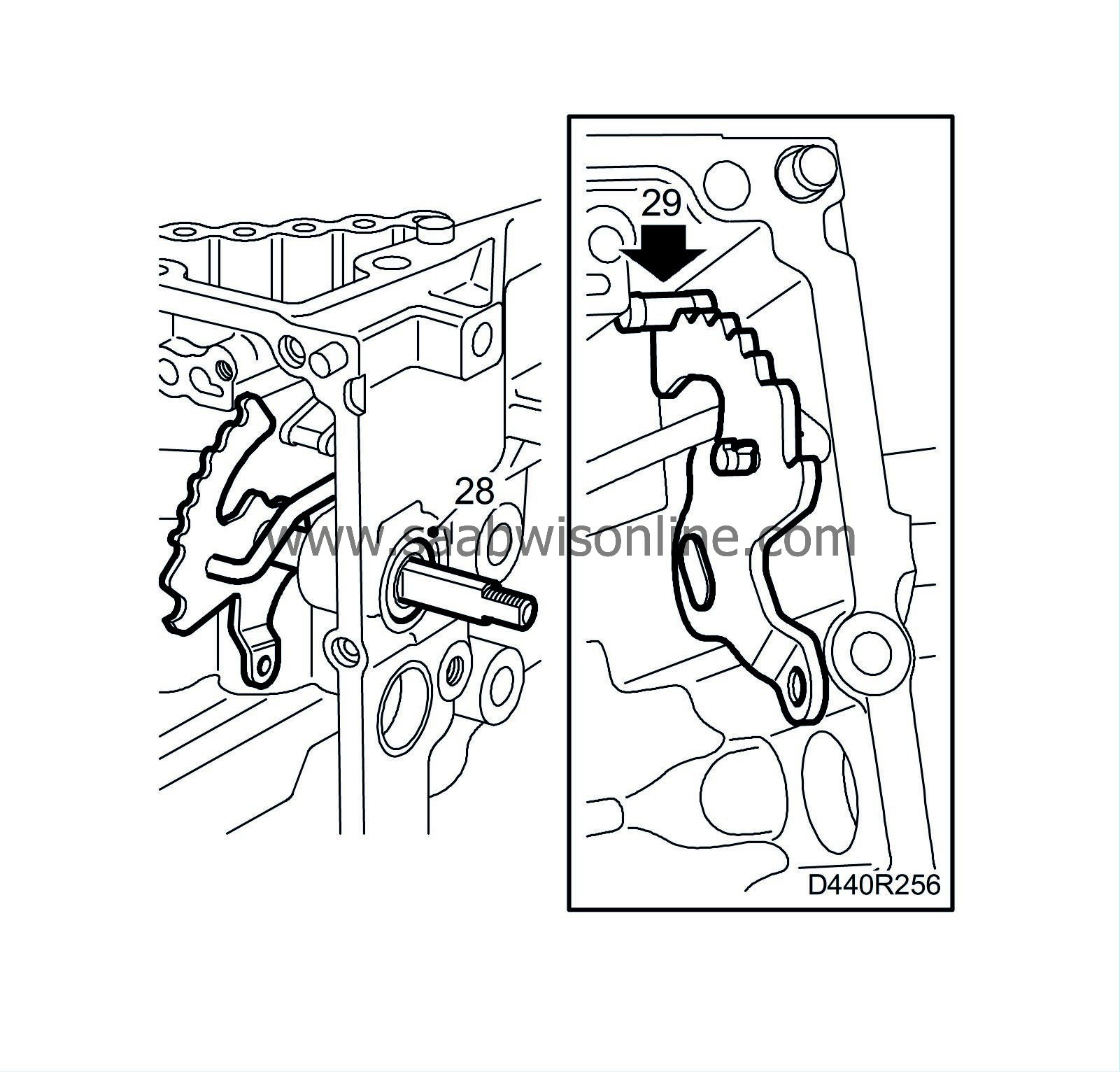

28.

|

Remove the handbrake control rod and the gear position disc. Release the detent spring.

|

|

29.

|

Remove the shaft seal for the selector lever shaft.

|

|

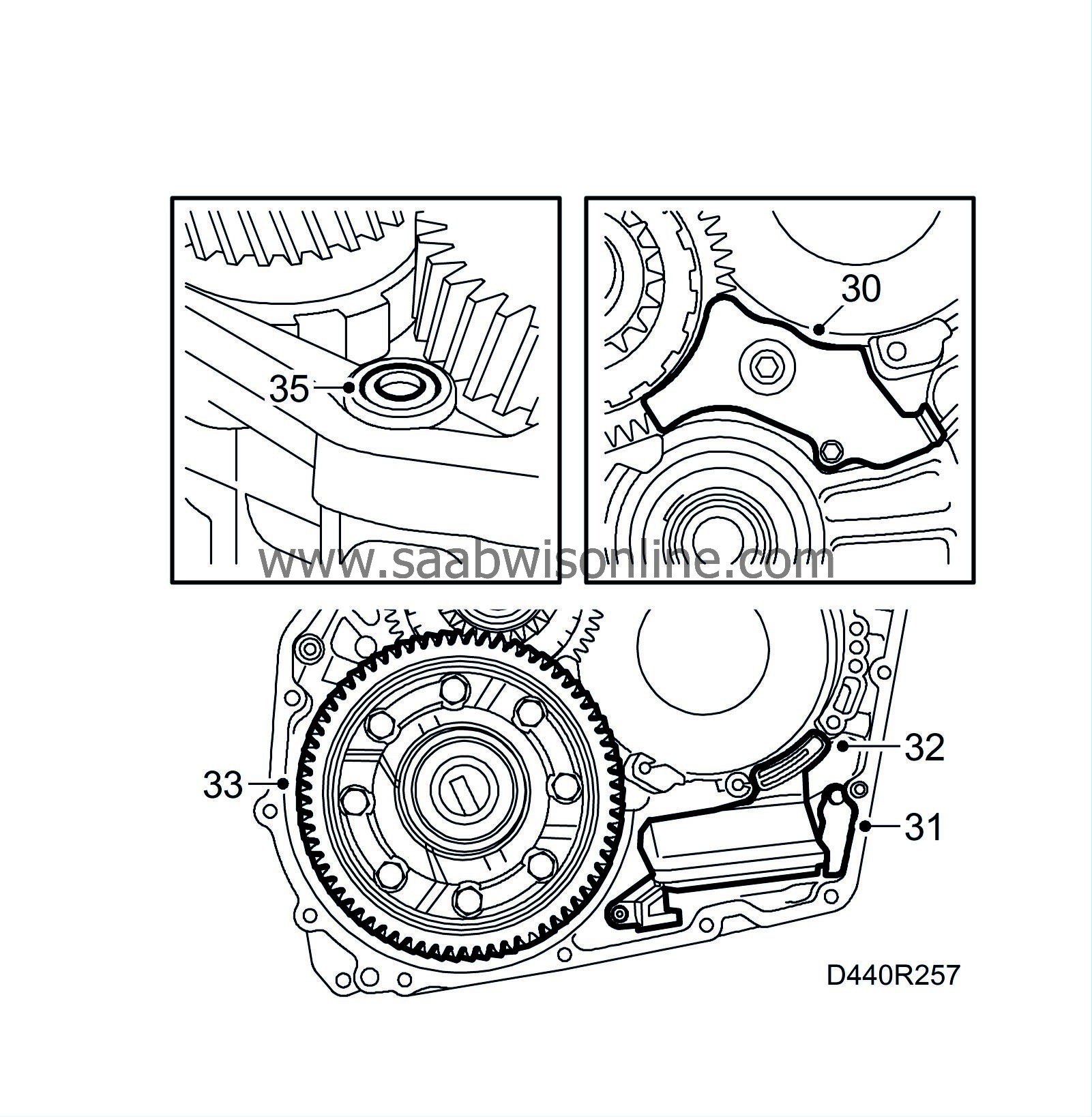

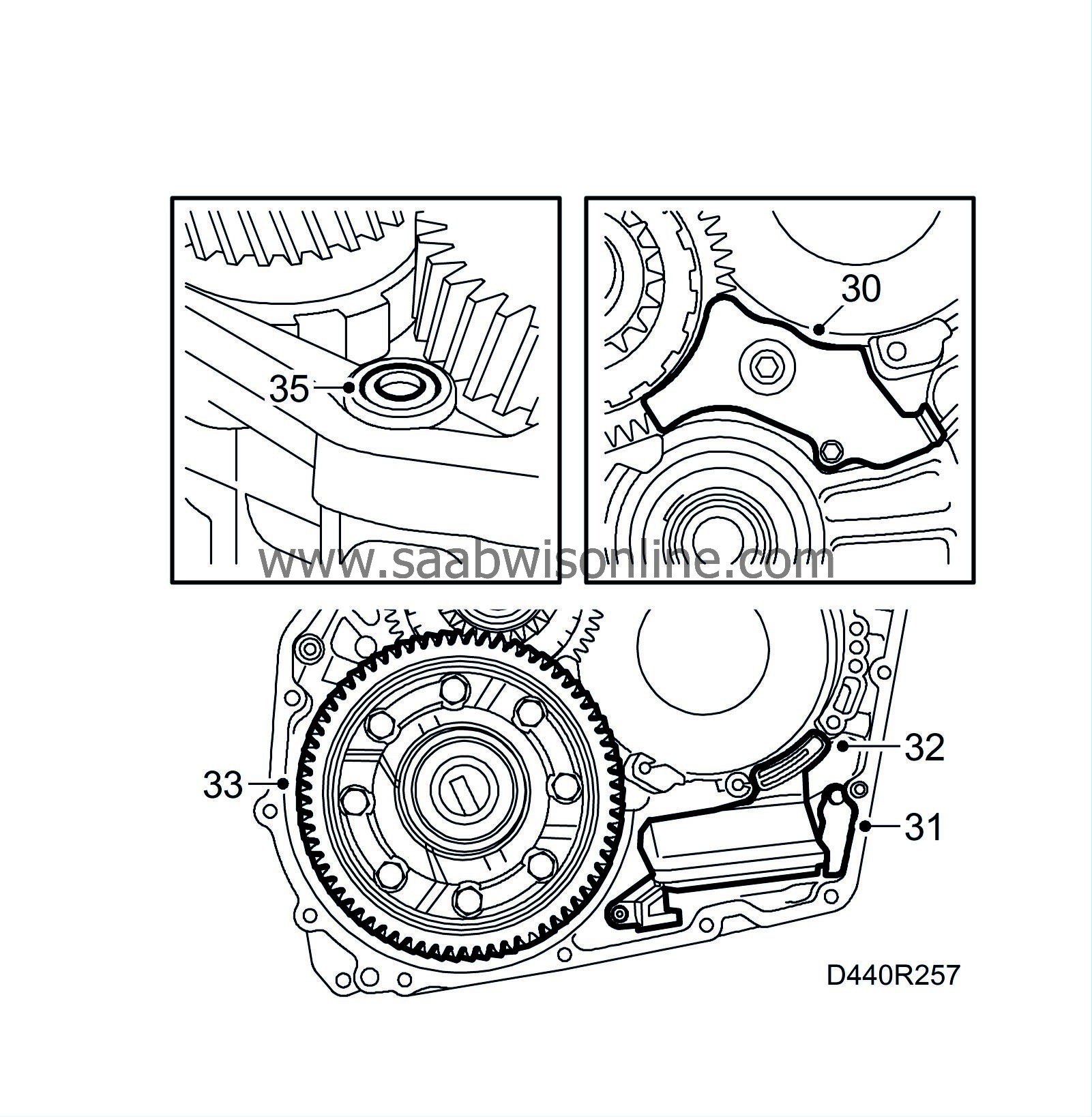

30.

|

Remove the holder for the handbrake control rod and the detent spring.

|

|

31.

|

Remove the handbrake ratchet and guide pin.

|

|

32.

|

Remove the holder and torsion spring.

|

|

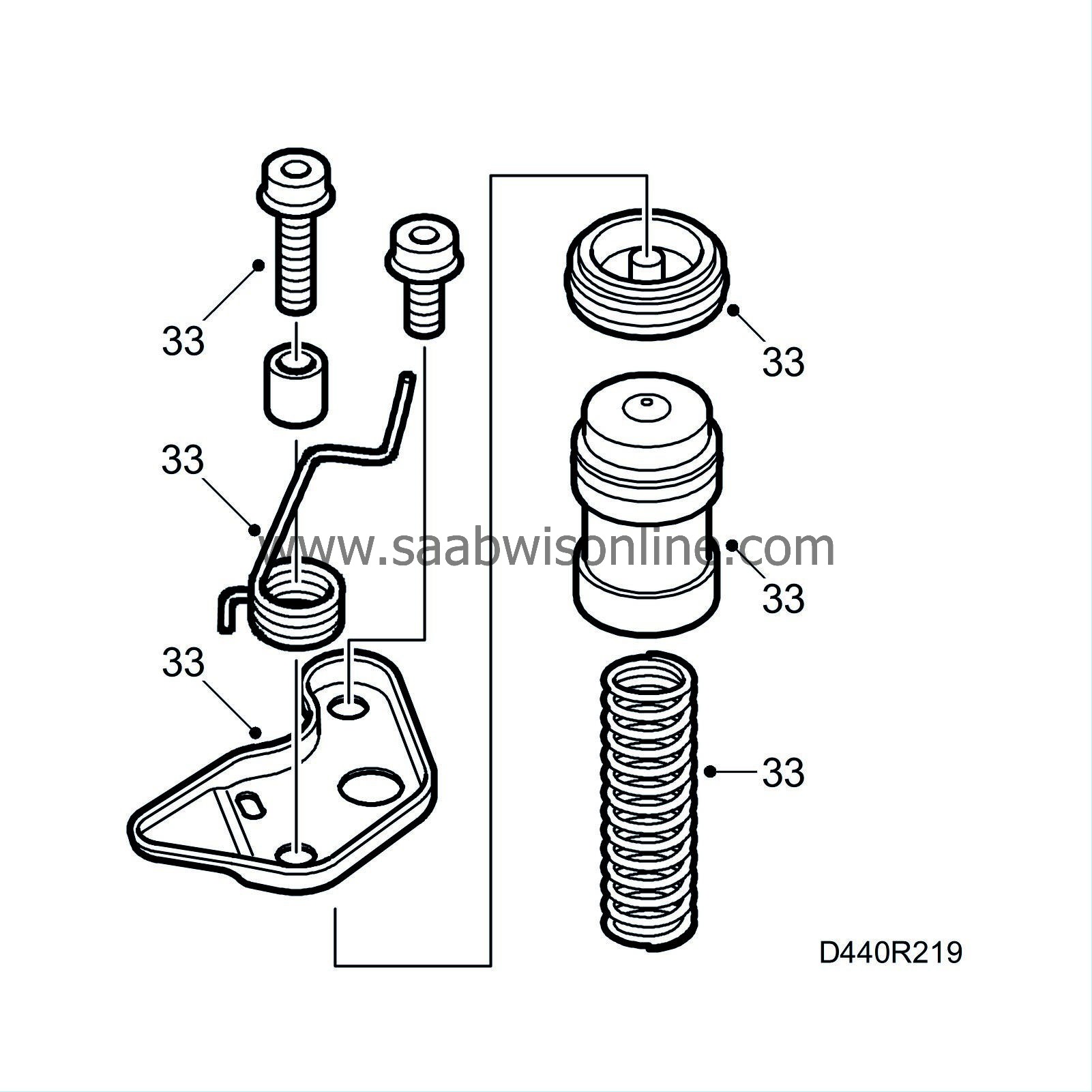

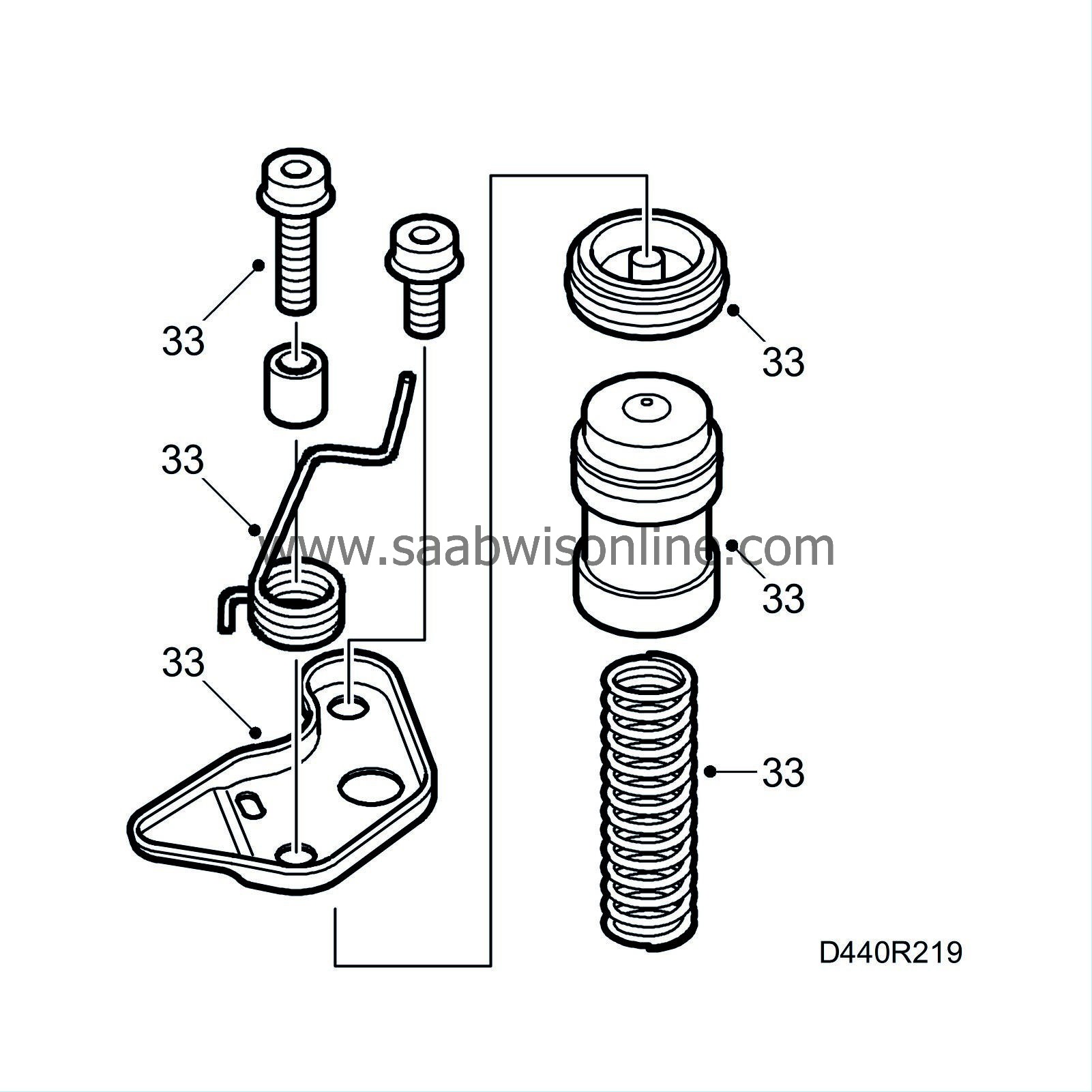

33.

|

Remove the cover with O-rings, plunger and spring.

|

|

34.

|

Lift out the output shaft assembly with thrust bearing and bearing races.

|

|

35.

|

Lift out the C3 clutch and bearing race. Retain the thrust bearing.

|

|

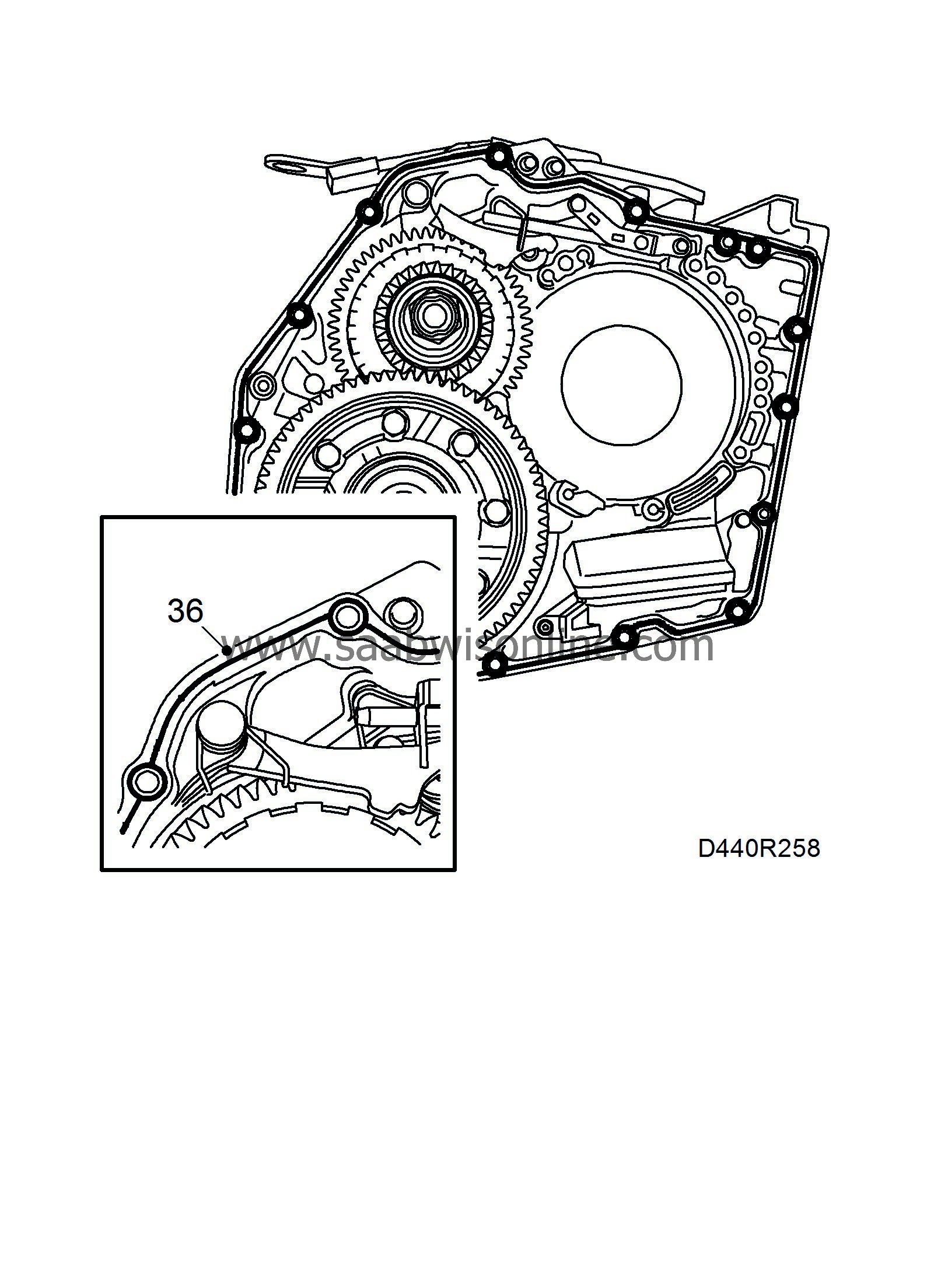

36.

|

Lift out the B4 brake bands from the gearcase.

|

|

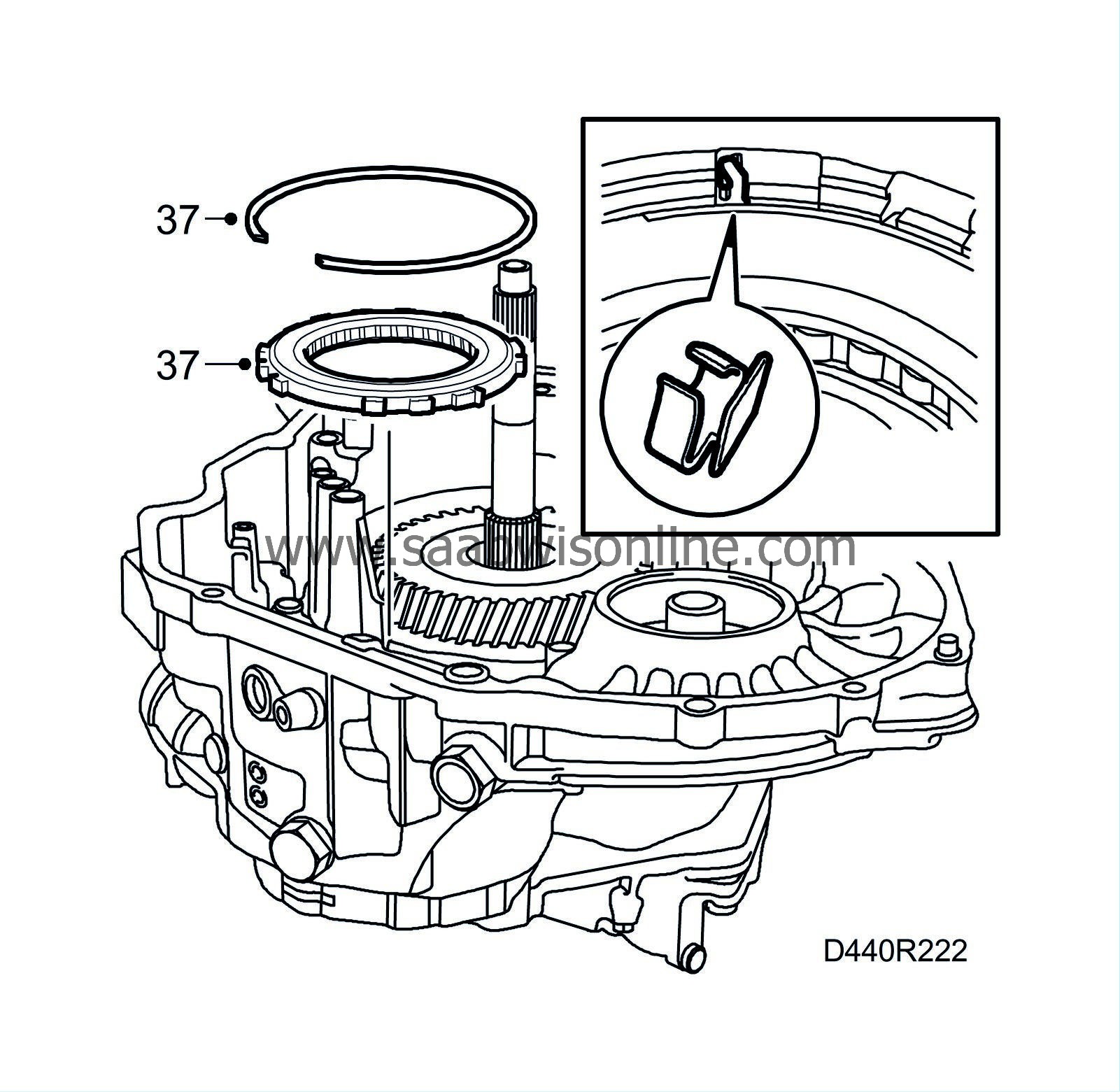

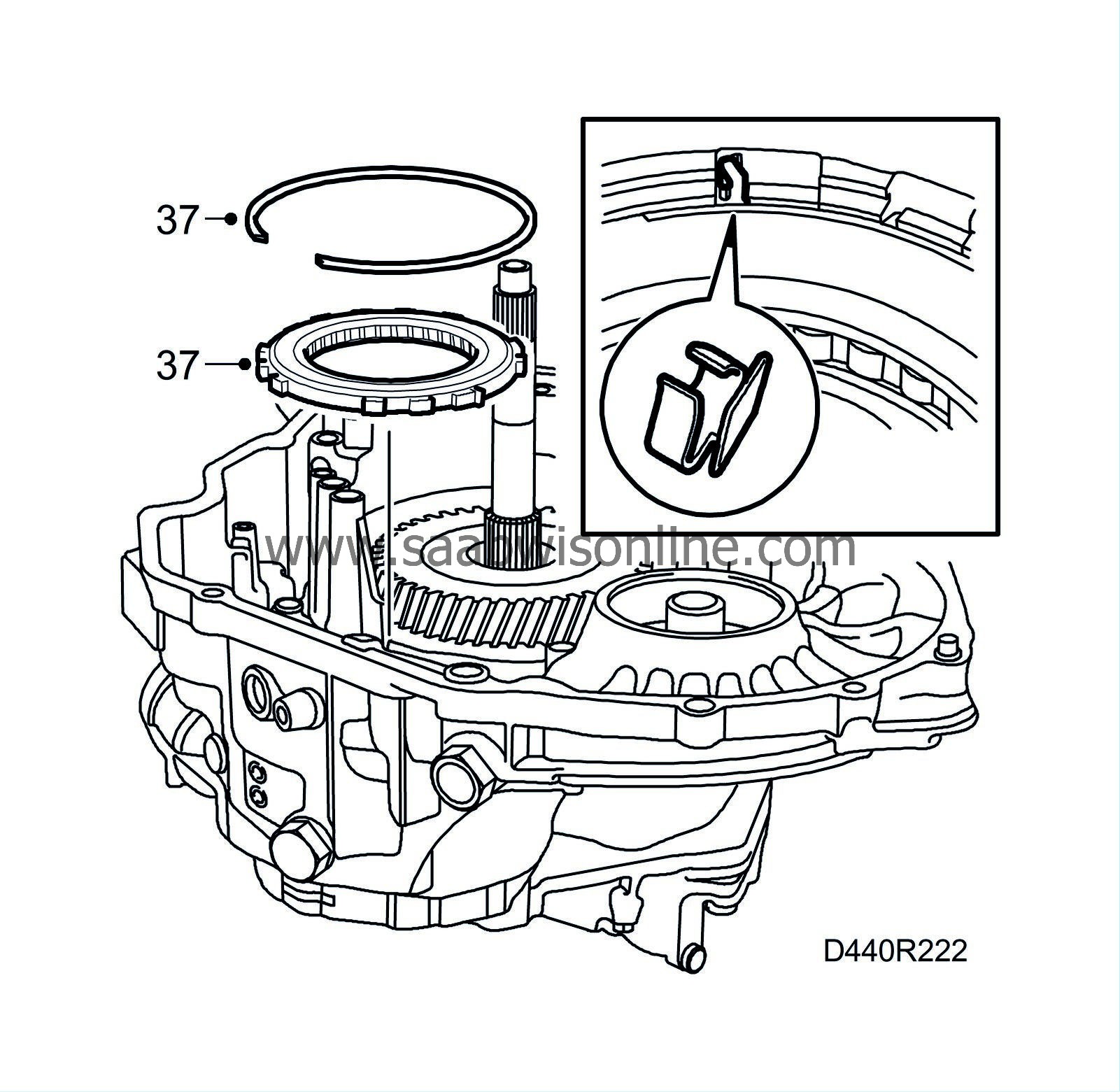

37.

|

Remove the circlip for the freewheel F3 from the gearcase. Lift out F3. Retain the small clip.

|

|

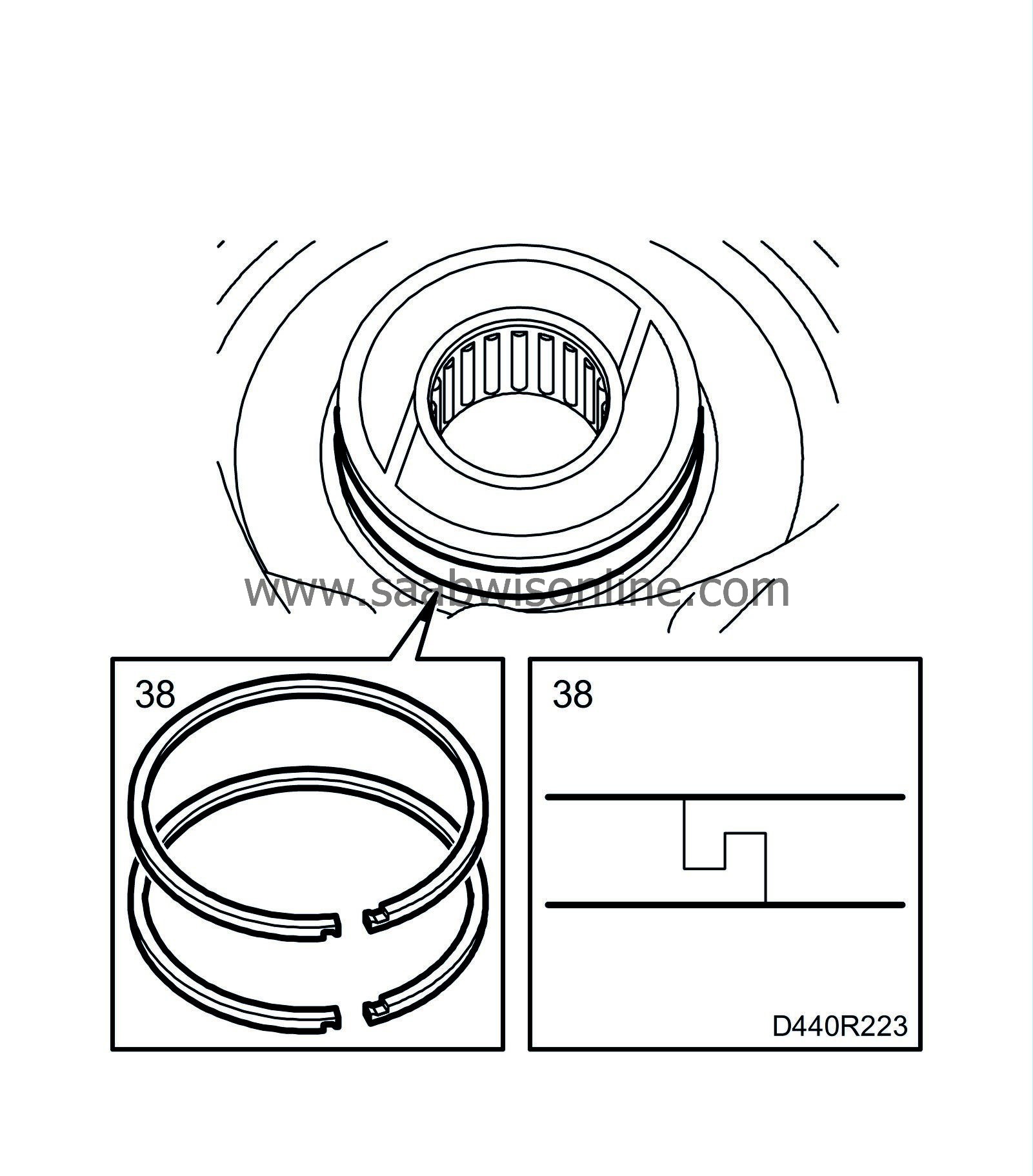

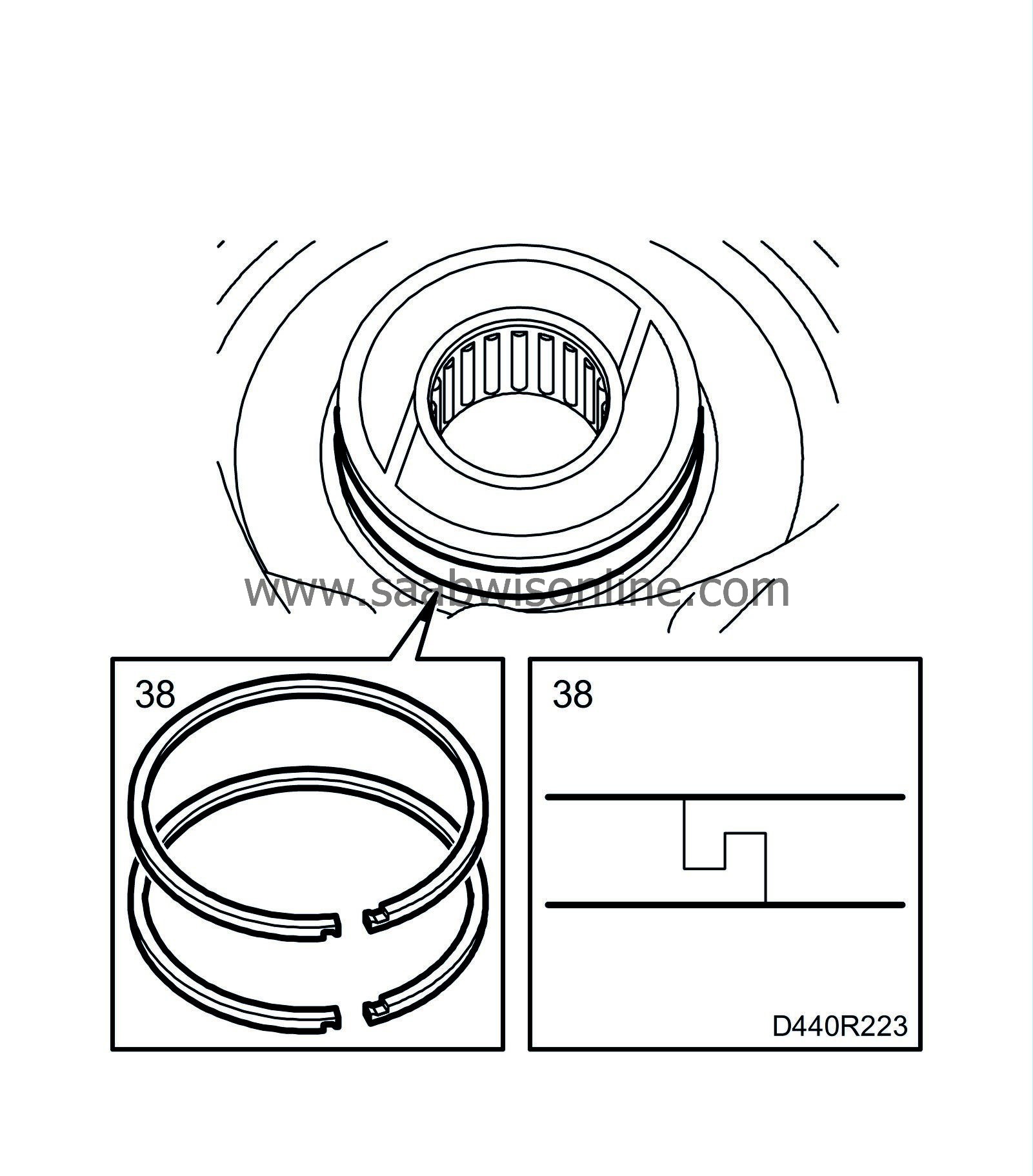

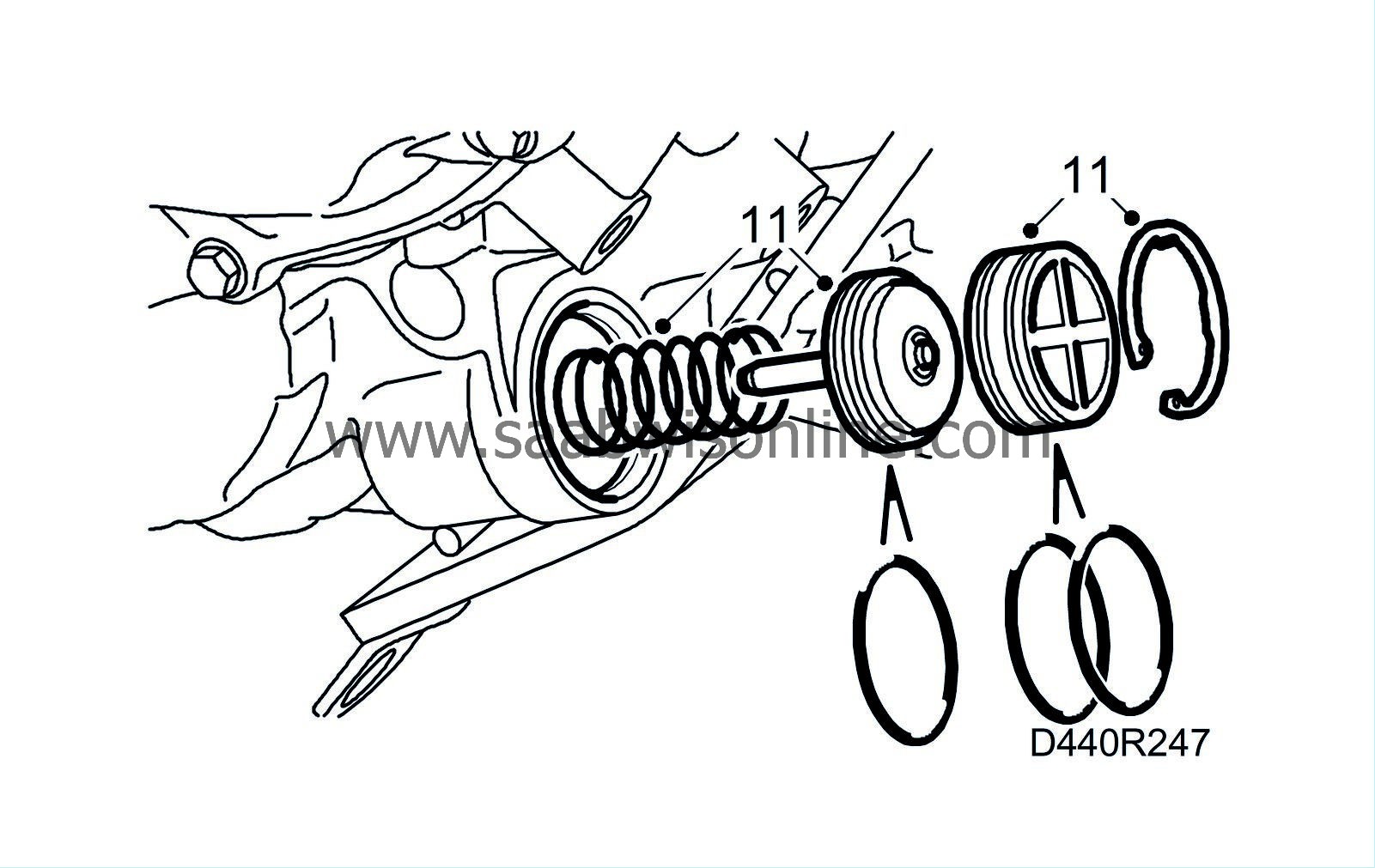

38.

|

Remove the oil sealing rings by pressing one side of the ring towards the groove and unhooking the ring.

|

|

39.

|

Turn the gearbox through 180°

|

|

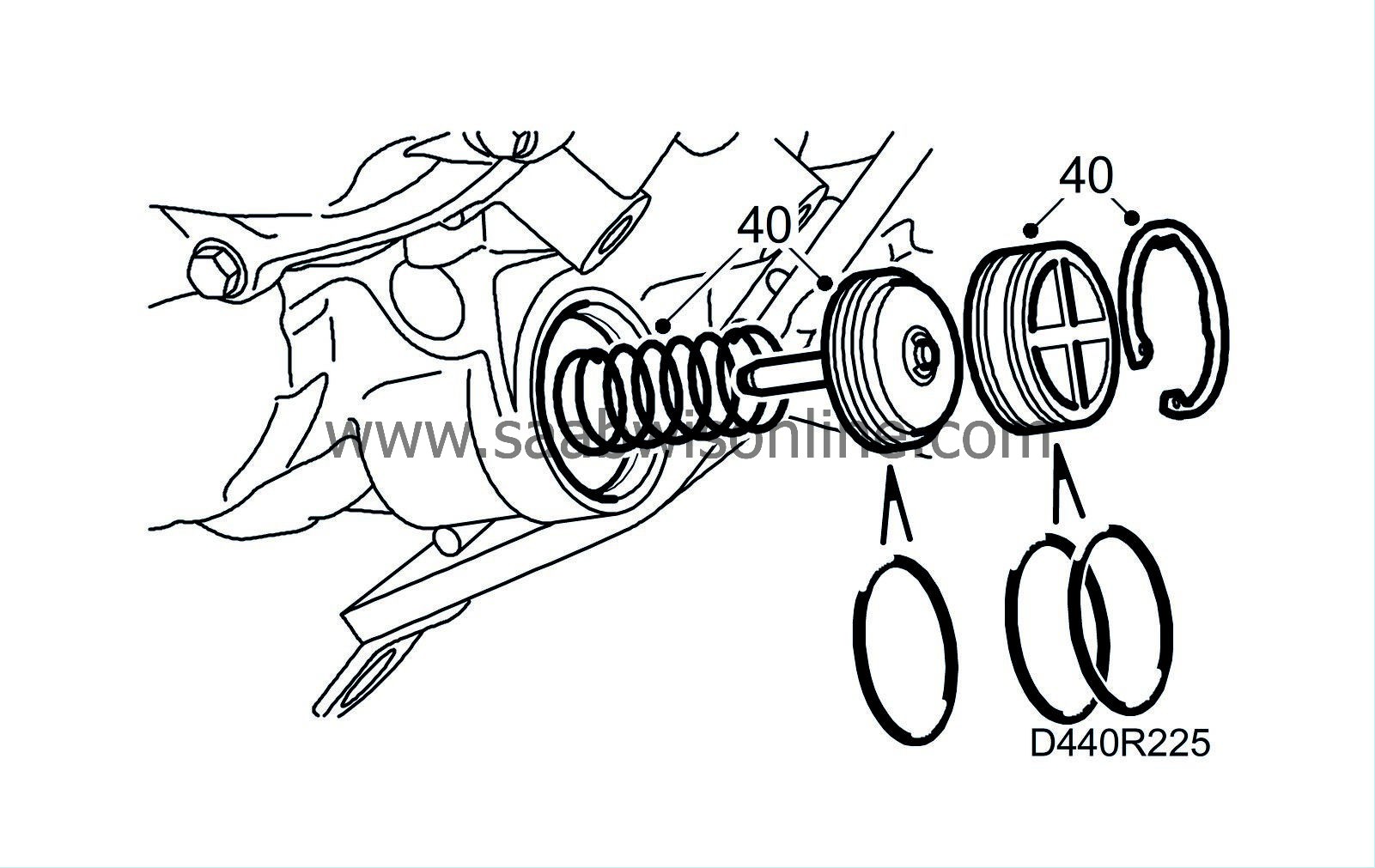

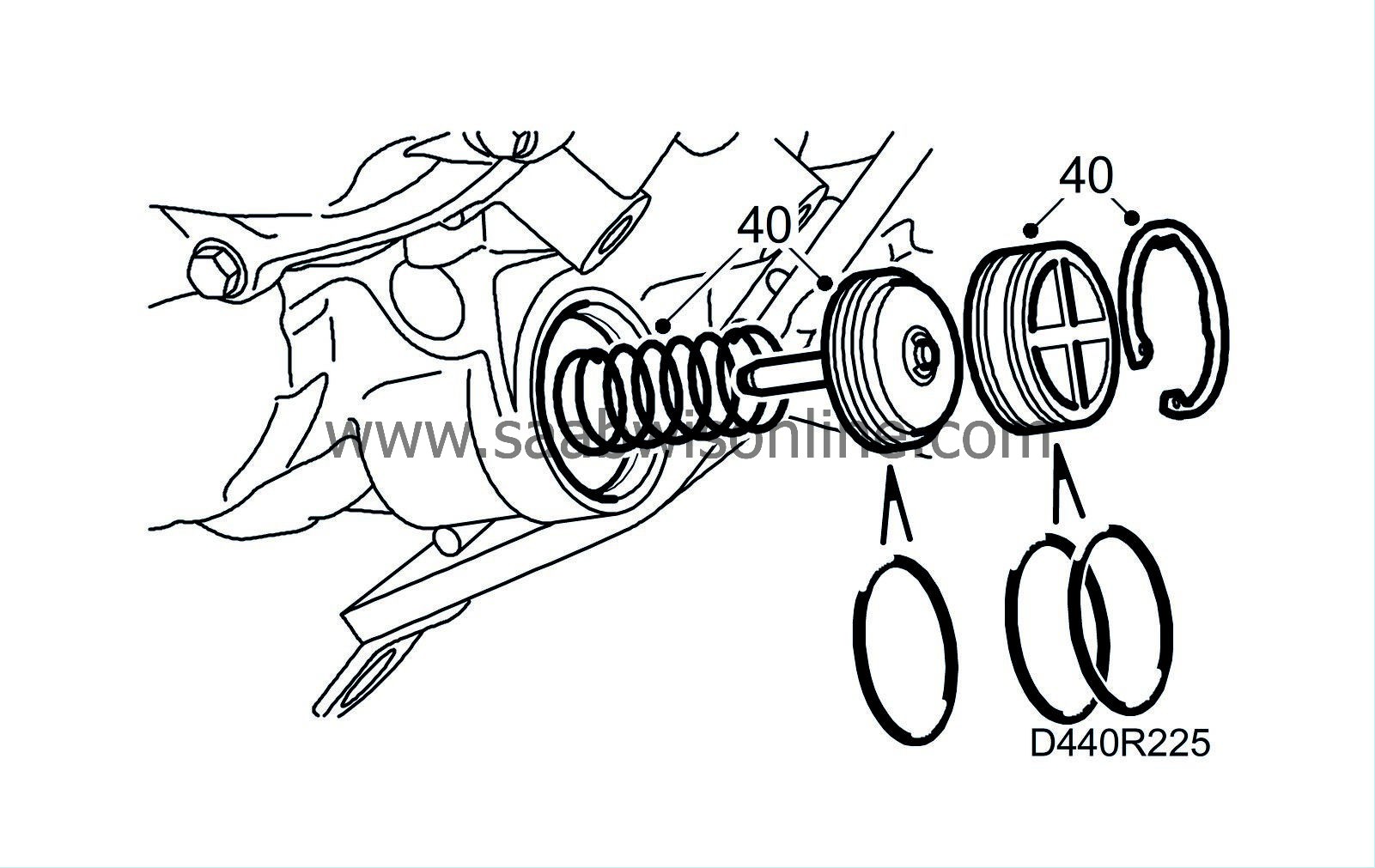

40.

