(440-2182) Common faults on automatic transmissions

|

TECHNICAL SERVICE BULLETIN

|

|

Bulletin Nbr:

|

440-2182

|

|

Date:

...........

|

Februari 2000

|

|

Market:

|

ej US, CA

|

|

|

Common faults on automatic transmissions

|

Saab 9-5, M98-99 with automatic transmission

|

1.

|

Engine runs unevenly

Symptoms:

The engine runs uneven at speeds between 60 and 80 km/h, and 90 and 125 km/h.

The engine may run unevenly under the following conditions: Start the engine. Select position D. Accelerate until 4th gear has engaged and release the accelerator pedal slightly so that the lock-up function engages. Then depress the accelerator pedal again. The engine may run unevenly.

Reason:

The probable reason for the engine running unevenly is that the clearance between the valve stems and the valve guides leads to a tendency to seize. The quality of the fuel can also have an effect.

|

|

2.

|

SID message: Transmission overheating.

Cause:

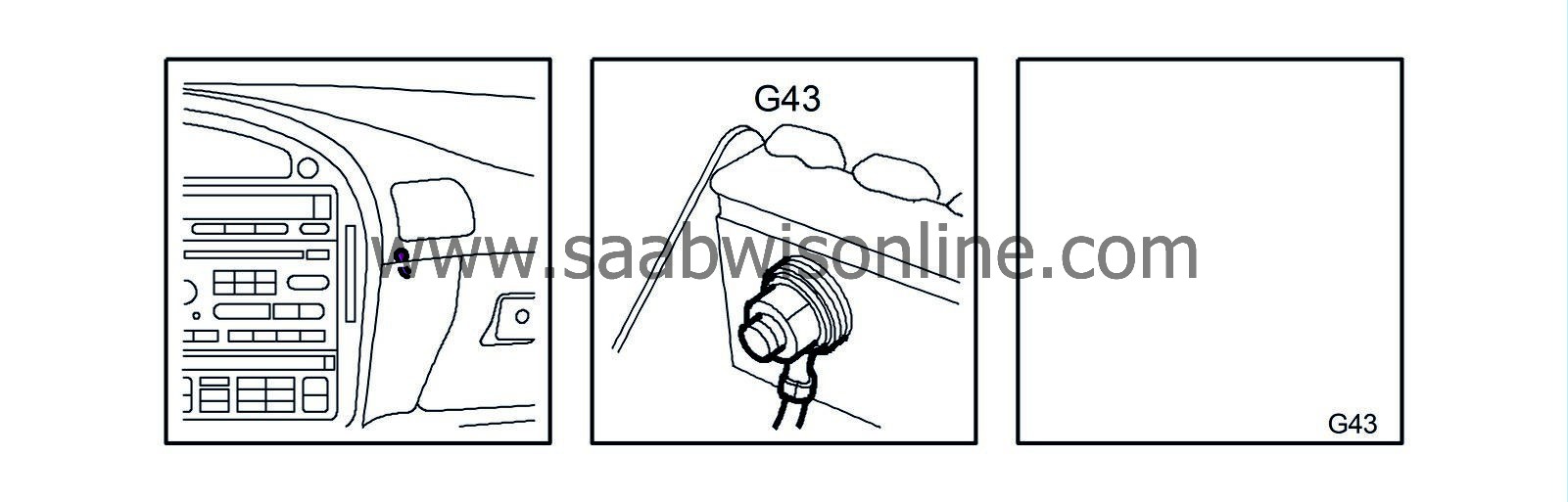

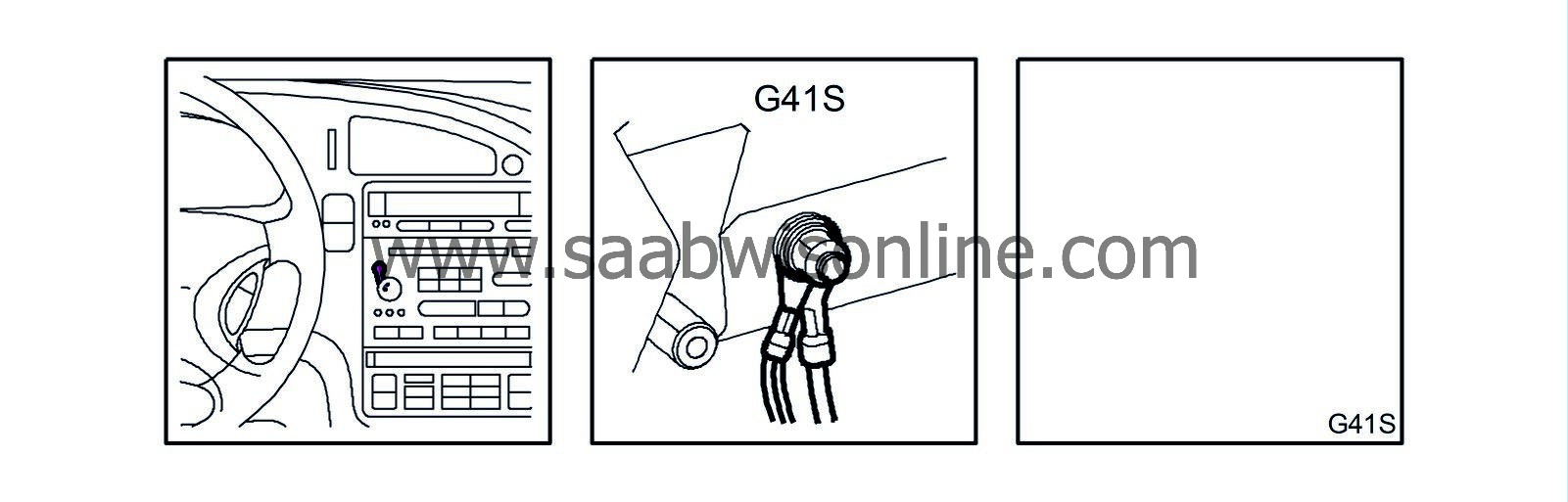

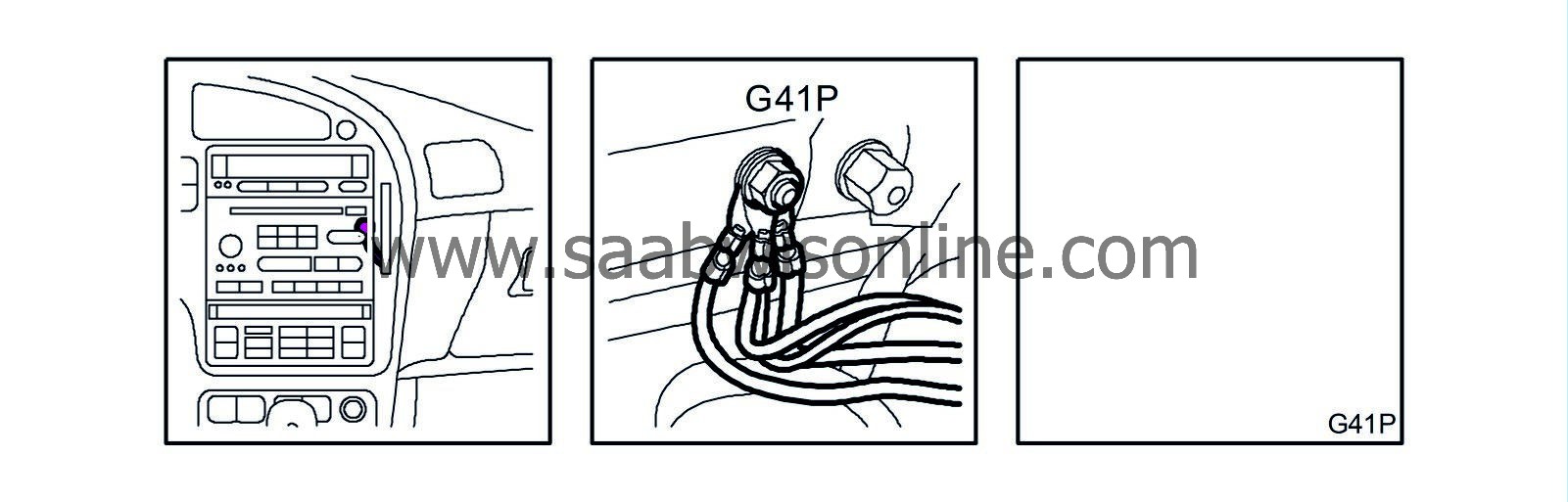

The SID message may be displayed without the transmission being overheated due to bad contact in the ground connections G41S, G41P and G43

|

|

3.

|

DTC P0705 generated (Gear selector position sensor, faulty signal).

Symptom:

CHECK GEARBOX lamp comes on and transmission goes to “Limp-home” mode. The fault arises intermittently in extremely cold and hot temperatures.

Cause:

The transmission control module receives a 12V signal from the four contacts in the gear selector position sensor. At least 2 contacts are active in all gear positions. If the control module does not receive a 12V signal from 2 of the contacts, a DTC will be generated. The DTC is generated 5 seconds after the signal is lost.

|

Dexron III, Mineral based fluid ATF fluid Texaco Texamatic US TL 1863, EU7045.

|

1.

|

Engine runs unevenly

Check for diagnostic trouble codes using Tech2. See WIS, T7, diagnostic trouble codes. If Tech2 displays an unusually high amount of engine knock on one or more cylinders, this is probably due to the exhaust valves sticking. See SI 210-2131. Also, check the lock-up function as described in WIS. Use Tech2, Menu 'Read Values', to determine whether the lock-up function is on or off. If the lock-up function is faulty, the engine will run unevenly for a short period of time while the function is engaged.

|

|

2.

