Clutch operation

| Clutch operation |

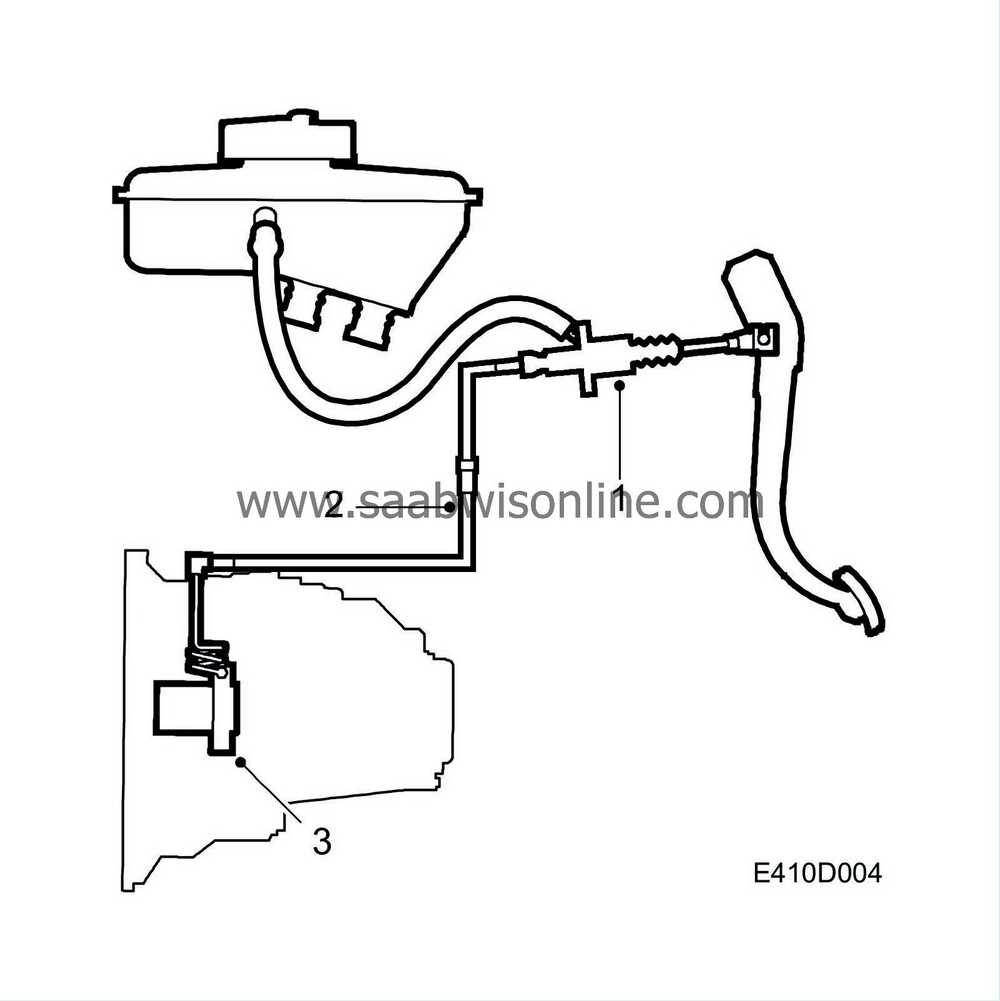

Clutch operation is hydraulic and entirely self-adjusting. The mechanism consists of a master cylinder (1), a clutch pipe (2) and a slave cylinder (3).

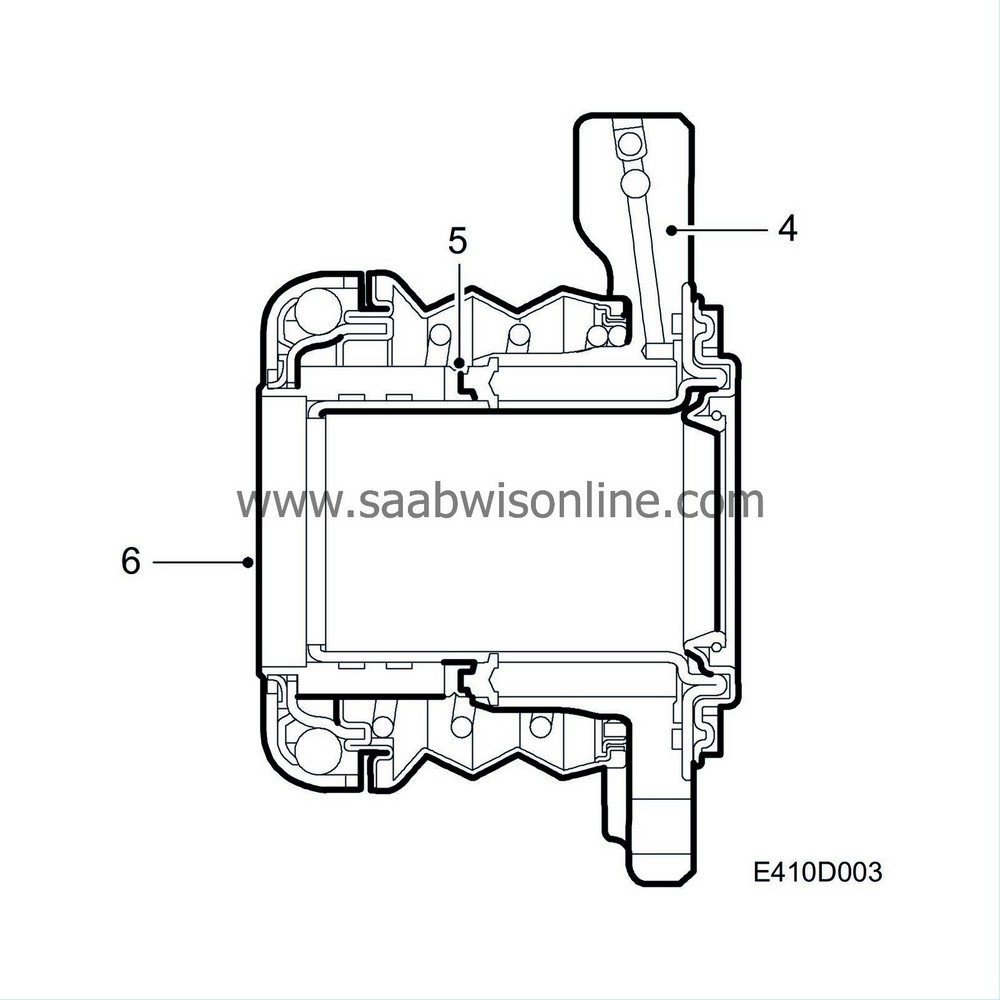

The master cylinder is mounted in the bulkhead wall and linked to the clutch pedal by a piston. The slave cylinder is an integrated unit mounted in the clutch housing and consists of a cylinder housing (4), a split piston (5) and a fixed release bearing (6). The slave cylinder cannot be dismantled. The hydraulic pressure from the master cylinder is led in and presses on the seal which then forces the piston and release bearing against the pressure plate. There is a spring mounted between the cylinder housing and release bearing which ensures that the release bearing is always held against the pressure plate, reducing play in the clutch pedal.

In order to prevent dirt from reaching sensitive parts of pistons and seals, a rubber gaiter is mounted between the cylinder and release bearing.

A hydraulic line links the master cylinder and the slave cylinder's damper pipe (to reduce pedal vibration) and has a quick-release coupling at each end. The lower quick-release coupling, to the slave cylinder, has a bleed nipple.