|

Remove the circlip, cover, plunger, spring and the two O-rings for the B4 brake plunger. NB. Take care as the spring can thrust off the cover and plunger.

|

|

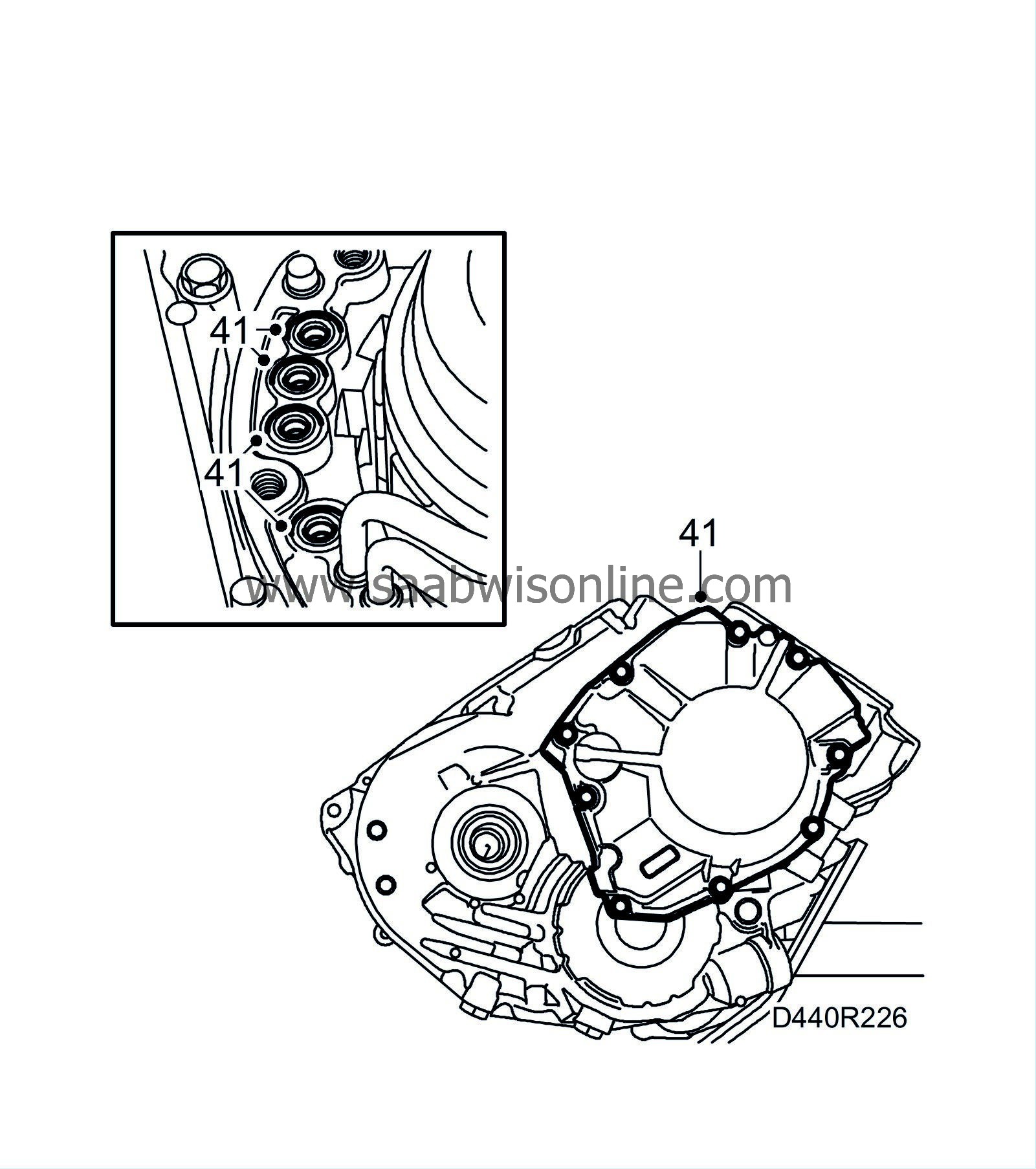

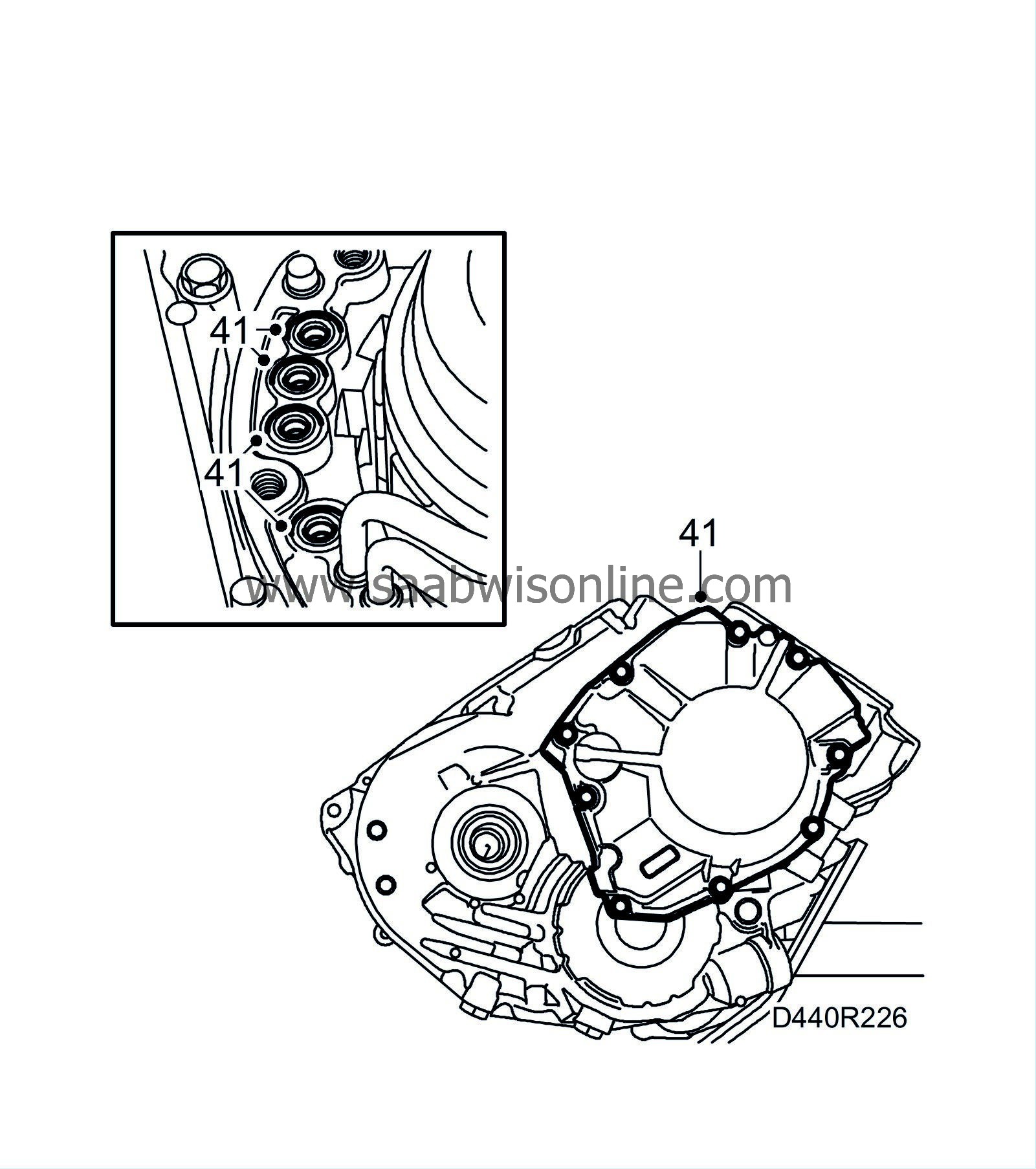

41.

|

Remove the bolts securing the end cover. Knock loose the cover with a plastic mallet. Remove the four seals.

|

|

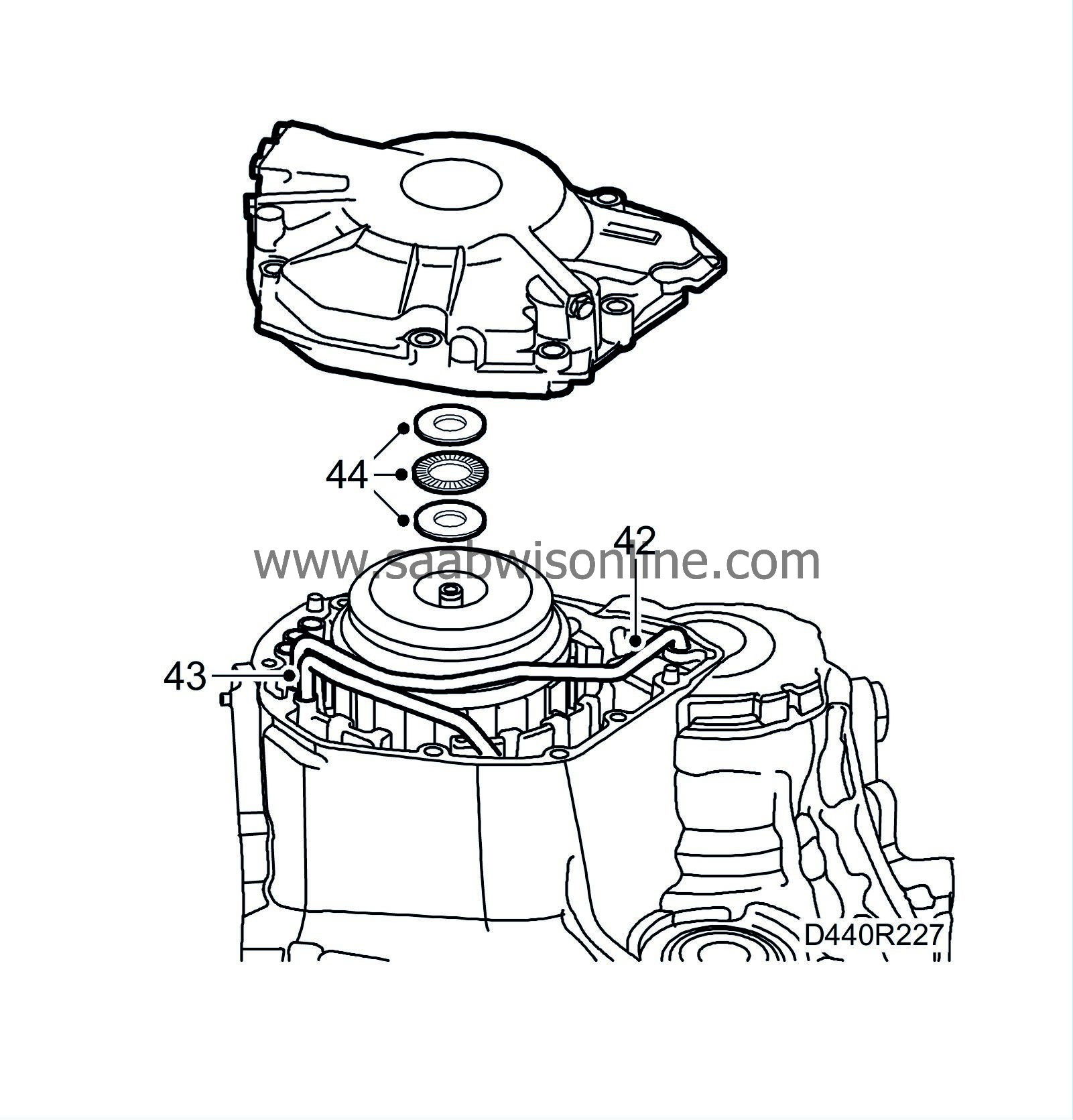

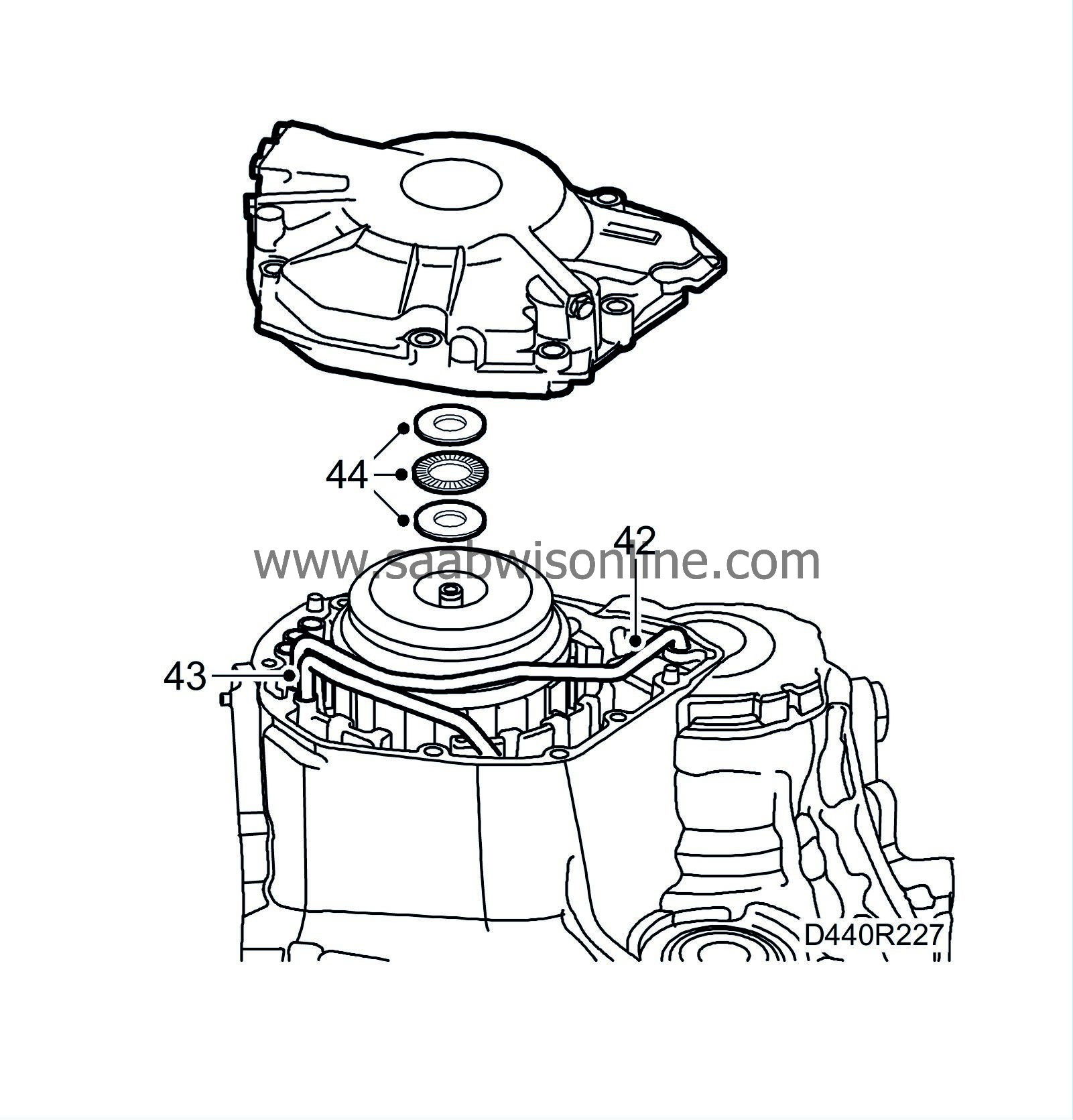

42.

|

Remove the pipe for the C3 solenoid. Use sliding hammer 83 90 270 and hook 87 92 384.

|

|

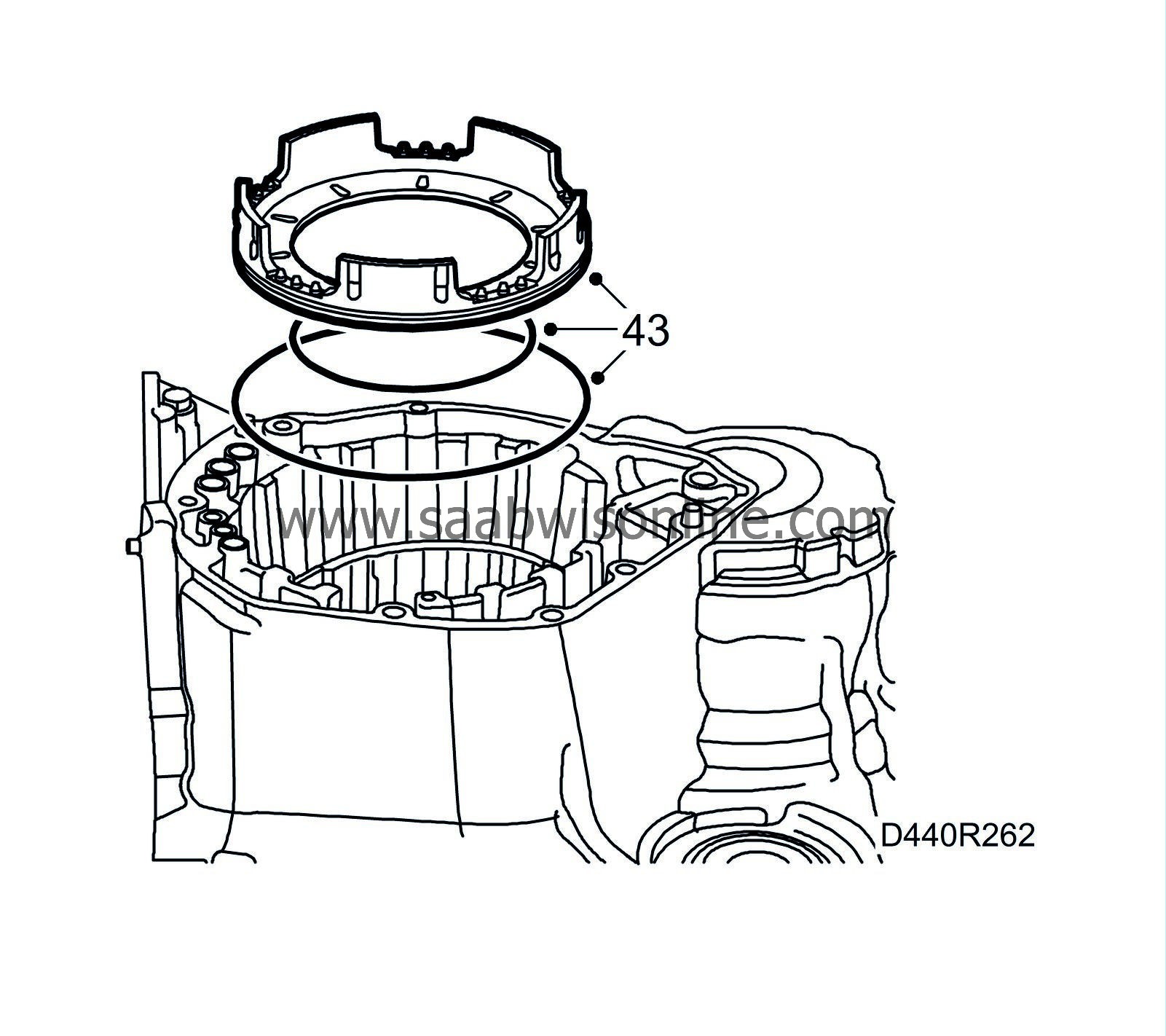

43.

|

Remove the pipe holder and the second pipe. Use sliding hammer 83 90 270 and hook 87 92 384.

|

|

44.

|

Remove the bearing and bearing race from the cover and the bearing race from the turbine shaft assembly with clutches C1 and C2.

|

|

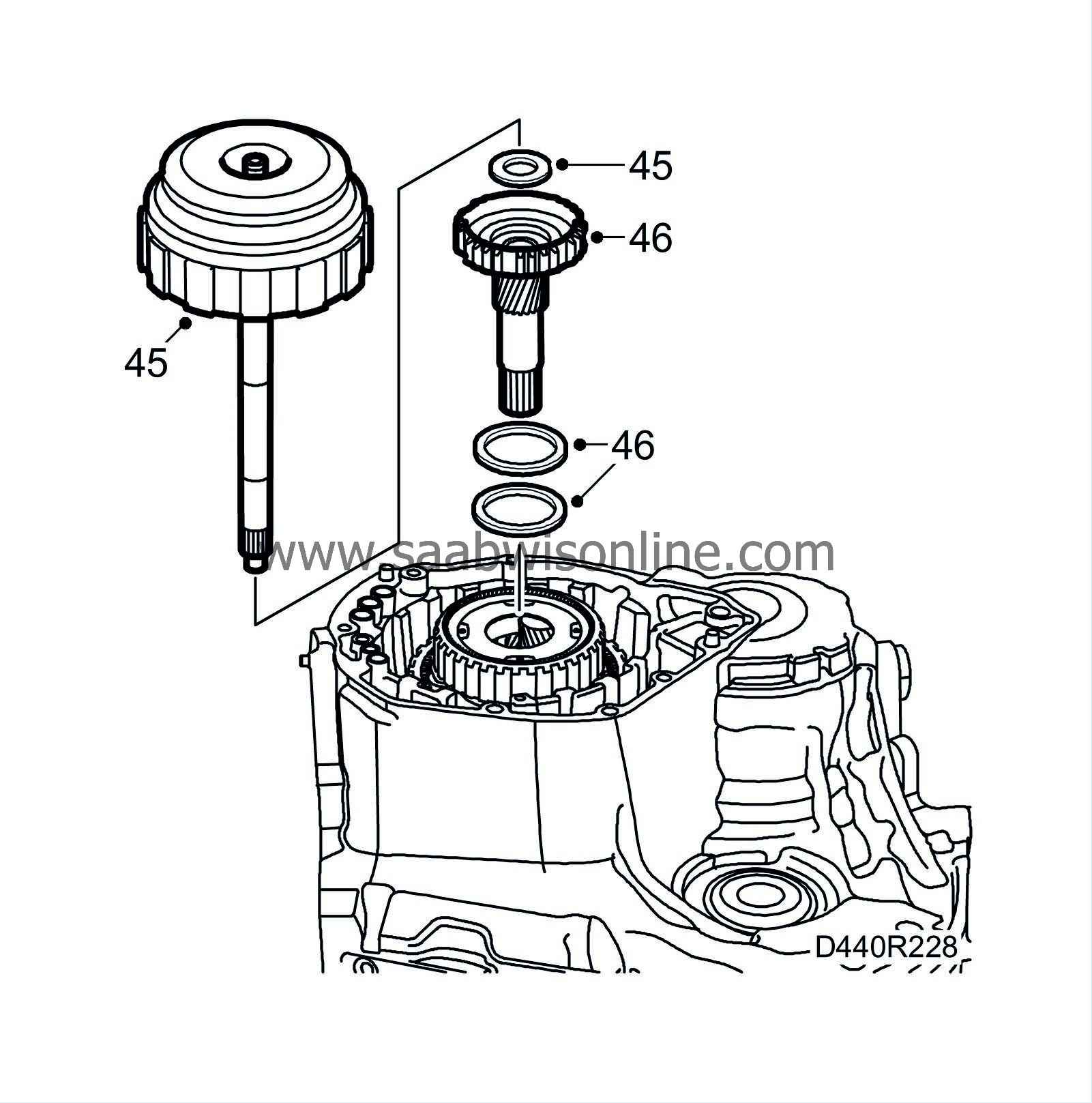

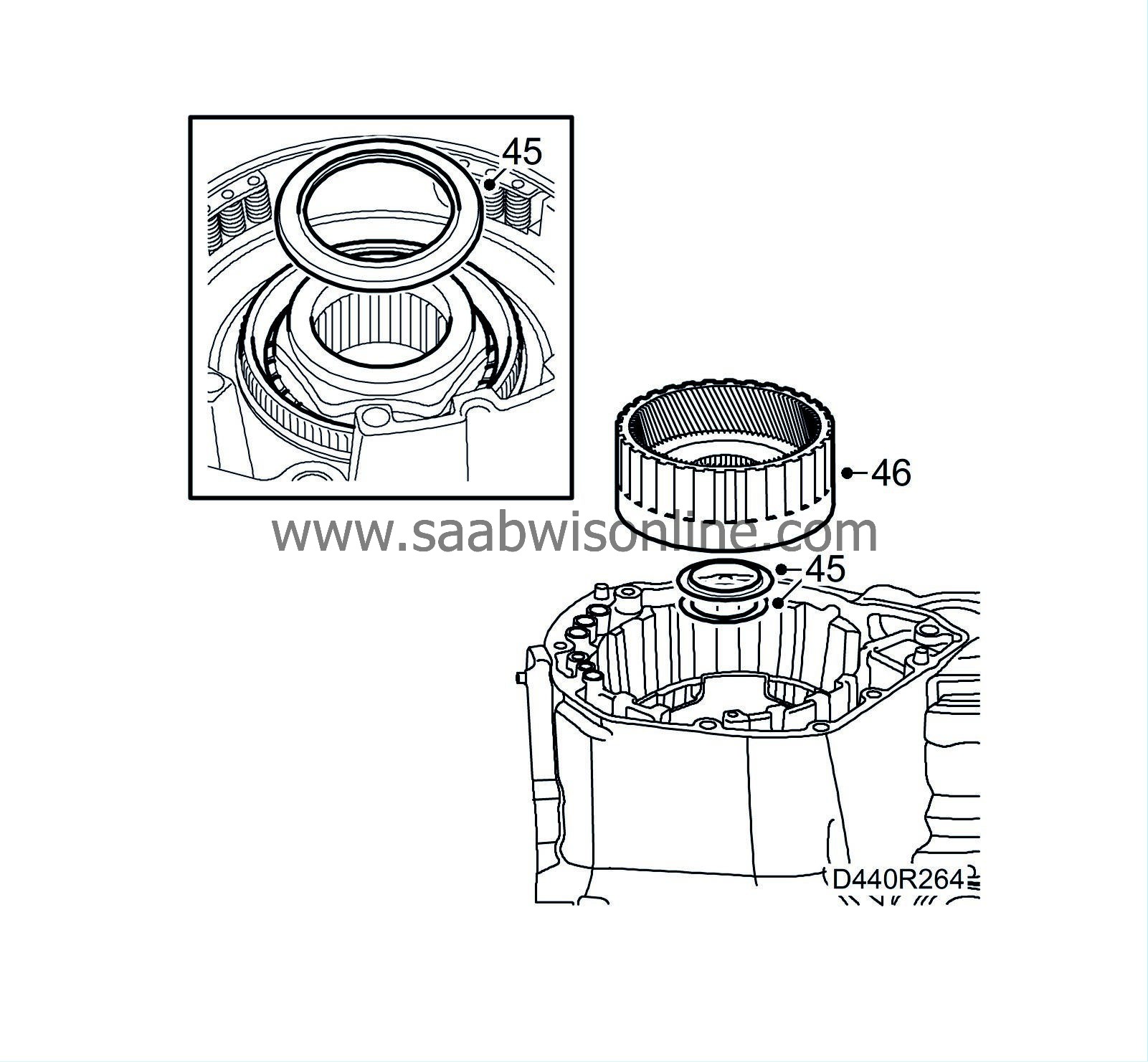

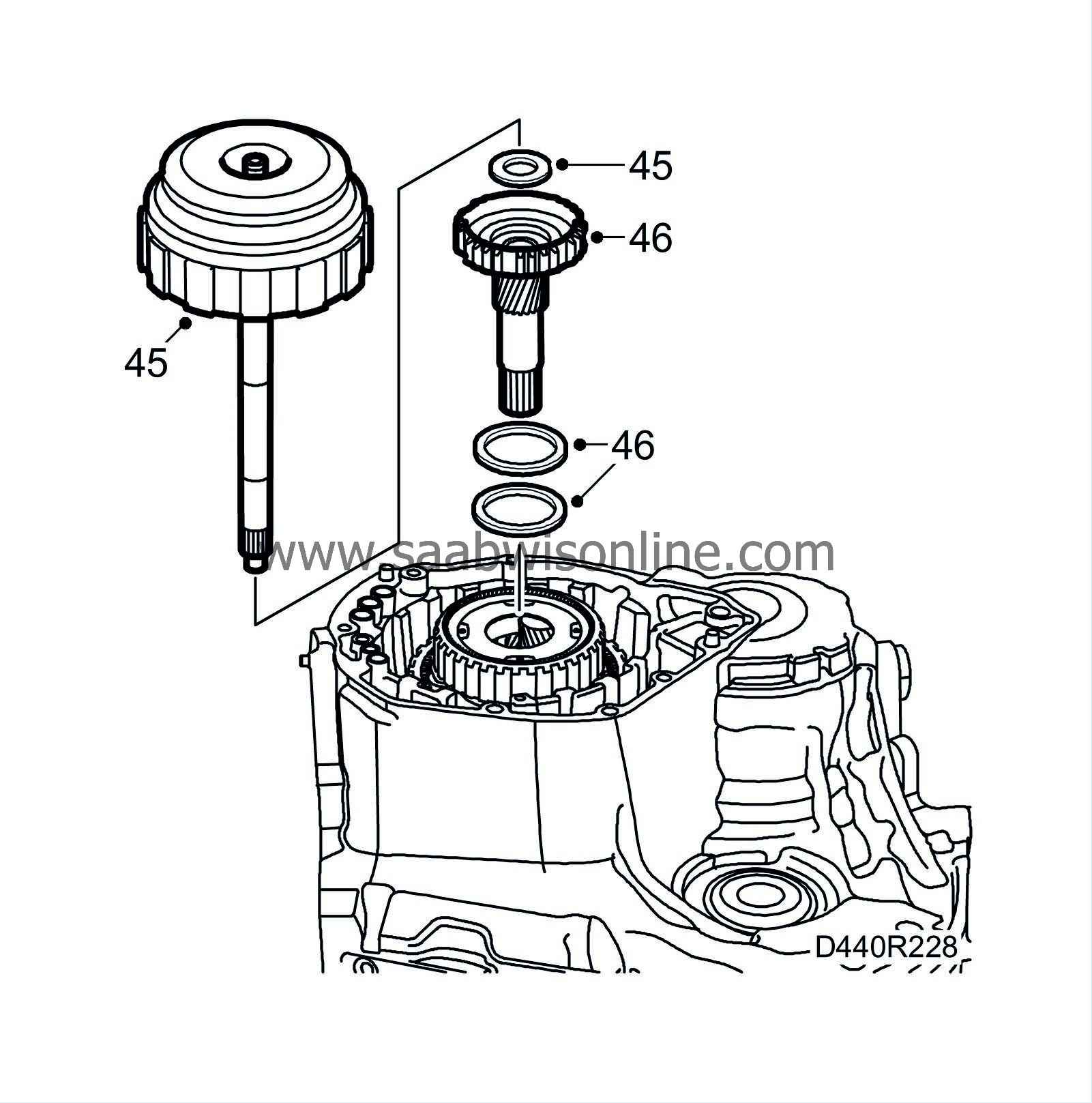

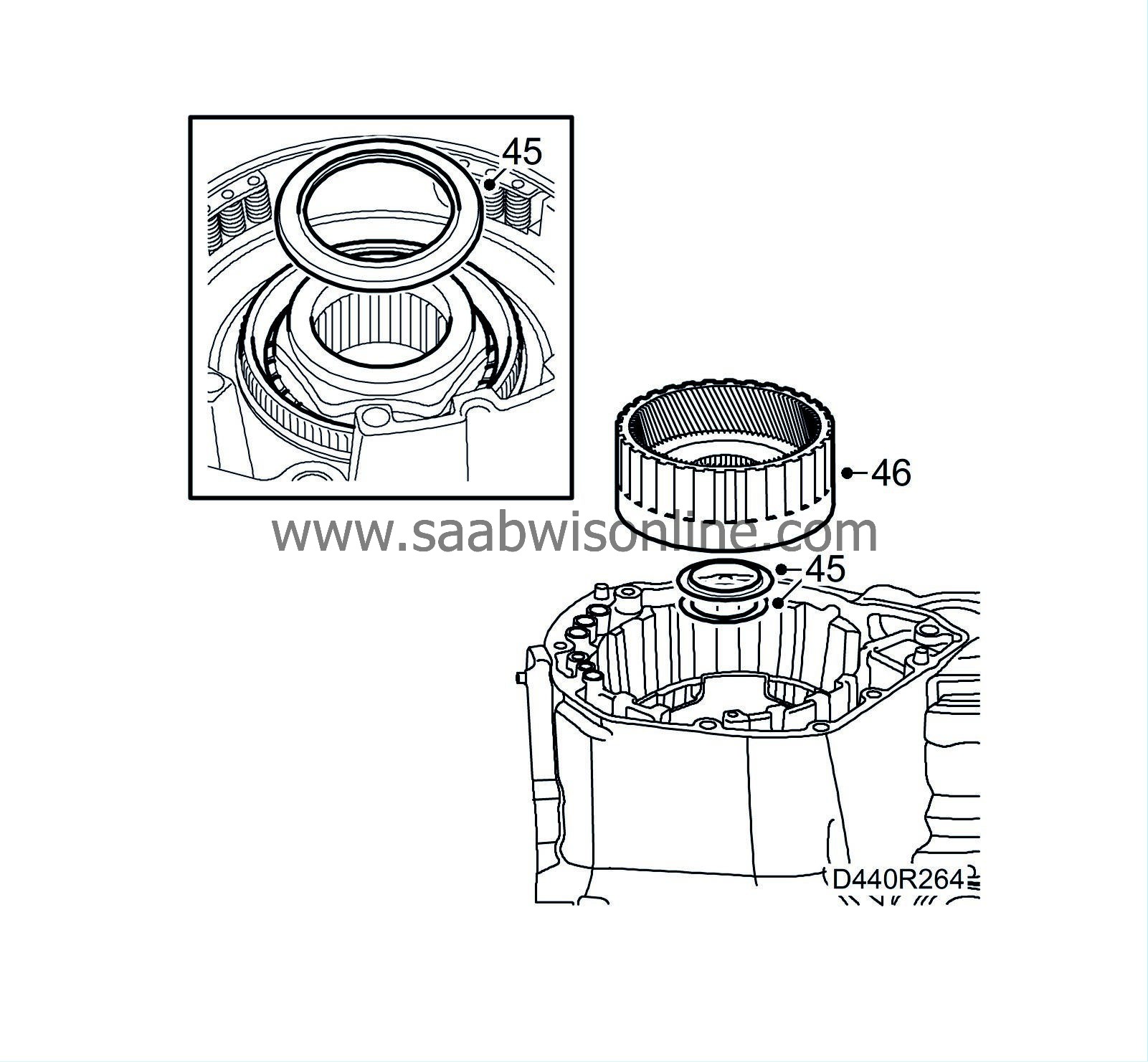

45.

|

Lift out the turbine shaft unit with clutches C1 and C2. Retain the thrust bearing and thrust bearing race.

|

|

46.

|

Lift out the planetary gear sun gear and thrust bearing. Retain the bearing race.

|

|

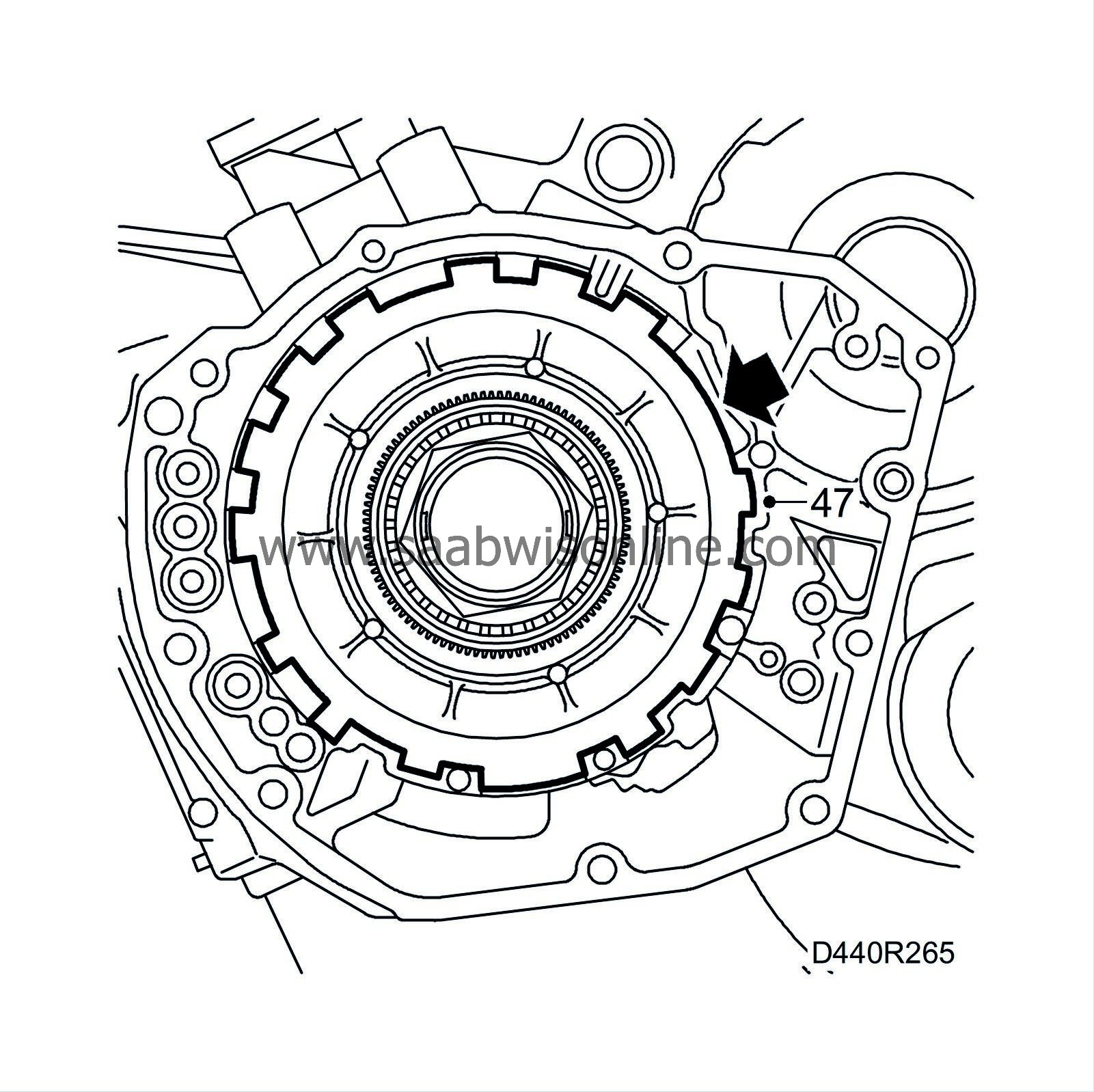

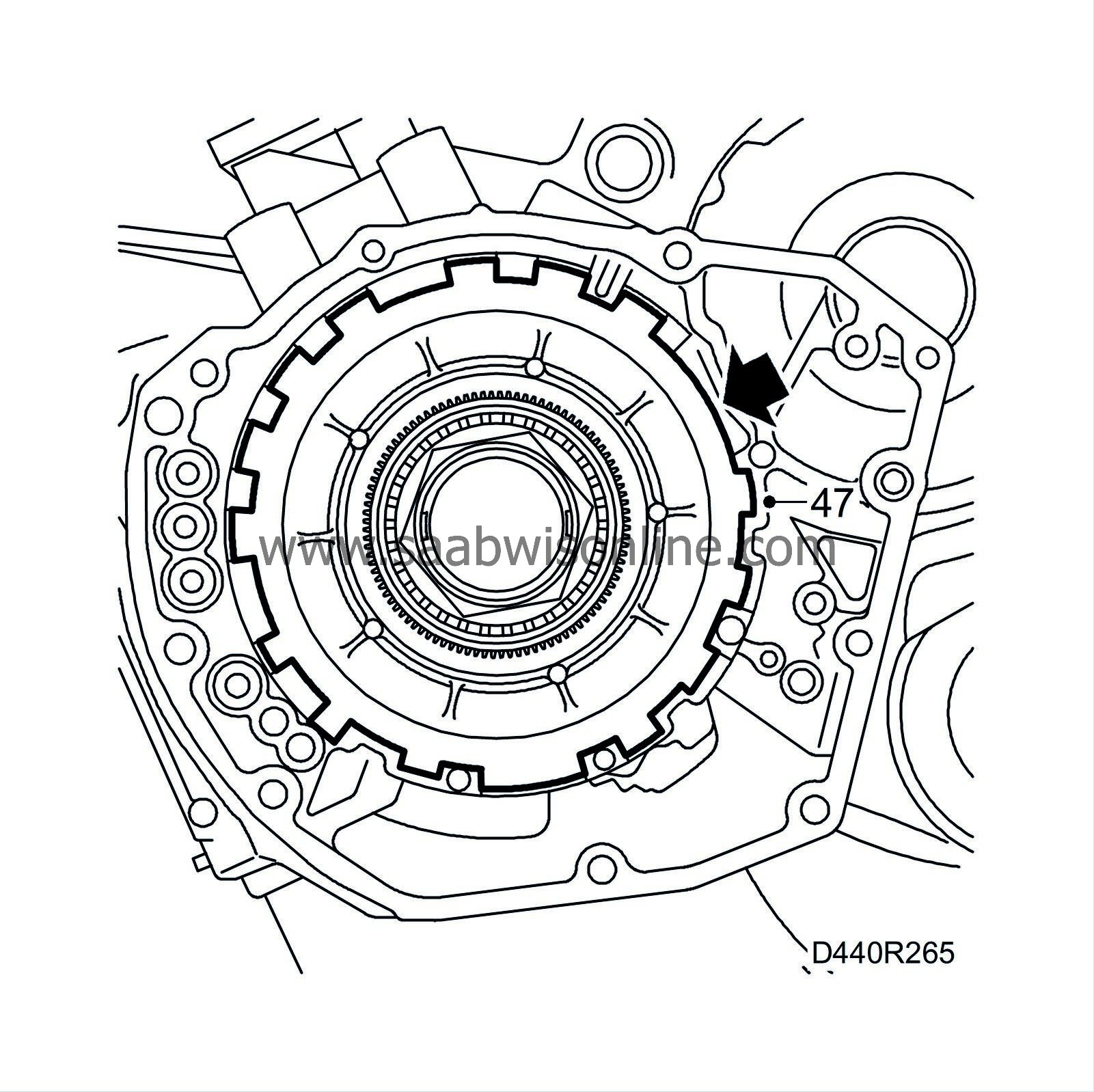

47.

|

Remove the rear ring gear. Retain the thrust bearing and bearing race.