|

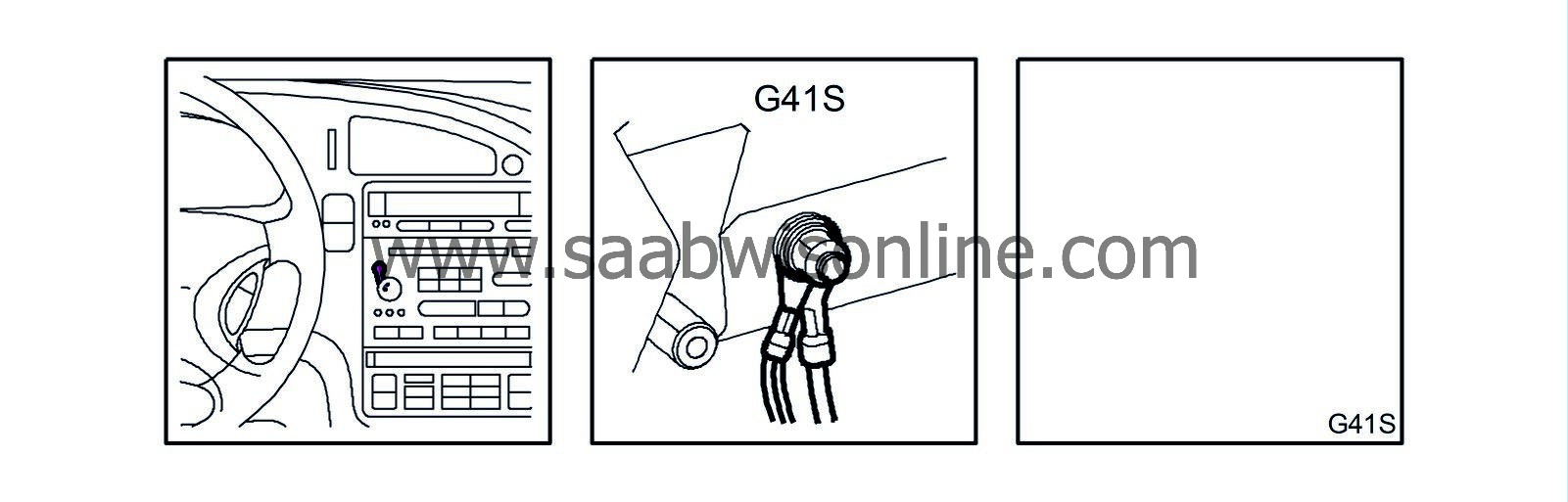

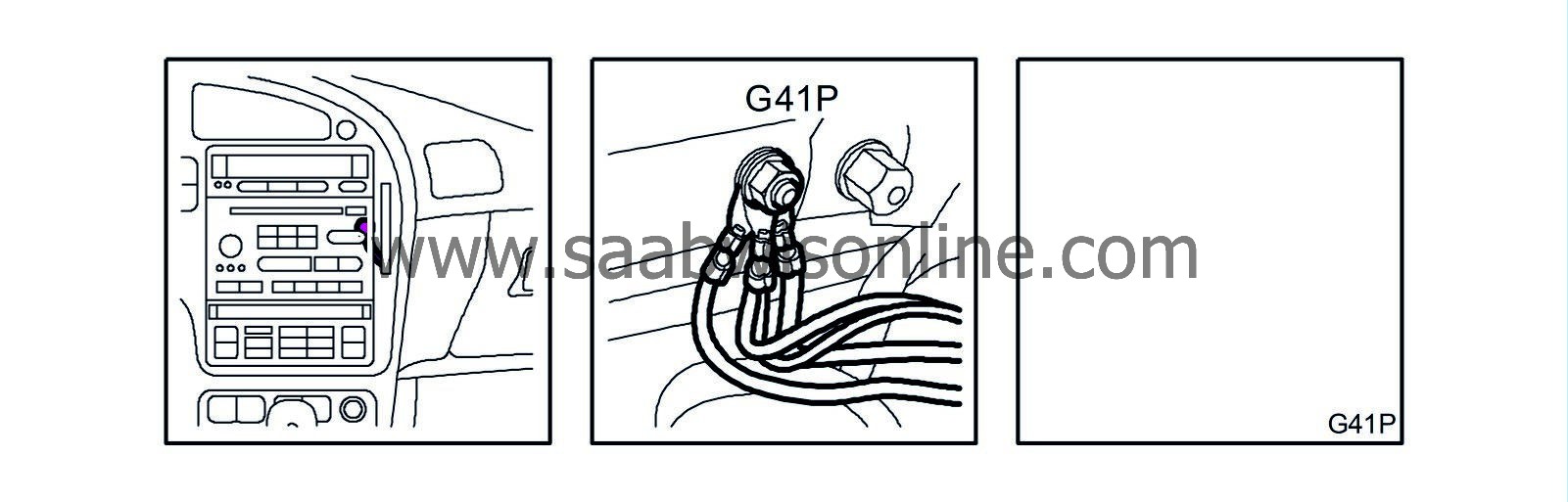

SID message: "Transmission overheating"