|

|

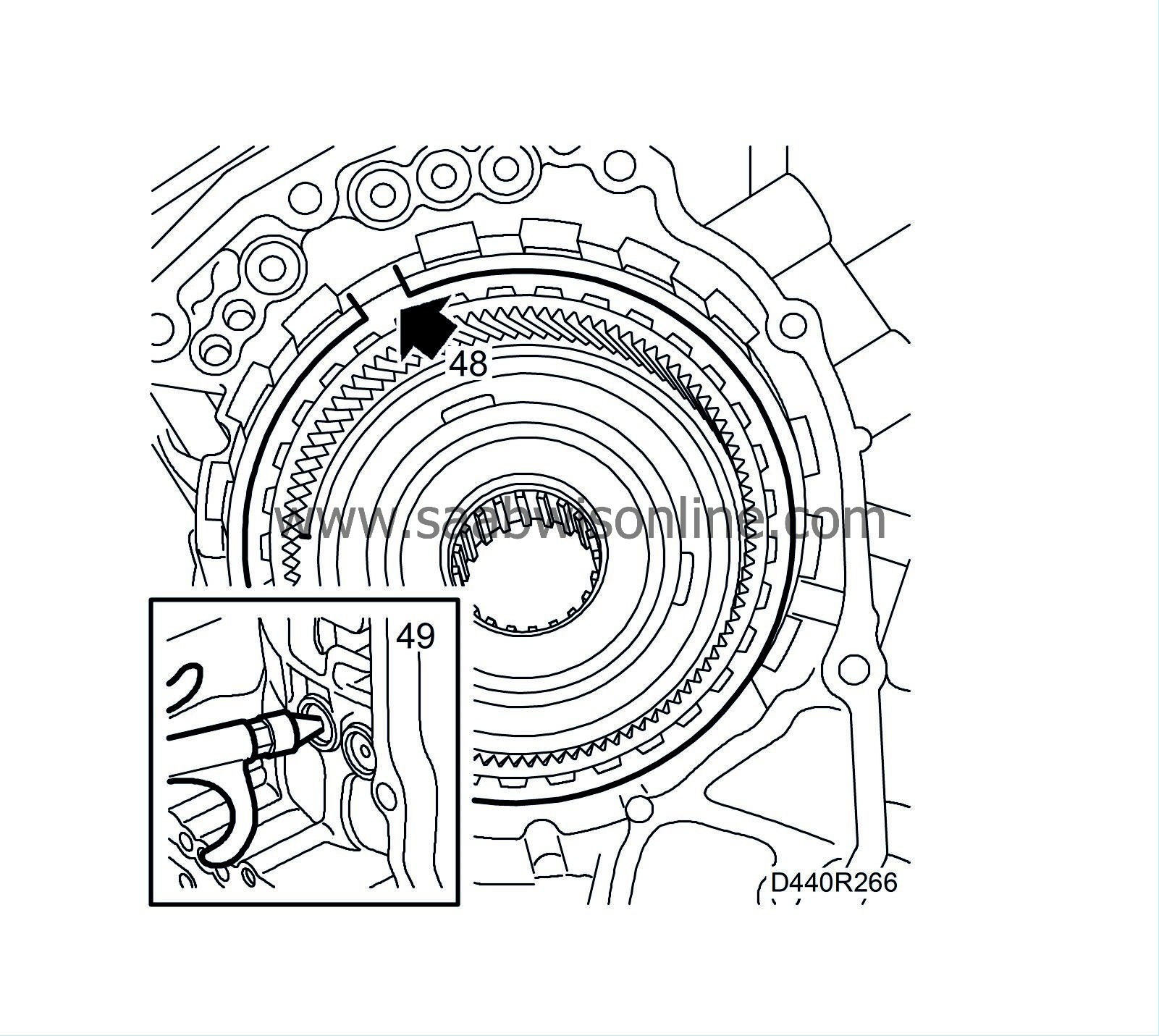

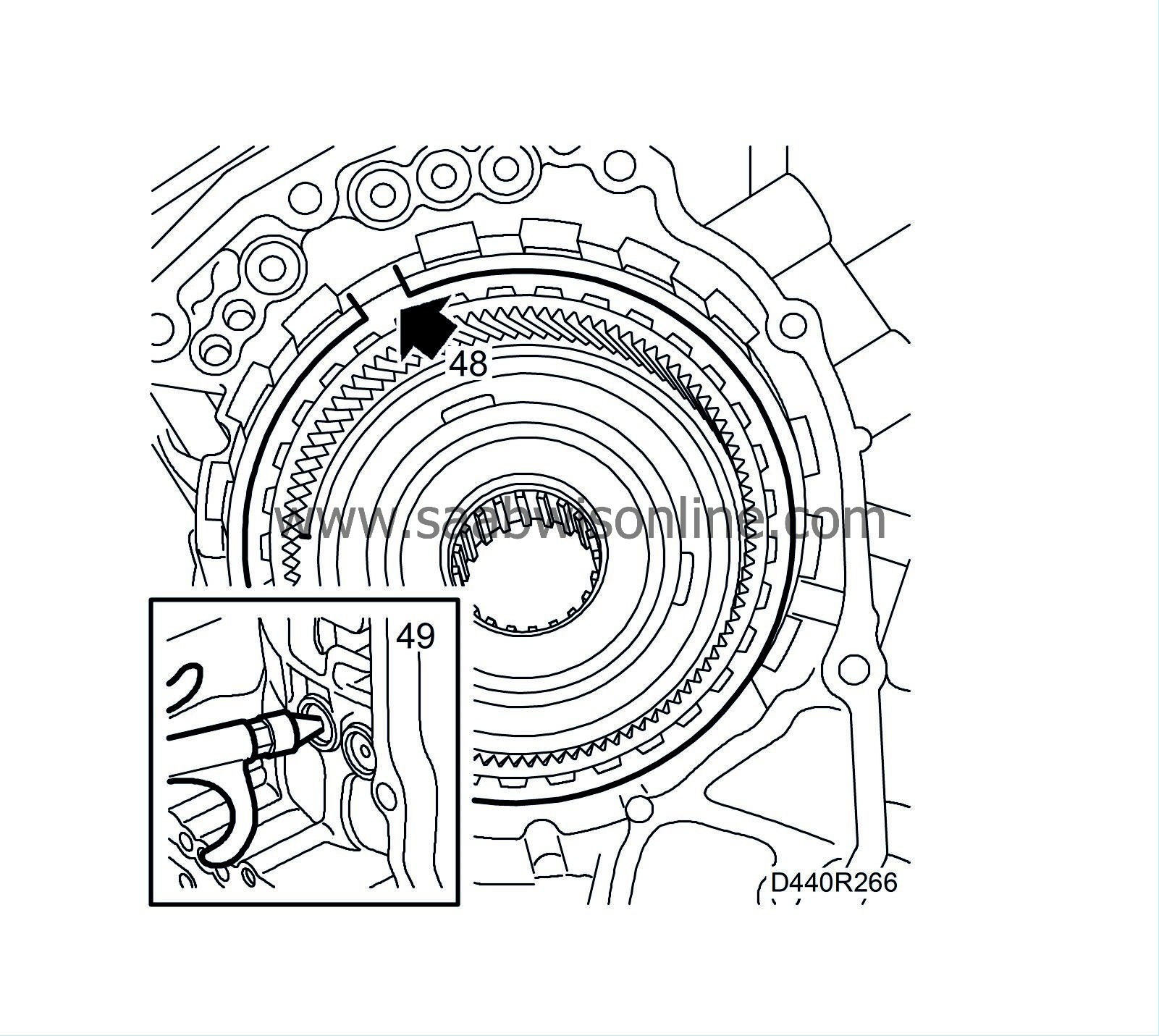

48.

|

Lift out the planetary gear unit with the large thrust bearing.

|

|

49.

|

Remove the circlip for freewheel F2 and brake B3 using a screwdriver. Lift out the ring gear with F2 and B3 that contain the clutch discs, disc plates and flange.

|

|

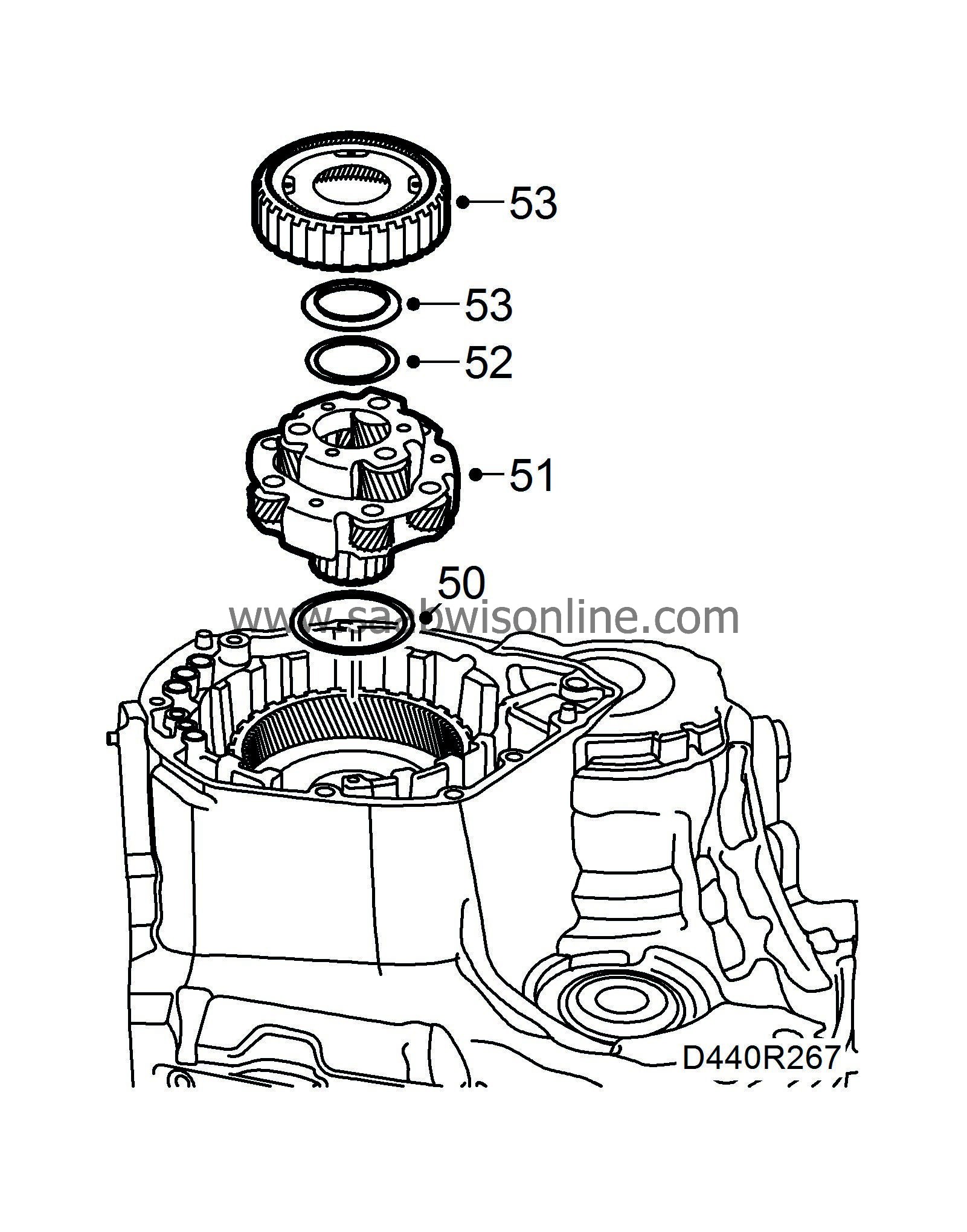

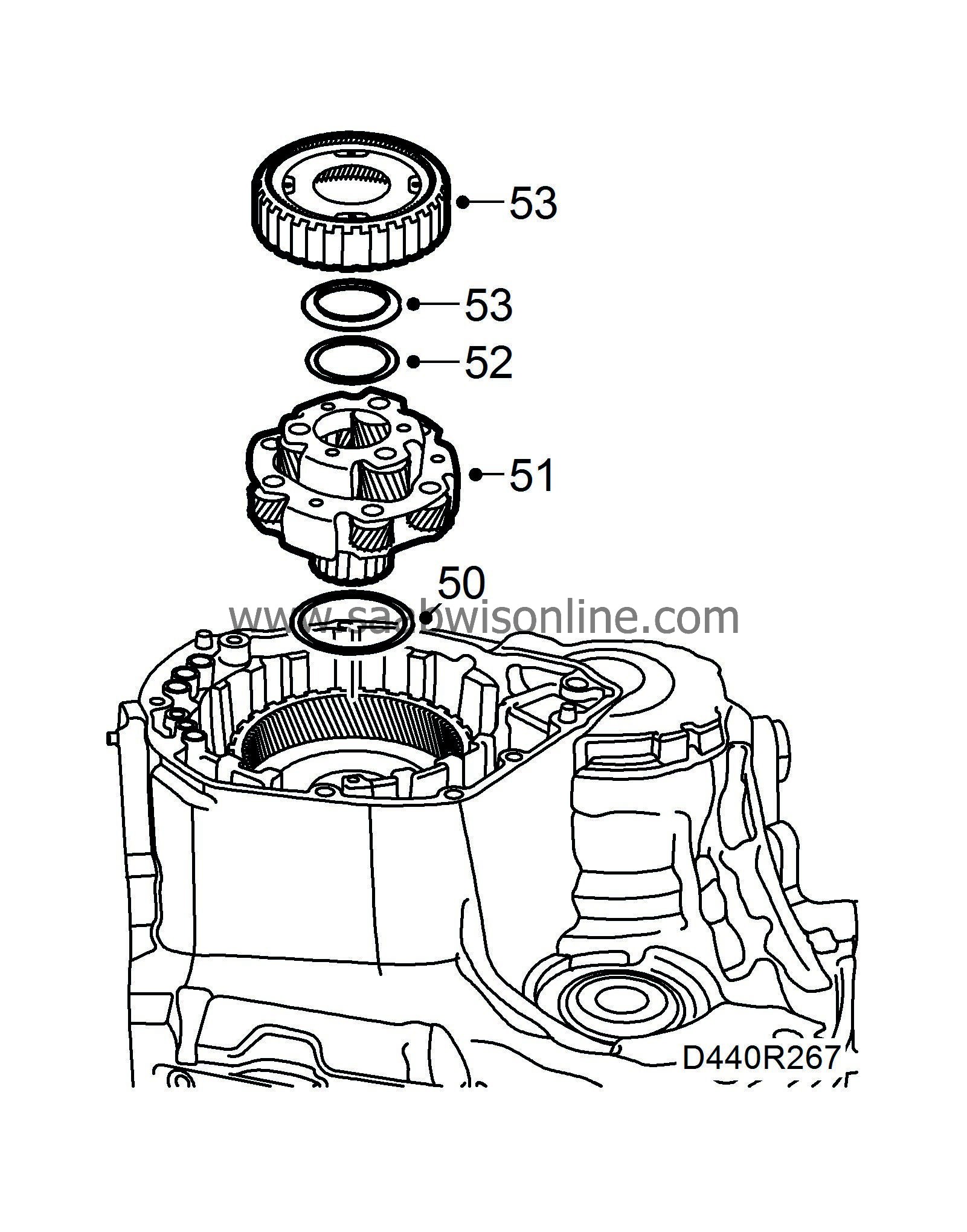

50.

|

Retain the thrust bearing and bearing race.

|

|

51.

|

Remove the circlip for the spring unit using a screwdriver. Lift out the spring unit.

|

|

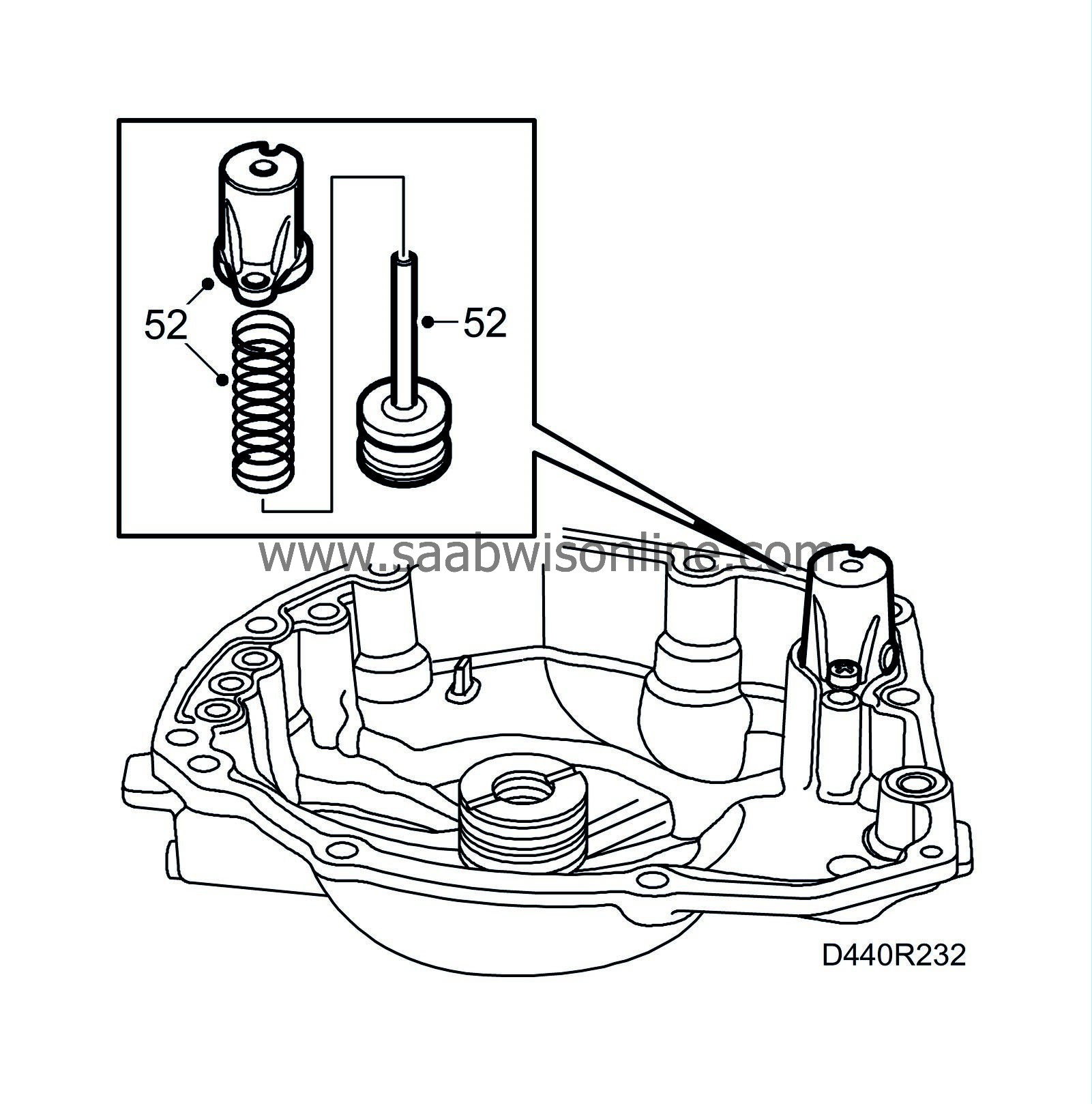

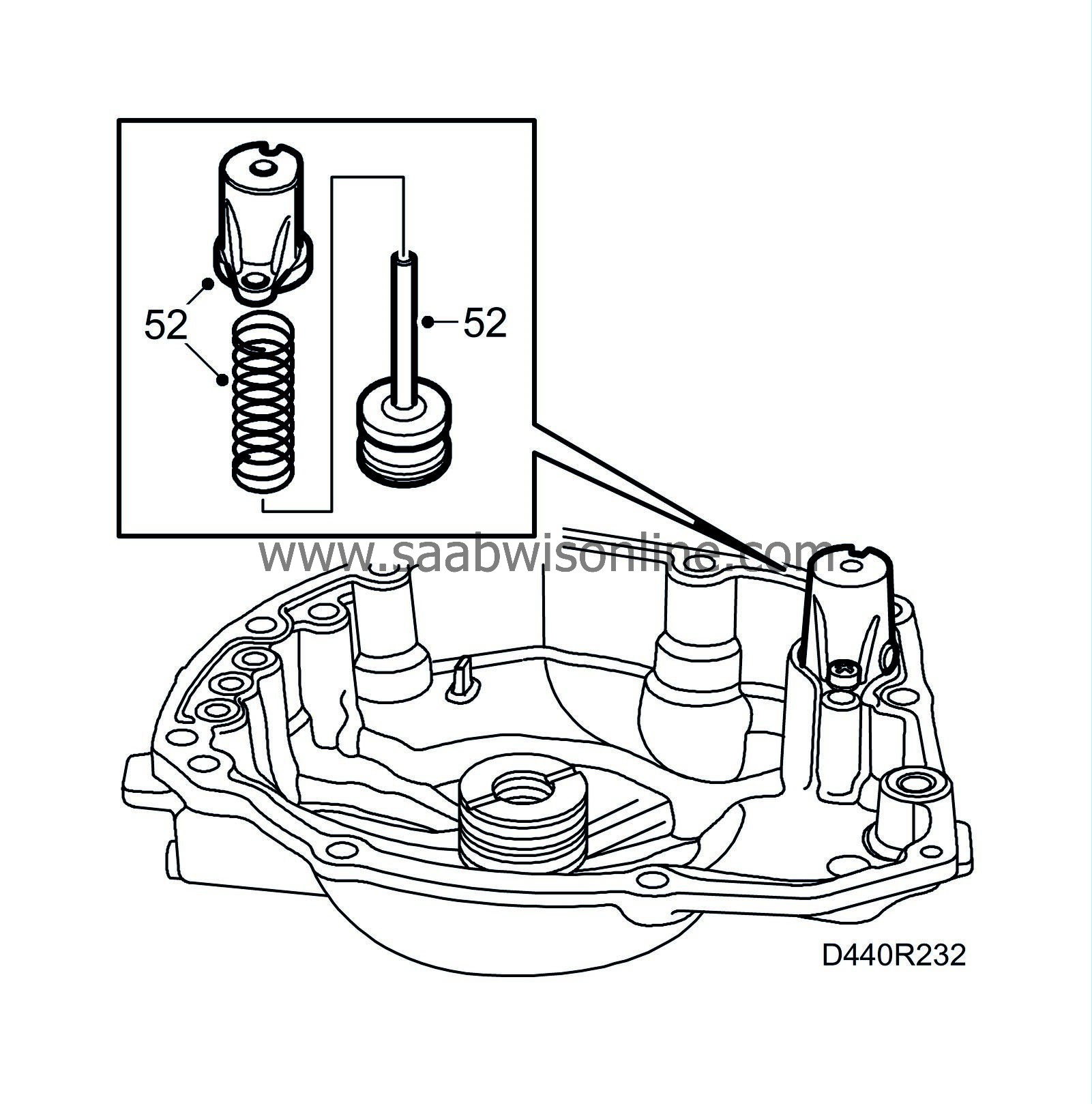

52.

|

If necessary, remove the accumulator for C1 from the end cover with spring and plunger.

|

|

53.

|

Remove the plug from the end cover

|

|

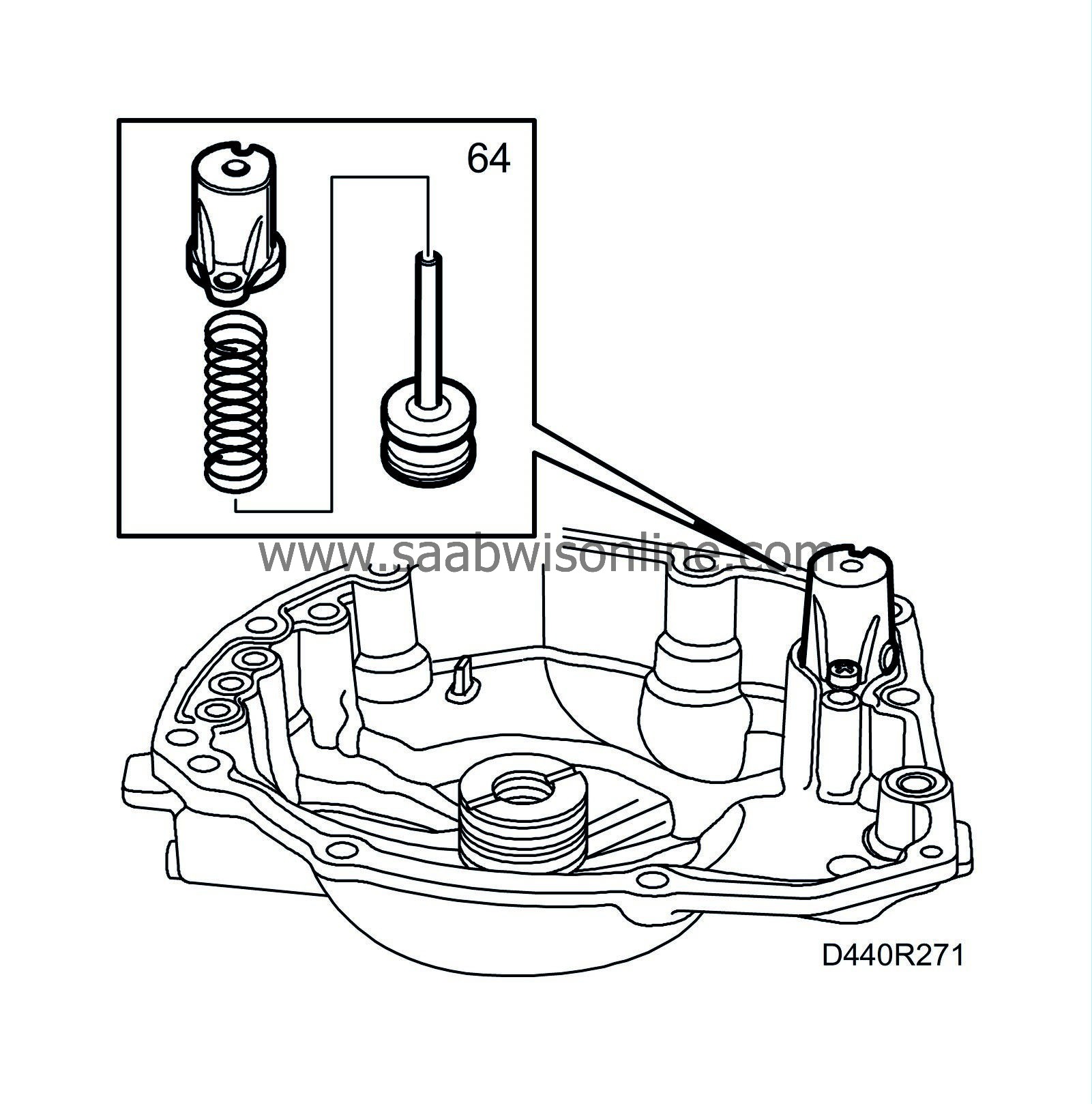

54.

|

Carefully apply an air pressure of 4 bar through the oil passage for B3 to remove the B3 plunger as illustrated. Use a pair of blunt nose pliers if the plunger will not come out.

|

|

55.

|

Turn the gearbox through 90°.

|

|

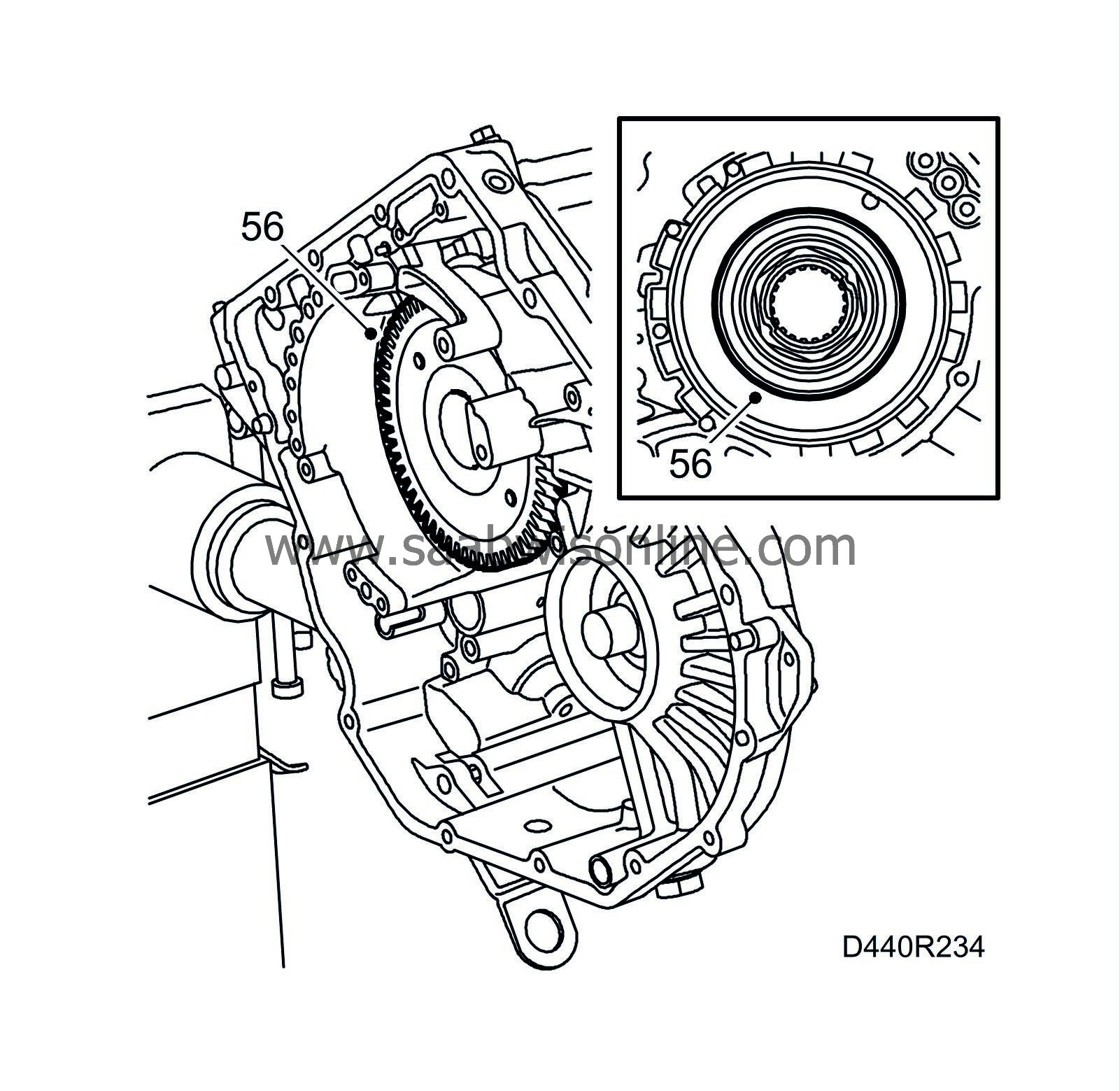

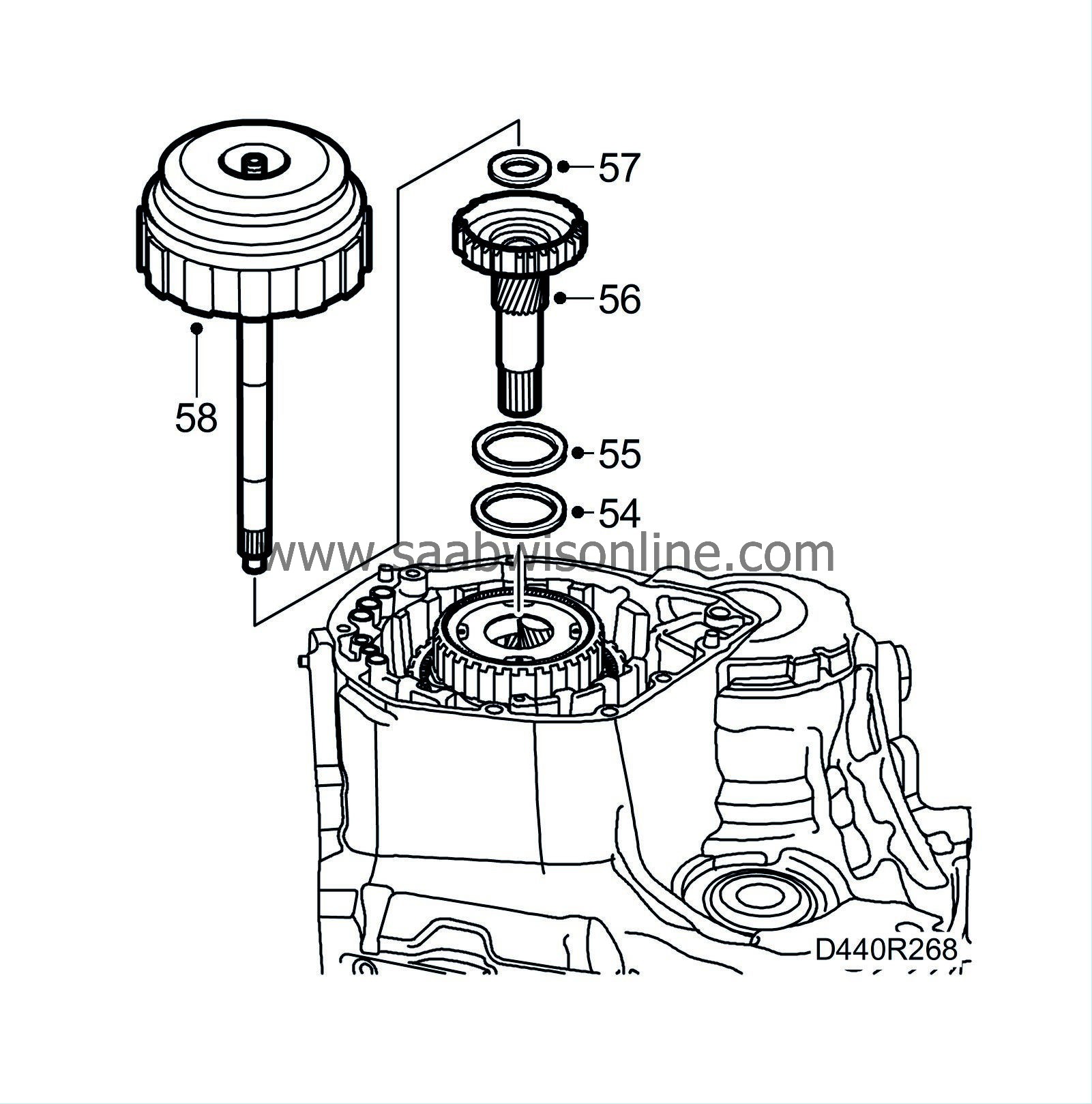

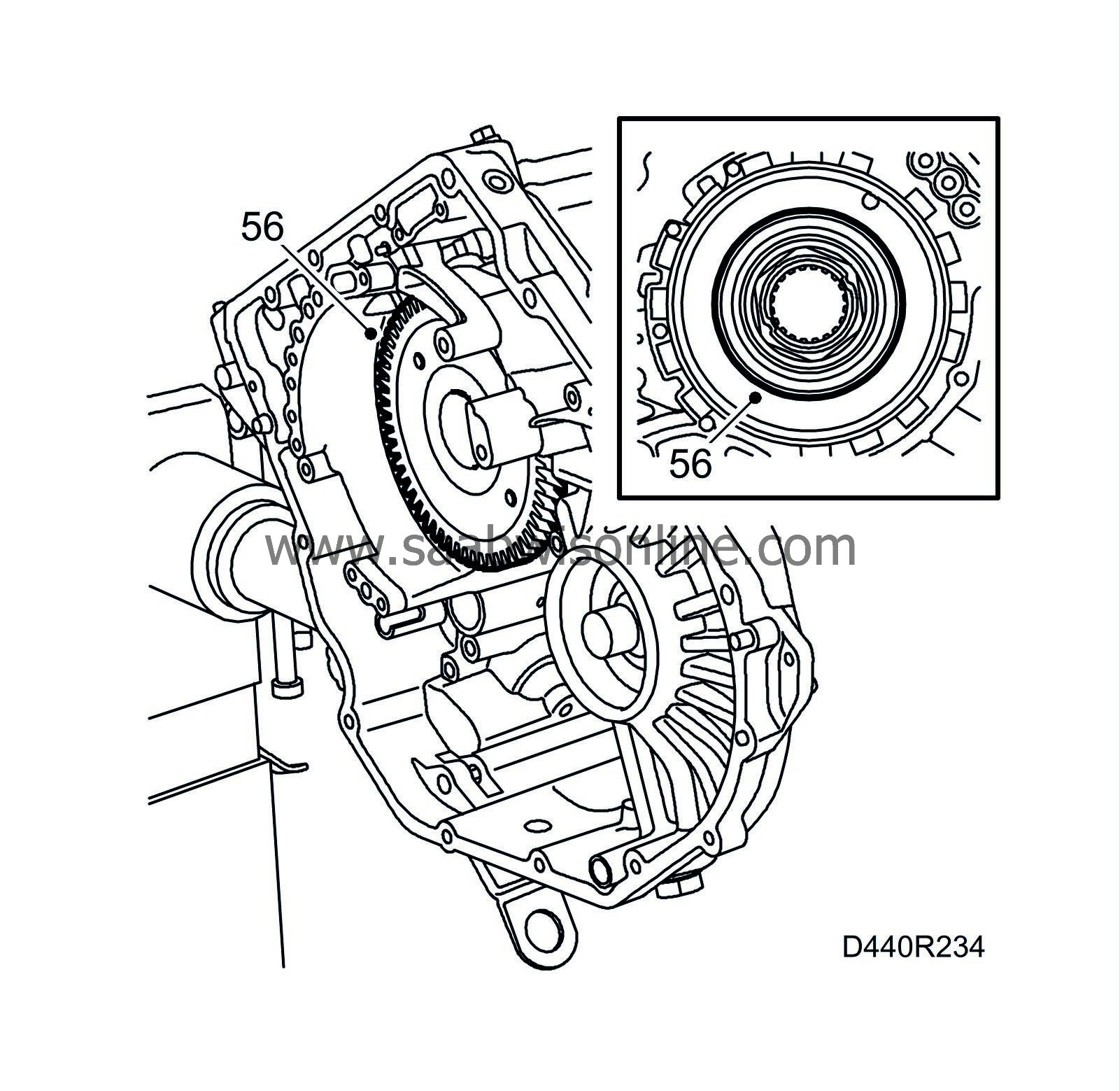

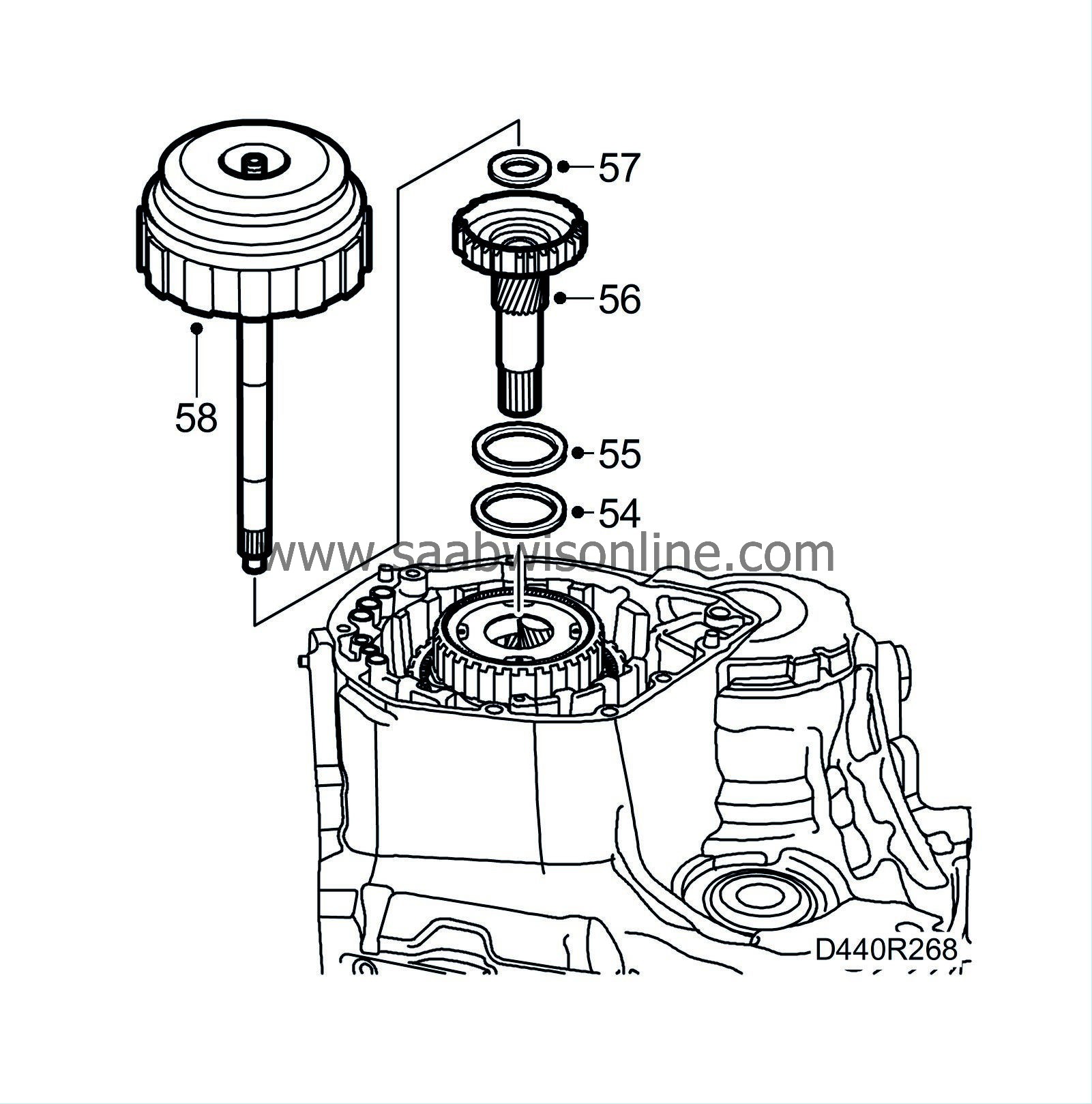

56.

|

Remove the circlip for the intermediate gear. Use circlip pliers 87 90 180 with tips 87 90 297 and a small screwdriver. Remove the intermediate gear.

|

|

57.

|

Turn the gearbox through 90°

|

|

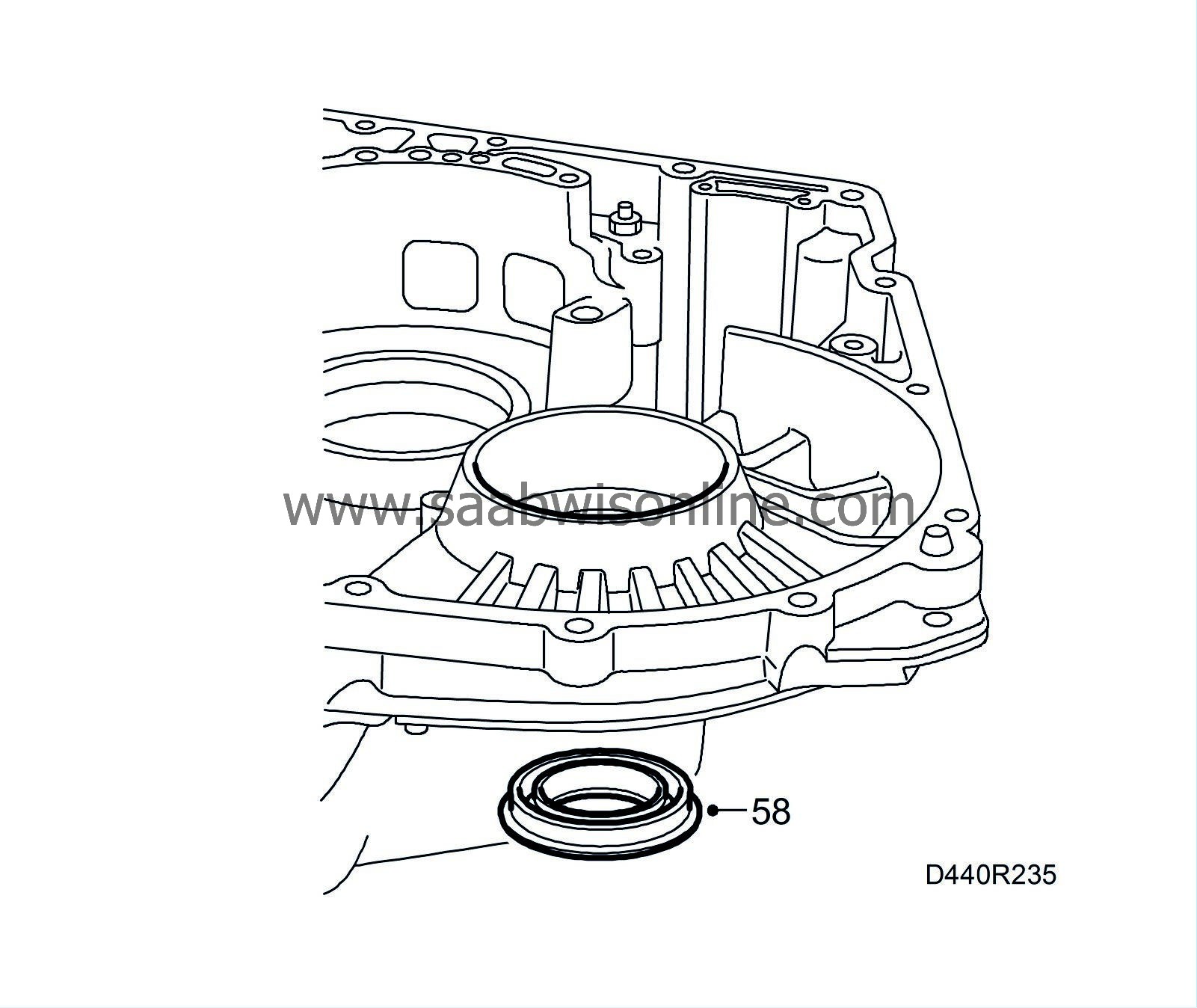

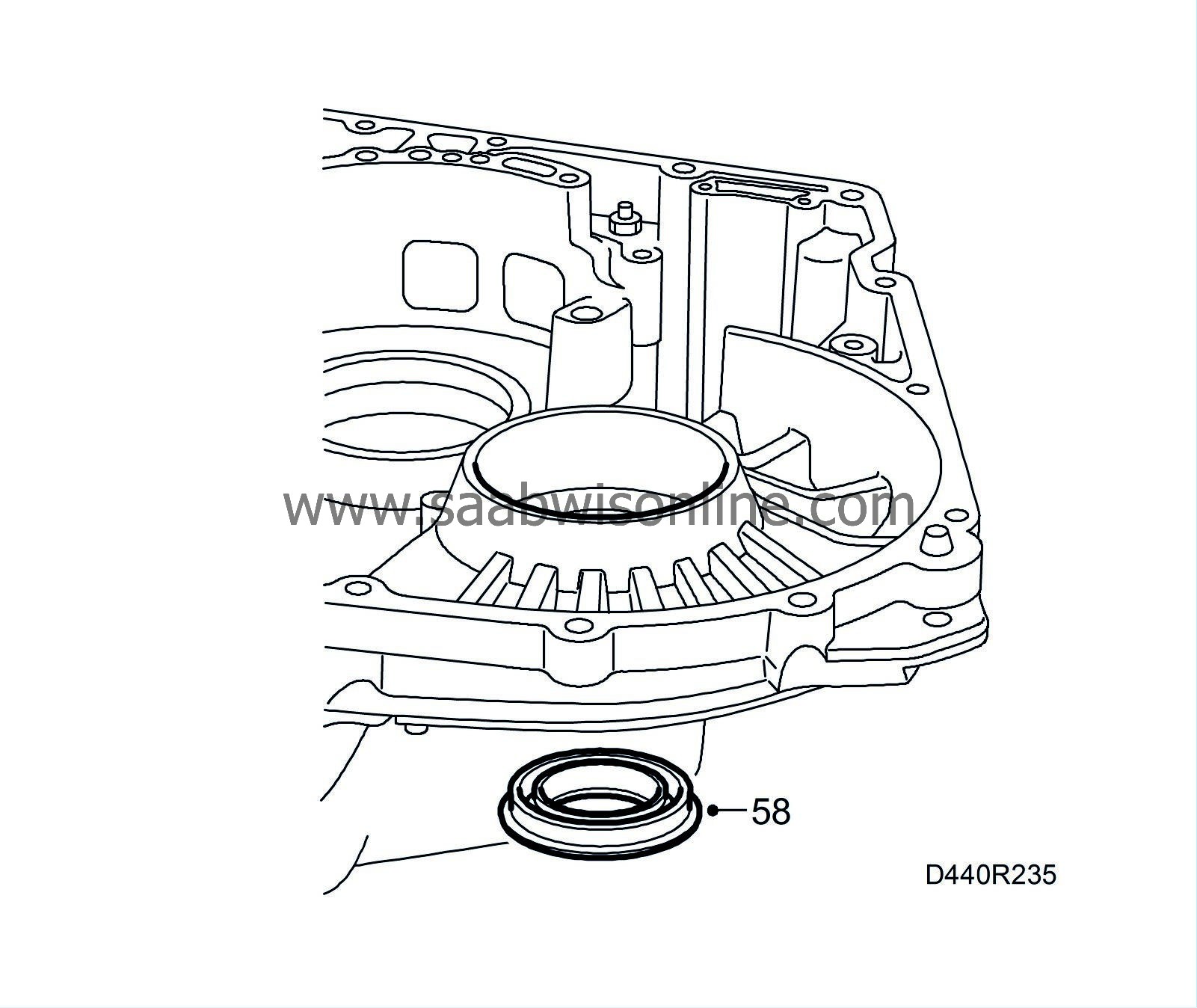

58.

|

Remove the drive shaft seal using a hammer and screwdriver.

|

|

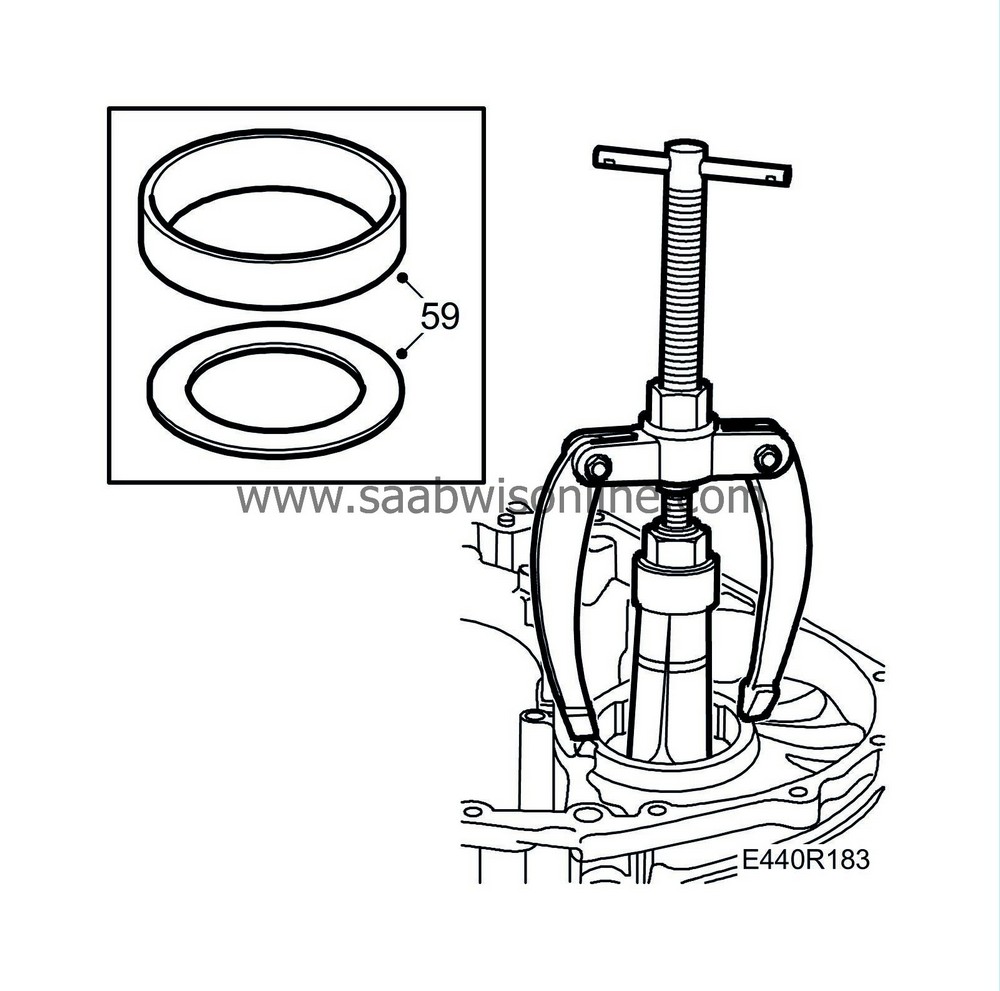

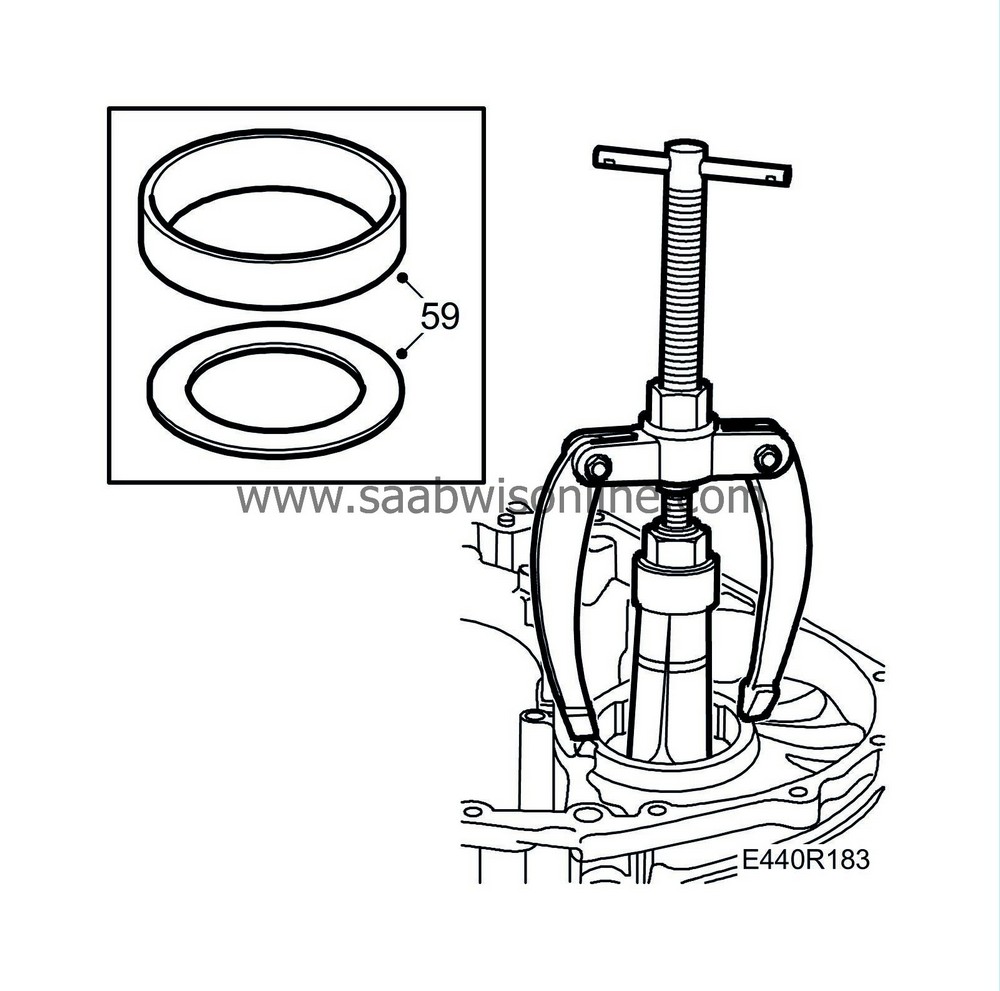

59.

|

Fit puller 87 91 683 and 87 91 675 and remove the bearing race from the gearcase by heating the case with a hot-air gun for about 5 minutes. Pull out the bearing race and retain the shim.

|

|

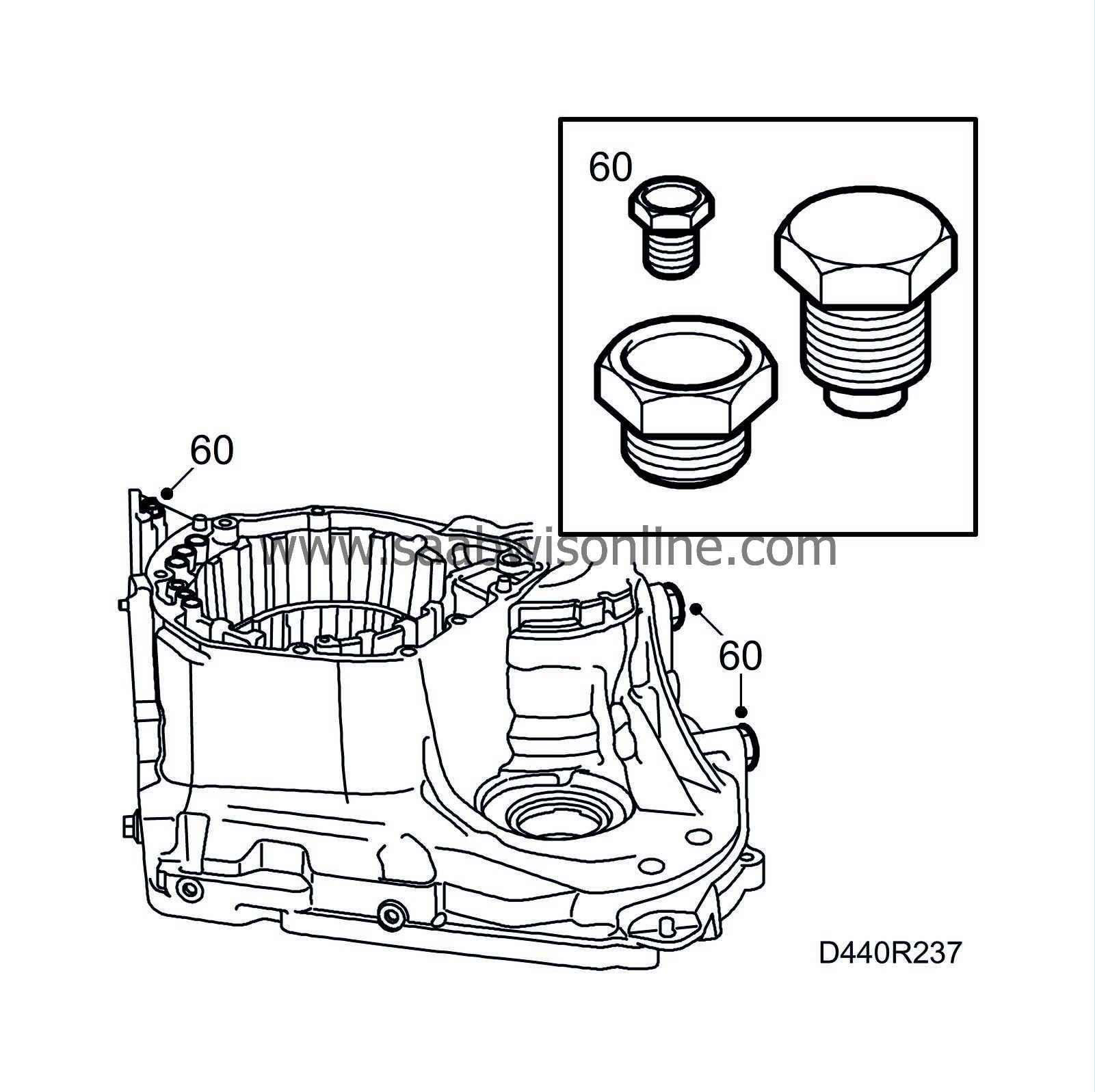

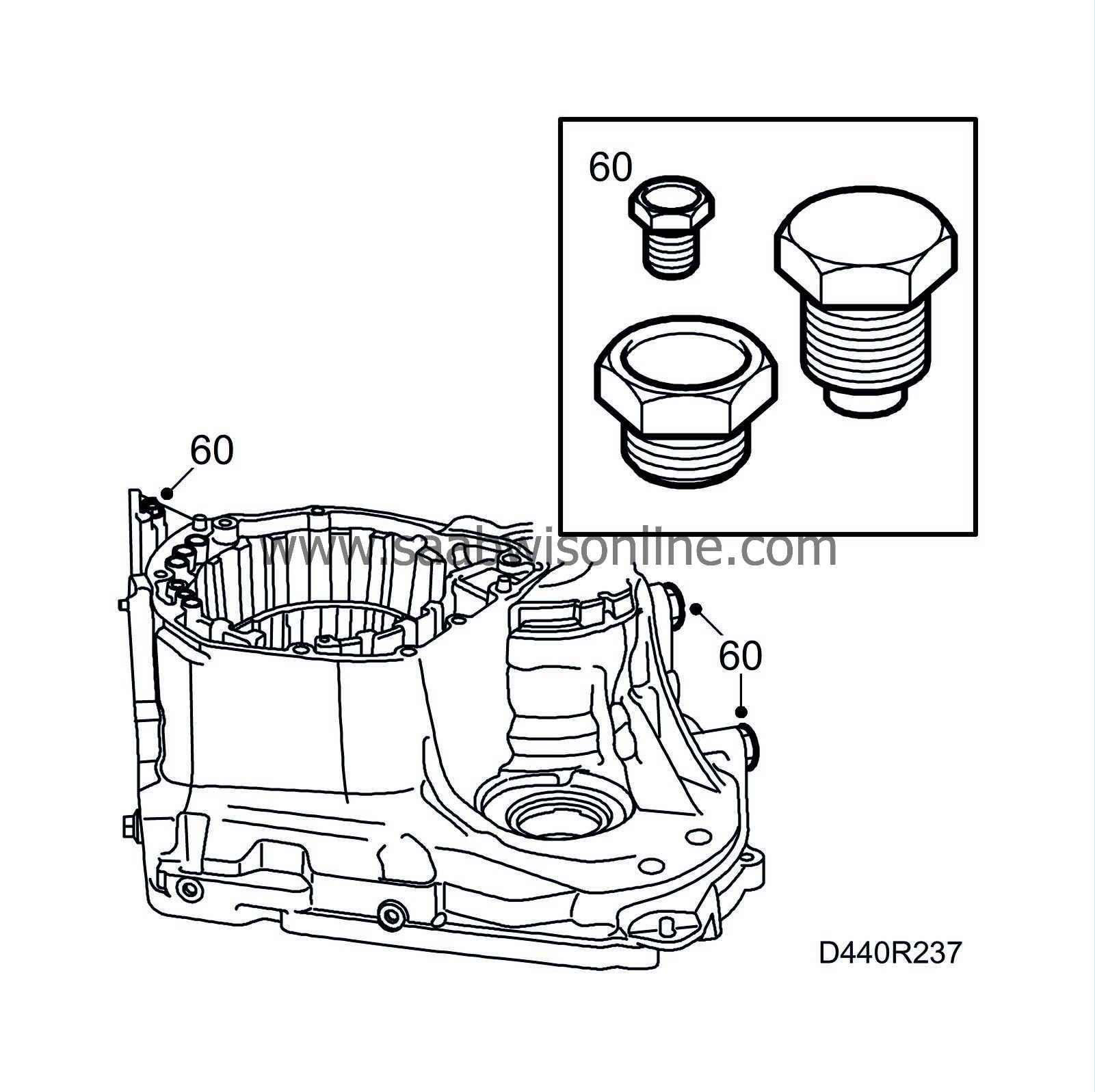

60.

|

Remove the brake band holders and the remaining plugs in the gearcase (do not get the plugs mixed up).

|

|

61.

|

Remove the screw and pipe clamp from the torque converter shell.

|

|

62.

|

Pull up both ends of the pipe with sliding hammer 83 90 270 and hook 87 92 384. Remove the pipe. Take care not to damage the pipe.

|

|

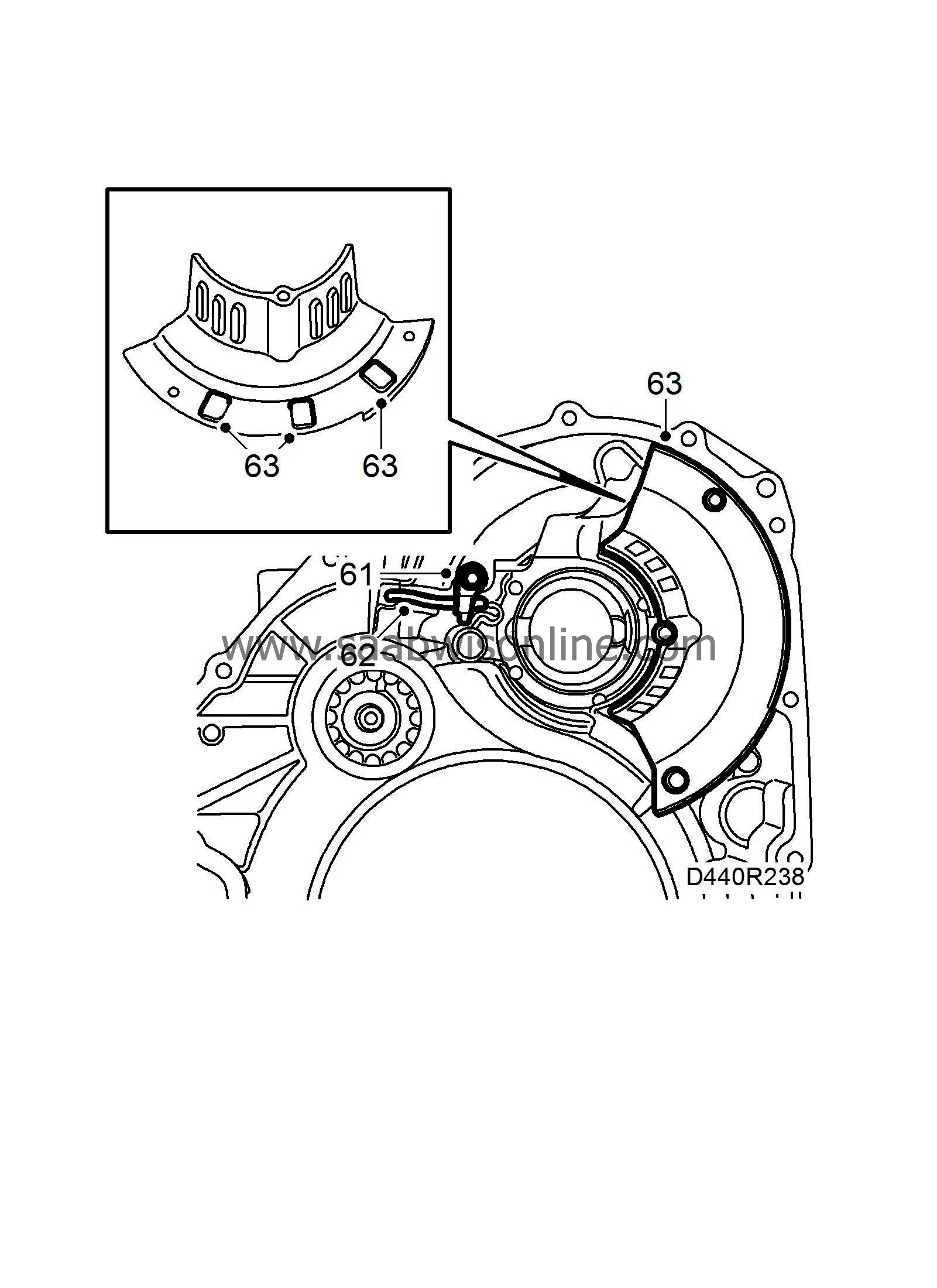

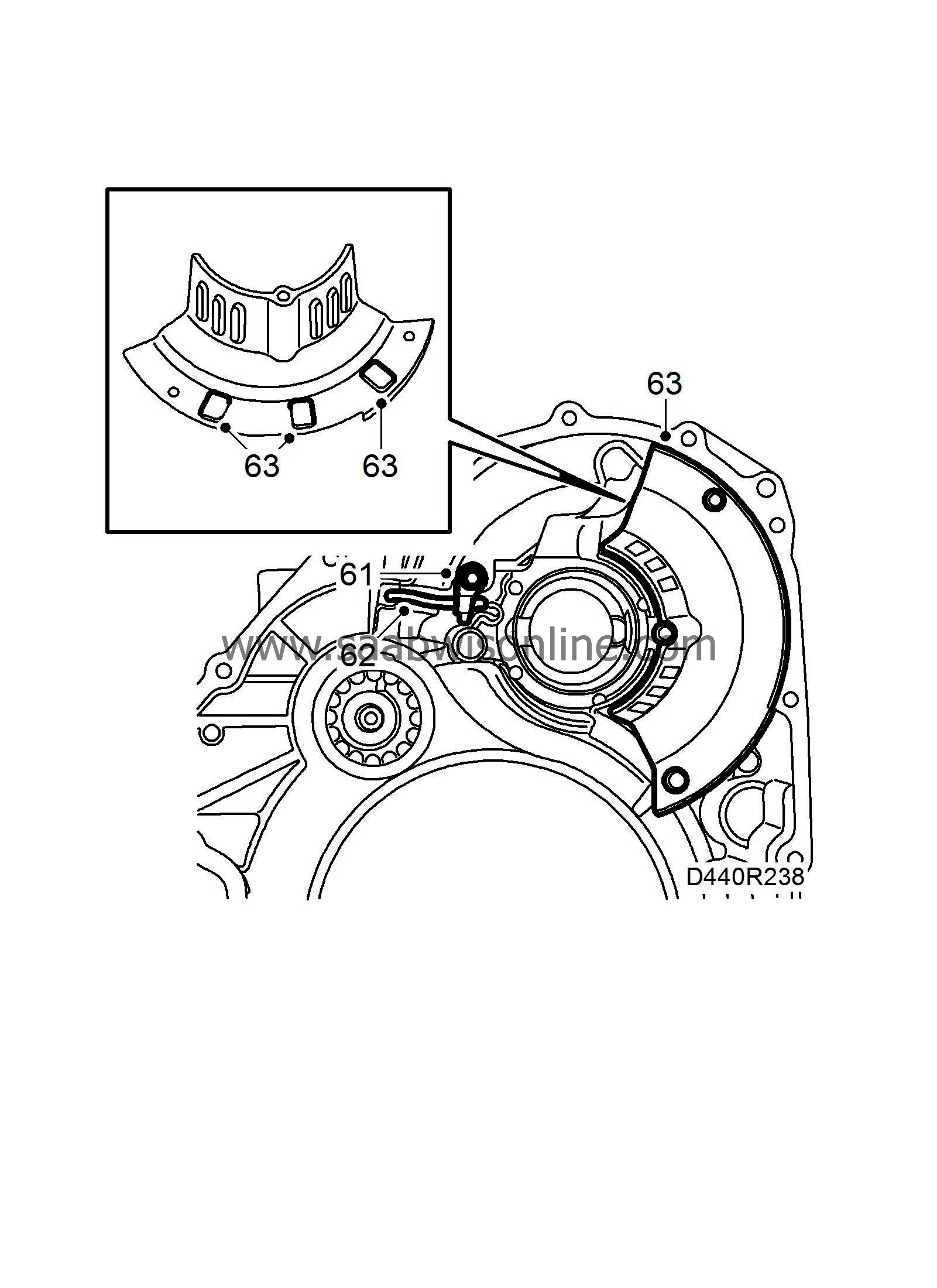

63.

|

Remove the oil channel plate (three bolts). Remove the three magnets.

|

|

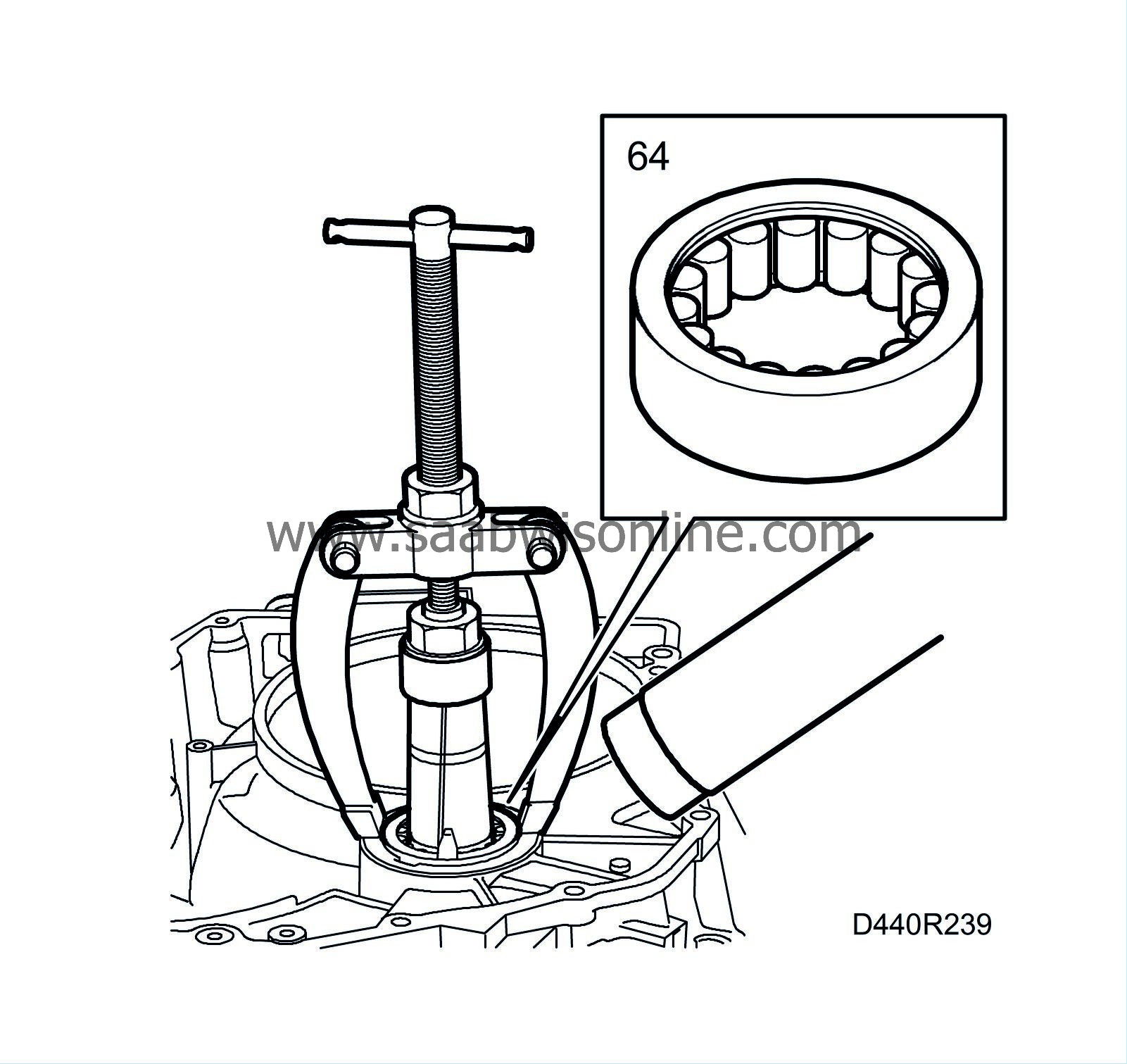

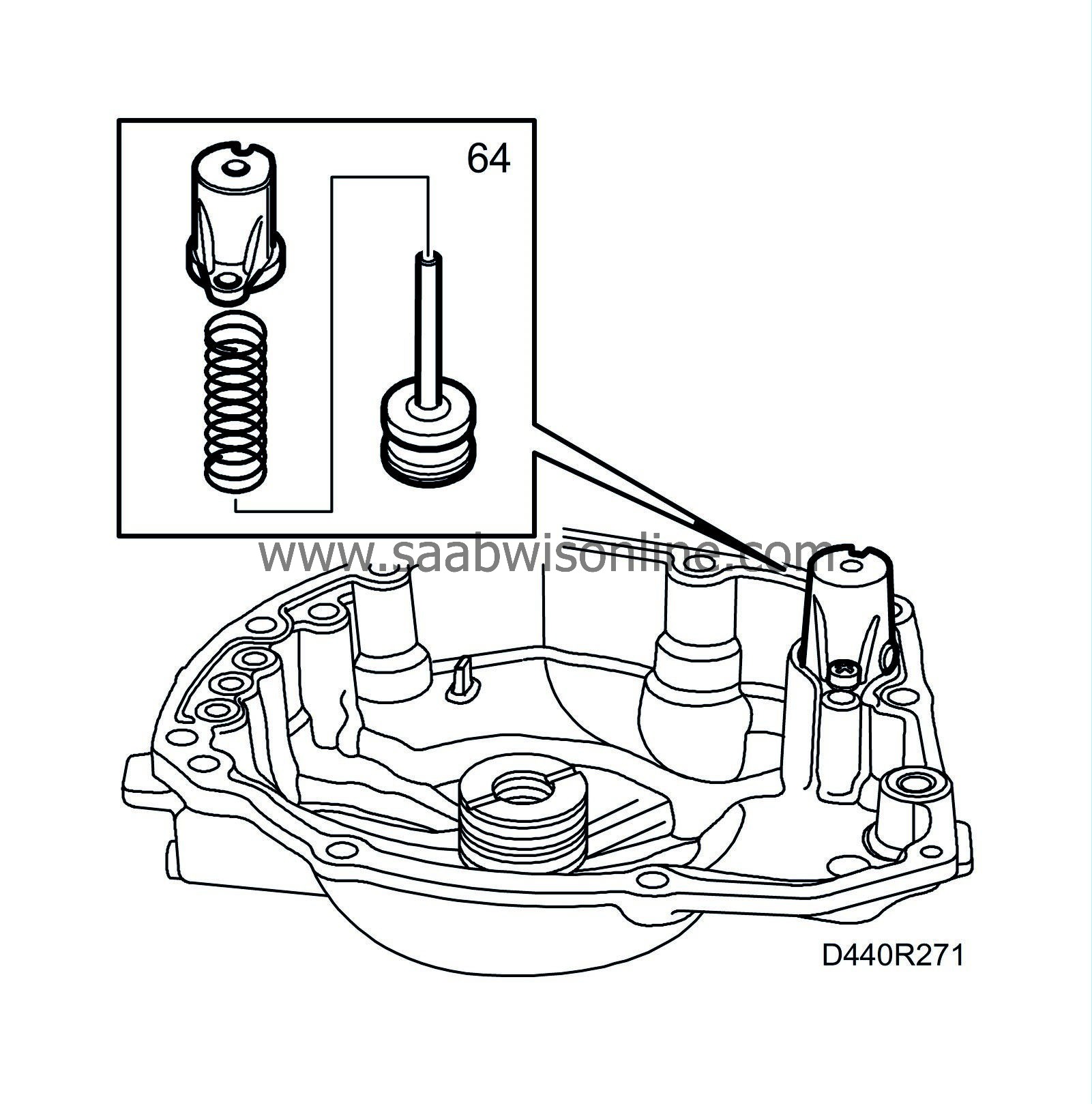

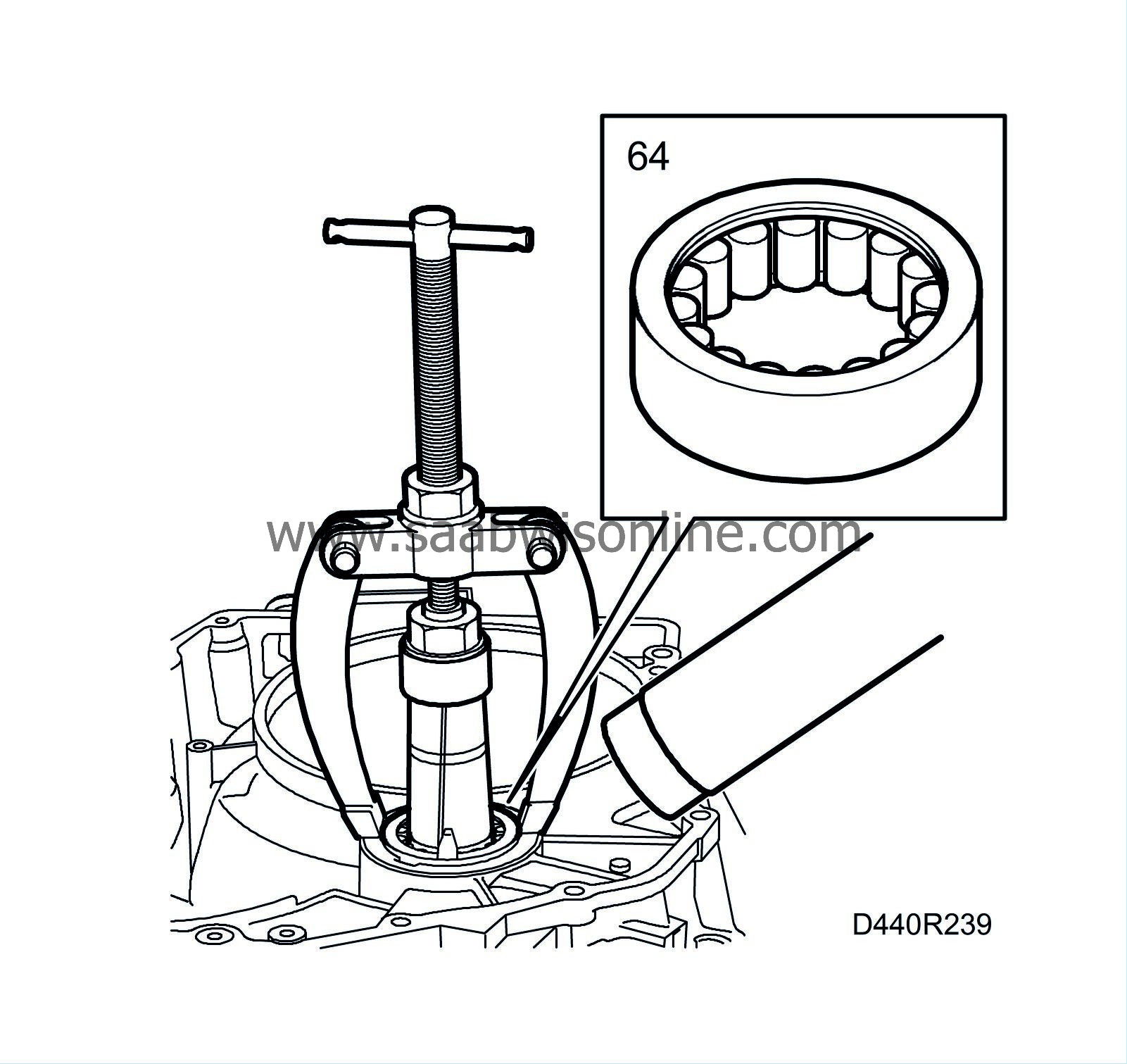

64.

|

Fit puller 87 91 675 and 87 91 683. Heat the bearing seat for about 5 minutes with a hot-air gun and pull out the roller bearing.

|

|

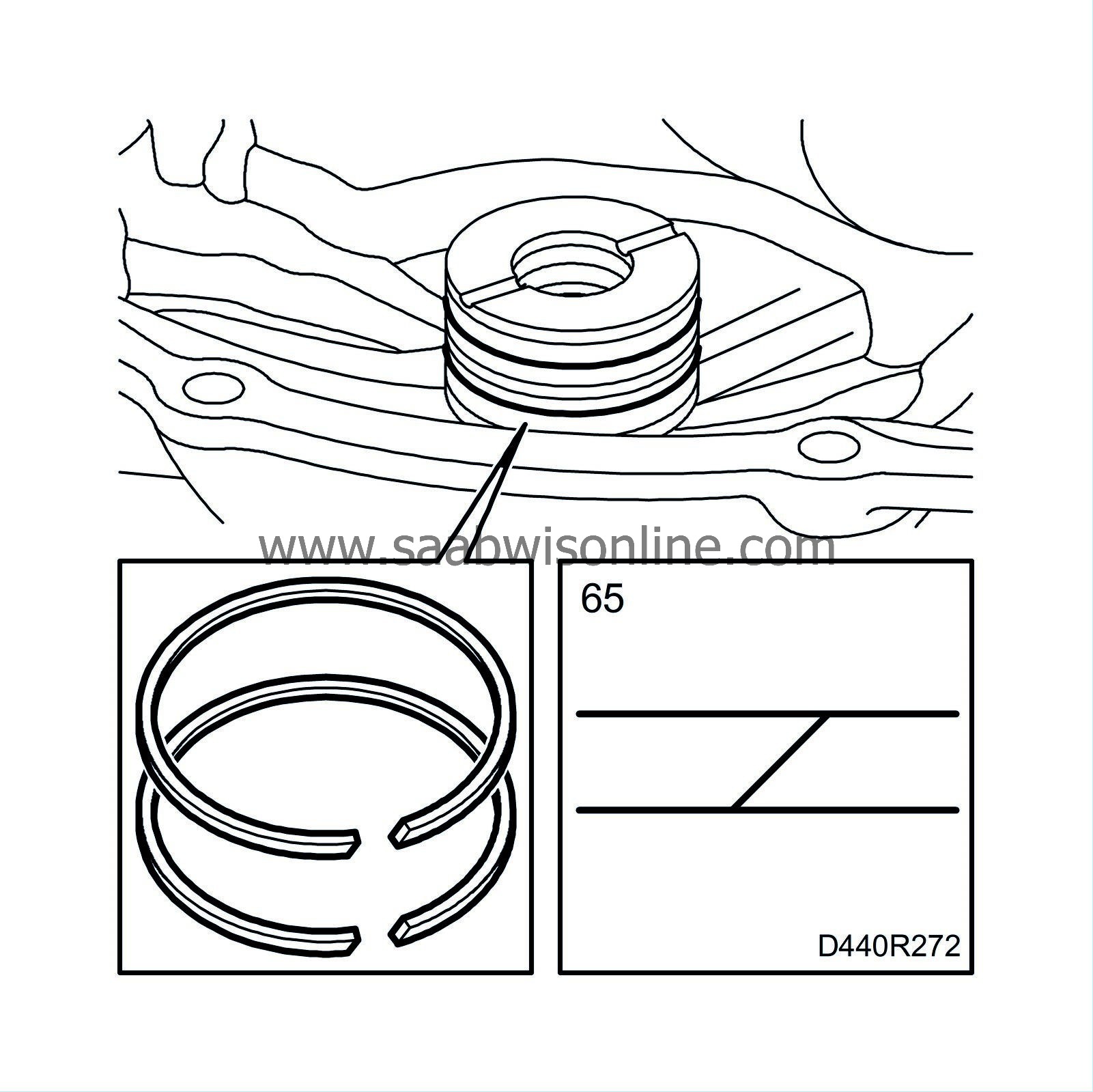

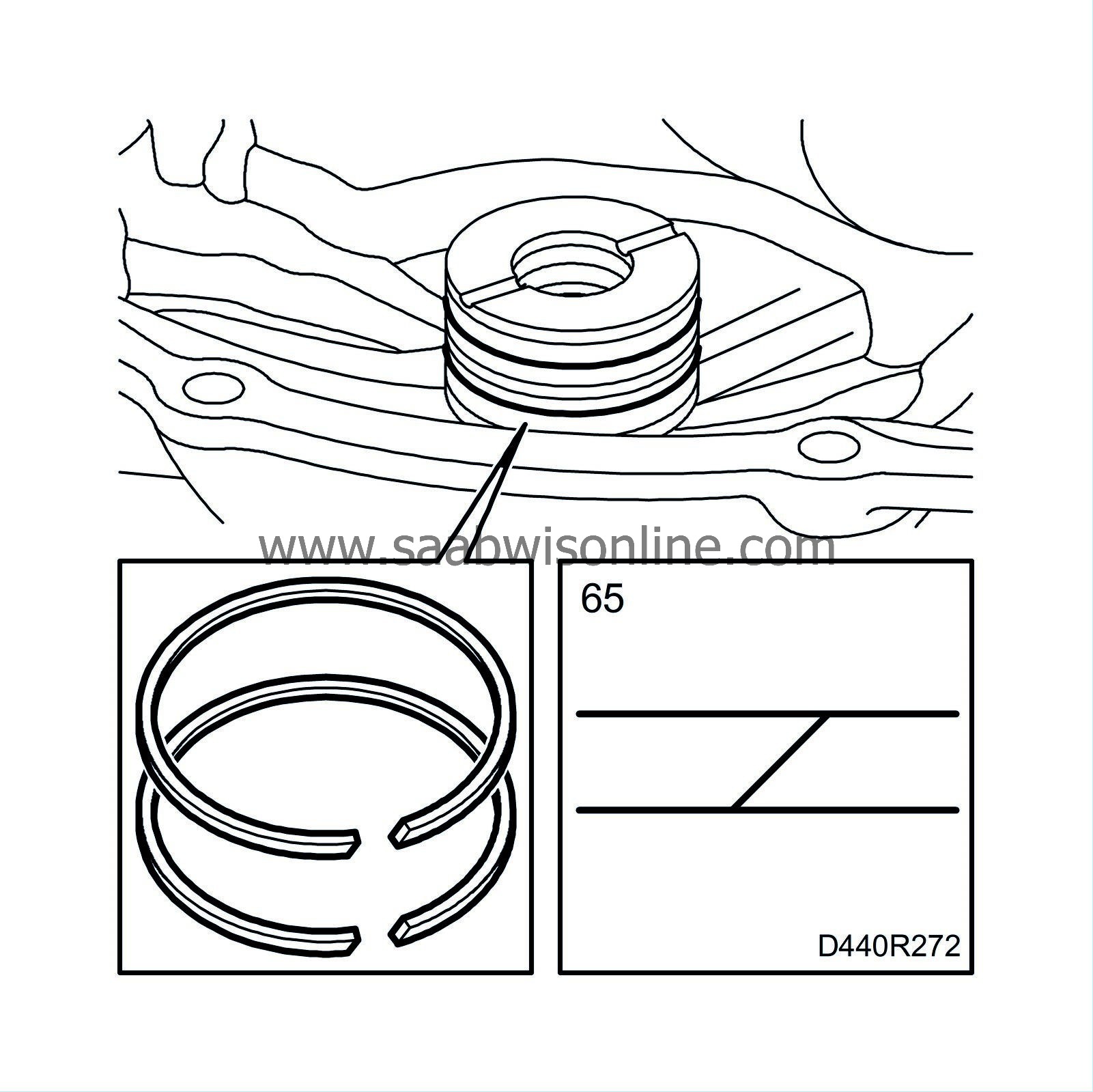

65.

|

Knock out the shaft seal.

|

|

66.

|

Remove the bearing race for the taper roller bearing in the torque converter shell by heating around the bearing seat with a hot-air gun for about 5 minutes. Pull out the bearing using puller 87 91 683 and 87 91 675. The bearing need only be removed when changing the torque converter shell or differential bearing.

|

|

Assembling the automatic transmission

|

|

1.

|

If changing the torque converter shell, transfer the outer plugs to the new shell. Carefully remove the old sealing compound from the sealing surface using a gasket scraper and wash the torque converter shell.

|

|

2.

|

Heat the bearing seat using a hot-air gun and knock down the roller bearing into the torque converter shell using drift 87 90 461 and shaft 83 90 189. Press in the bearing with the text face down until it bottoms in the torque converter shell. The side of the roller bearing will be the bearing race for the thrust bearing on the output shaft.

|

|

3.

|

Heat the bearing seat for the differential bearing race in the torque converter shell. Fit the bearing race. Make sure the bearing race is all the way home.

|

|

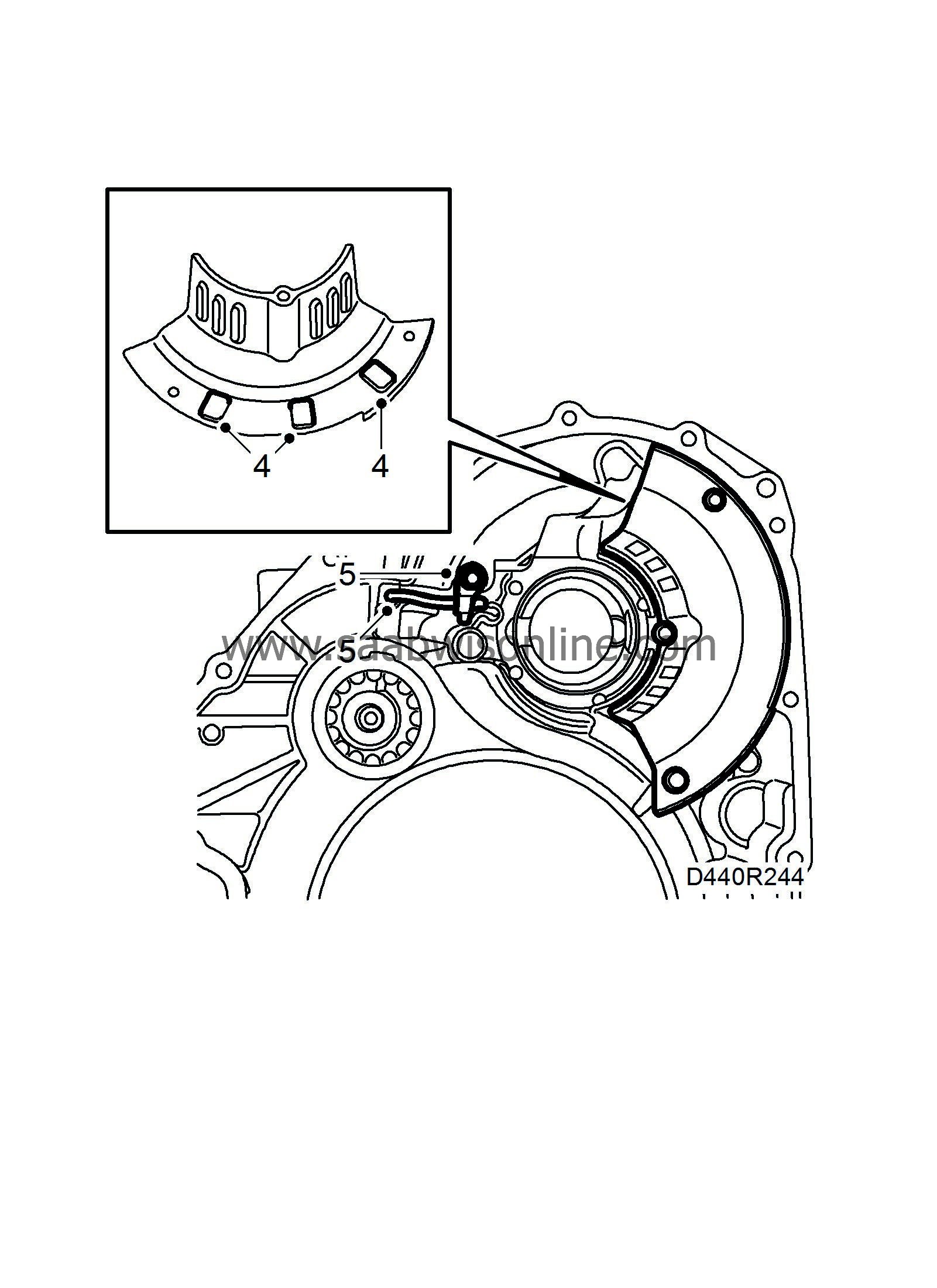

4.

|

Place the three cleaned magnets on the oil channel plate. Apply thread locking compound 74 96 268 to the bolts and fit the oil channel plate.