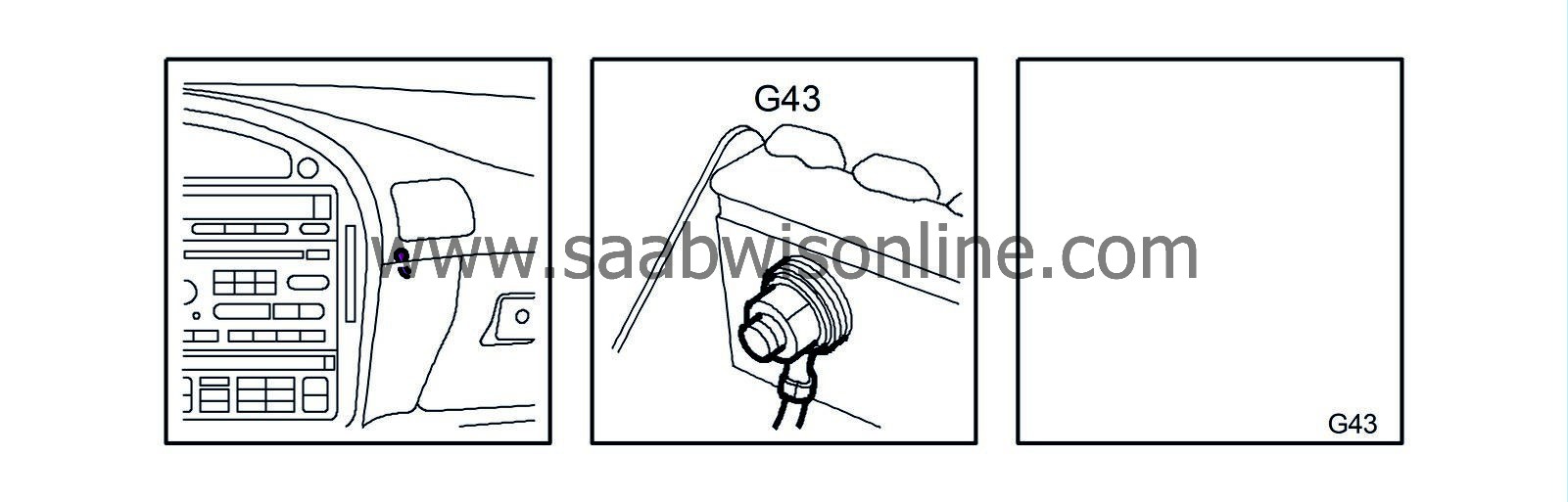

If electrical faults are suspected, remove and clean grounding points G41S, G41P and G43. Use a knife, wire brush or similar as well as electronic cleaning fluid part no. 30 09 461. Fit the grounding point with a serrated washer.

G41S is located behind the radio on the left side behind the knee protection.

G41P is located to the right of the radio behind the knee protection.

G43 is located on the right behind the radio.

Check also the SID message based on the assumption that the transmission really is overheated. See the owner's manual, which describes extreme driving conditions such as driving in mountainous areas and driving with a caravan.

If the transmission has been overheated, check the transmission fluid. If the fluid is a dark colour or smells burnt, change it. See the method below.

|

|

|

2.A.

|

Raise the car and place a receptacle under it.

|

|

|

2.B.

|

Empty the transmission fluid via the plug. Fit the plug with a new seal part no. 44 91 015.