Tightening torque 5.5 Nm (4 lbf ft)

|

|

5.

|

Fit the pipe using a splinter-free plastic mallet. Take care not to bend or damage the pipe. Fit the pipe clamp.

|

|

6.

|

Heat the bearing seat for the differential bearing race in the gearcase for about 5 min. Refit the shim and fit the bearing race. Make sure the bearing race is all the way home.

|

|

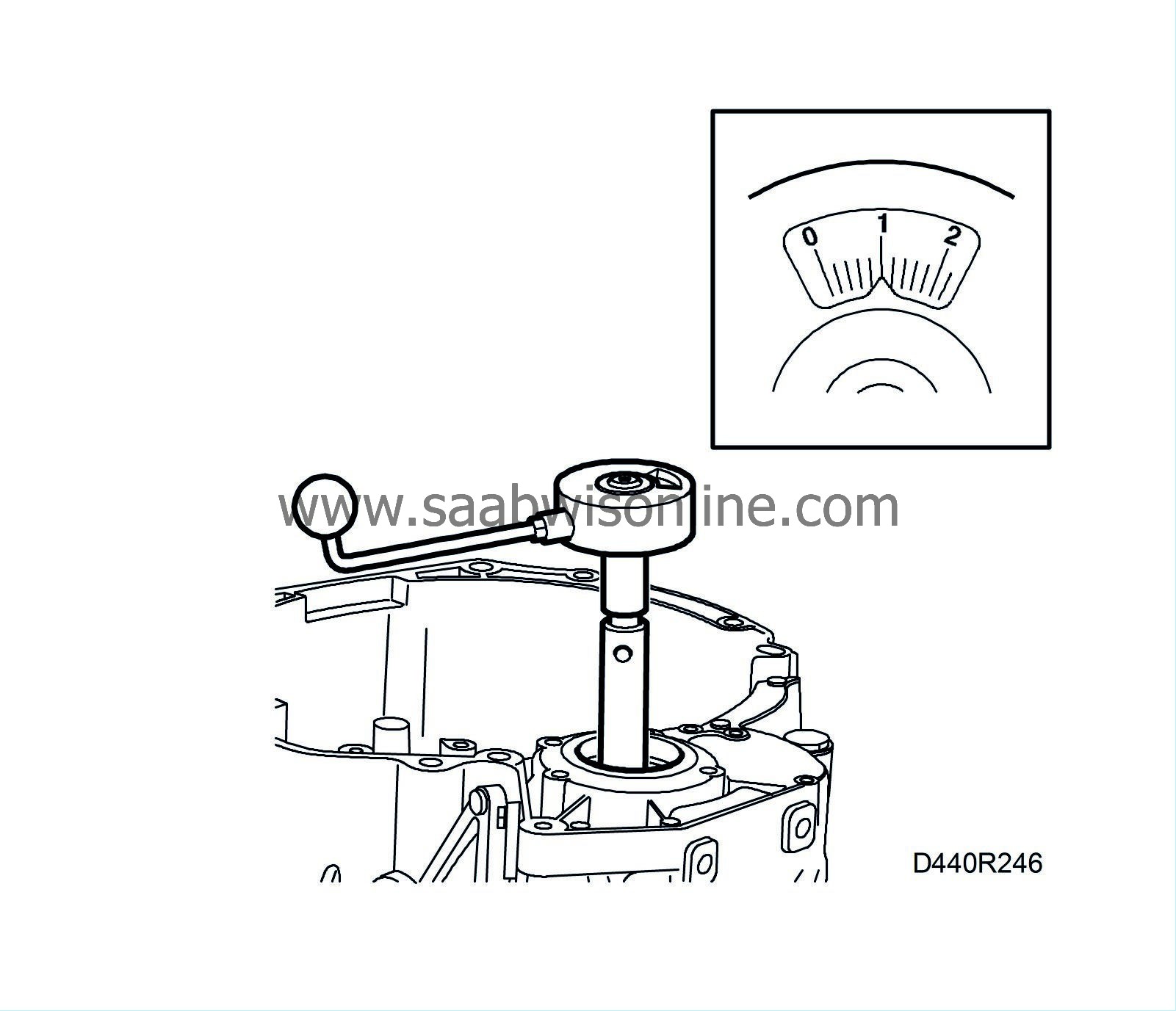

7.

|

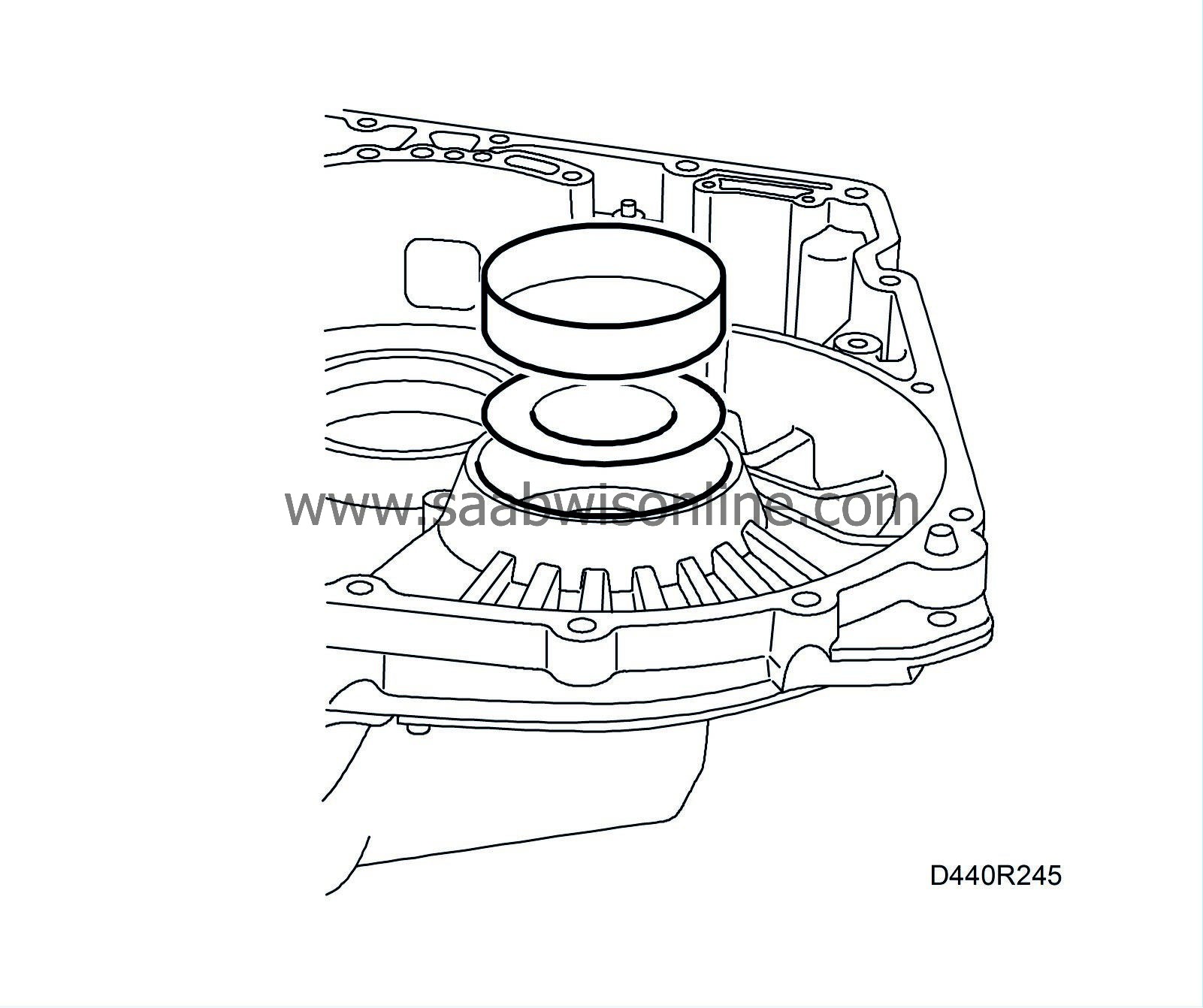

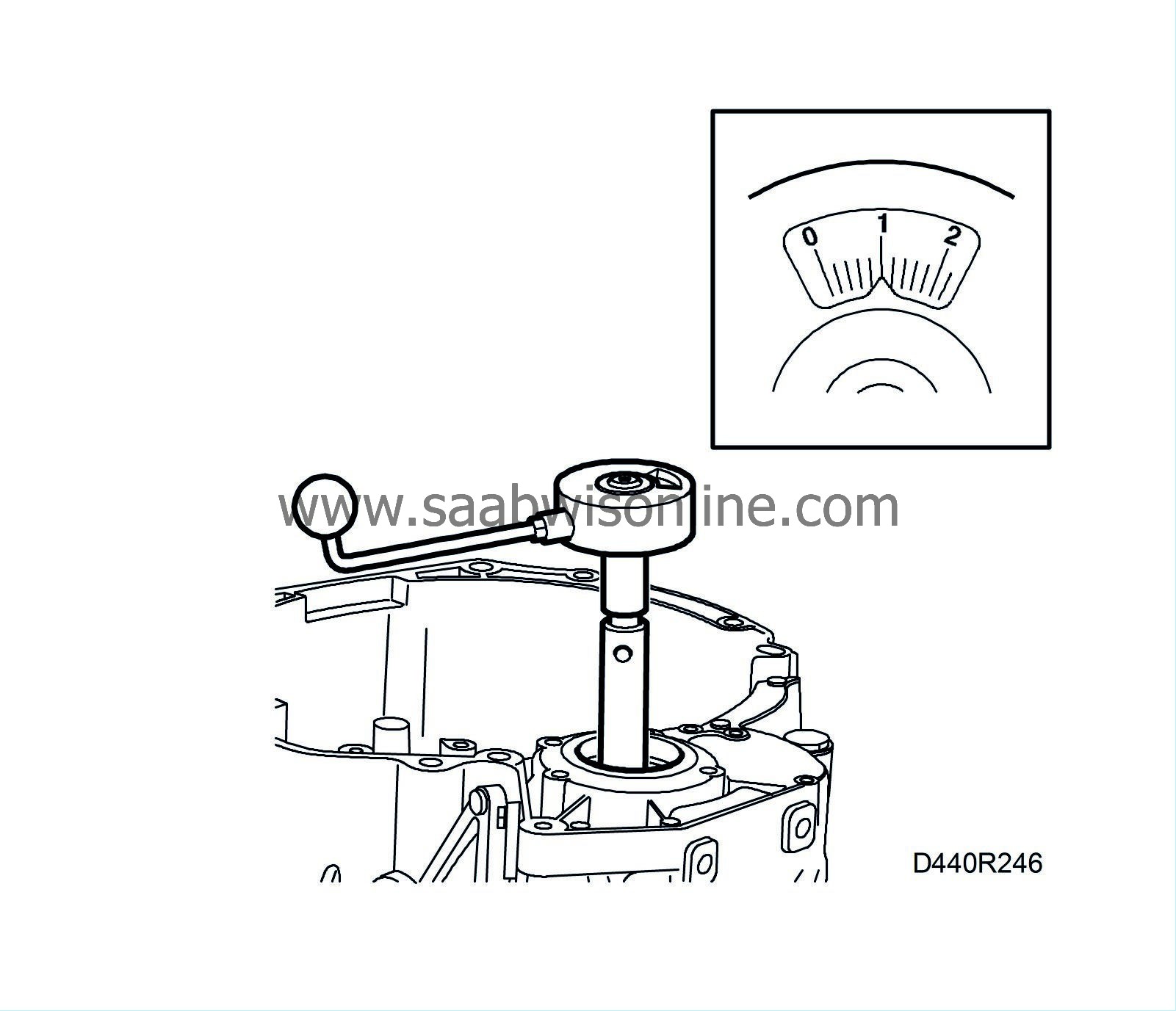

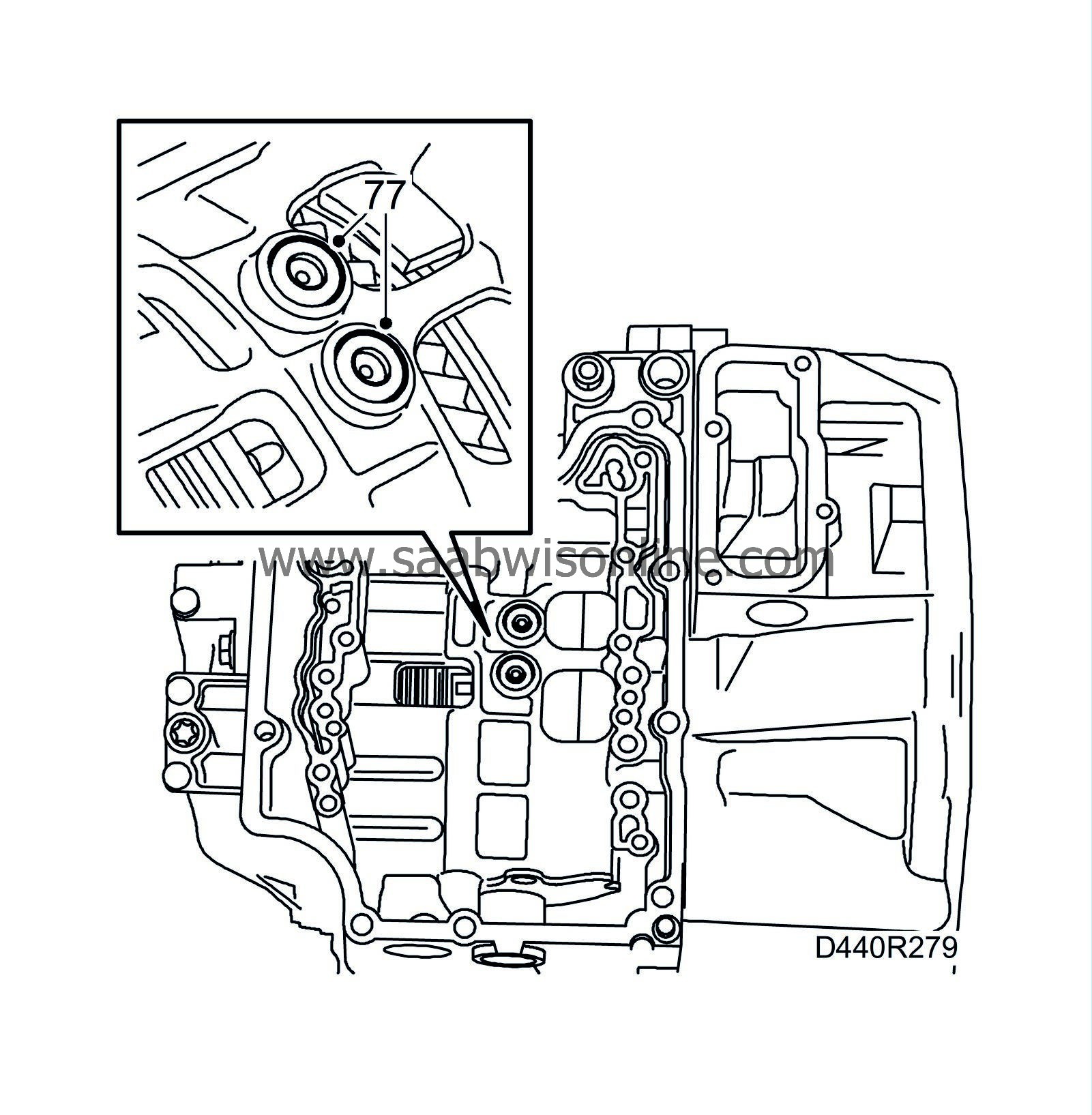

Lubricate the bearings with automatic transmission fluid. Put in place the differential and fit the torque converter shell. Fit only every other bolt. Fit the dynamometer 87 92 483 and drift 87 91 337 into the differential housing. Turn until a stable value is obtained.

Tightening torque 24 Nm (18 lbf ft)

Measure the prestress. Start value:

New bearing

|

1.0 Nm (7 lbf ft)

|

Refitted bearing

|

0.5 Nm (3.5 lbf ft)

|

|

|

8.

|

If the prestress is not within specified limits, remove the differential and bearing race from the gearcase and change shim. If the reading exceeds the specified value, change to a thinner shim. If the reading is lower than the specified value, change to a thicker shim. Shims are available between 1.0 - 1.90 mm in small intervals.

|

|

9.

|

Remove the torque converter shell and lift out the differential.

|

|

10.

|

Turn the gearbox through 90°.

|

|

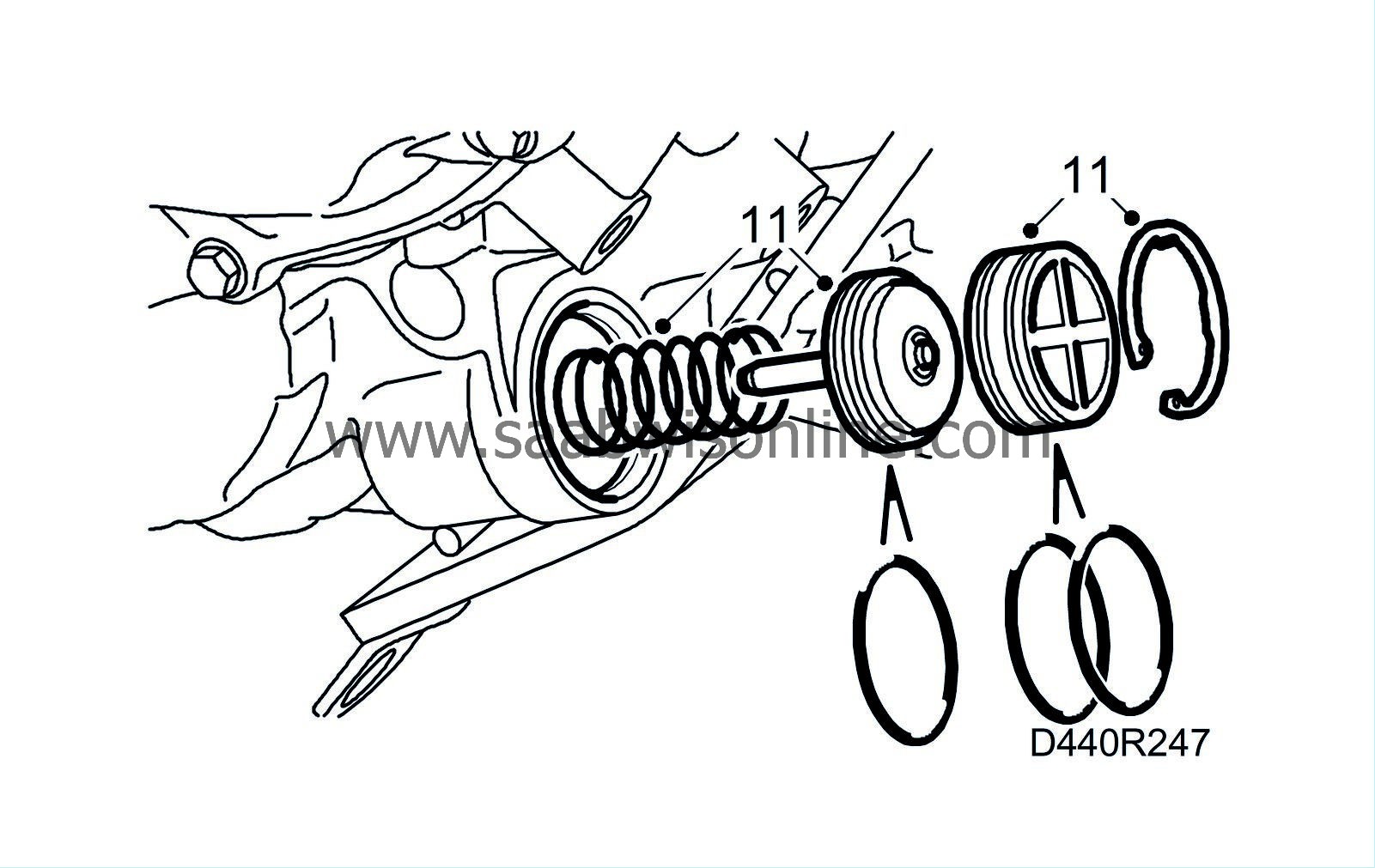

11.

|

Fit new O-rings on the B4 brake plunger and plunger cover. Lubricate with petroleum jelly and fit the servo plunger with cover. Fit the circlip.

|

|

12.

|

Turn back the gearcase 90°

|

|

13.

|

Bend out the rings and fit them in their grooves. Do not bend more than necessary.

|

|

14.

|

Lubricate the two oil sealing rings for clutch C3 with petroleum jelly.

|

|

15.

|

Lubricate new O-rings with petroleum jelly and fit them on the accumulator plunger and cover. Fit the spring and plunger. Fit the cover and holder with torsion spring. Press down the holder and tighten the bolts.

Tightening torque 10 Nm (7 lbf ft)

|

Important

|

|

Do not press the accumulator cap further down than the holder allows. The O-ring can be damaged on sharp internal edges.

|

|

|

|

|

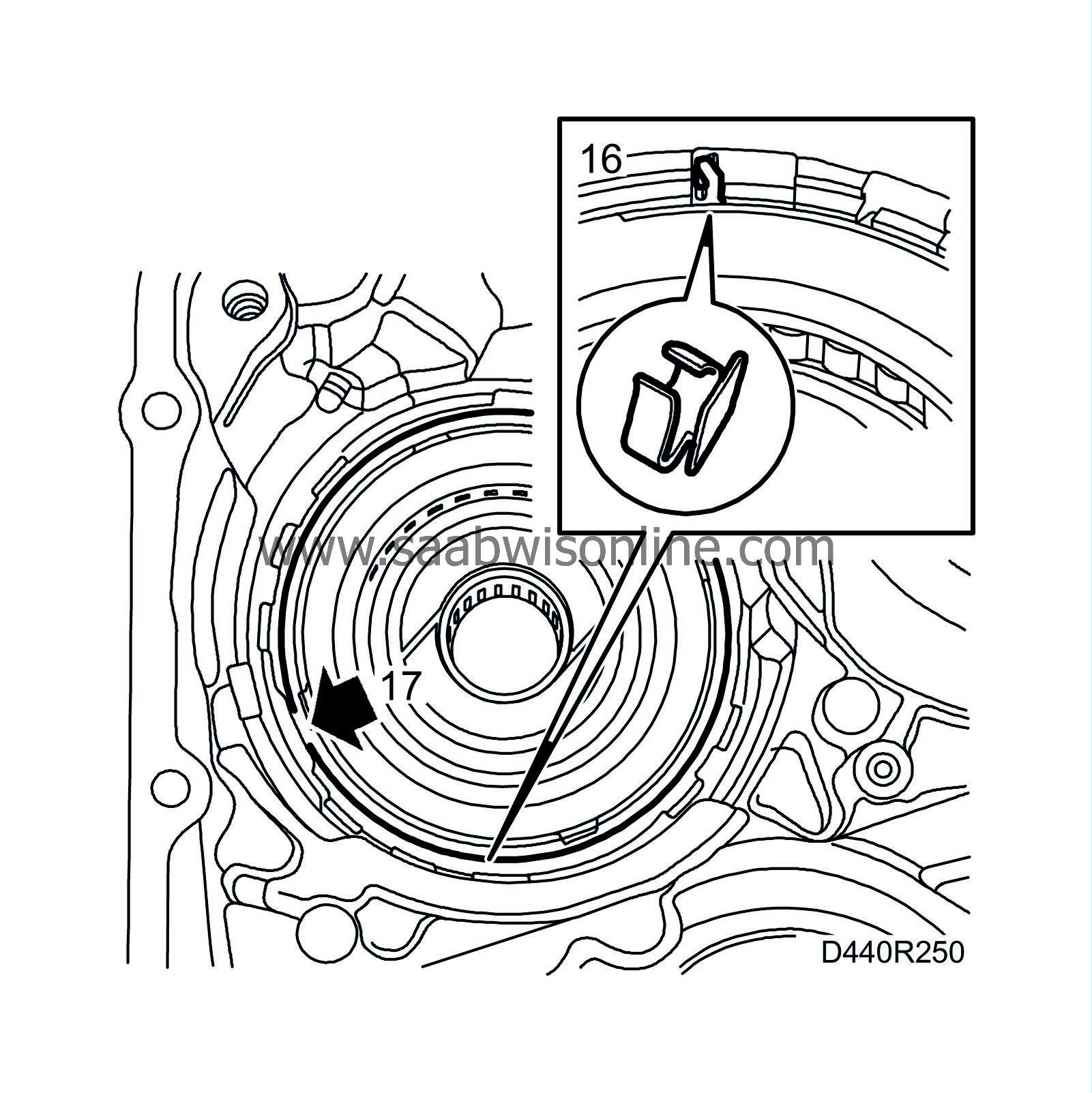

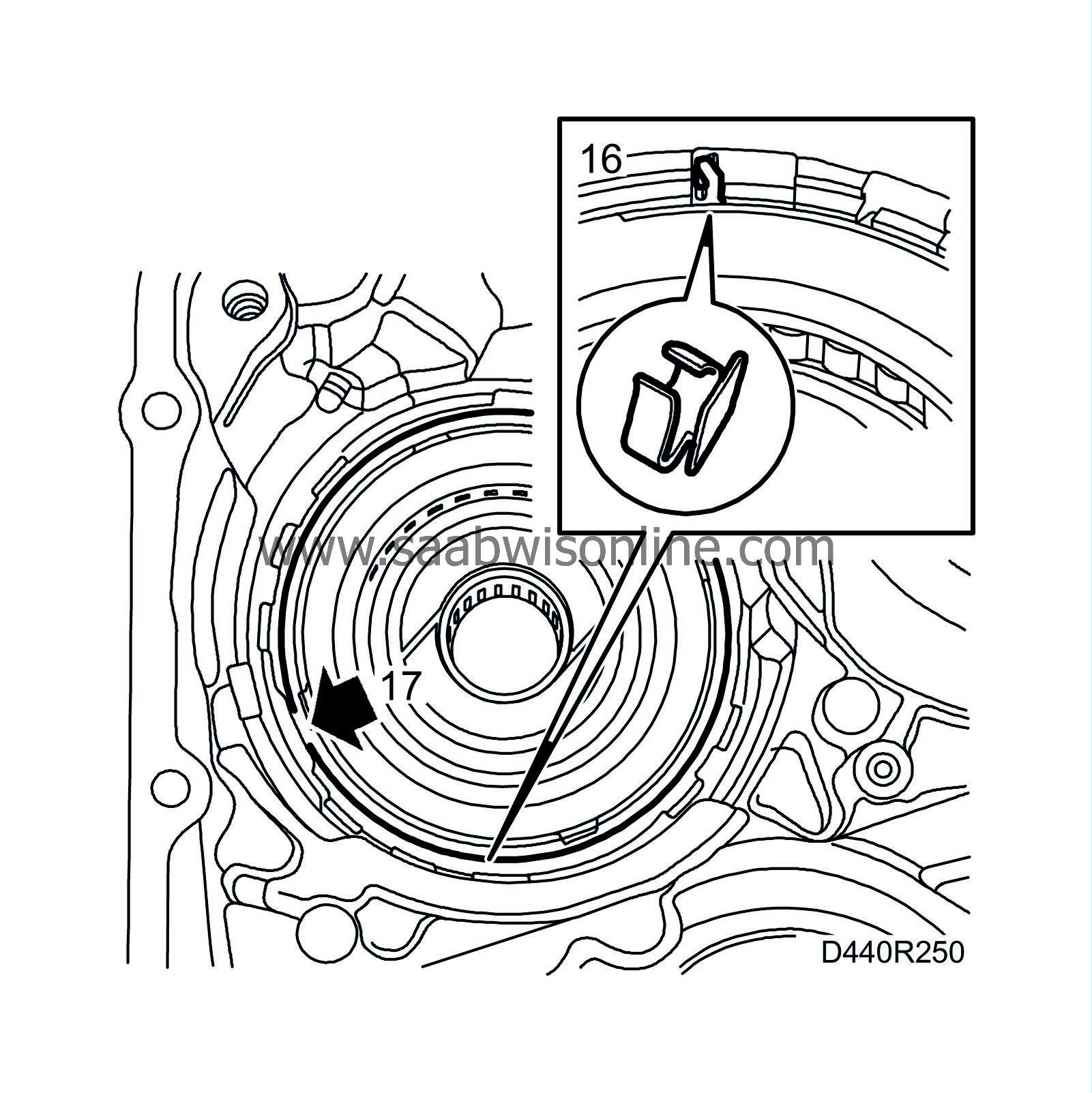

16.

|

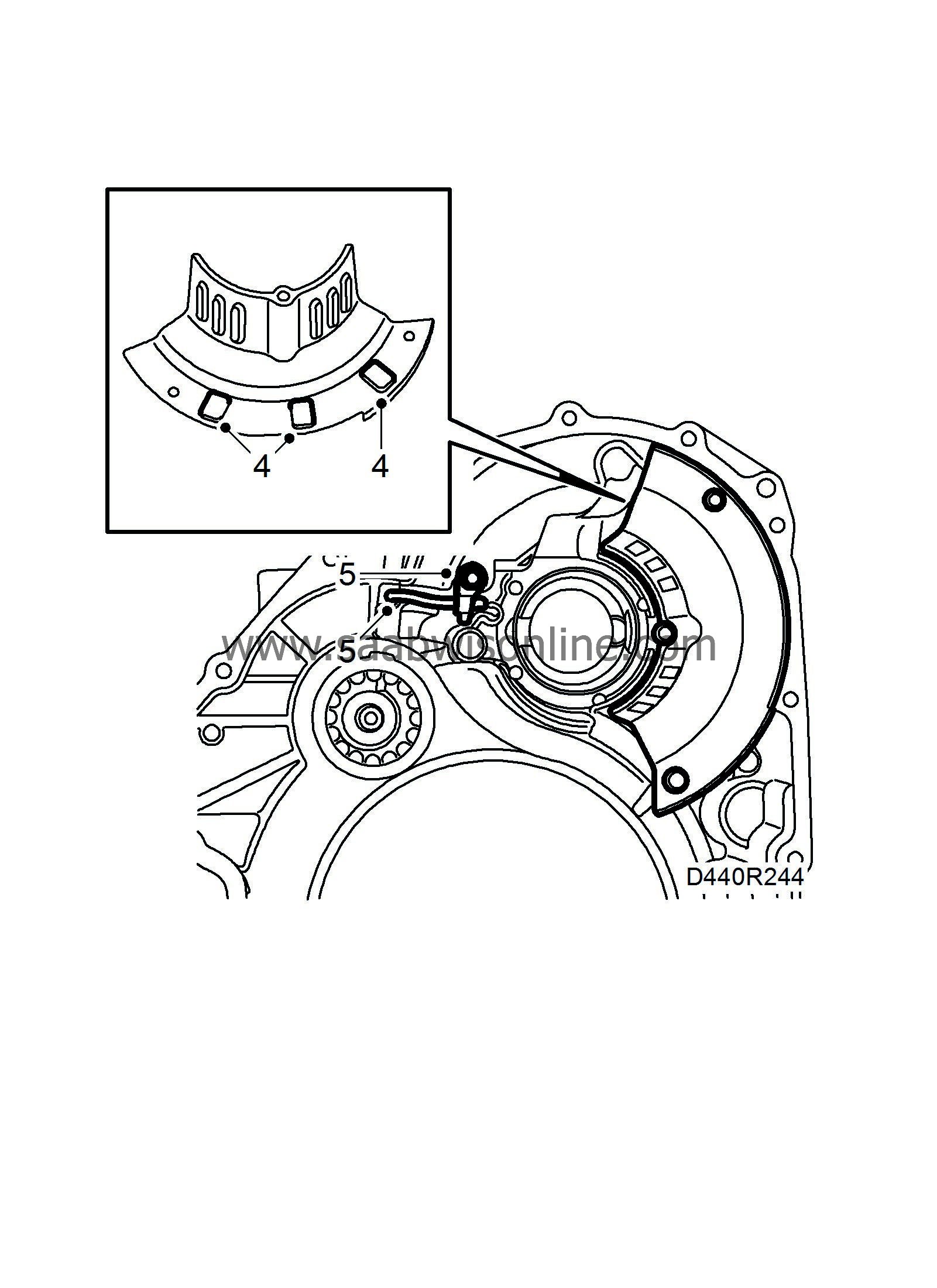

Fit freewheel F3 into the bottom of the gearcase and fit the small clip. (NB. Note its location)

|

|

17.

|

Fit the circlip using a screwdriver. Make sure the circlip opening is not in line with any of the recesses in the groove.

|

|

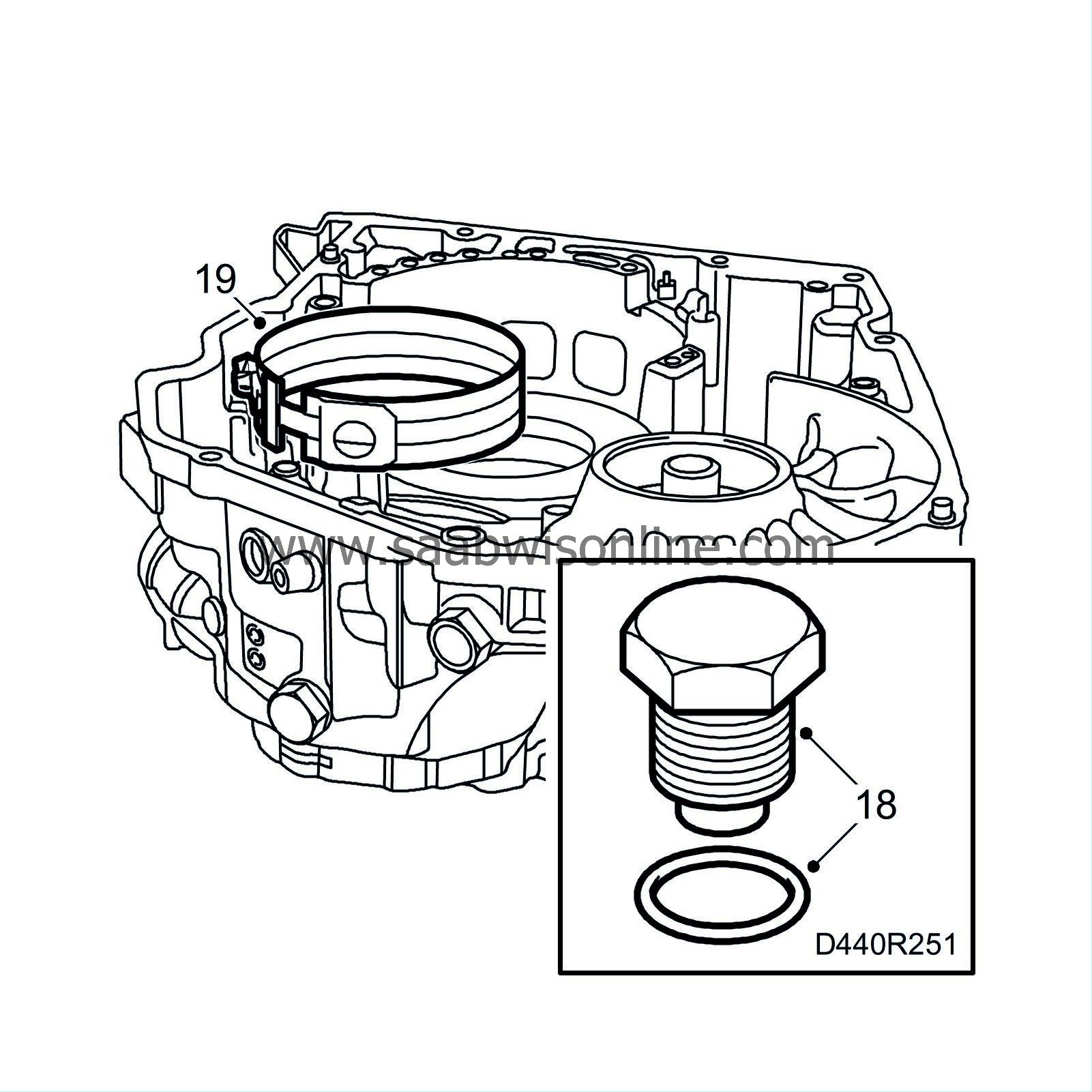

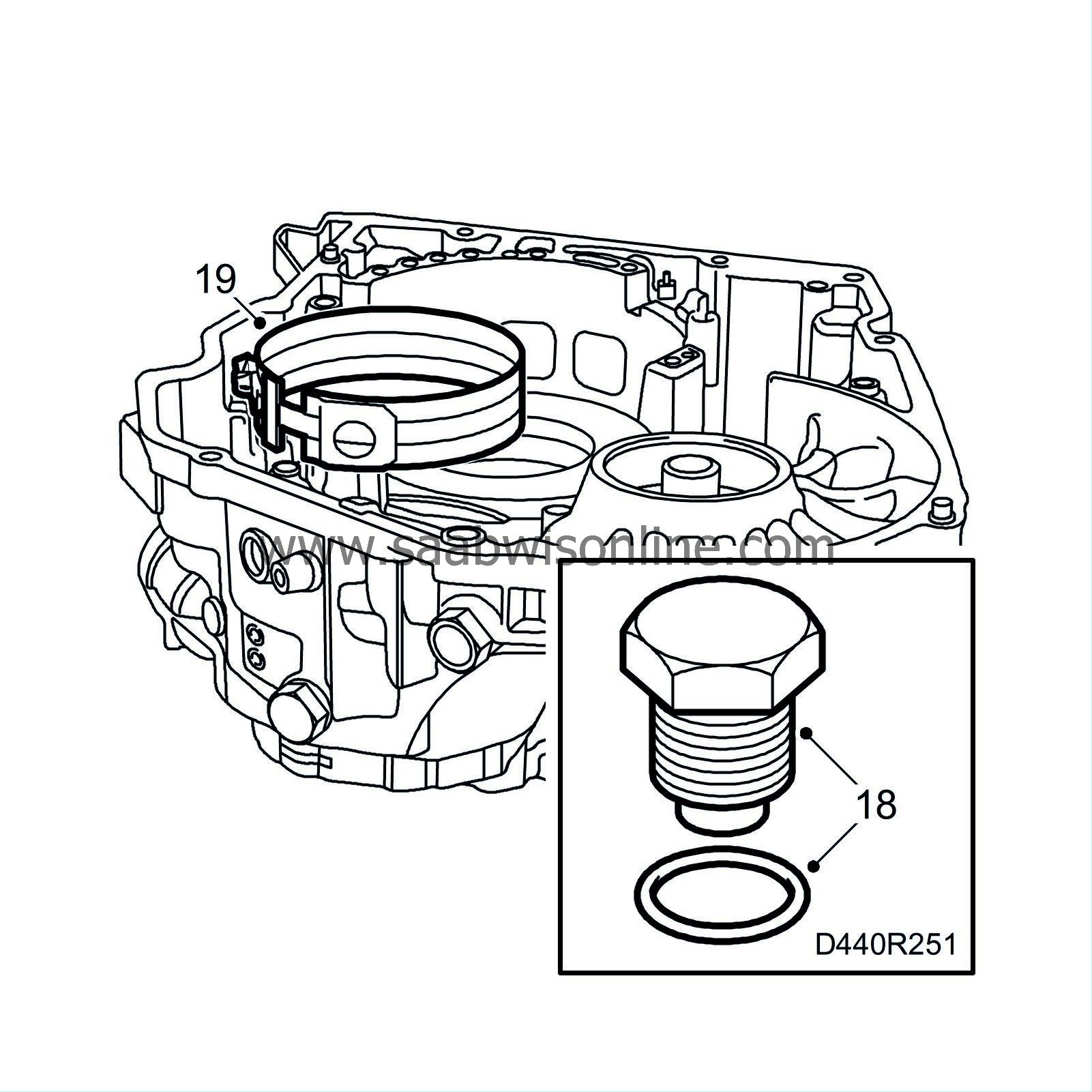

18.

|

Lubricate the O-ring for the hold-down bolt with petroleum jelly and tighten it.

Tightening torque 140 Nm (104 lbf ft)

|

|

19.

|

Lubricate the brake band with automatic transmission fluid. Fit the brake band with the pin of the hold-down bolt in the recess of the brake band.

|

|

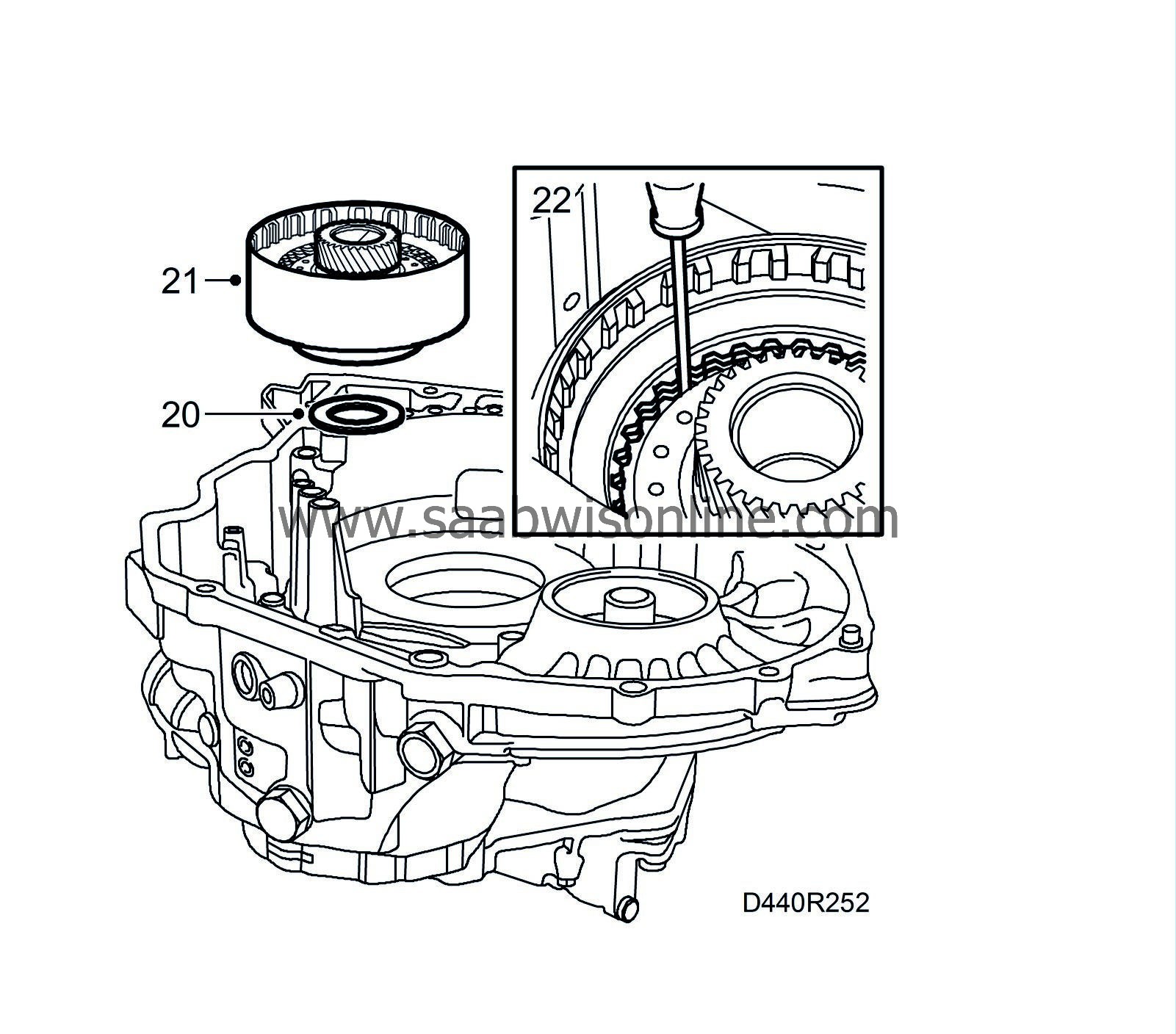

20.

|

Fit the thrust bearing lubricated with petroleum jelly. Place the black part towards the gearcase.

|

|

21.

|

Fit clutch C3 into the gearcase while lifting the brake band slightly to facilitate fitting. Make sure the clutch rotates freely anticlockwise and is locked clockwise.

|

|

22.

|

Align the teeth of the C3 clutch using a small screwdriver.

|

|

23.

|

Fit the bearing race on the sun gear and the thrust bearing in the planetary gear. Fit the output shaft assembly into clutch unit C3. Make sure the shaft falls in place correctly in the recess for the large gear. Check that the shaft and gear rotate freely.

|

|

24.

|

Fit the thrust bearing race and the thrust bearing on the output shaft unit.

|

|

25.

|

Put in place the ratchet on the correct side of the spring.

|

|

26.

|

Fit the guide pin into the hole and put in place the guide fork and the ratchet spindle and spring.

|

|

27.

|

Fit the ratchet sector gear position spring. (Note the different bolt lengths.)

Tightening torque 5.5 Nm (4 lbf ft)

|

|

28.

|

Press a new oil seal lubricated with petroleum jelly into the selector lever shaft. Apply petroleum jelly to the lips of the oil seal.

|

|

29.

|

Fit together the control rod and the ratchet sector and slacken the spring. Make sure the handbrake detent falls into position and is in working order. Put the selector lever in neutral.

|

|

30.

|

Fit the oil control plate onto the gearcase (short bolts). Tighten the bolts.

Tightening torque 5.5 Nm (4 lbf ft)

|

|

31.

|

Fit the cover with two bolts.

Tightening torque 5.5 Nm (4 lbf ft)

|

|

32.

|

Fit a new oil strainer and tighten the bolts. Make sure the seals are positioned correctly, one on each side.

Tightening torque 5.5 Nm (4 lbf ft)

|

|

33.

|

Fit the differential housing unit.

|

Important

|

|

Check the differential housing internally for damage. Also check the drive shaft surfaces.

|

|

|

|

|

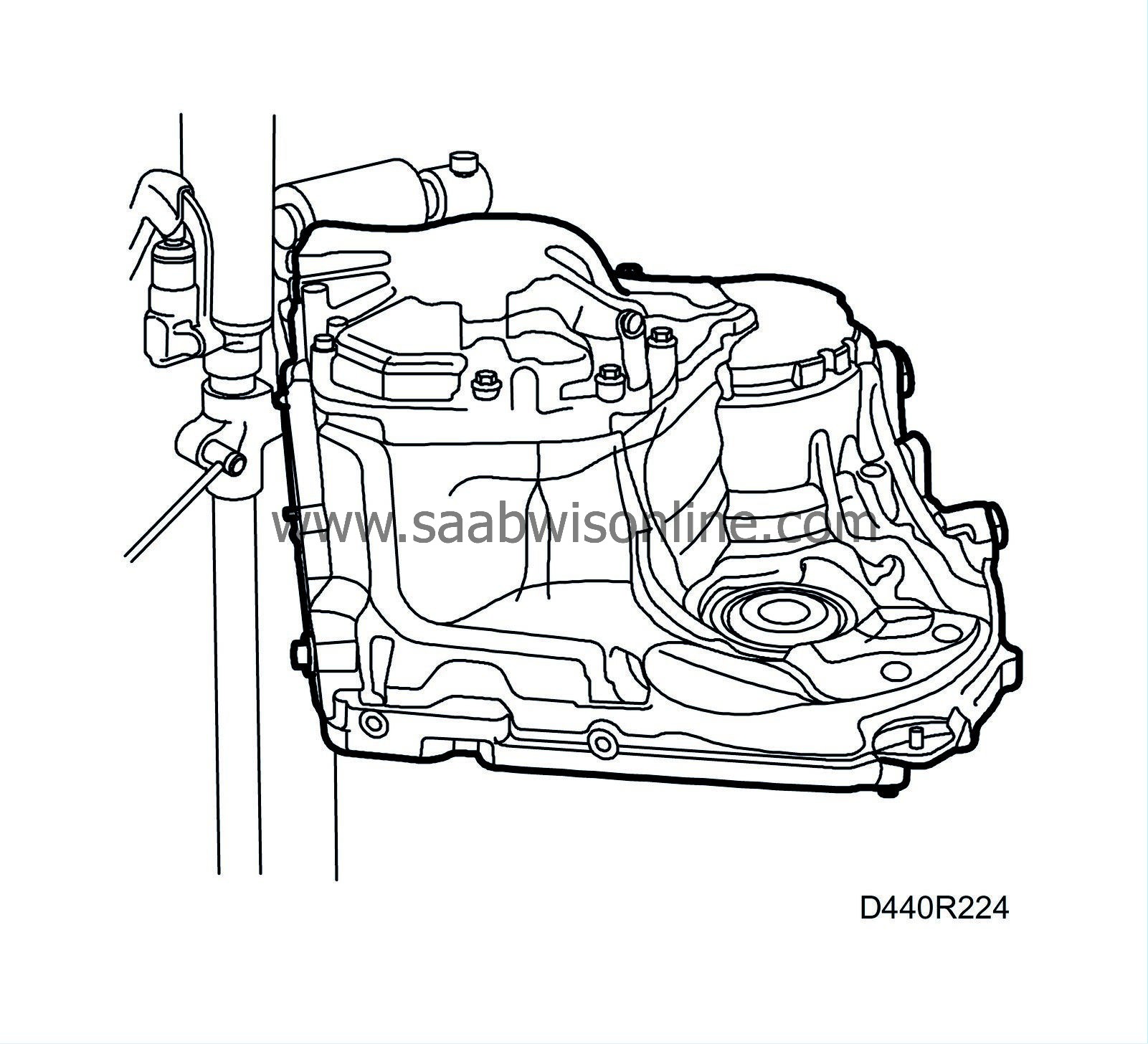

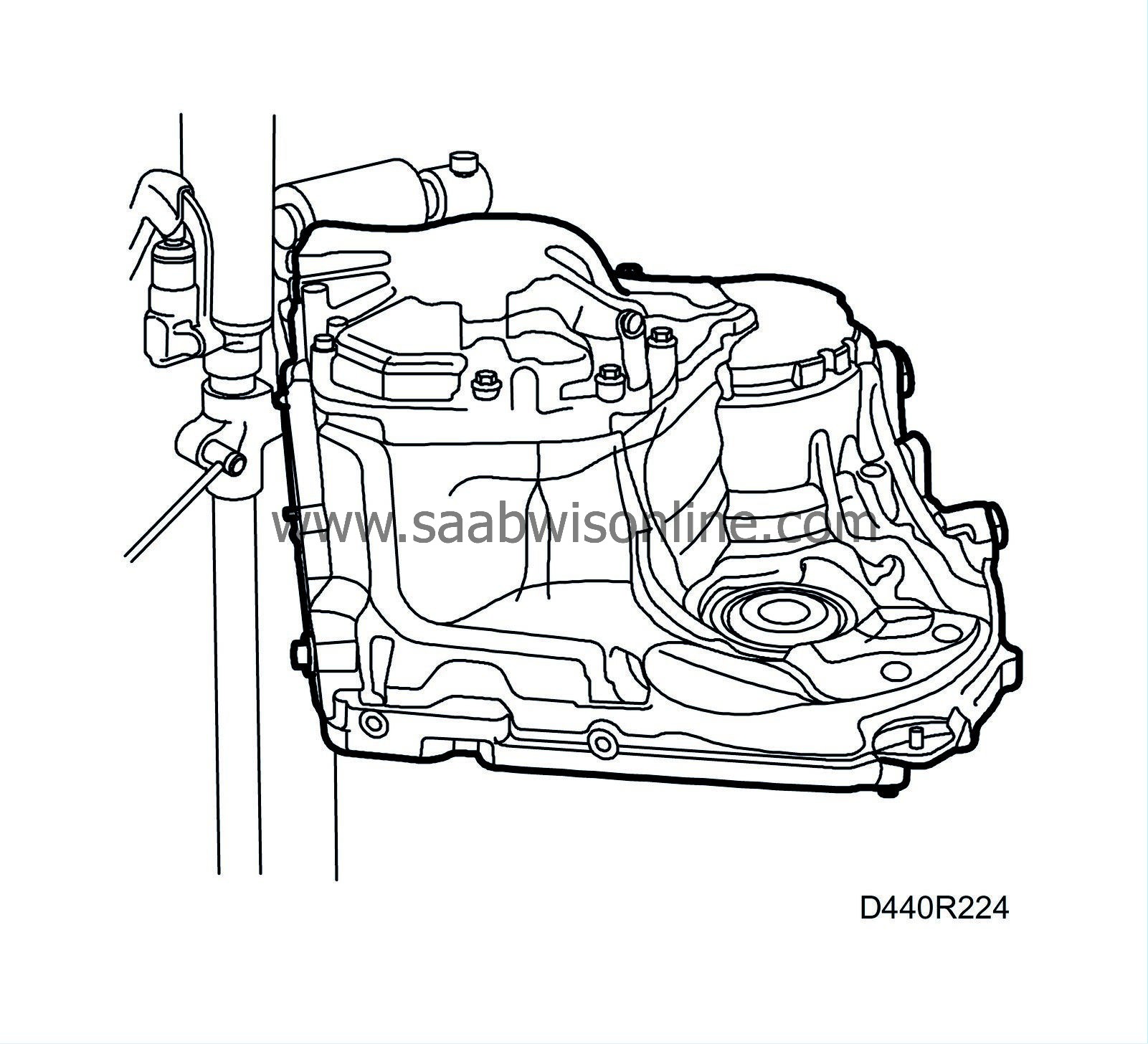

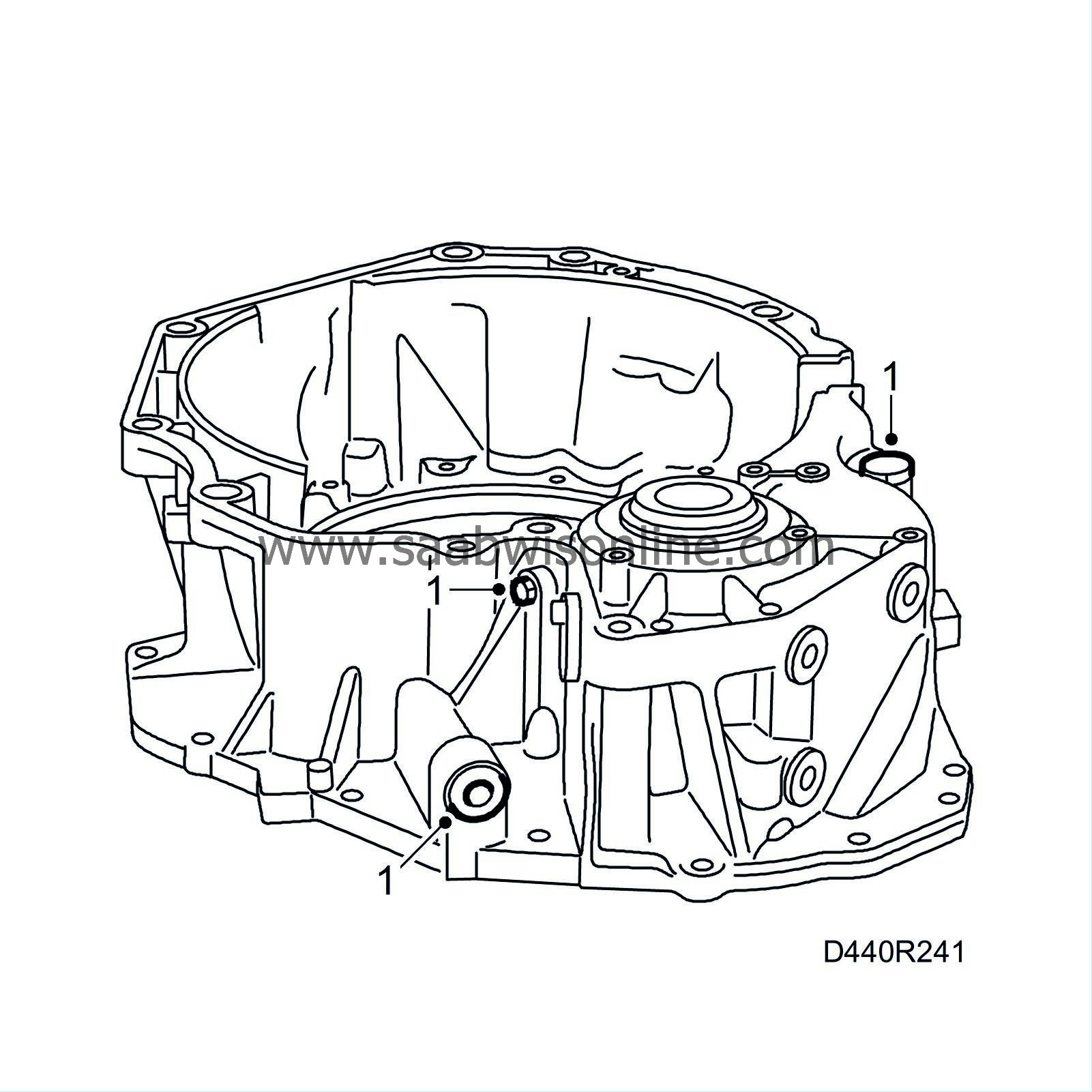

34.

|

Clean the sealing surfaces on the gearcase and torque converter shell. Use cleaner 30 02 599. Keep the surfaces free from grease.

|

|

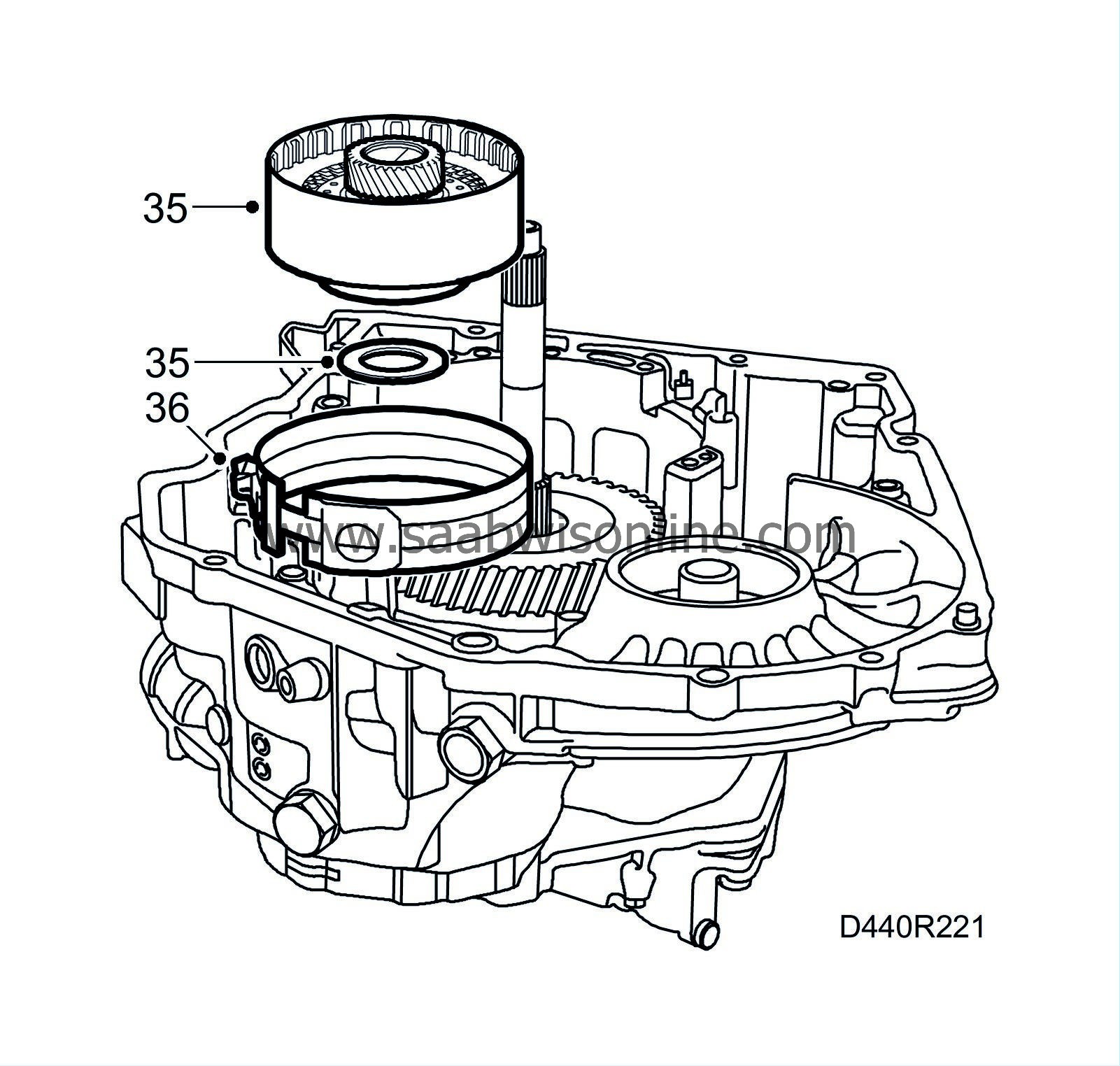

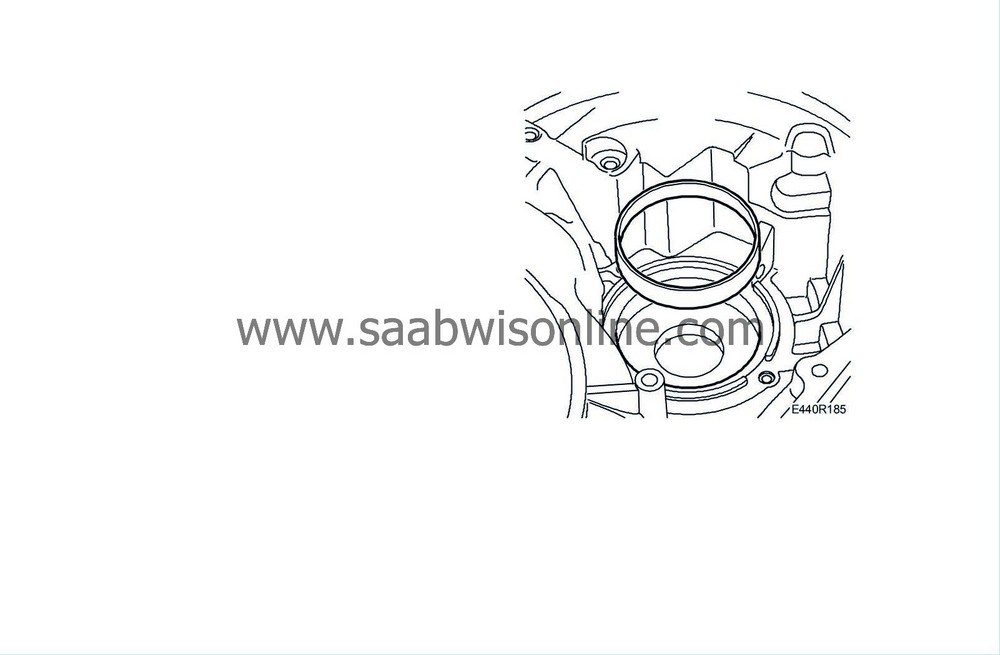

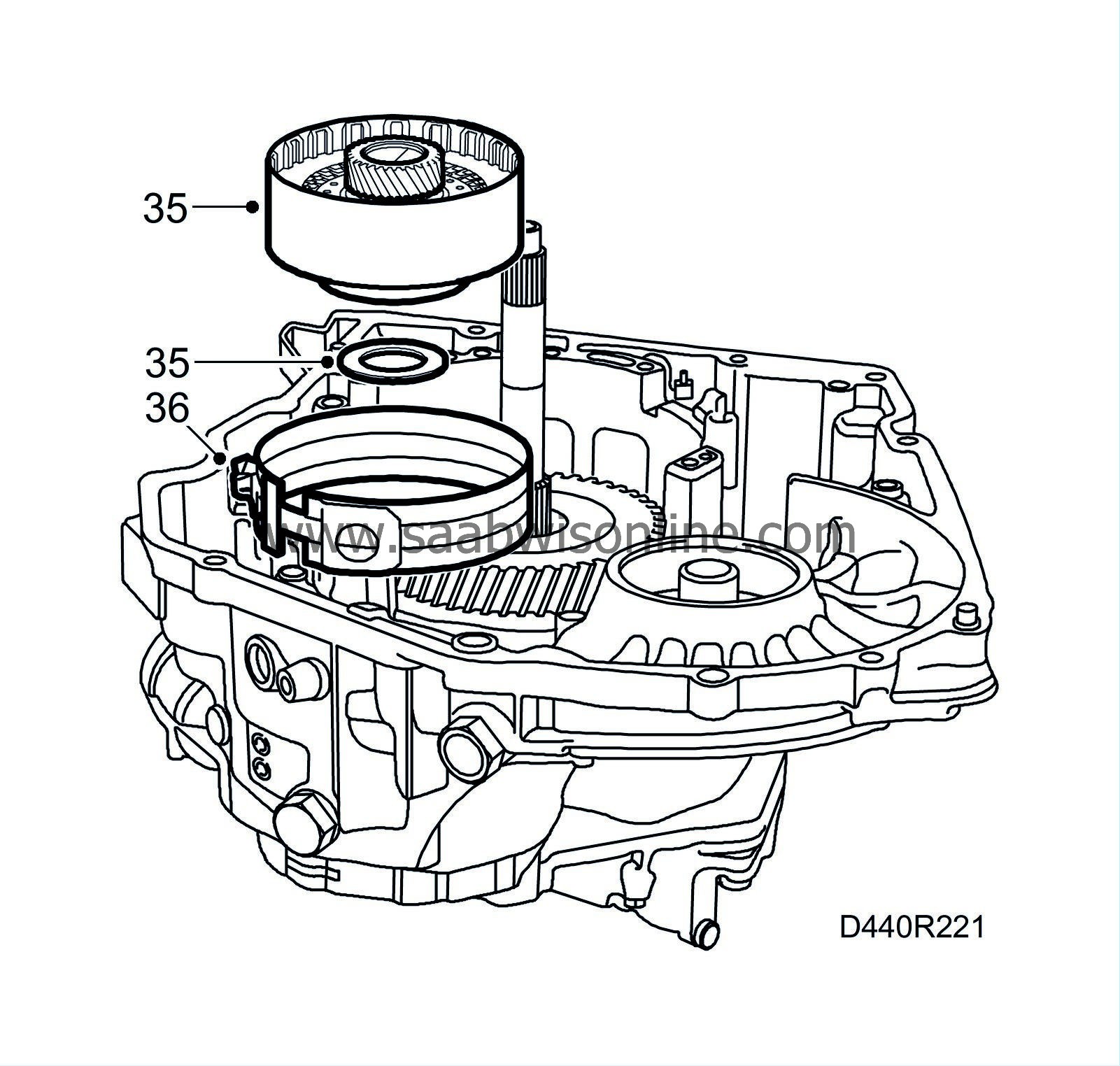

35.

|

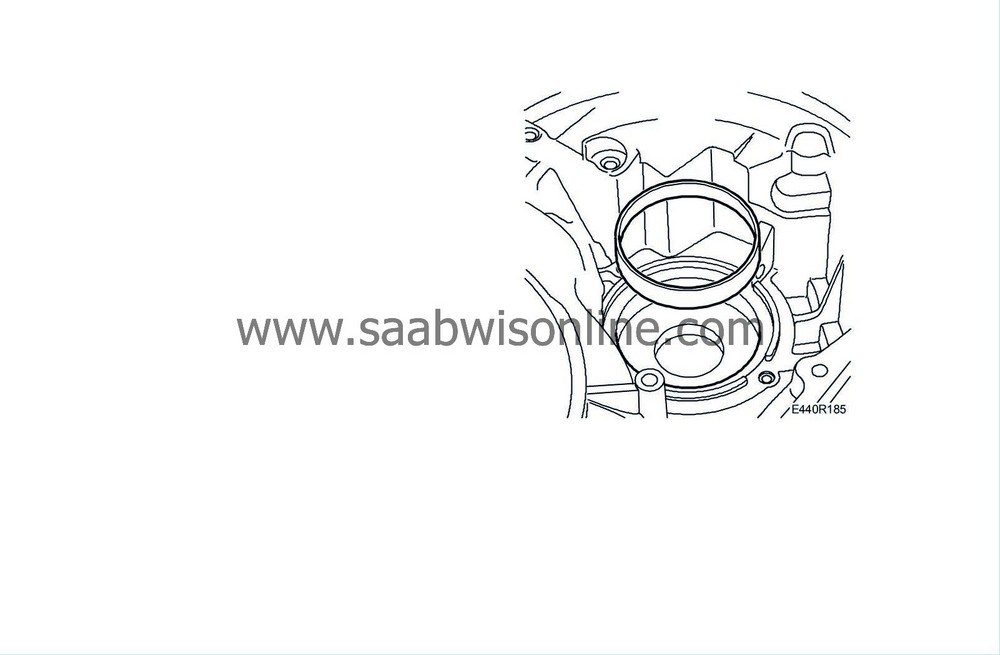

Fit a new seal in the gearcase.

|

|

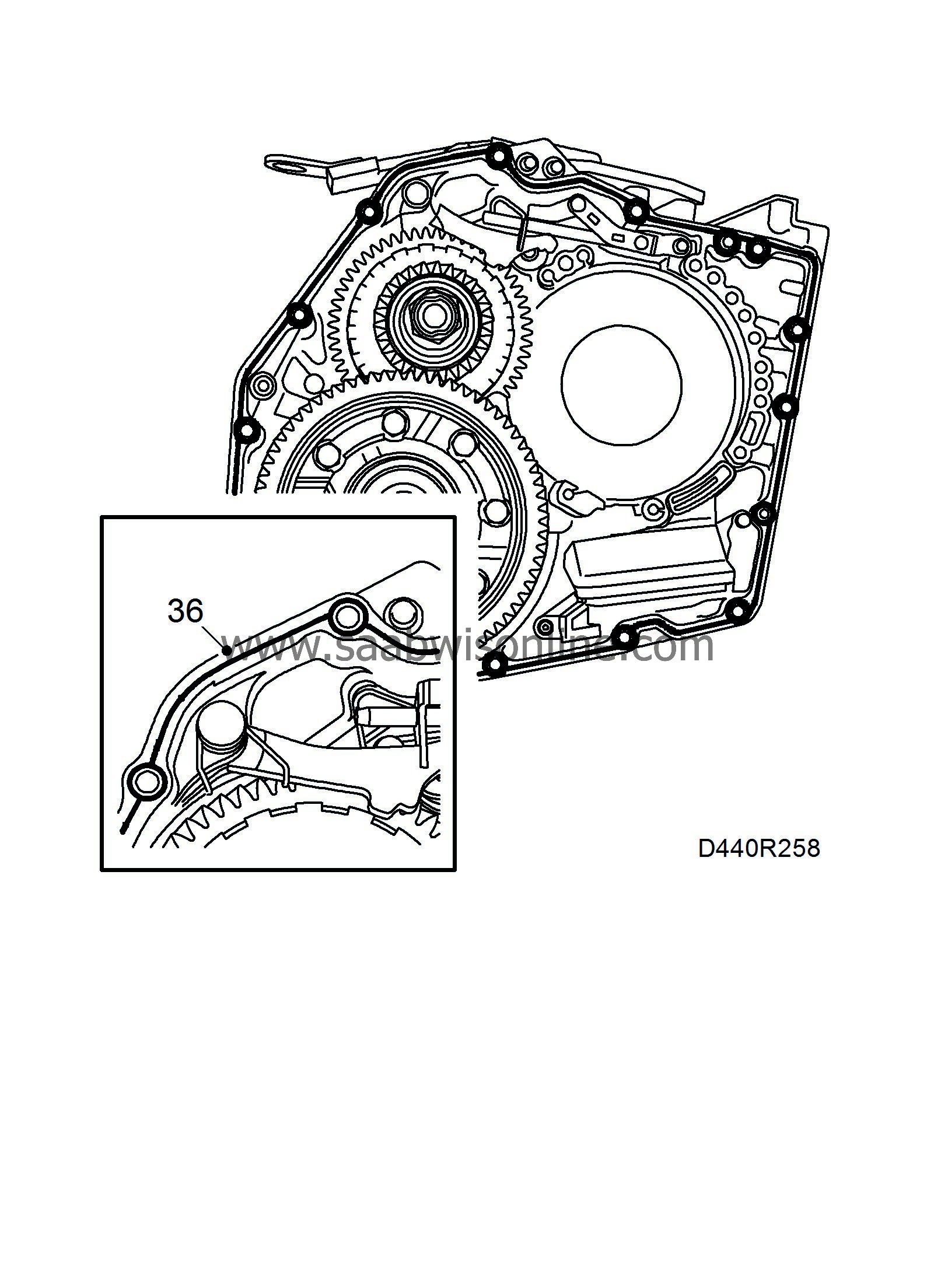

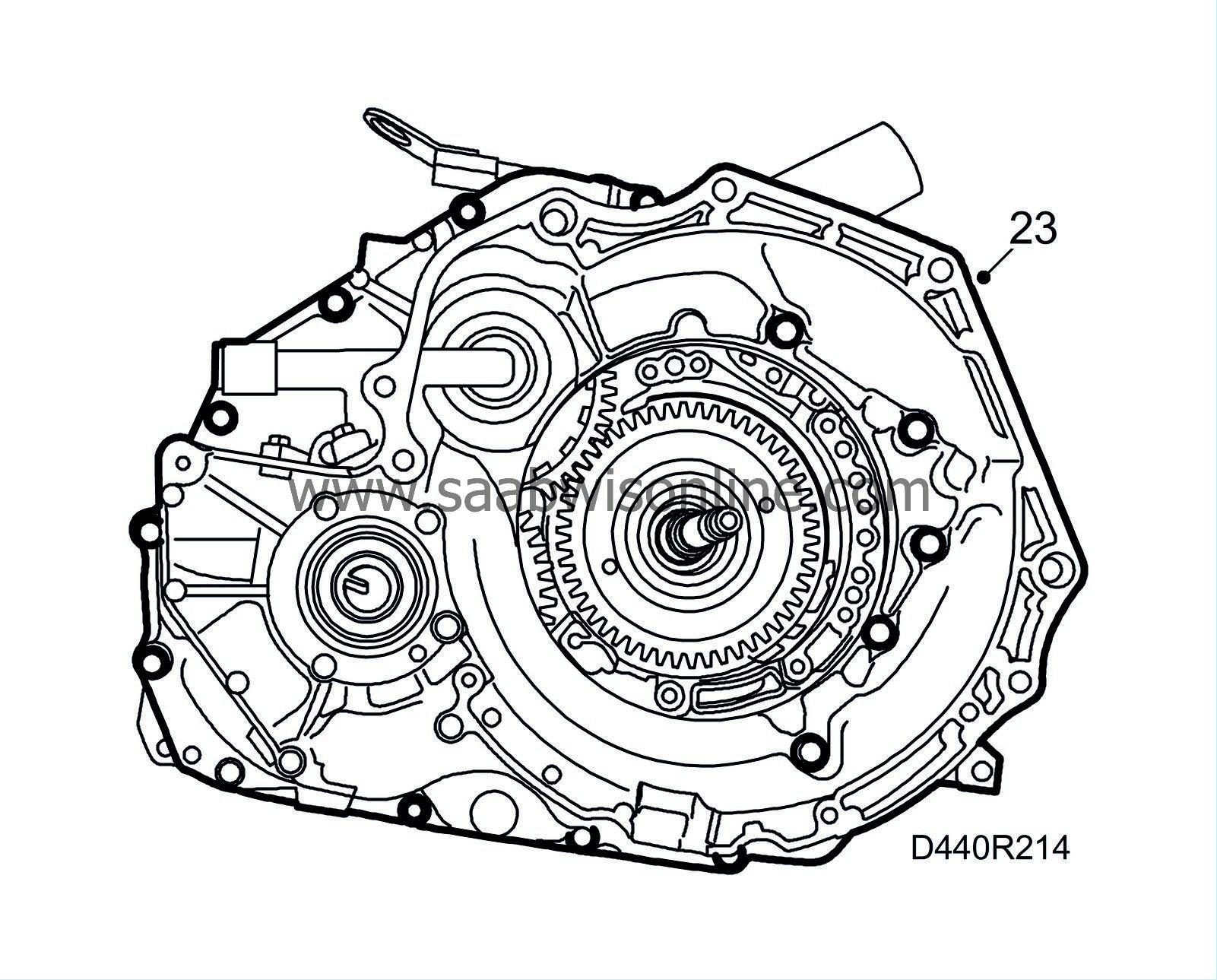

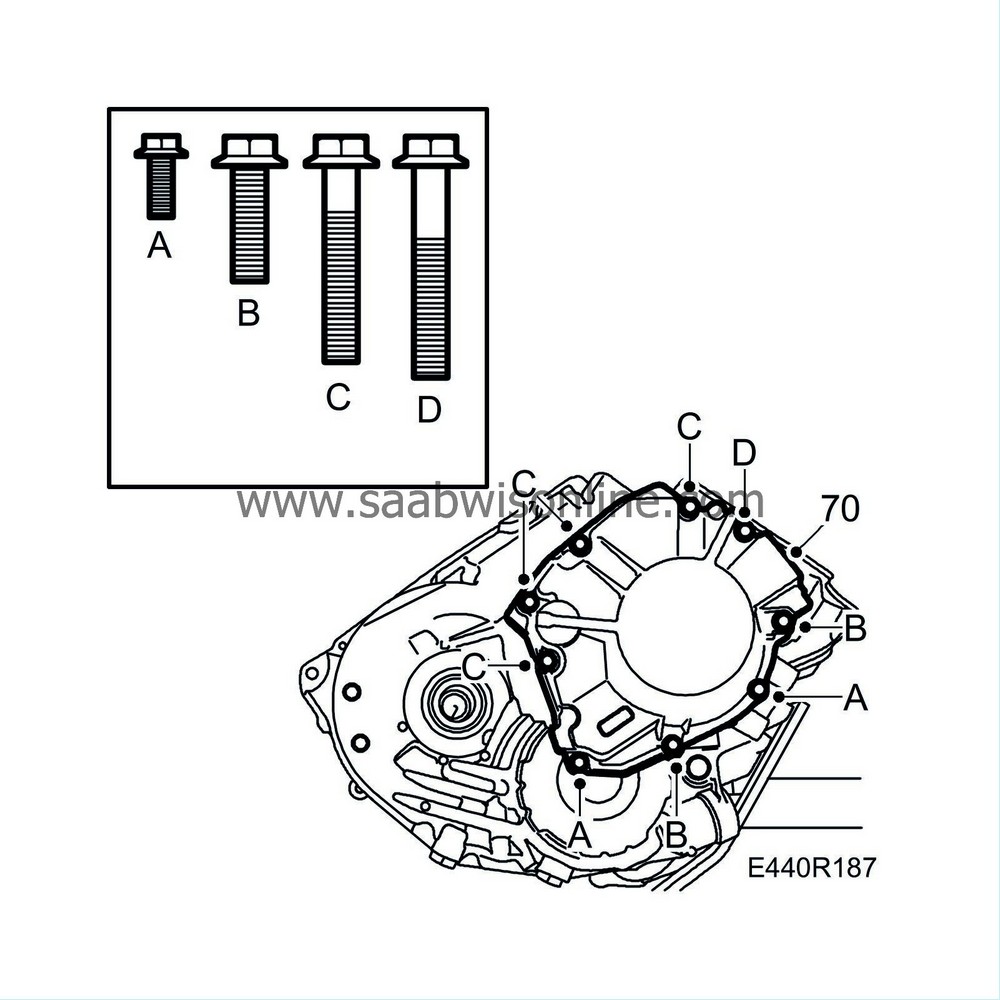

36.

|

Apply a bead of flange sealant 87 81 841 approximately 1 mm wide to the gearcase as illustrated and fit the torque converter shell.

|

|

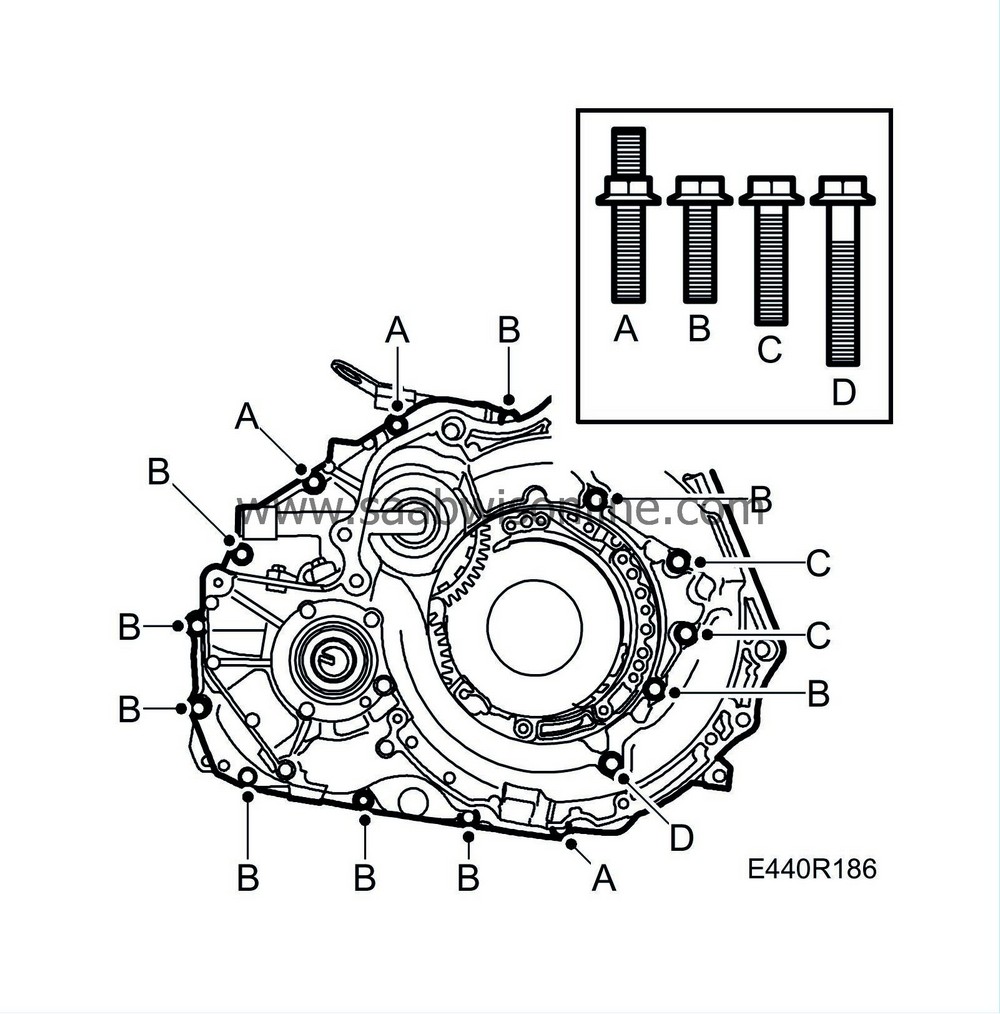

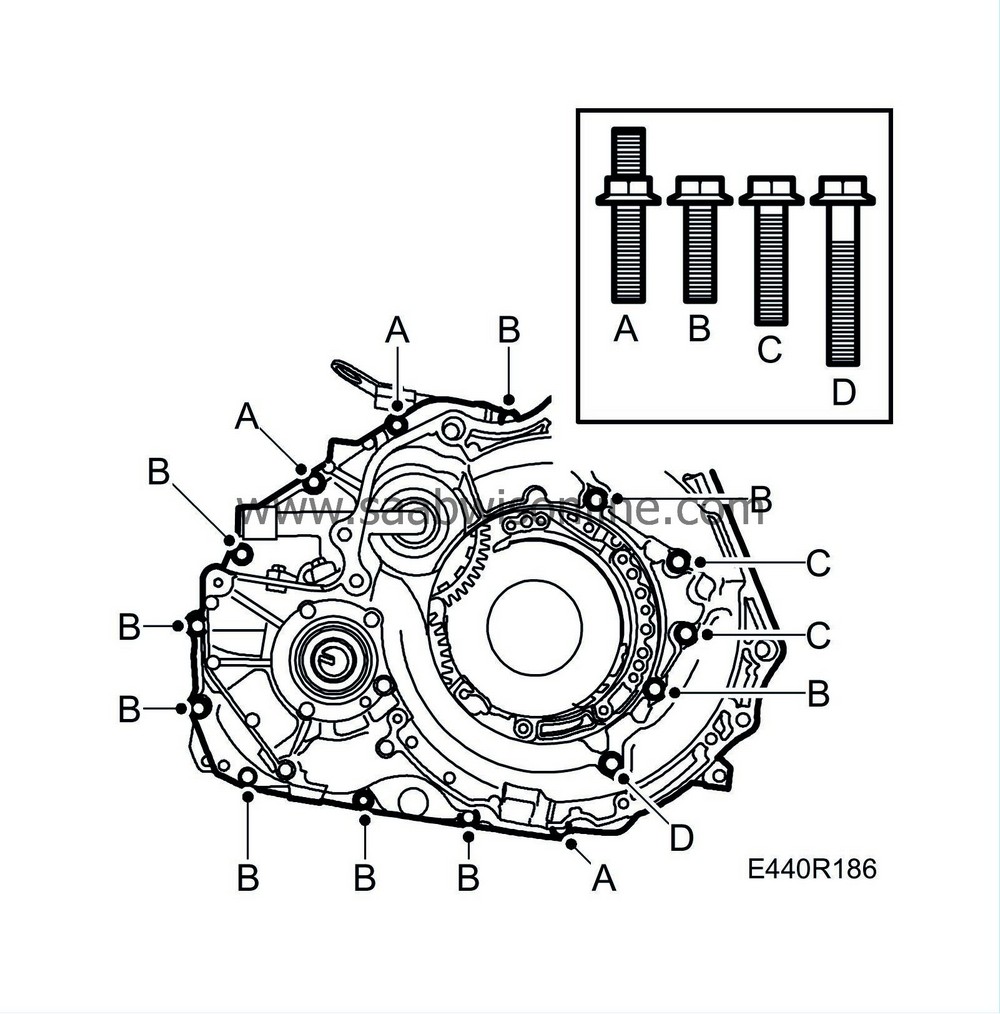

37.

|

Apply thread locking compound 74 96 284 to the internal bolts. Fit the bolts (different lengths). Tighten the bolts.

Tightening torque 25 Nm (18 lbf ft)

|

|

38.

|

Clean the magnetic surface on the drain plug and fit it with a new gasket.

Tightening torque 40 Nm (30 lbf ft)

|

|

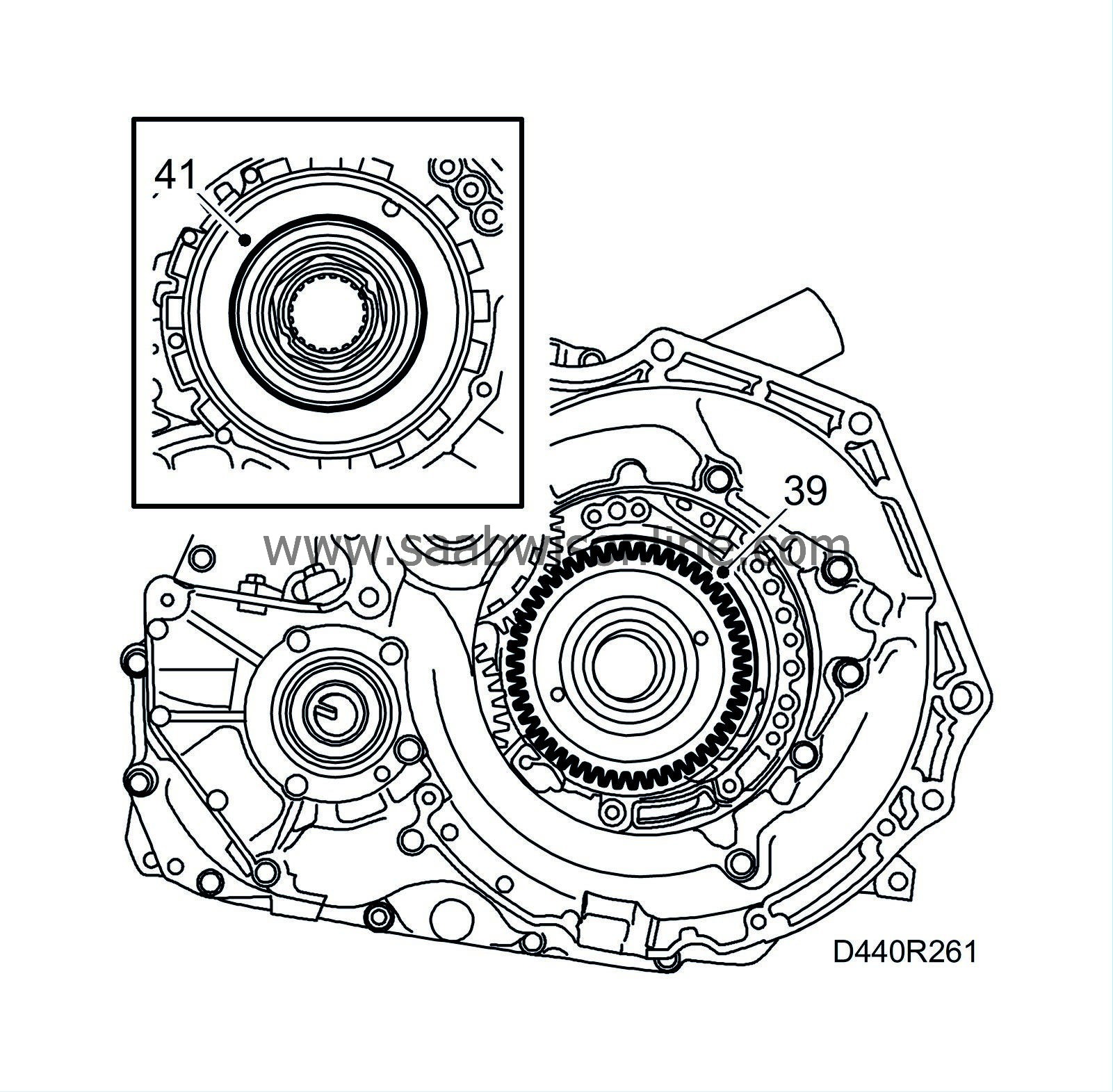

39.

|

Put in place the intermediate gear assembly in the gearcase.

|

|

40.

|

Turn the gearbox 90°.

|

|

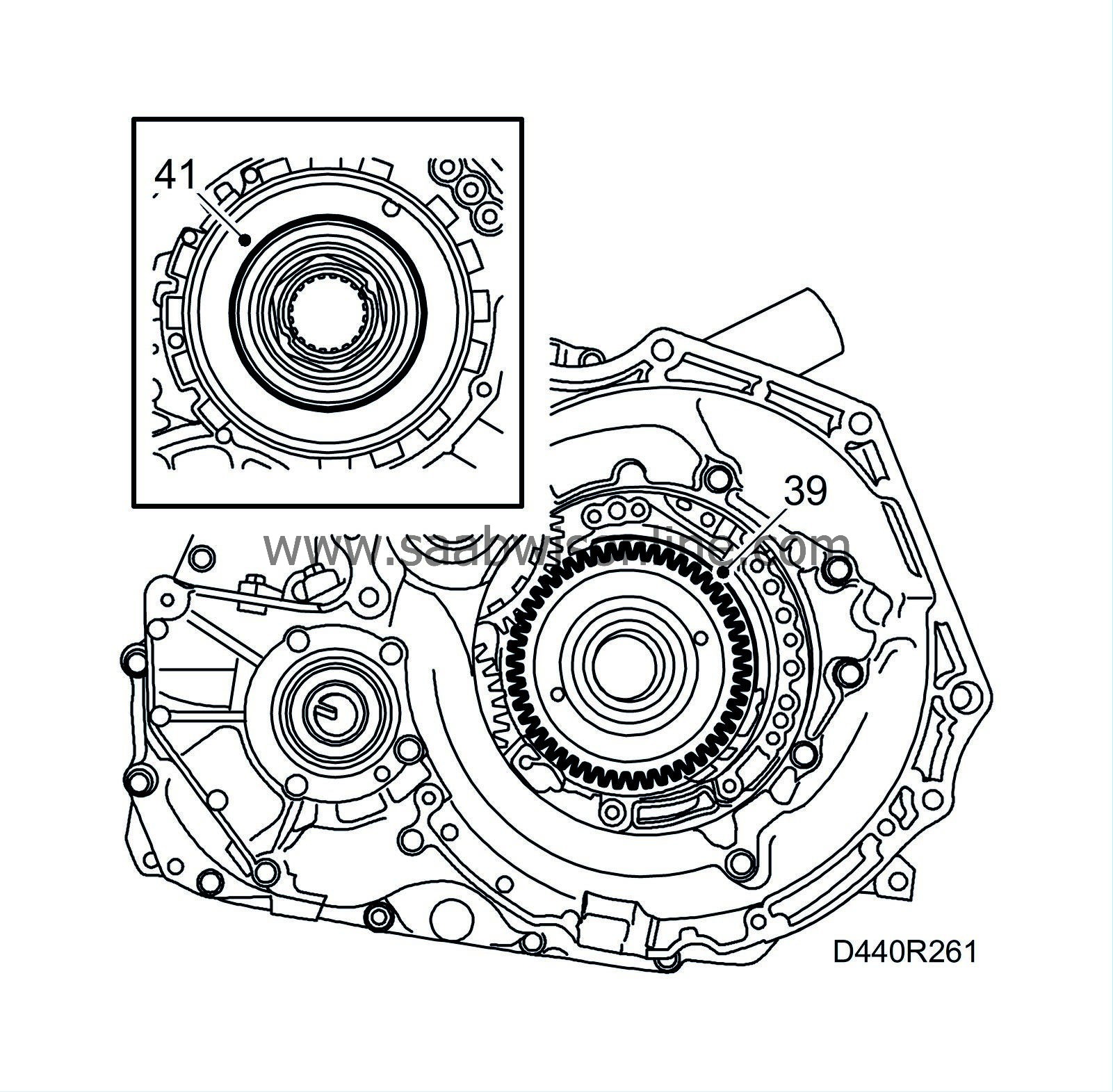

41.

|

Use circlip pliers 87 90 180 with tips 87 90 297 and fit the circlip. Press the circlip into the groove with a pair of pliers.

|

|

42.

|

Turn the gearbox 90°.

|

|

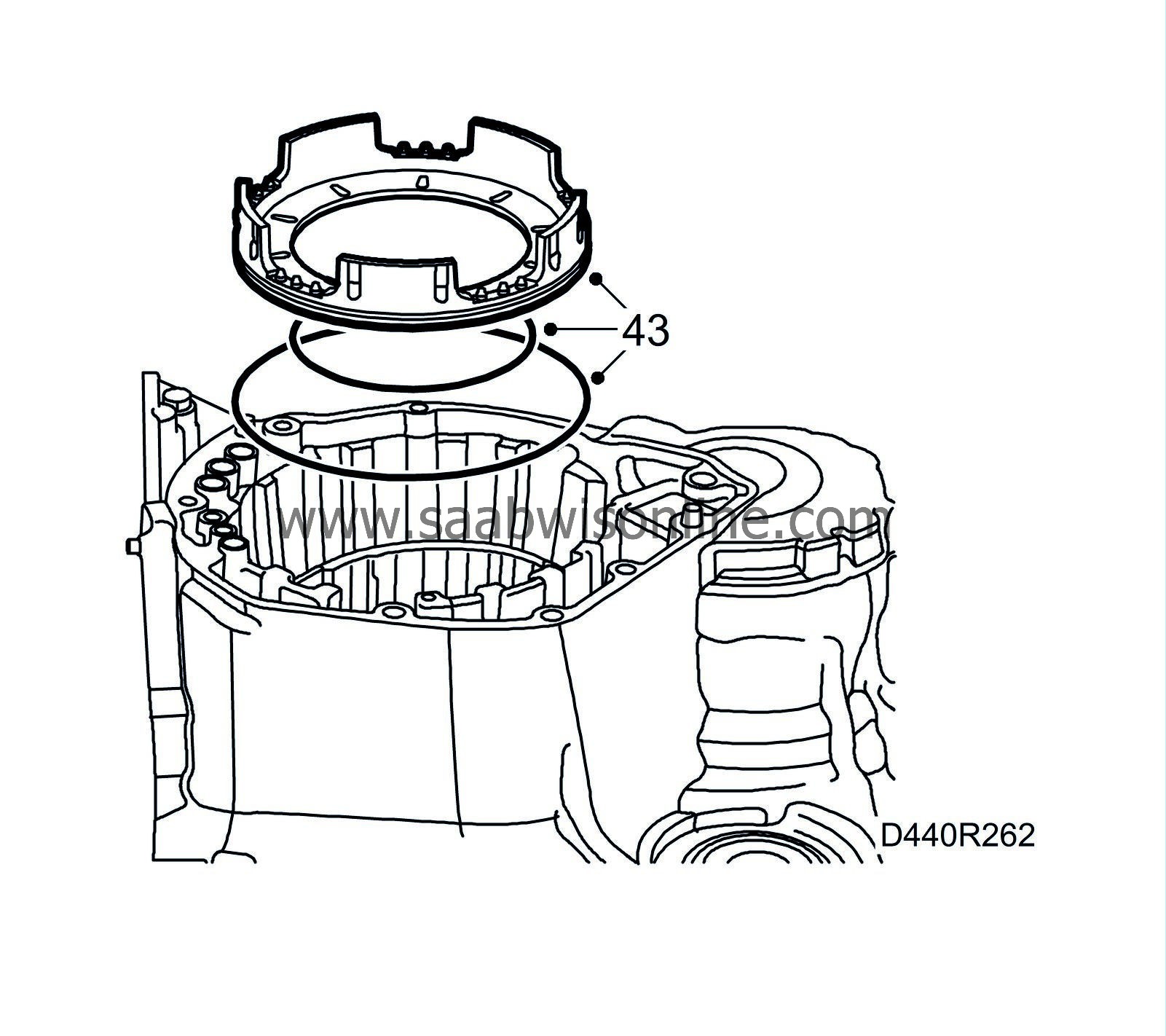

43.

|

Apply petroleum jelly to two new O-rings for brake B3 and fit them on the brake plunger. Take care not to damage the O-rings. Press the plunger into the gearcase.

|

|

44.

|

Put in place the return spring unit on the plunger and fit the circlip in the groove on the gearcase. Make sure the opening in the circlip is not aligned with the large recess. Use a screwdriver to make sure the entire circlip is in the groove.

|

|

45.

|

Lay the bearing race and thrust bearing on the intermediate gear hub.

|

|

46.

|

Fit the front ring gear and freewheel F3. Make sure the thrust bearing is positioned correctly and that the ring gear rotates freely anticlockwise and is locked clockwise.

|

|

47.

|

Fit flanges, clutch discs and disc plates as illustrated.

|

Important

|

|

The large recess in the flanges and plates must be aligned in front of the brake bands to B4. Make sure that they are fitted in the correct order.

|

|

|

|

|

48.

|

Fit the circlip into the gearcase. Make sure the opening in the circlip is not in line with the recesses.

|

|

49.