|

|

|

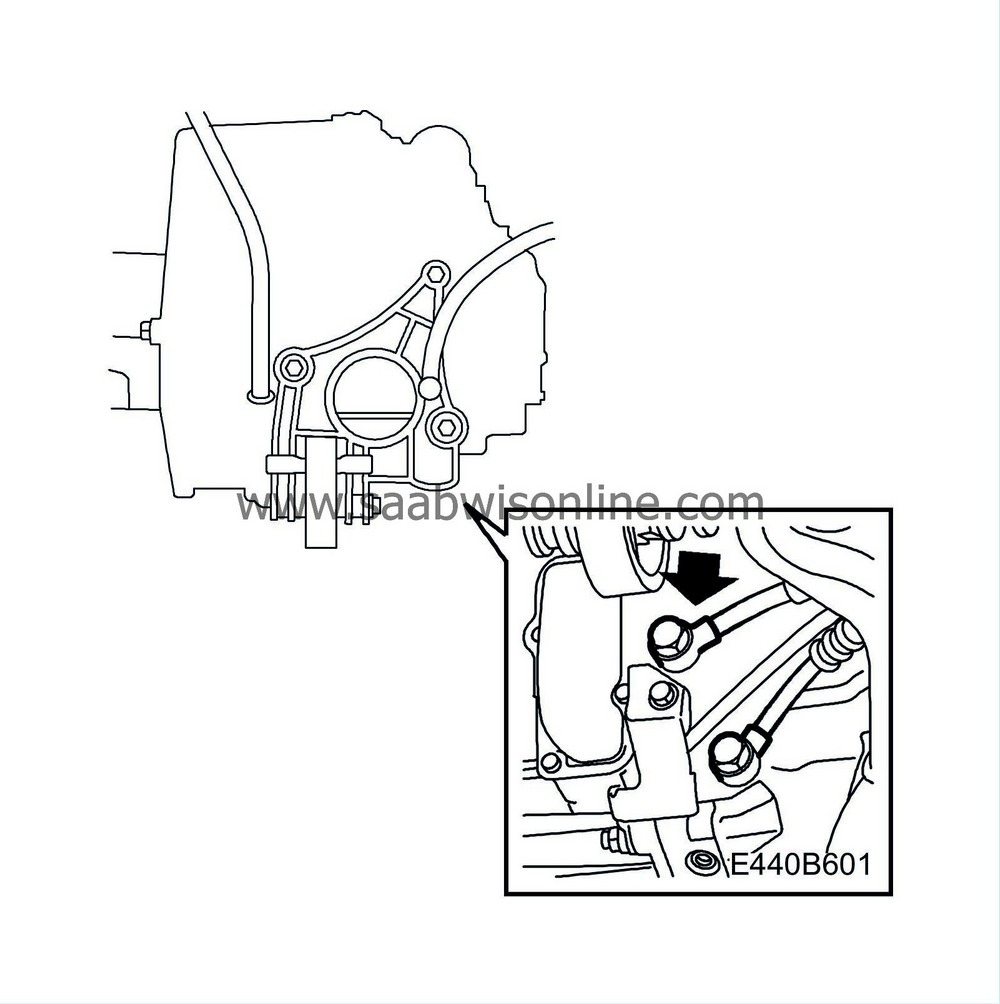

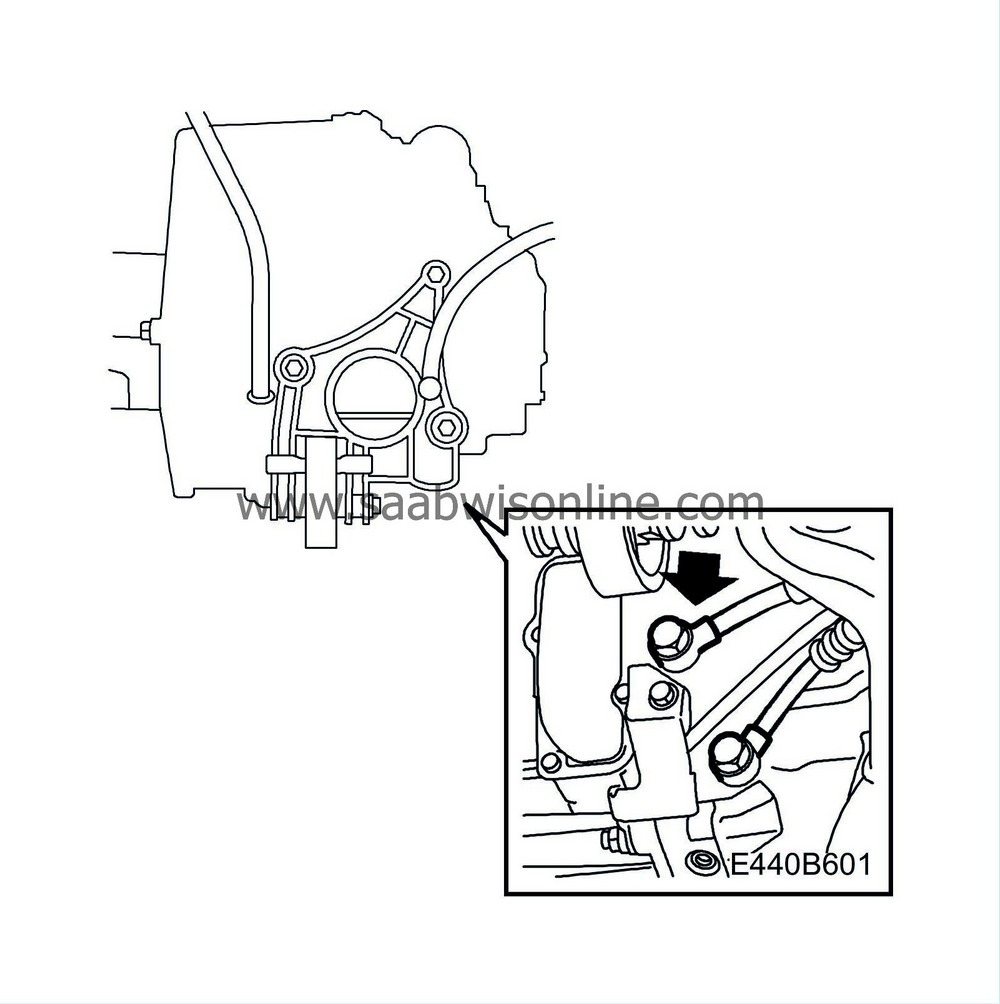

2.C.