|

Apply an air pressure of 4 bar in the oil passage as illustrated. Make sure the plunger moves easily.

|

|

50.

|

Lubricate the thrust bearing for the planetary gear with petroleum jelly and place the bearing on the front ring gear. Check that the black side is face up.

|

|

51.

|

Fit the planetary gear.

|

|

52.

|

Place the thrust bearing race on the planetary gear lubricated with petroleum jelly.

|

|

53.

|

Lubricate the thrust bearing for the planetary ring gear with petroleum jelly and place the bearing on the front of the planetary ring gear. Lay the planetary ring gear on the planetary gear.

|

|

54.

|

Lubricate the bearing race for the planetary gear ring with petroleum jelly. Fit the bearing race.

|

|

55.

|

Lubricate the thrust bearing with petroleum jelly and fit the sun gear shaft.

|

|

56.

|

Fit the planetary gear sun gear unit into the planetary gear.

|

|

57.

|

Lubricate the thrust bearing for the planetary gear sun gear with petroleum jelly and place the bearing on the sun gear. Make sure the bearing is fitted correctly with the black side face up.

|

|

58.

|

Centre the clutch discs and plates using a screwdriver. Fit ring gear and clutch C1 as a complete unit. Turn the intermediate gear and C1 towards each other so that the planetary gear engages in the ring gear.

|

|

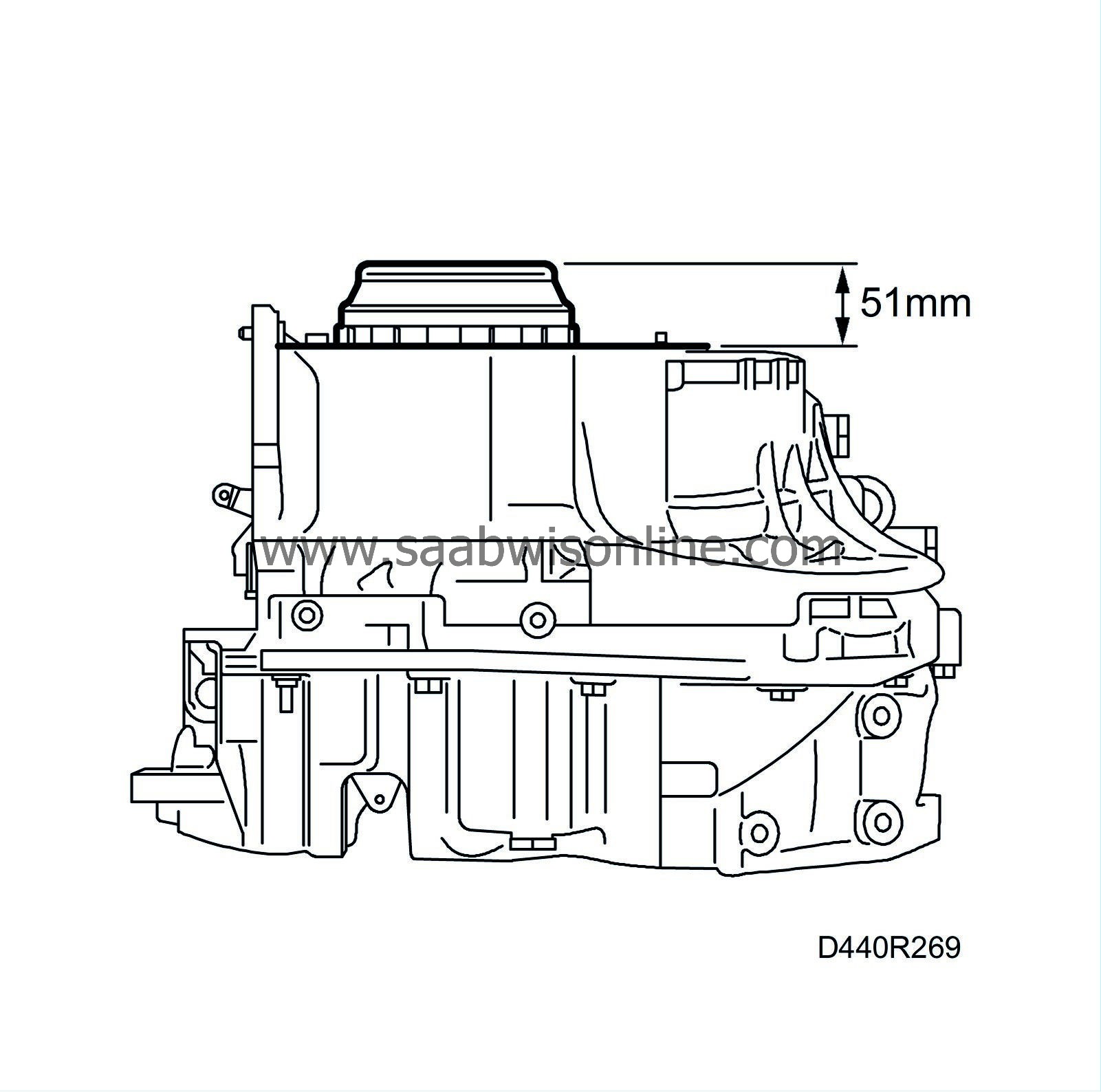

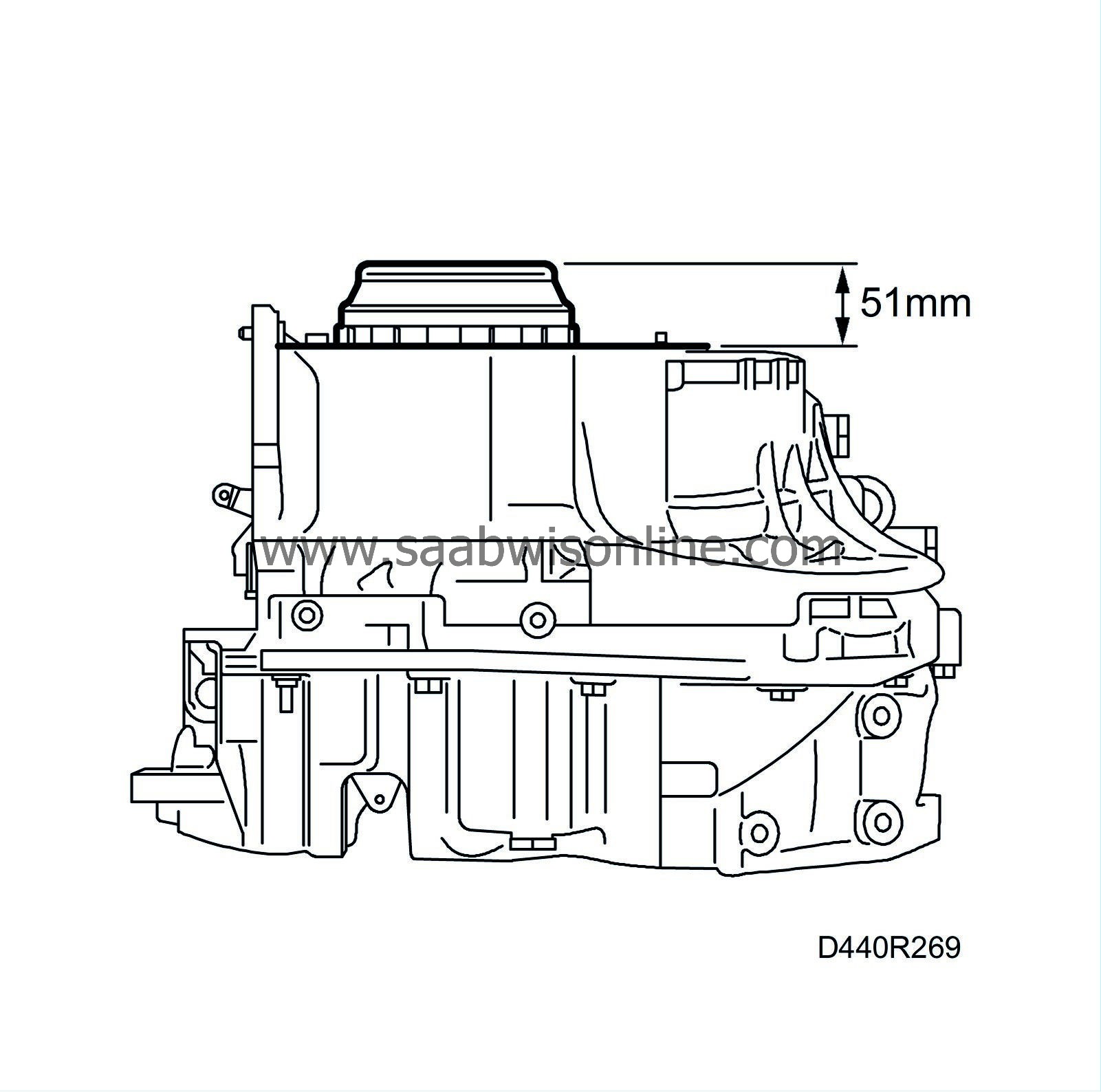

59.

|

Make sure the ring gear and clutch C1 have fallen in place by measuring as illustrated. The distance must be approximately 51 mm.

|

|

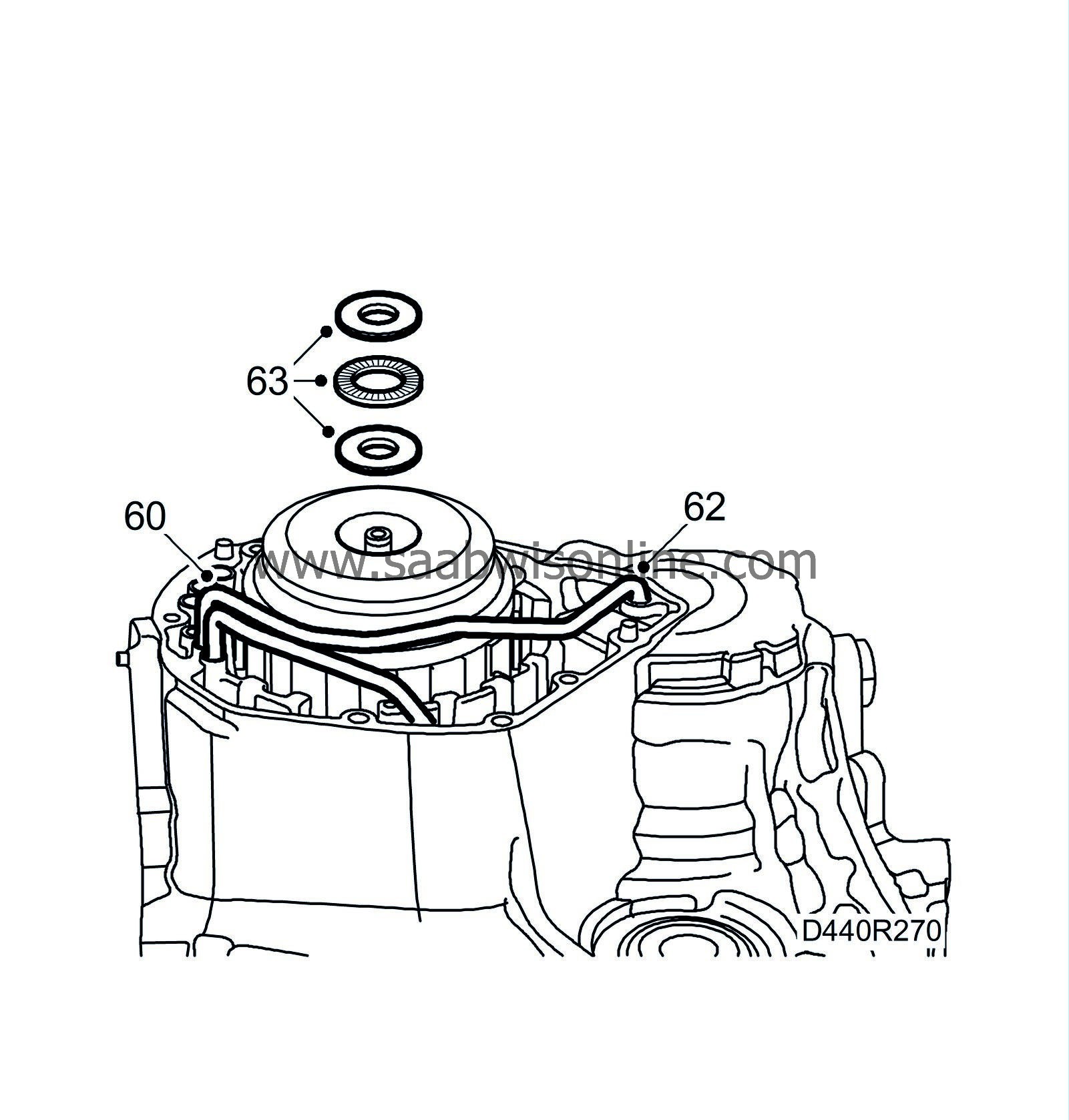

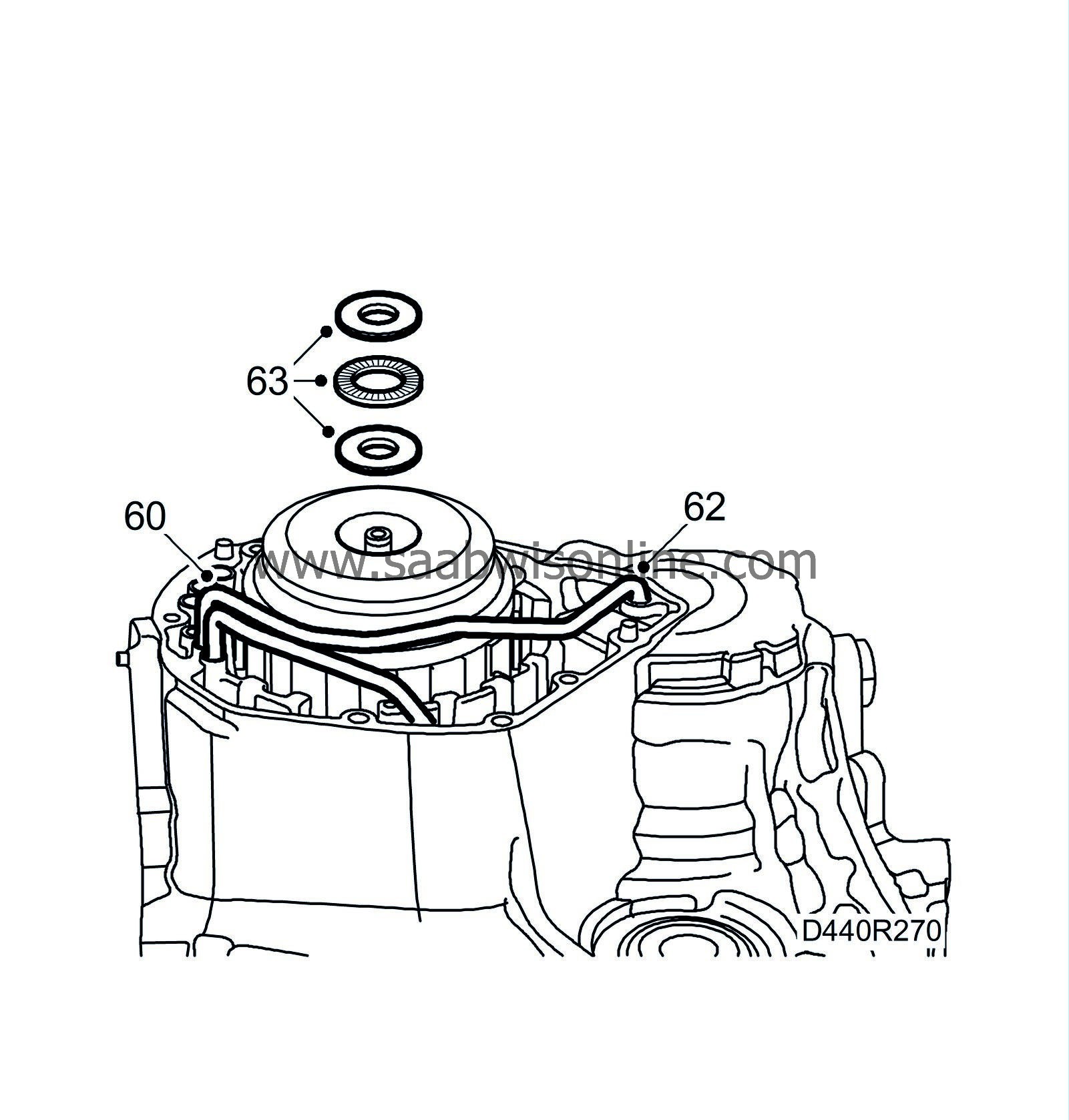

60.

|

Fit the oil pipe. Use a splinter-free plastic mallet. Take care not to bend or destroy the pipe.

|

|

61.

|

Place the clamp on the pipe and tighten the bolt.

Tightening torque 5.5 Nm (4 lbf ft)

|

|

62.

|

Fit the oil pipe for clutch C3 as illustrated. Use a splinter-free plastic mallet. Take care not to bend or damage the pipe.

|

|

63.

|

Fit the bearing race for the rear cover. Lubricate the bearing race with petroleum jelly. Lay the bearing race and the thrust bearing in the C1/C2 unit.

|

|

64.

|

Fit the accumulator for C1 into the end cover.

|

|

65.

|

When changing the end cover, fit the oil sealing rings onto the needle bearing housing. Do not bend the rings more than necessary.

|

|

66.

|

Fit a new sealing ring lubricated with petroleum jelly onto the shaft for C1/C2

|

|

67.

|

Clean the sealing surfaces with cleaning fluid 30 02 599. Keep the sealing surfaces free from grease.

|

|

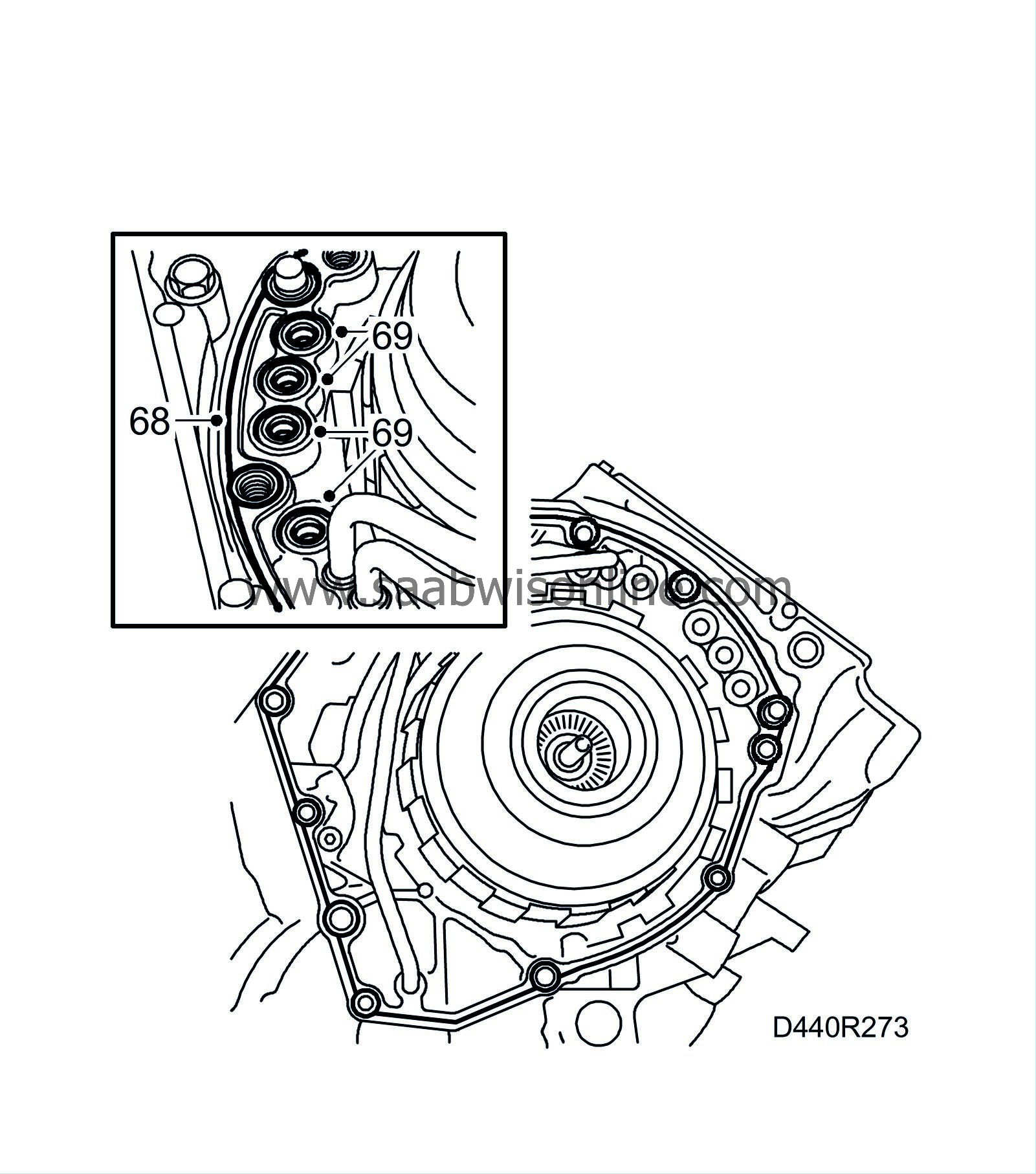

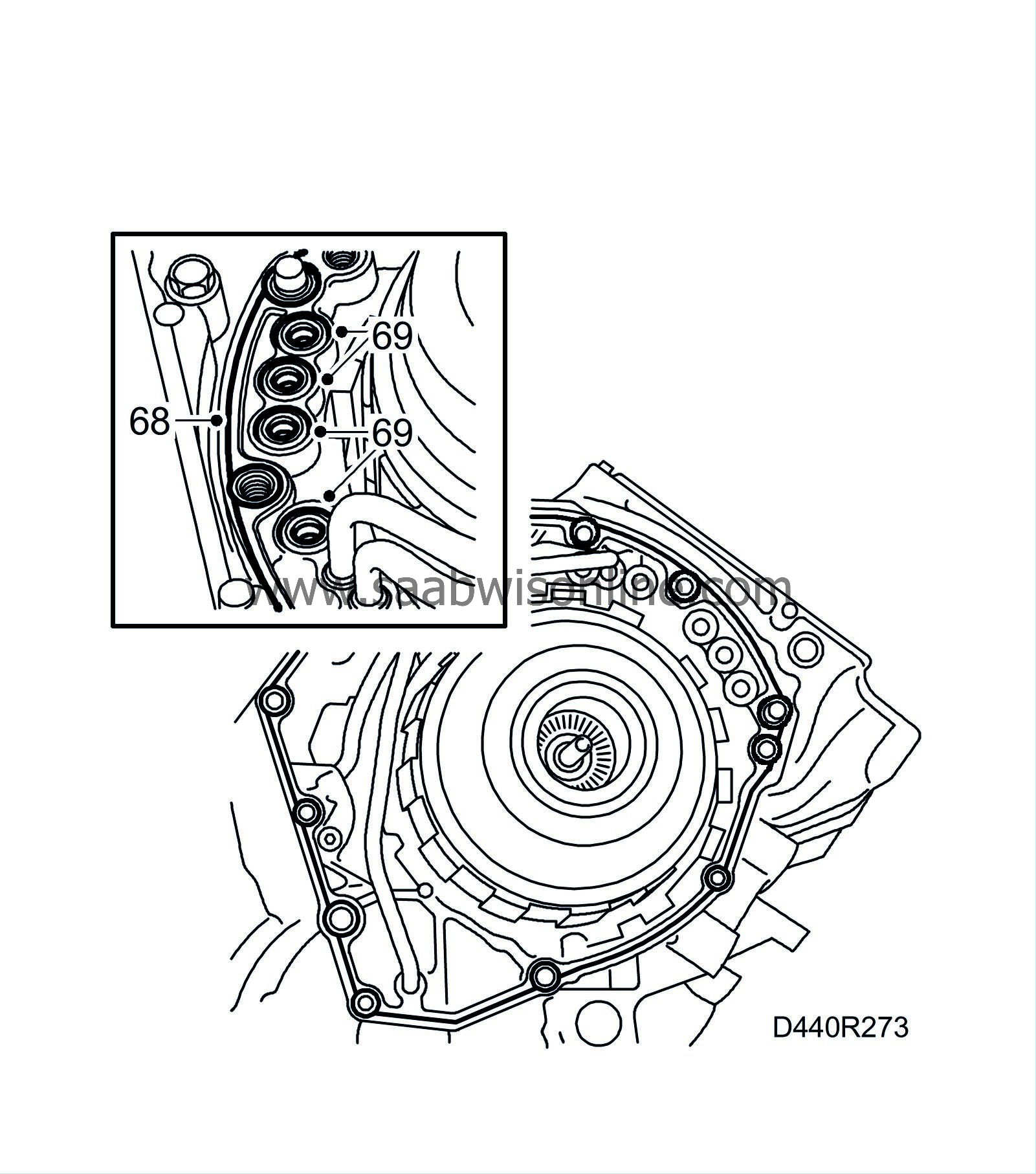

68.

|

Apply a bead of flange sealant 87 81 841 approximately 1 mm thick on the rear cover.

|

|

69.

|

Lubricate four new sealing rings for the oil holes with petroleum jelly and fit them on the gearcase.

|

|

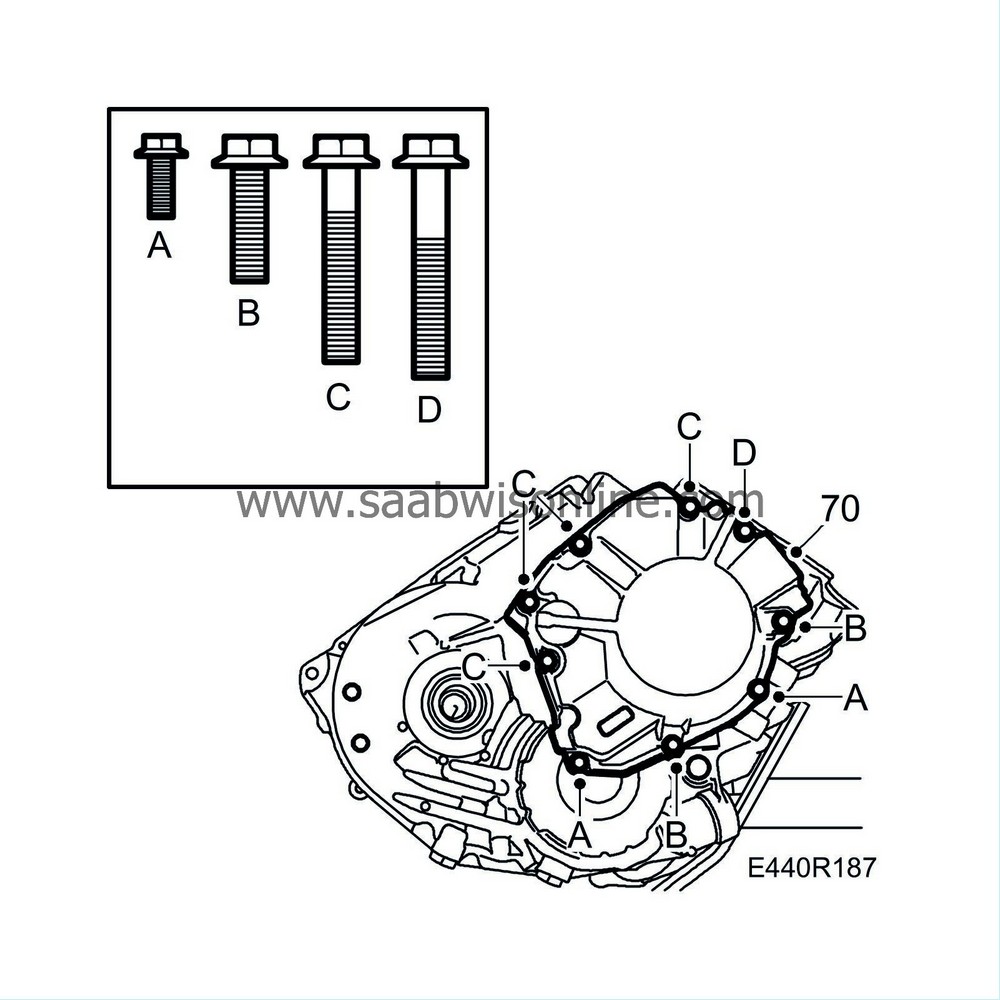

70.

|

Fit the end cover on the gearcase. Apply thread locking compound 74 96 284 to the bolts and tighten alternately. (Different lengths)

Tightening torque M6 10 Nm (7 lbf ft)

Tightening torque M8 25 Nm (18 lbf ft)

|

|

71.

|

Turn the gearbox with turbine shaft 45° downward.

|

|

72.

|

Apply petroleum jelly to the O-rings for the oil pump unit. Align the disc package with a small screwdriver. Fit thrust washers lubricated with petroleum jelly on brake B1/B2.

|

|

73.

|

Fit freewheel F1 and the bearing race for brake B1 and B2 on the oil pump unit. Lubricate the bearing race for F1 with petroleum jelly and fit it.

|

|

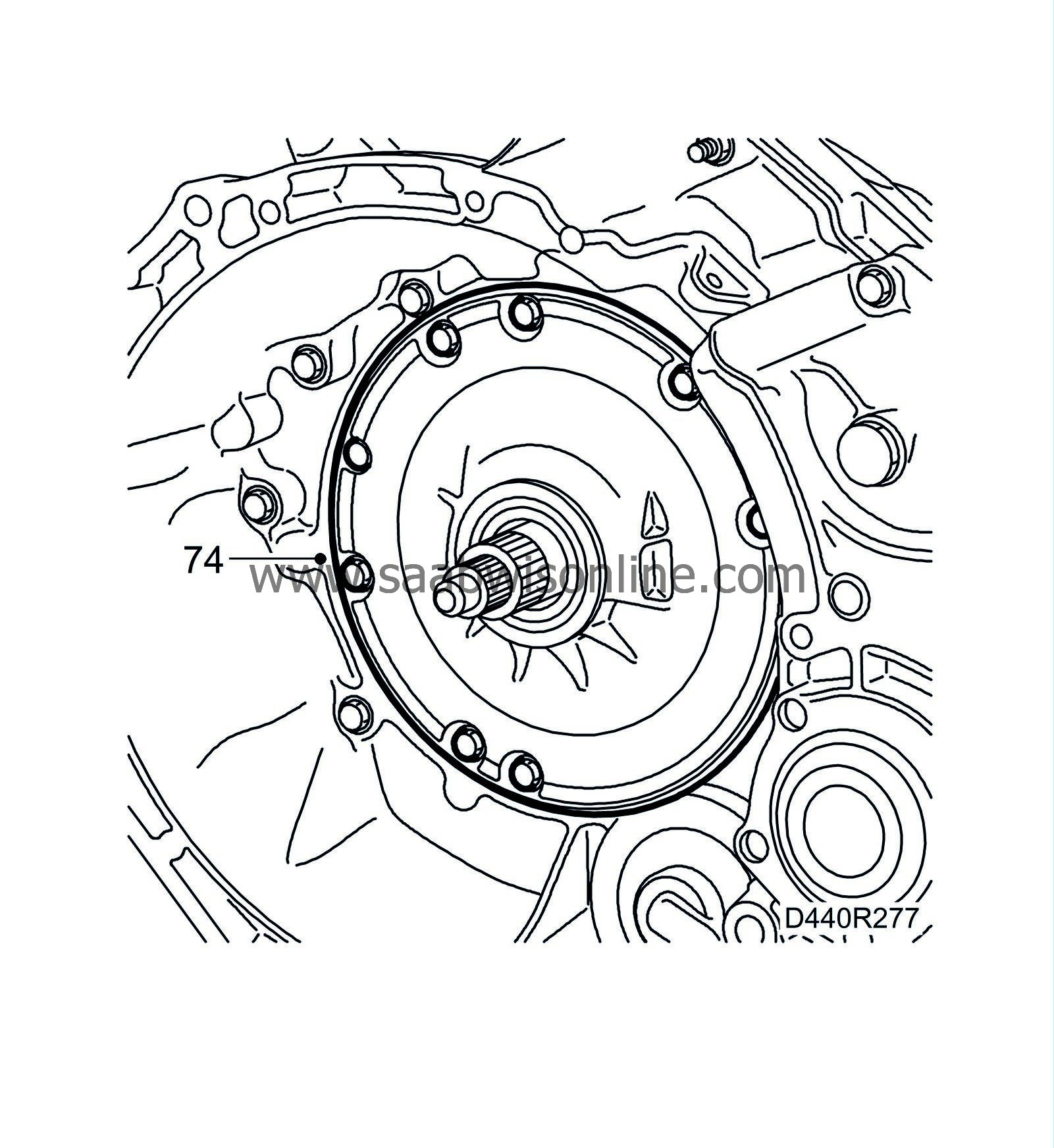

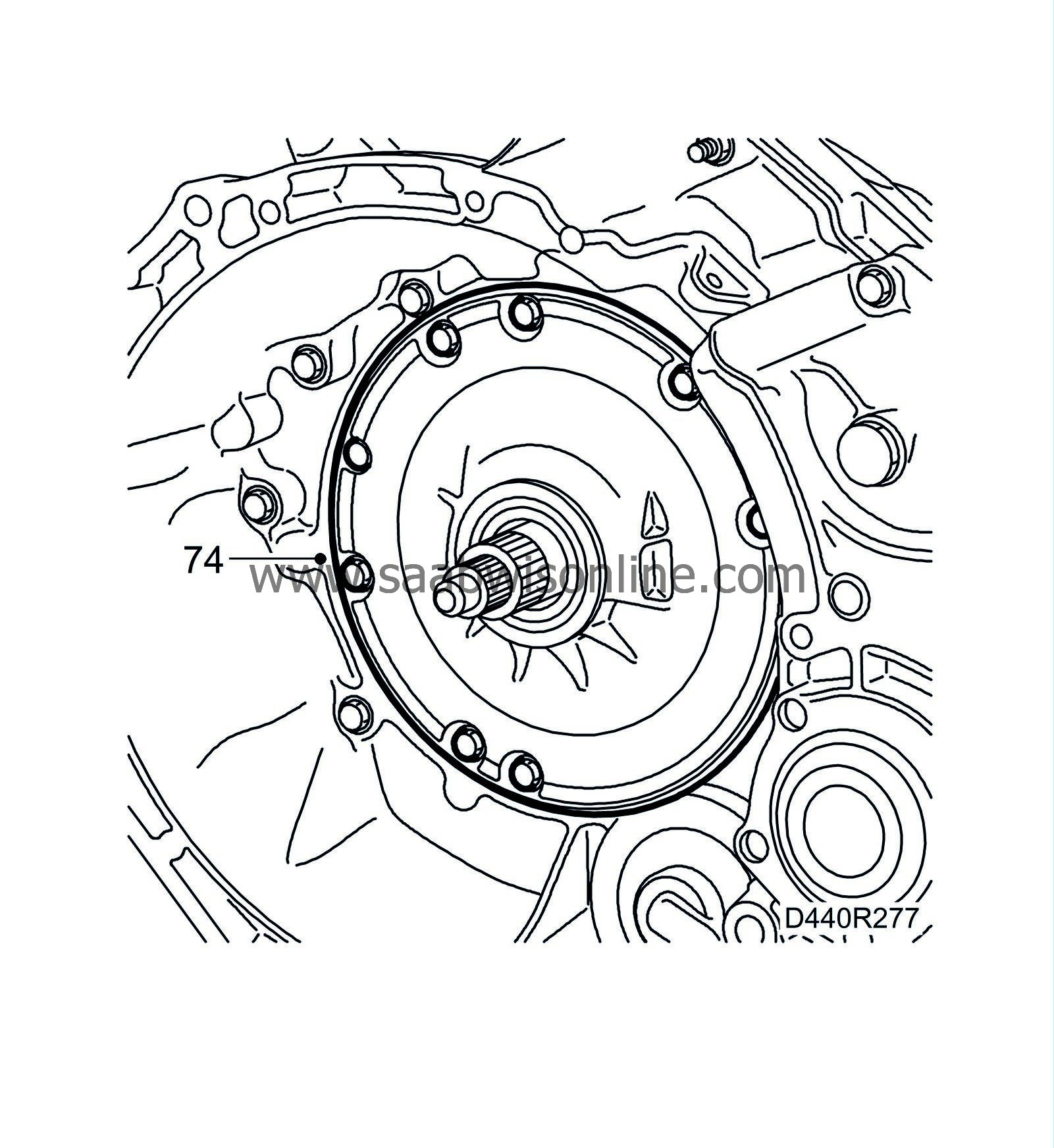

74.

|

Place the oil pump unit so its bolt holes are aligned with those in the gearcase. Press the pump unit in place carefully. Tighten the bolts carefully and alternately.

Tightening torque 25 Nm (19 lbf ft)

|

|

75.

|

Turn back the gearcase 45°

|

|

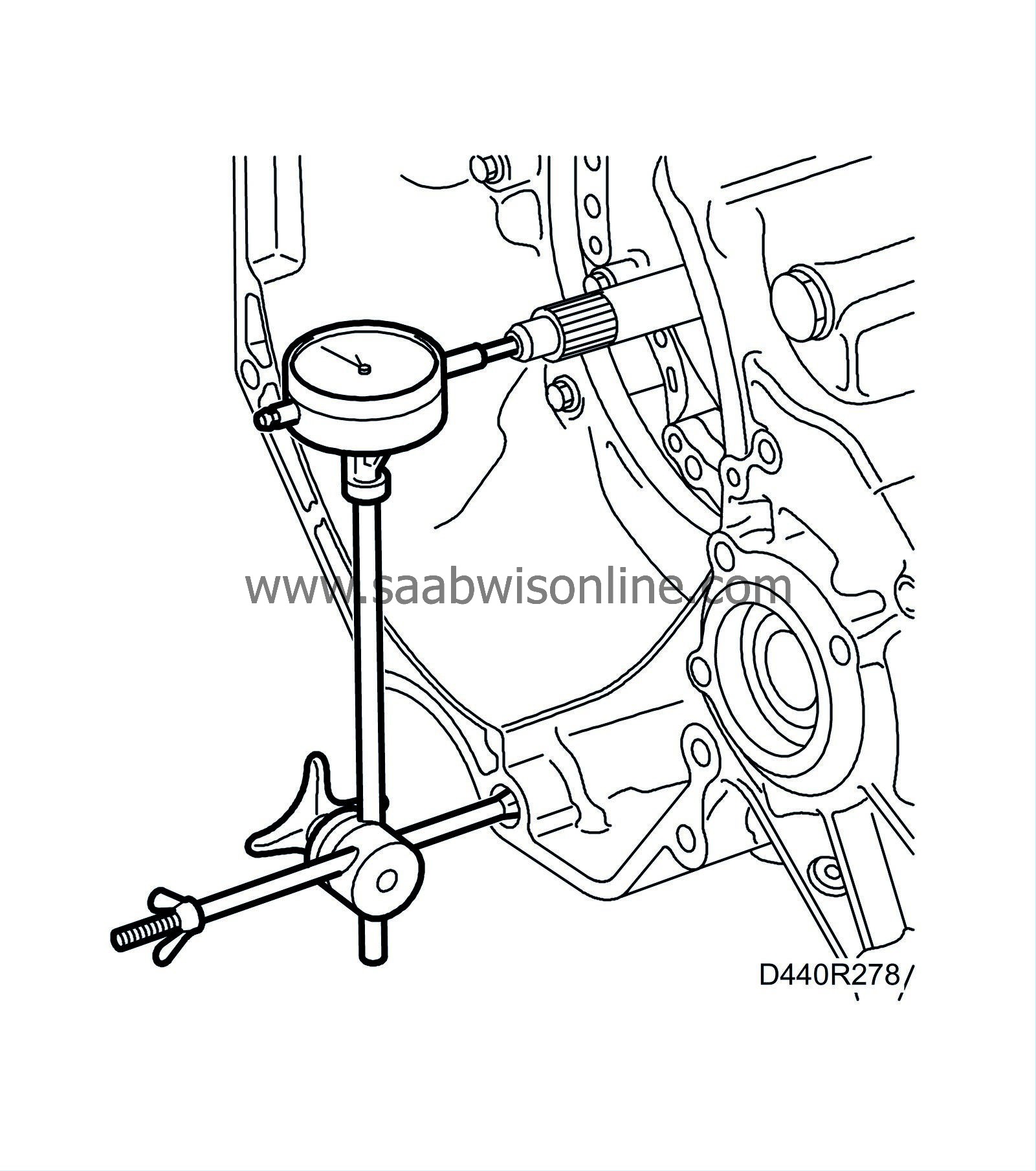

76.

|

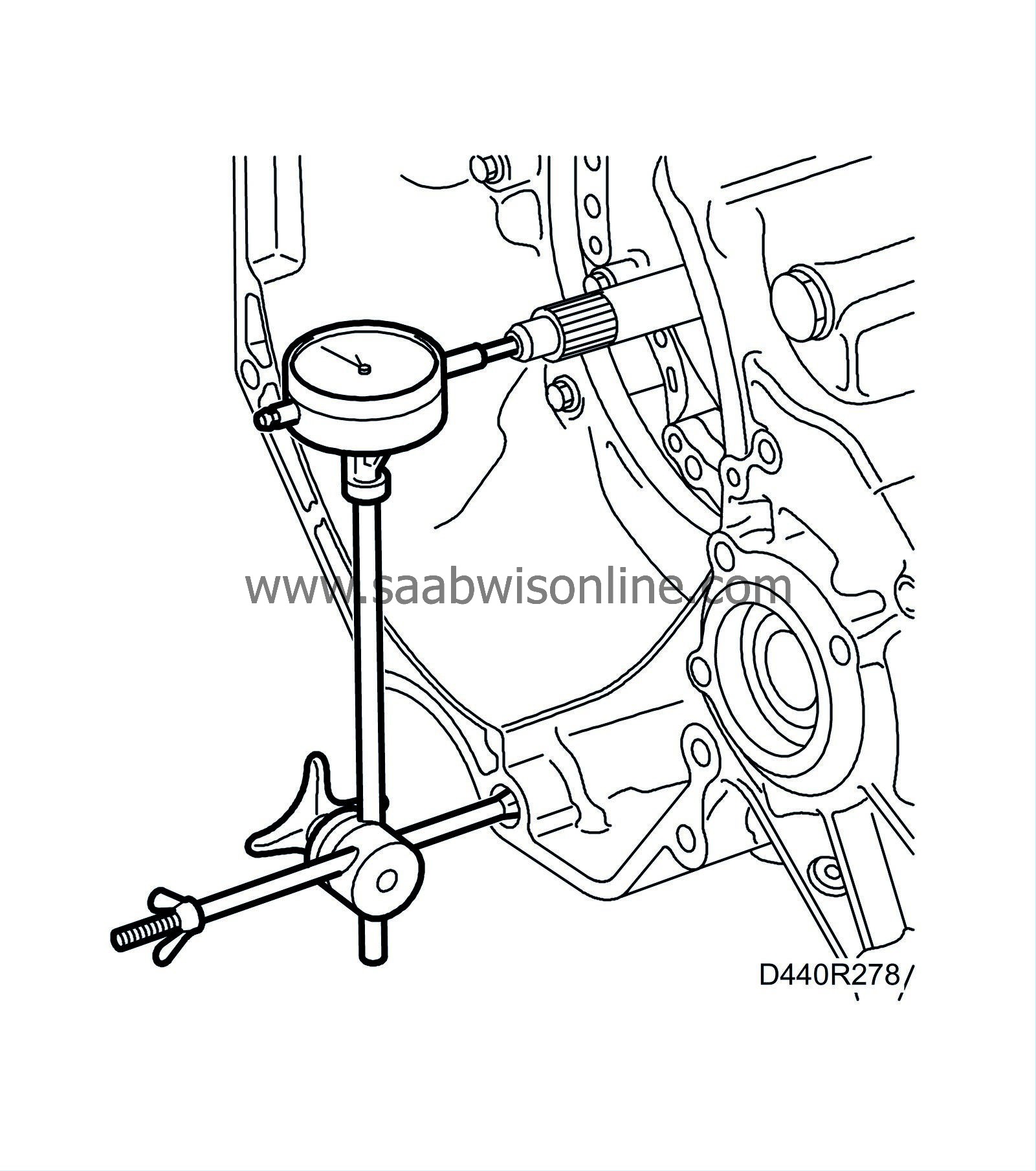

Make sure the turbine shaft has an axial clearance of 0.37 - 0.9 mm. Use dial gauge 78 40 622 and stand 87 90 727.

|

|

77.

|

Fit the two sealing rings.

|

|

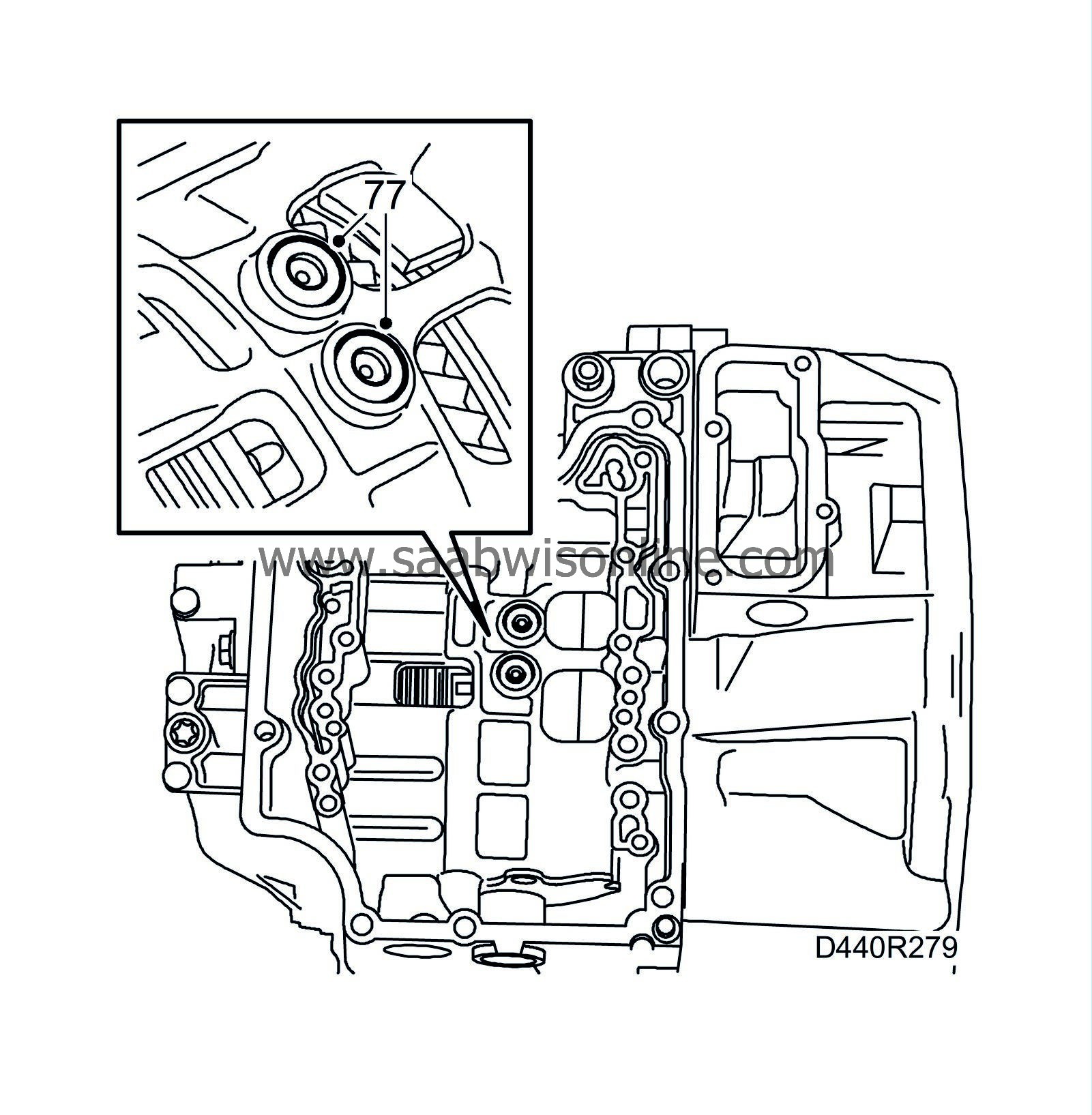

78.

|

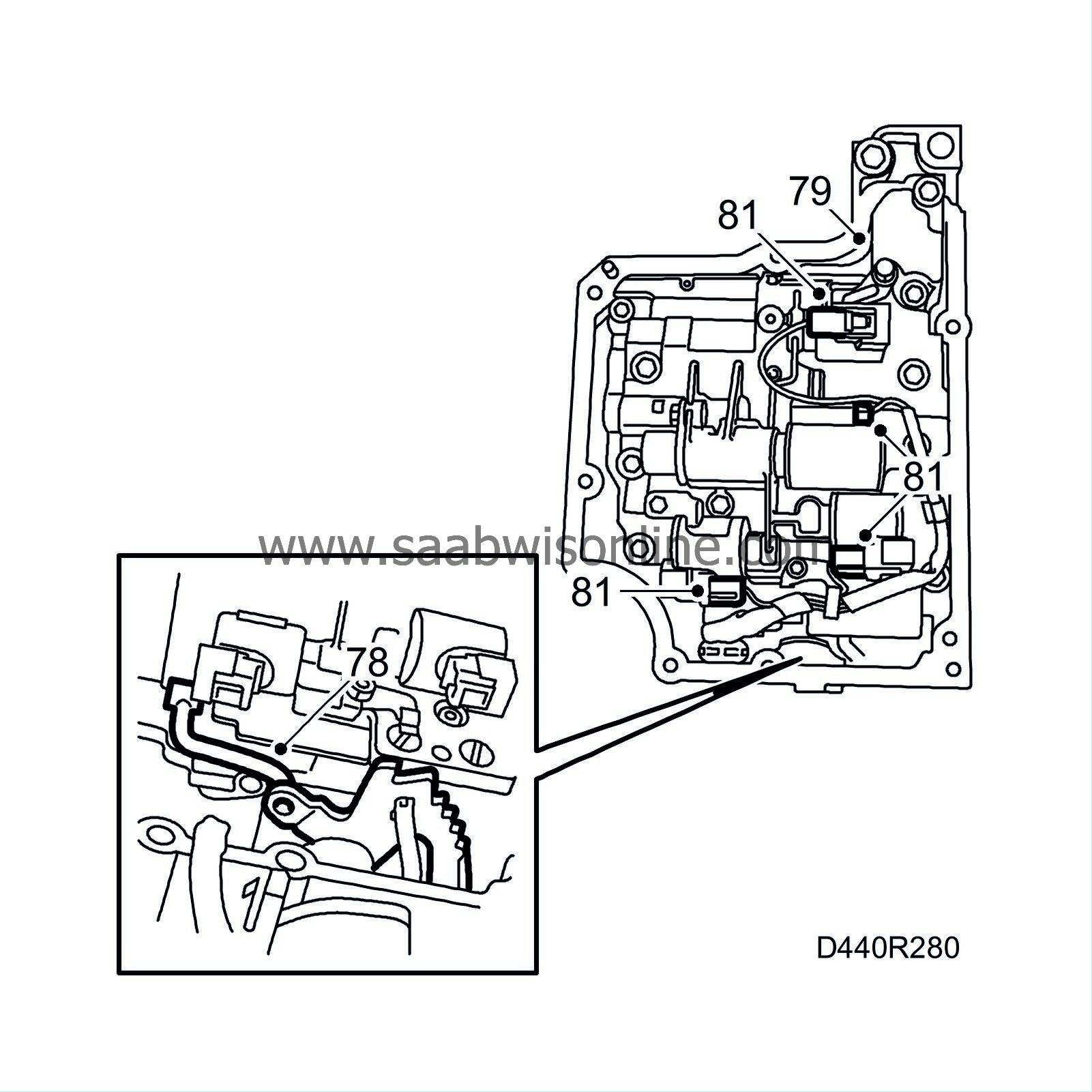

Connect the manual valve connecting rod to the manual valve control on the valve body unit. Screw in the bolts loosely. Take care not to fold the gasket.

|

|

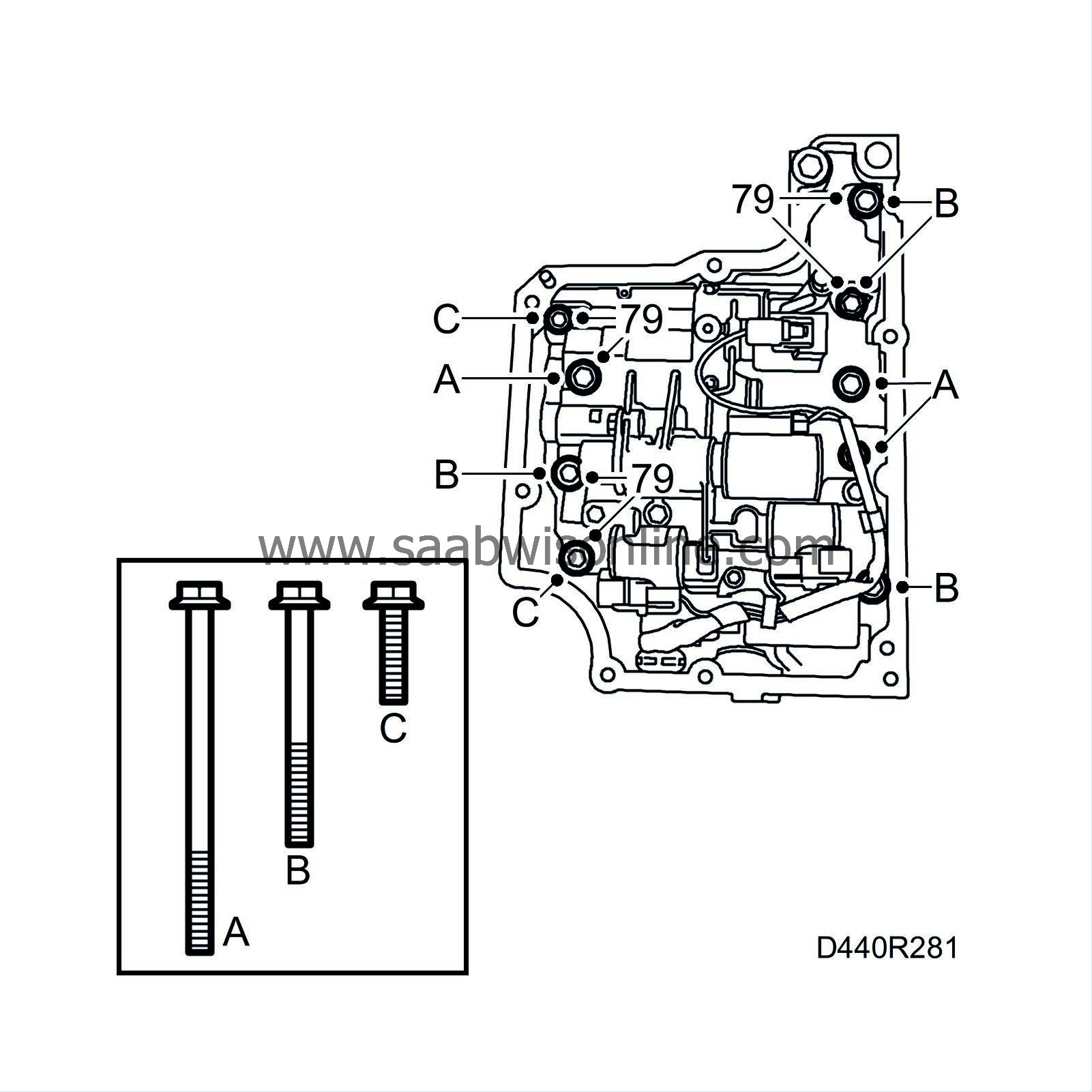

79.

|

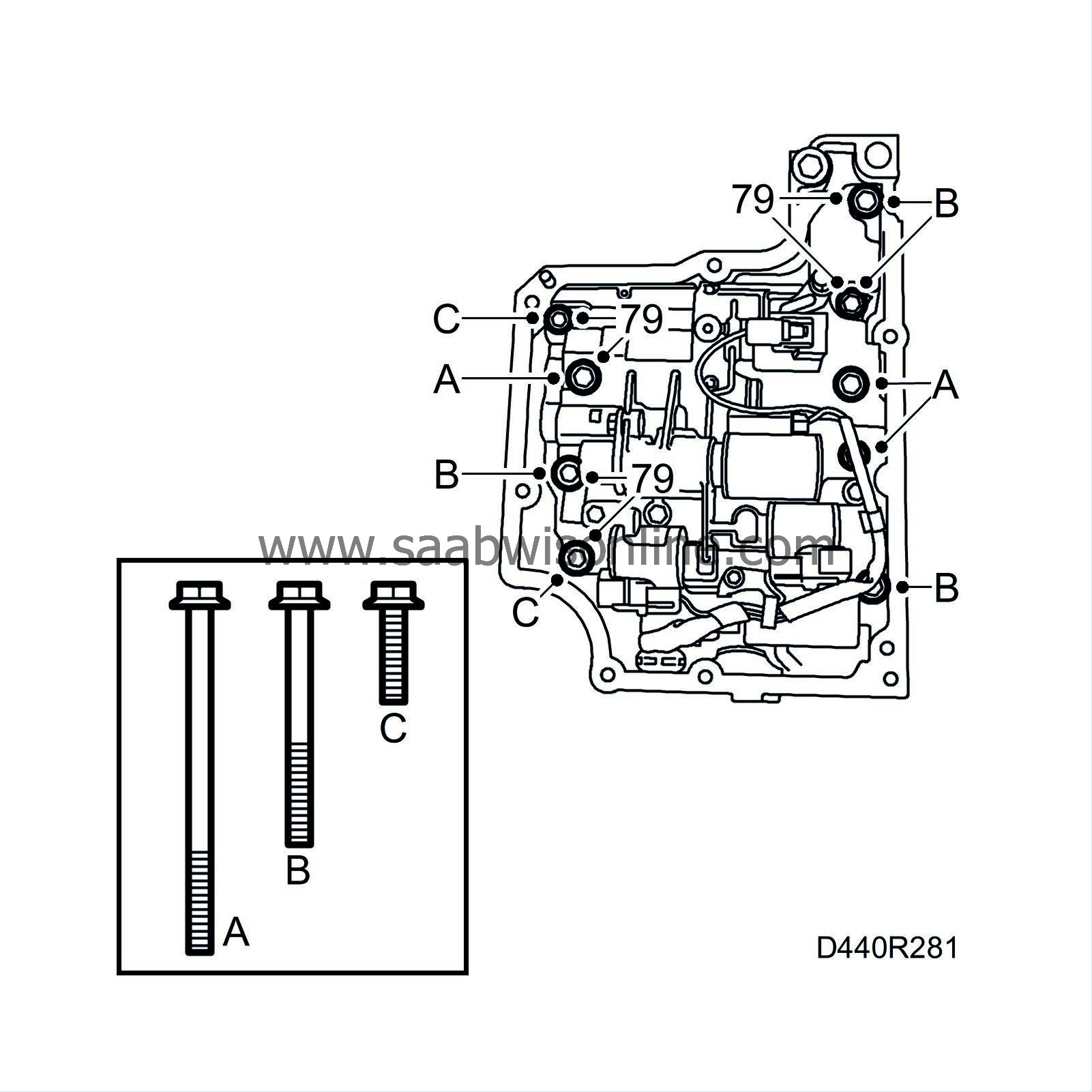

Fit the gasket on the cover, fit the cover bolts. Tighten all the valve body bolts alternately.

Tightening torque 10 Nm (7 lbf ft)

|

|

80.

|

Apply petroleum jelly to a new O-ring and fit it together with the cable grommet and the wiring harness for the solenoids on the gearcase.

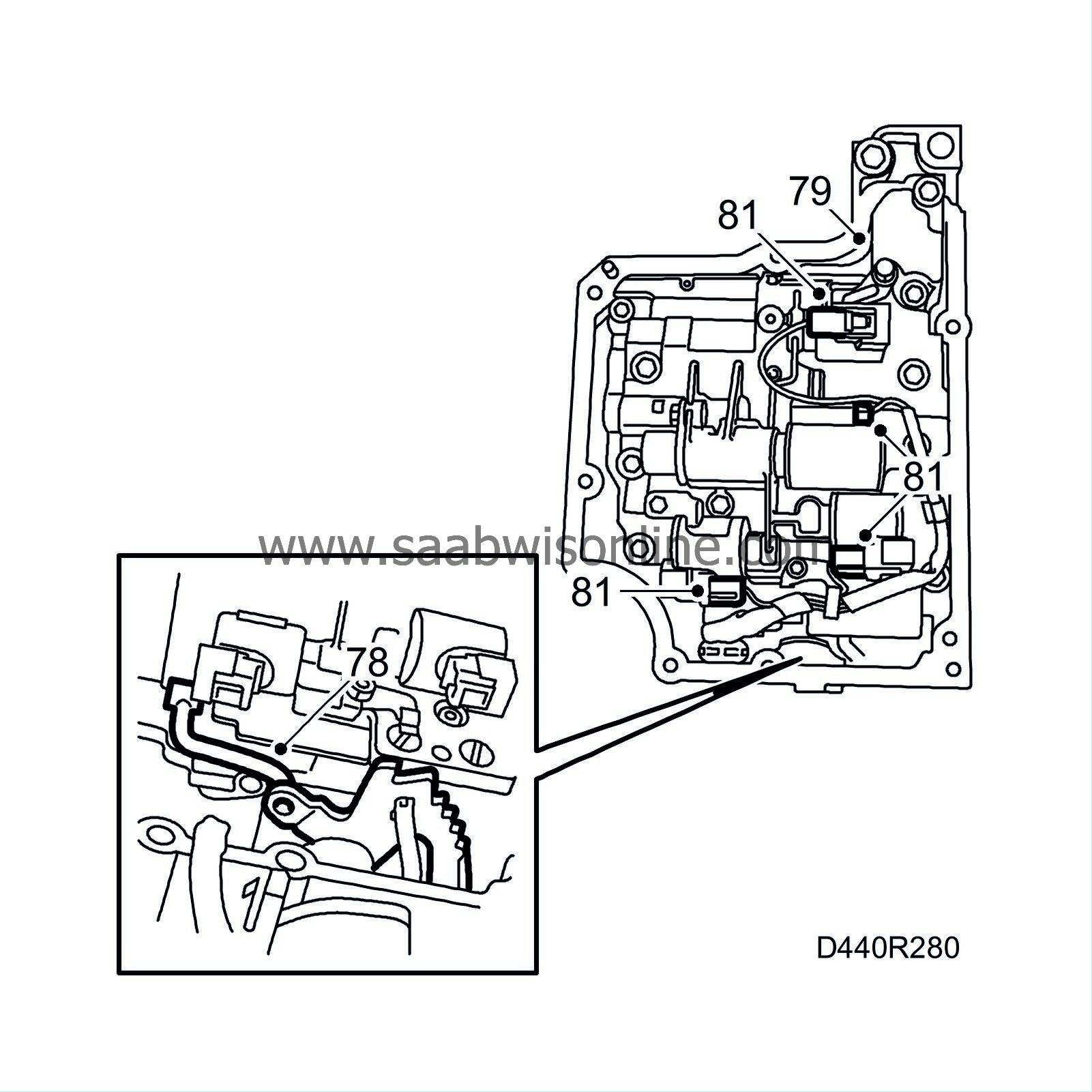

|

|

81.

|

Plug in the connectors to the four solenoids and secure the cables.

|

|

82.

|

Clean inside the valve body cover. Remove any gasket remains from the contact surfaces on the cover and gearcase. Clean the sealing surfaces with cleaning agent 30 02 599. Apply a bead of sealing compound 87 81 841 approximately 1 mm thick to the cover and fit the cover onto the gearcase. Apply thread sealant 74 76 284 to the bolts (different lengths) and tighten the bolts alternately.

Tightening torque 25 Nm (19 lbf ft)

|

|

83.

|

Fit the oil temperature sensor in the gearcase. Fit a new O-ring lubricated with petroleum jelly.

Tightening torque 10 Nm (7 lbf ft)

|

|

84.

|

Fit the oil temperature sensor cover plate with nut, washer and bolt.

Tightening torque, bolt 25 Nm (19 lbf ft)

Tightening torque, nut 10 Nm (7 lbf ft)

|

|

85.

|

Clean the plate cover sealing surface and apply a 2 mm thick bead of sealing compound 87 81 841. Fit and tighten the bolts.

Tightening torque 7.5 Nm (6 lbf ft)

|

|

86.

|

Turn the gearbox 180°

|

|

87.

|

Fit new O-rings on the speed sensors. Clean the speed sensors and make sure there are no metal cuttings on the magnets. Apply petroleum jelly to the O-rings. Fit the two speed sensors in their correct positions. Note that on models where the cables are connected directly to the sensor, they are different lengths. Long cable = input shaft (A), short cable = output shaft (B). Plug in the connectors to the speed sensors and temperature sensor. Tighten the bolts.

Tightening torque 5.5 Nm (4 lbf ft)

|

|

88.

|

Fit the gear selector position sensor. Fit the holder for the cable grommet. Tighten the bolts on the gear selector position sensor first (important). Then tighten the nut on the gear selector position sensor and bend up the lock washer.

Tightening torque 8 Nm (6 lbf ft)

|

|

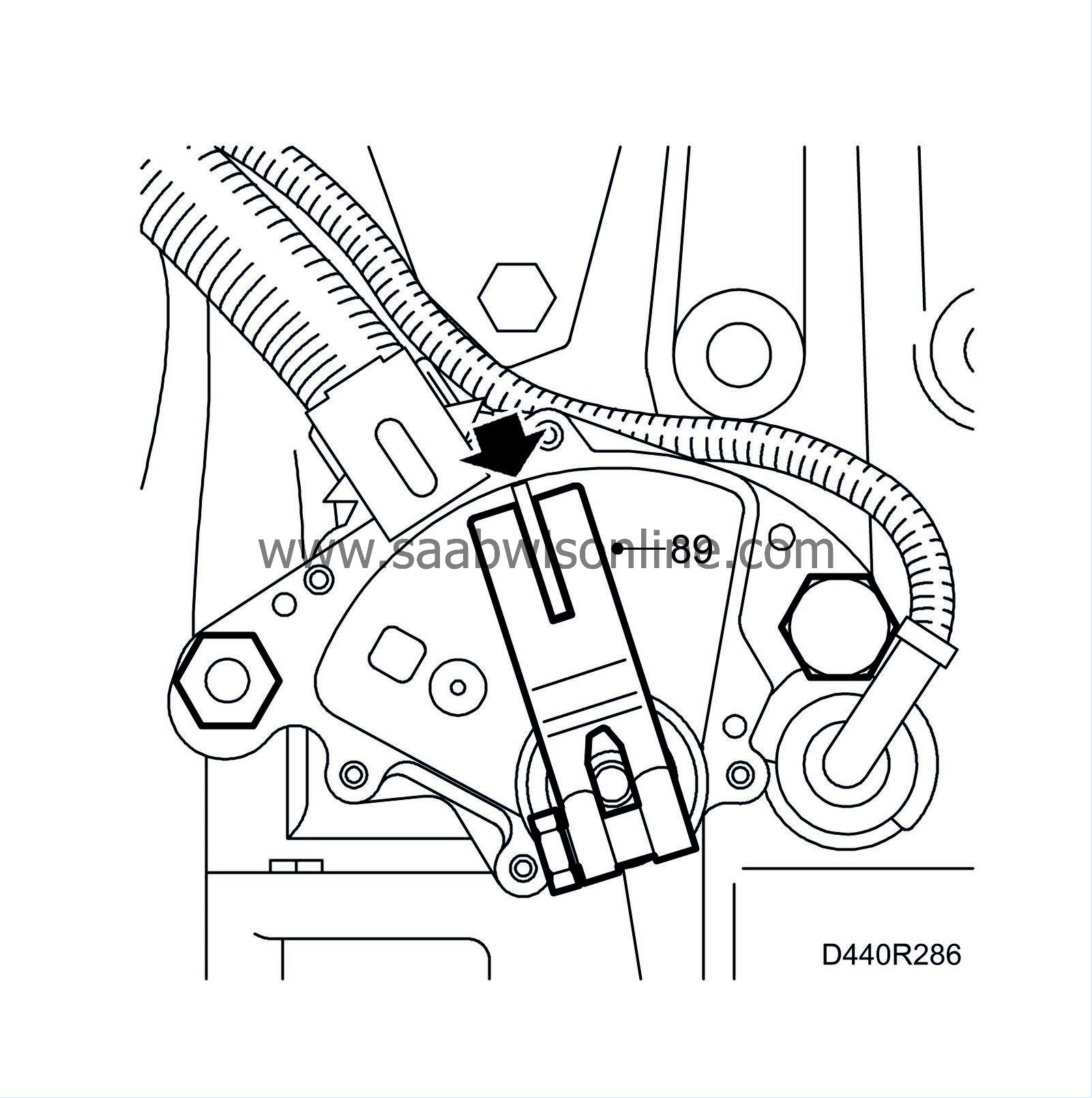

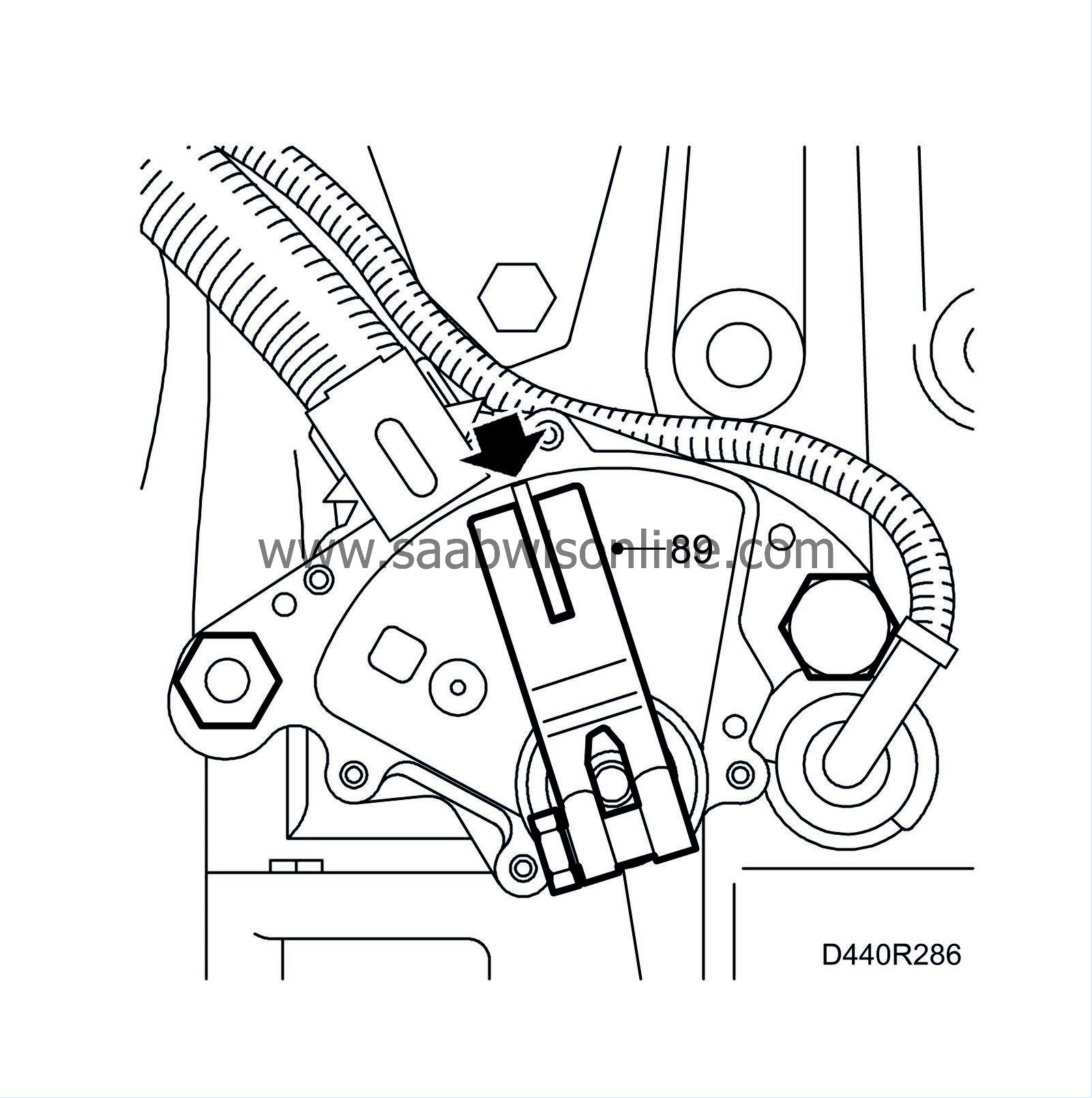

89.

|

Engage neutral and fit setting tool 87 92 467. Undo the bolts for the gear selector position sensor and adjust it so that the line is visible in the centre of the groove in the setting tool. Tighten the bolts.

Tightening torque 25 Nm (18 lbf ft)

|

|

90.

|

Remove the setting tool.

|

|

91.

|

Turn the gearbox through 90°.

|

|

92.

|

Change the torque converter seal, see adjustment/replacement Torque converter seal.

|

|

93.

|

Fit the torque converter. Use holder 87 91 766. Fit locking device 87 92 574.

|

|

94.

|

Make sure the torque converter has been fitted in the correct position and lay a steel rule on the mating face of the torque converter. Measure the distance between the mating face and the drive plate contact surface on the torque converter. The distance must be at least 15 mm.

|

|

95.

|

Remove holder 87 92 681.

|

|

96.

|

Fit new drive shaft seals. Use drift 83 90 122

|

|

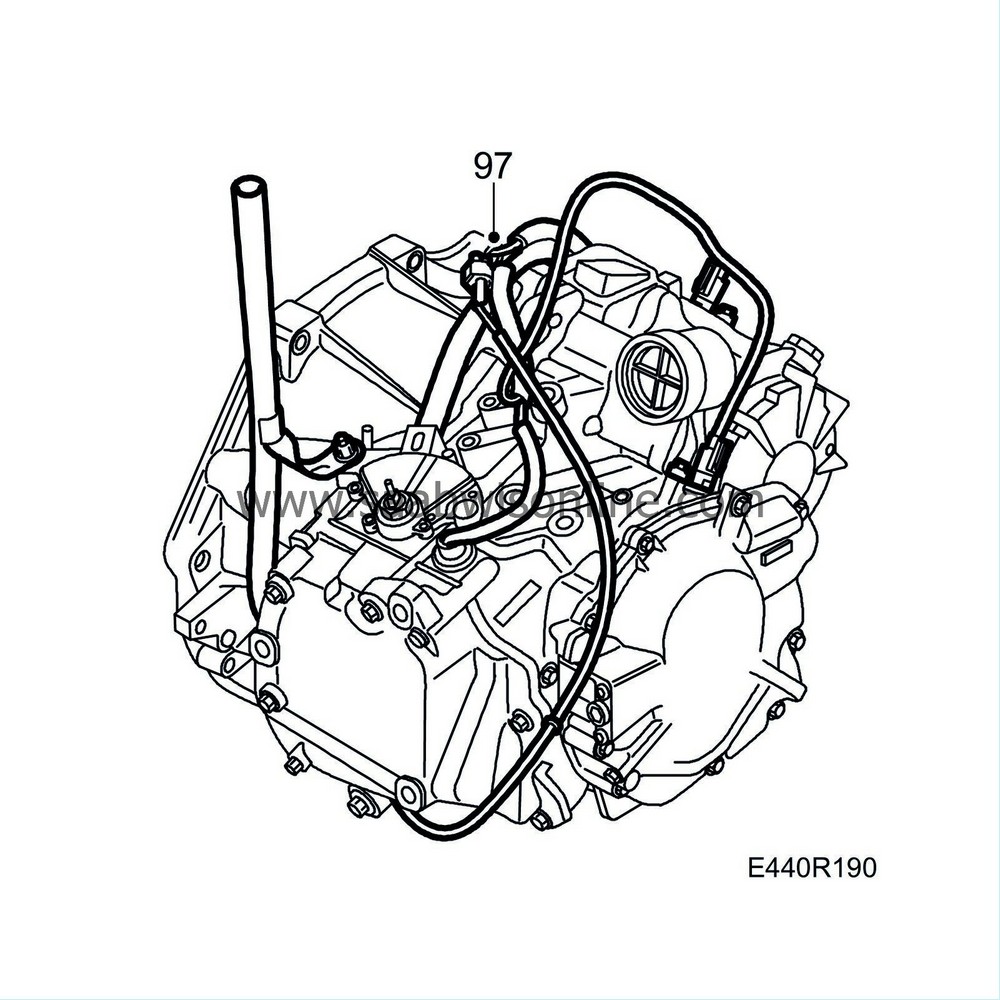

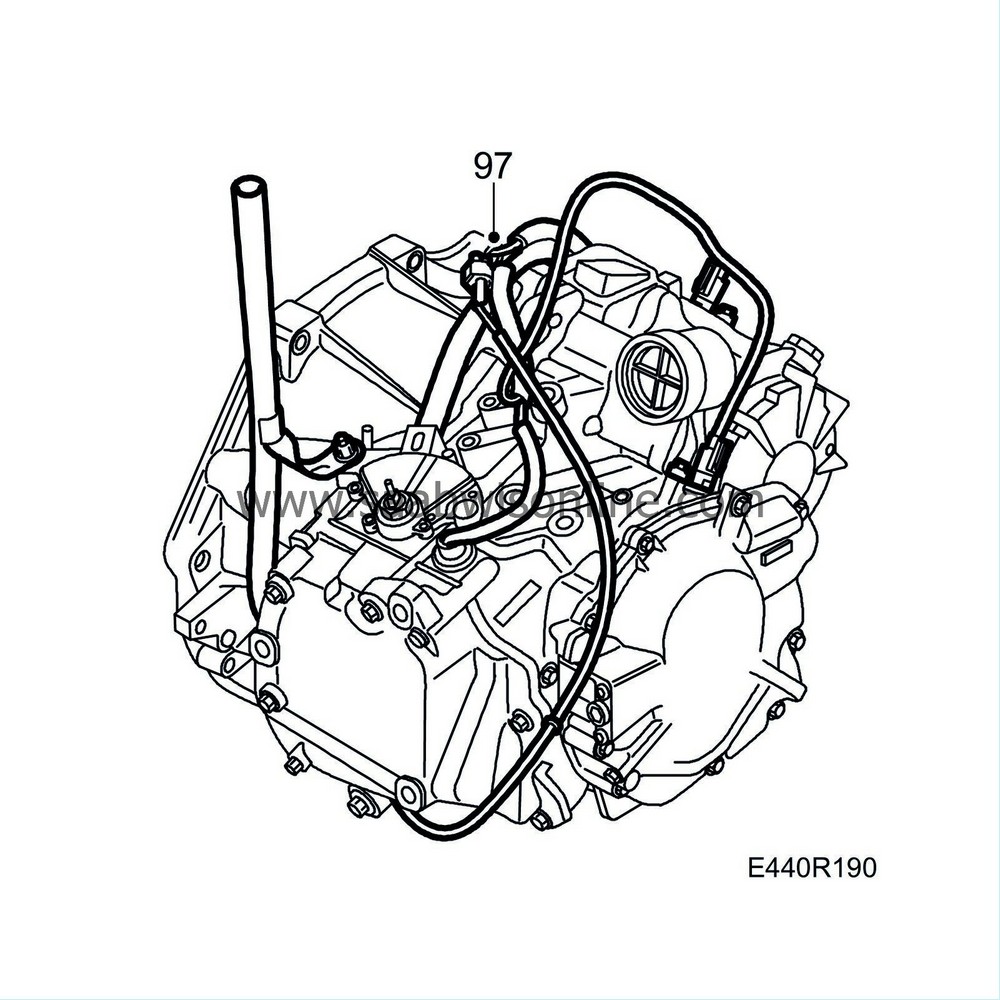

97.

|

Bind the wiring harness with cable ties.

|

|

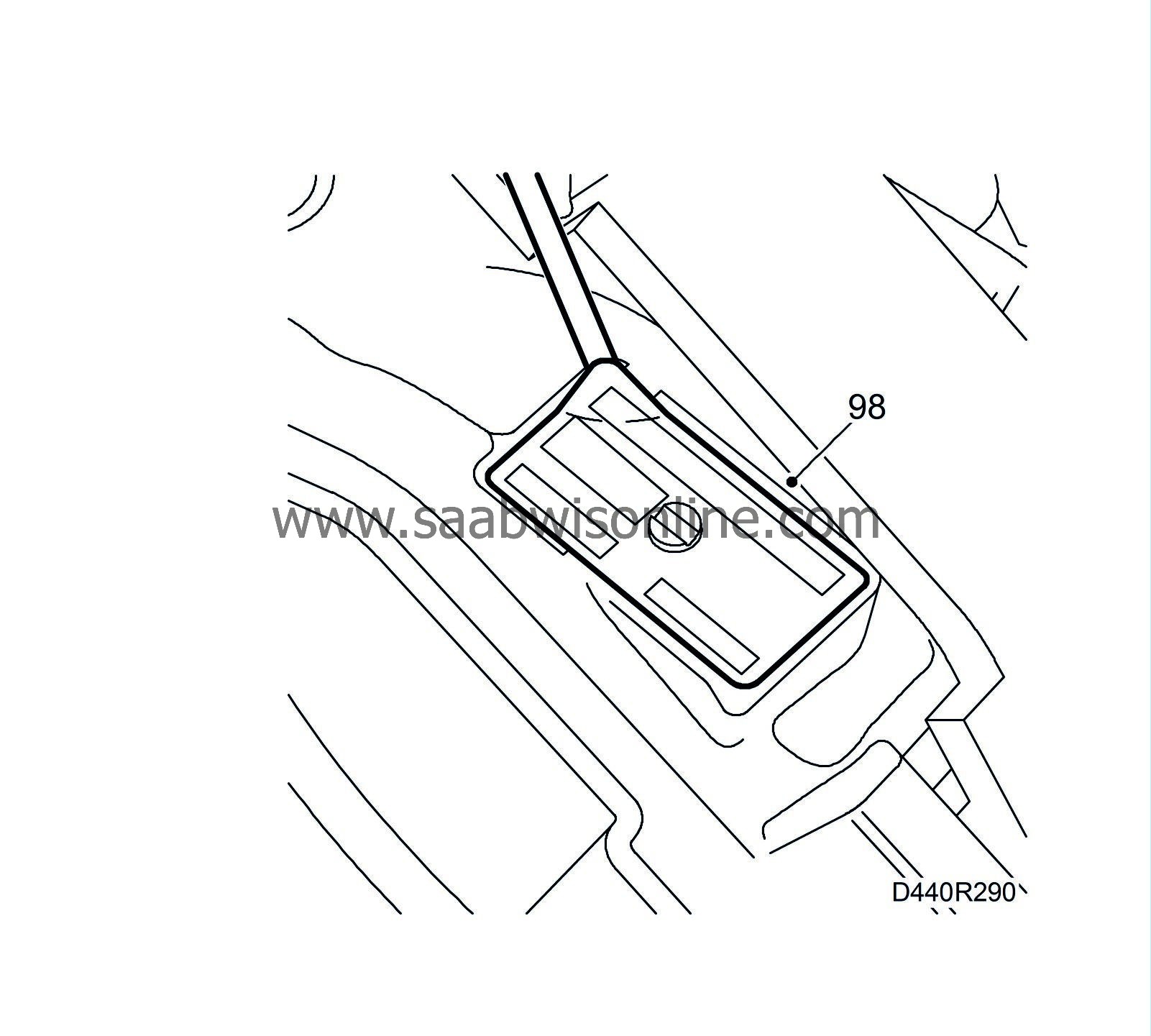

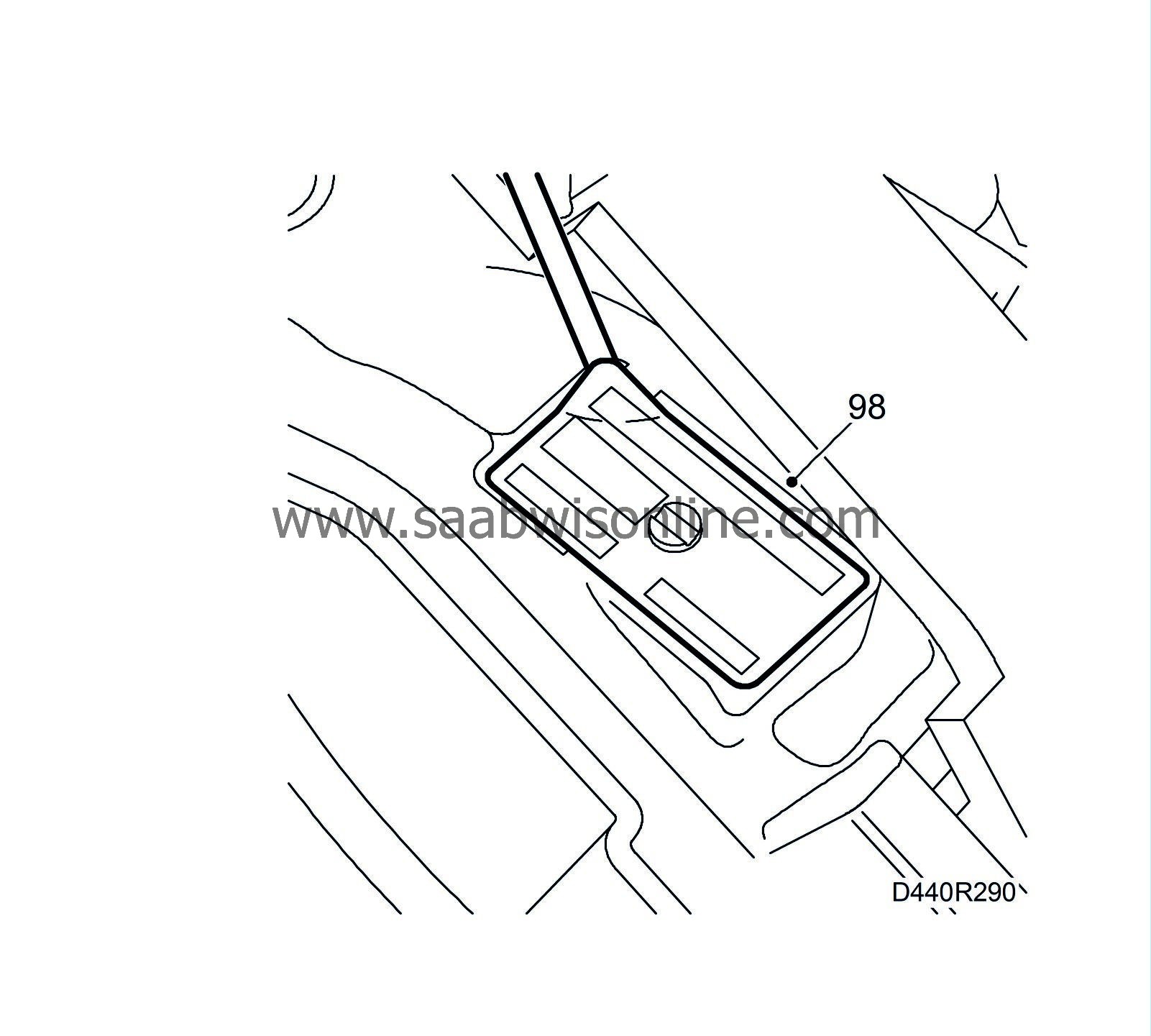

98.

|

Prise off the type plate from the changed case using a screwdriver.

|

|

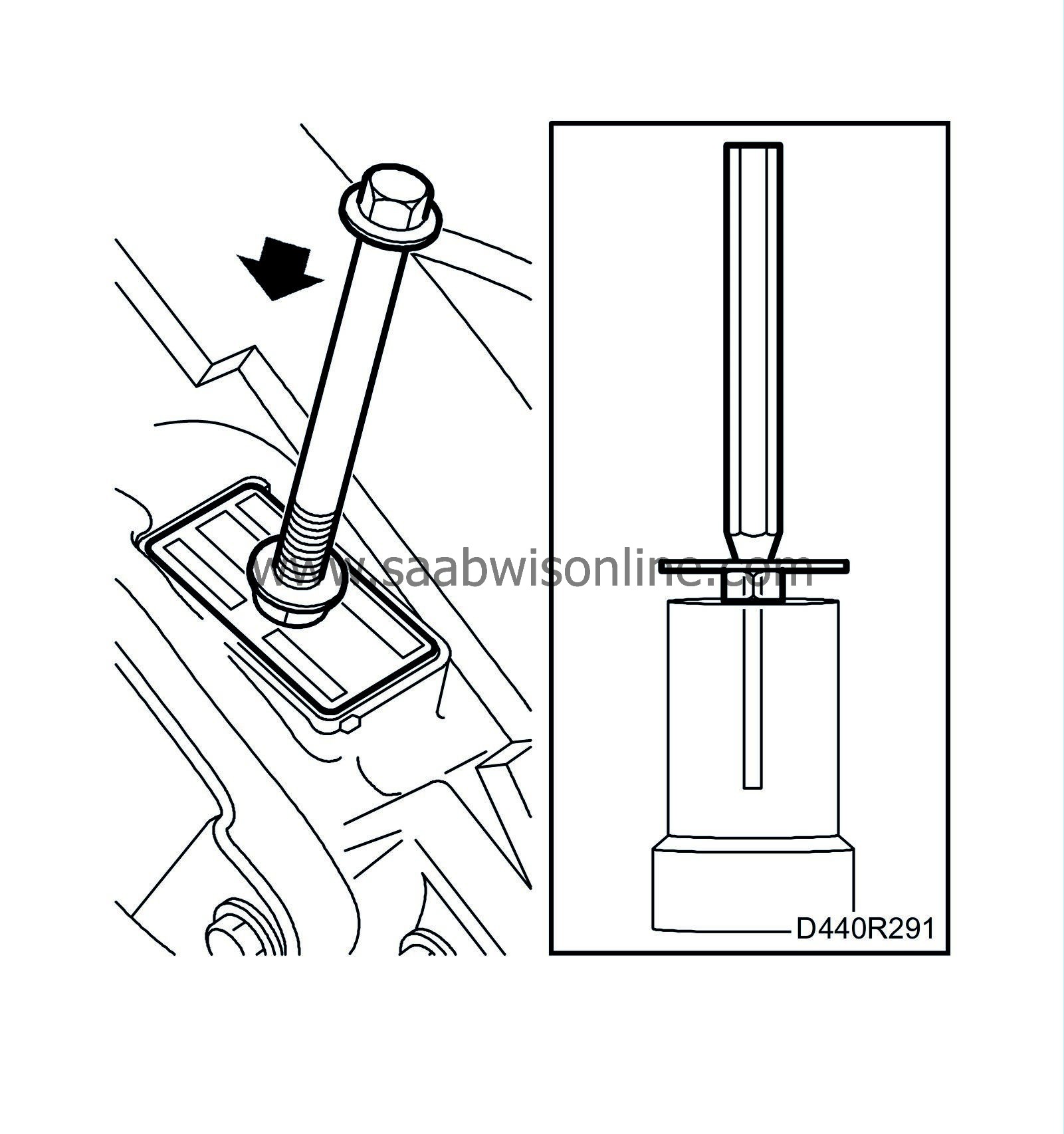

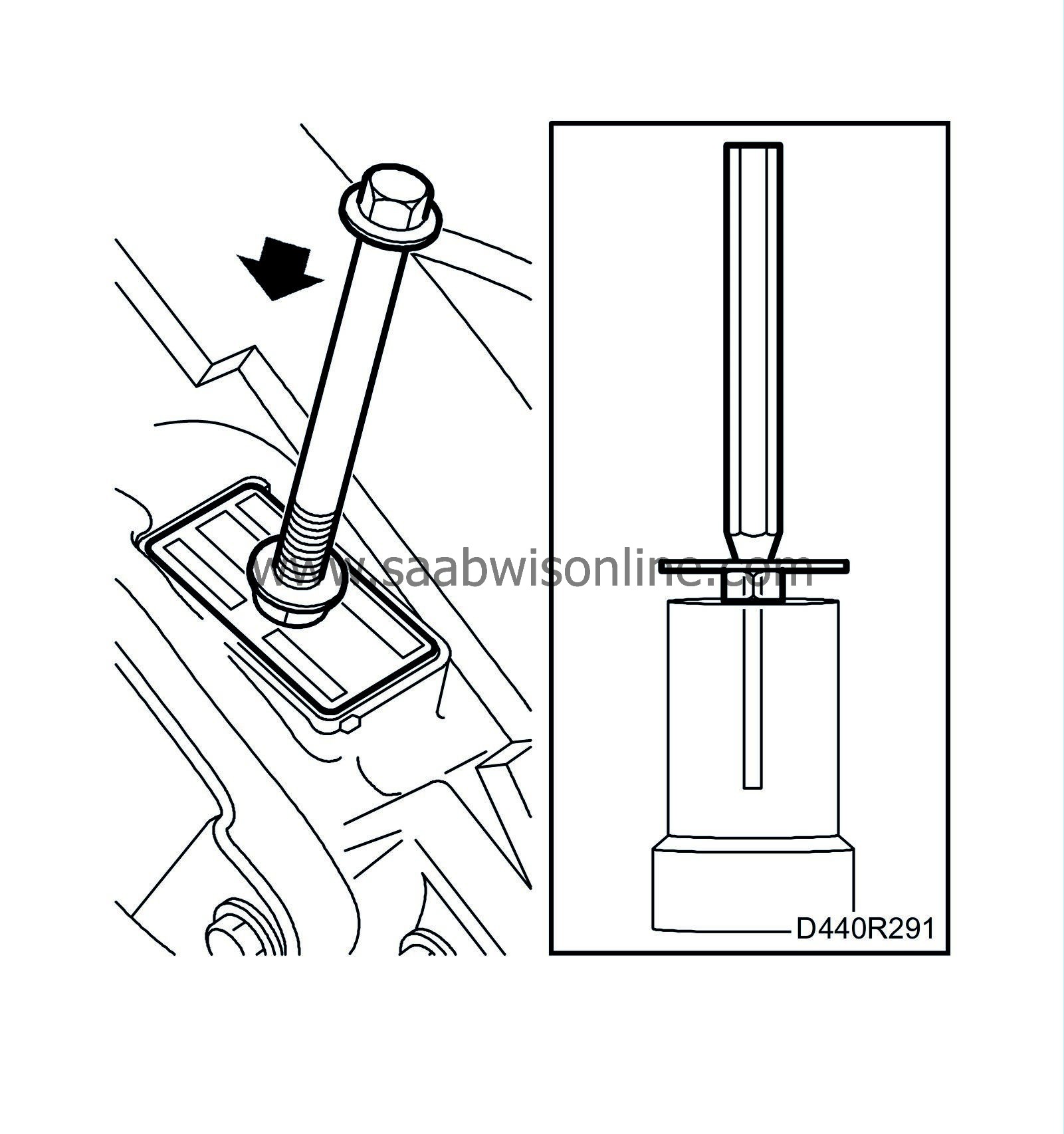

99.

|

Straighten the plate with a hammer. Widen the hole with a tapered drift and an M10 nut for support. Lay the plate on the new gearcase and press it on. Use an M8 nut for support over the centre pin and seal with a hammer.

|

|

100.

|

Remove holder 87 92 392 form the gearbox.

|

|

101.

|

Fit the gearbox in the car. See fitting gearbox assembly. Remember to clean the oil cooler with flushing equipment 87 91 824.

|