|

Undo the return hose banjo union in the gearbox. Attach a hose from the flushing equipment part no. 87 91 931 as an extension of the return hose. Plug the hole in the gearbox with plug (10) 91 32 929, (10) 91 32 937.

|

|

|

2.D.

|

Fill with 4 l of transmission fluid, mineral based fluid Dexron III, in the gearbox.

|

|

|

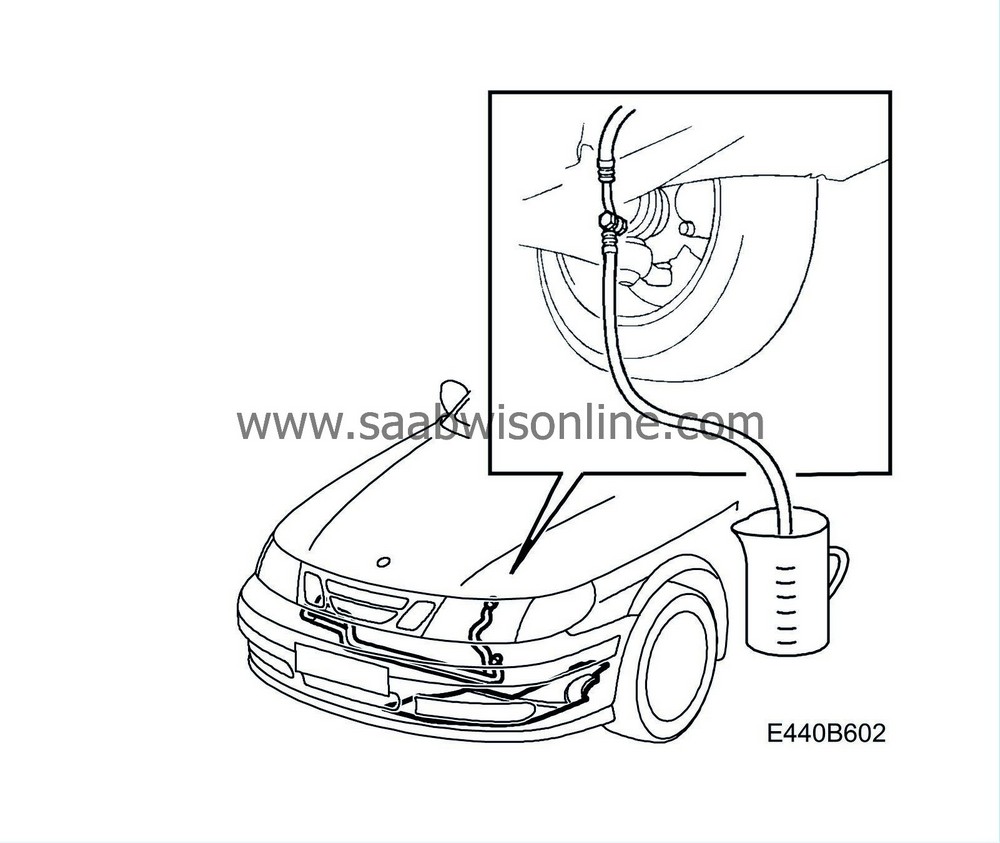

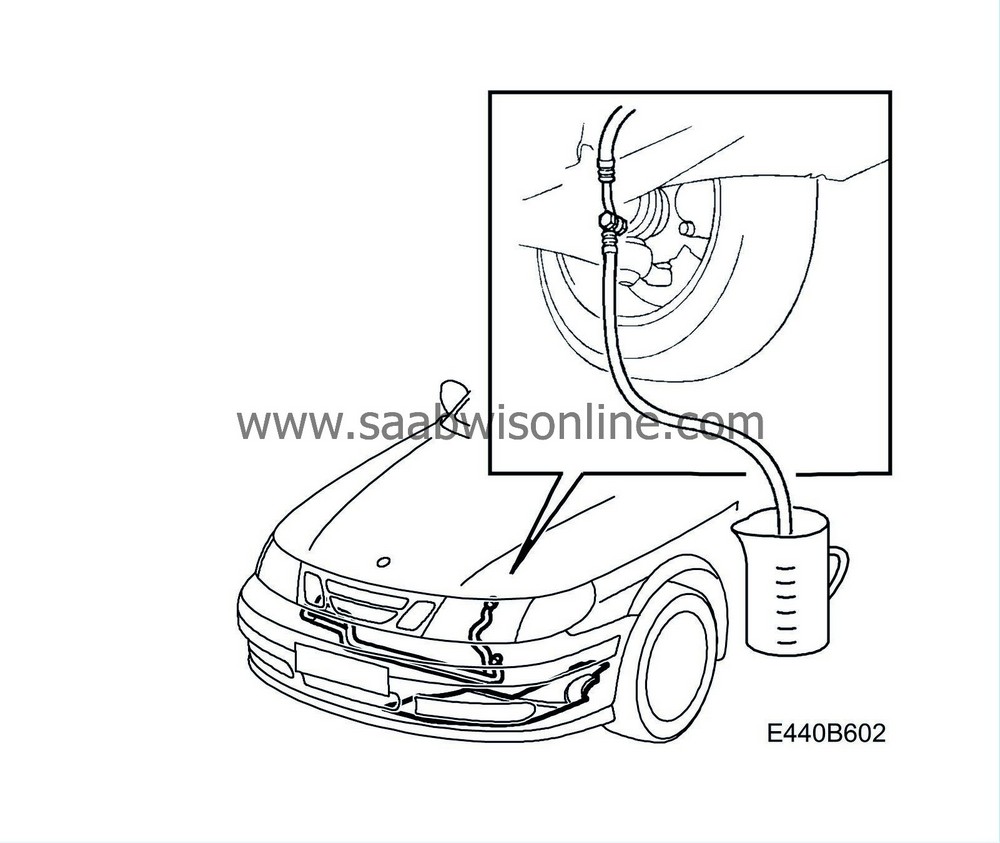

2.E.

|

Place the hose in a graduated receptacle that holds at least 2 l. Start the engine with the selector lever in the P position. Draw off 2 l of used fluid. Turn off the engine.

|

|

|

2.F.

|

Fill with 2 l of new fluid in the gearbox.

|

|

|

2.G.

|

Start the engine and draw off 2 l of used fluid. Turn off the engine.

|

|

|

2.H.

|

Fill with 2 l of new fluid in the gearbox.

|

|

|

2.I.

|

Start the engine and draw off 2 l of used fluid. Turn off the engine.

|

|

|

2.J.

|

Remove the extension hose and the plug in the gearbox. Fit the return hose. Use new seals part no. 41 61 162.

Tightening torques banjo union in gearbox: 27 Nm (20 lbf ft)

|

|

|

2.K.

|

Check the fluid level, top up and adjust the fluid level.

|

|

|

2.L.

|

Start the engine with Tech 2 connected, drive until the temperature is 80°C as described in Menu Read TCM values. Check the fluid level and top up if necessary.

|

|

|

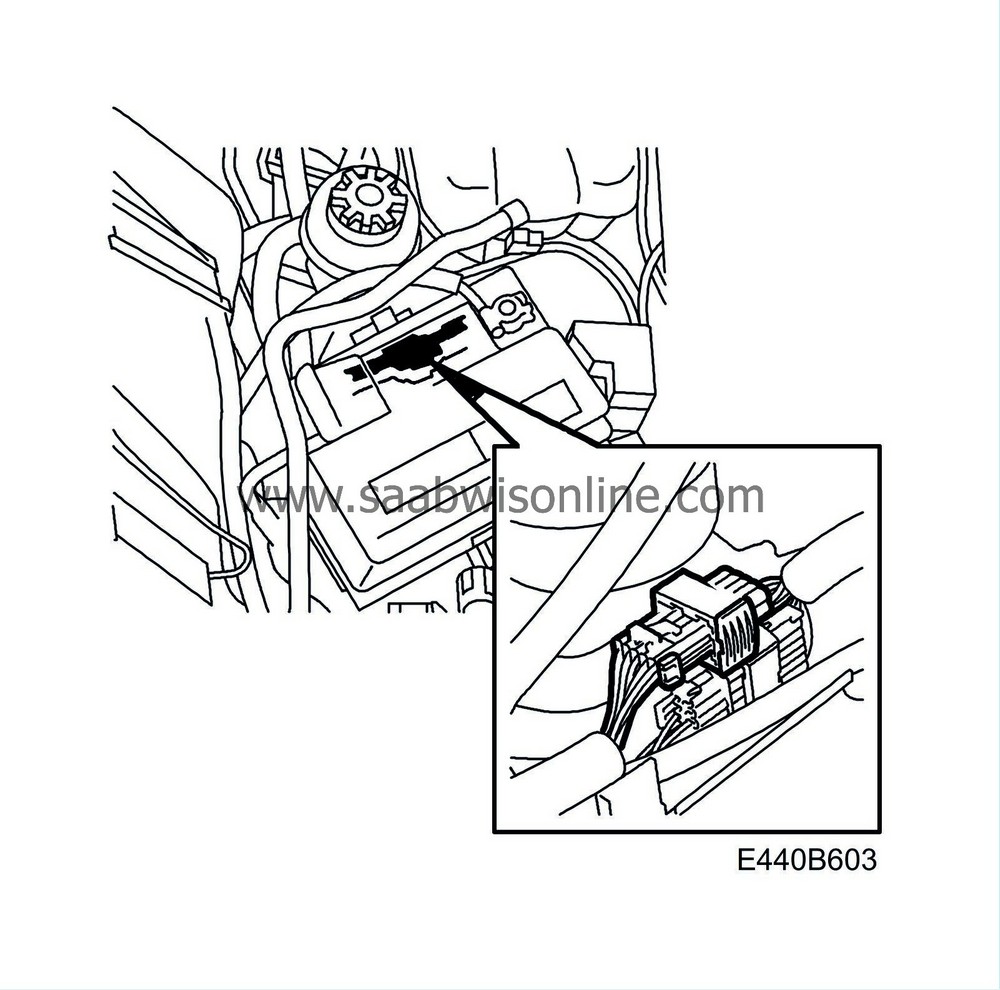

•

|

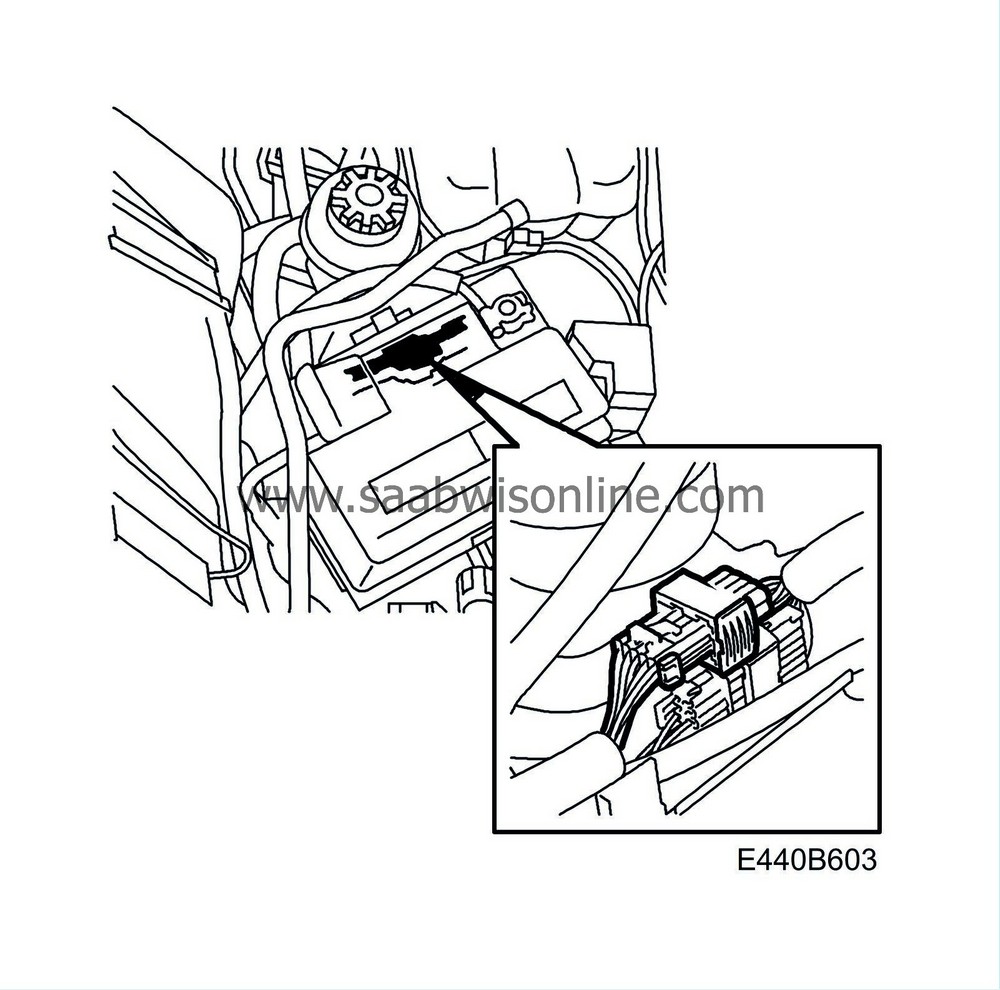

The connectors H10-7 and H16-4 are located under the battery tray, which means that they are more exposed to corrosion. Clean using electronic cleaning fluid part no. 30 09 461 and then spray with Kontakt 61, part no. 30 04 520.

|

|

|

•

|

Change to a new gear selector position sensor, see WIS, Transmission, Automatic transmission, Adjustment/replacement, Gear selector position sensor.

|

Important

|

|

New method for setting the gear selector position sensor in WIS

|

|

|

|

|

Warranty/Time information

|

Procedure 1

Object code: 44000

Fault/Reason code: 71

Location code: 09

Repair/Action code: 08

Time: 12410 = 0.5 h

Procedure 2

Object code: 44000

Fault/Reason code: 61

Location code: 09

Repair/Action code: 01

Time: 12410 = 0.6 h; 12407 = 0.6 h

Procedure 3

Object code: 36439

Fault/Reason code: 61

Location code: 09

Repair/Action code: 01

Time: 12410 = 0.4 h; 36439 = 0.8 h