Input shaft

| Input shaft |

| 1. |

Mount the shaft in a vice with protective jaws.

|

|

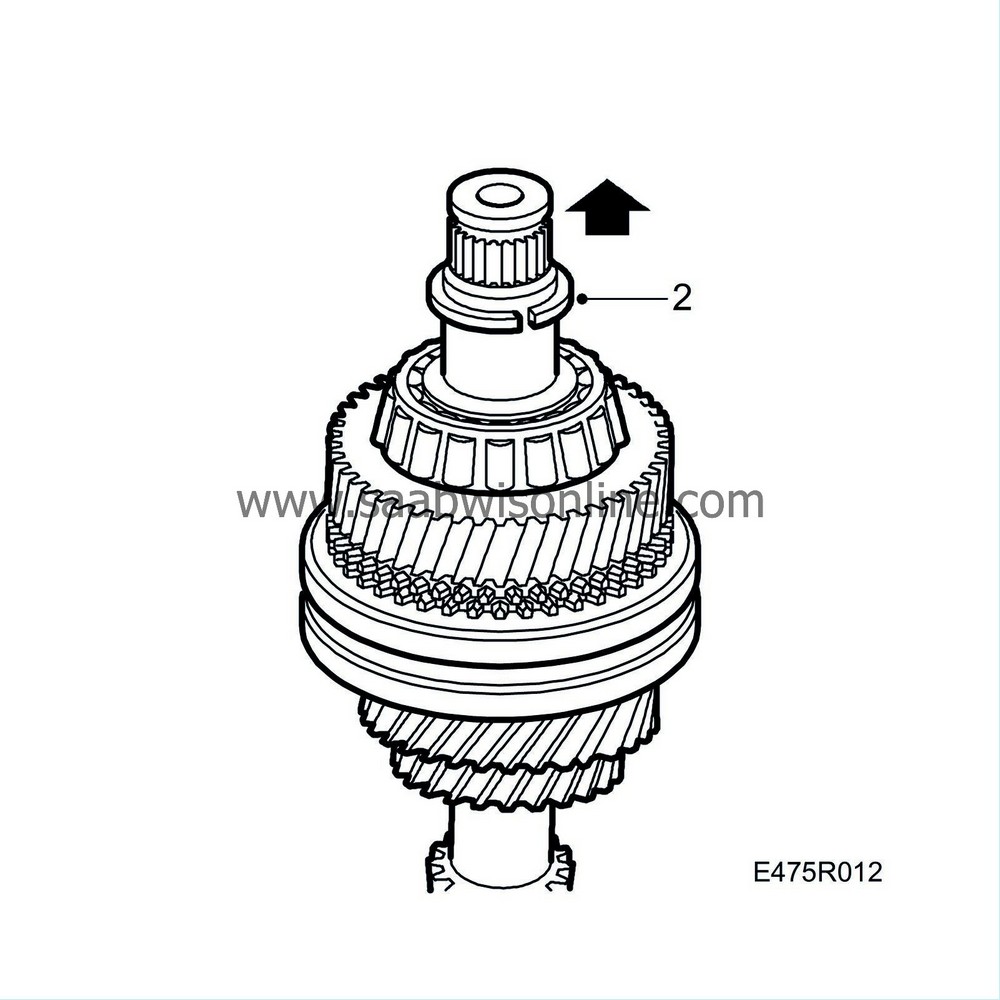

| 2. |

Remove circlip.

|

|

| 3. |

Press the bearing off the shaft. Use puller 87 92 152

and basic tool 87 91 642.

and basic tool 87 91 642.

|

||||||||||

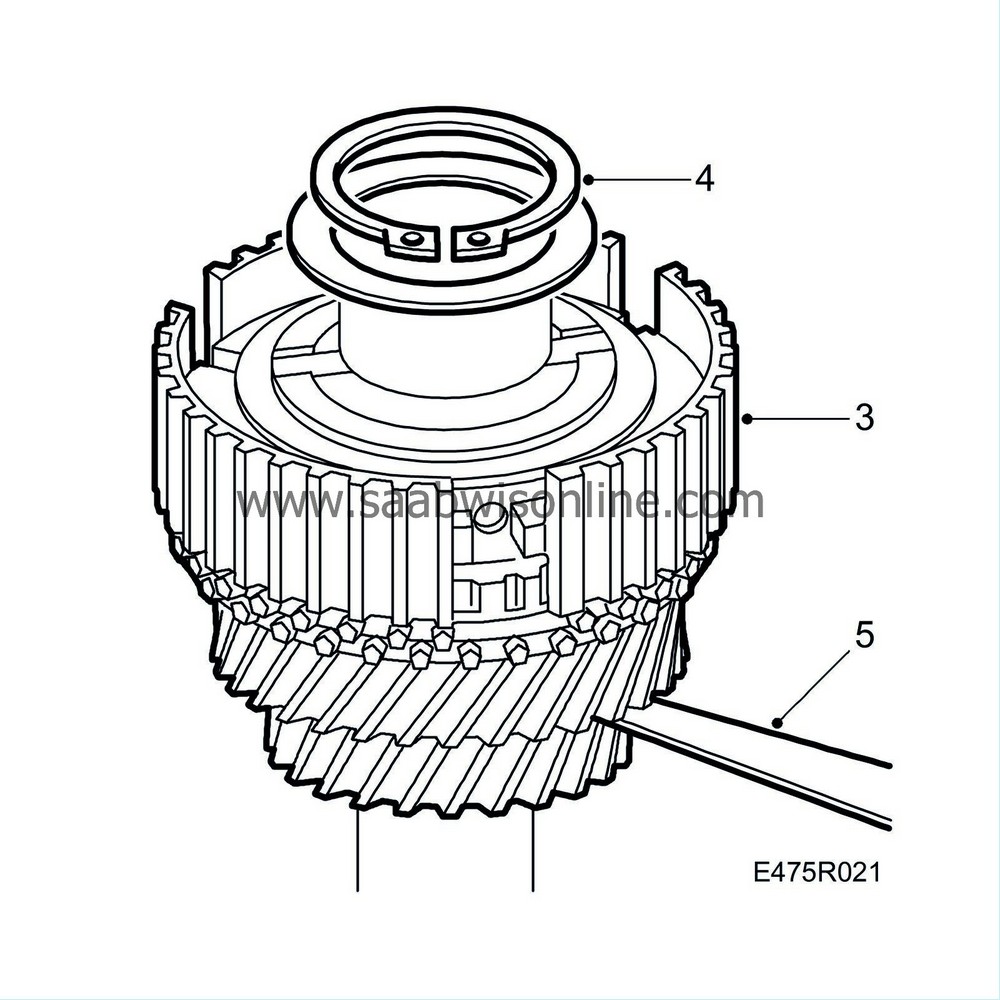

| 4. |

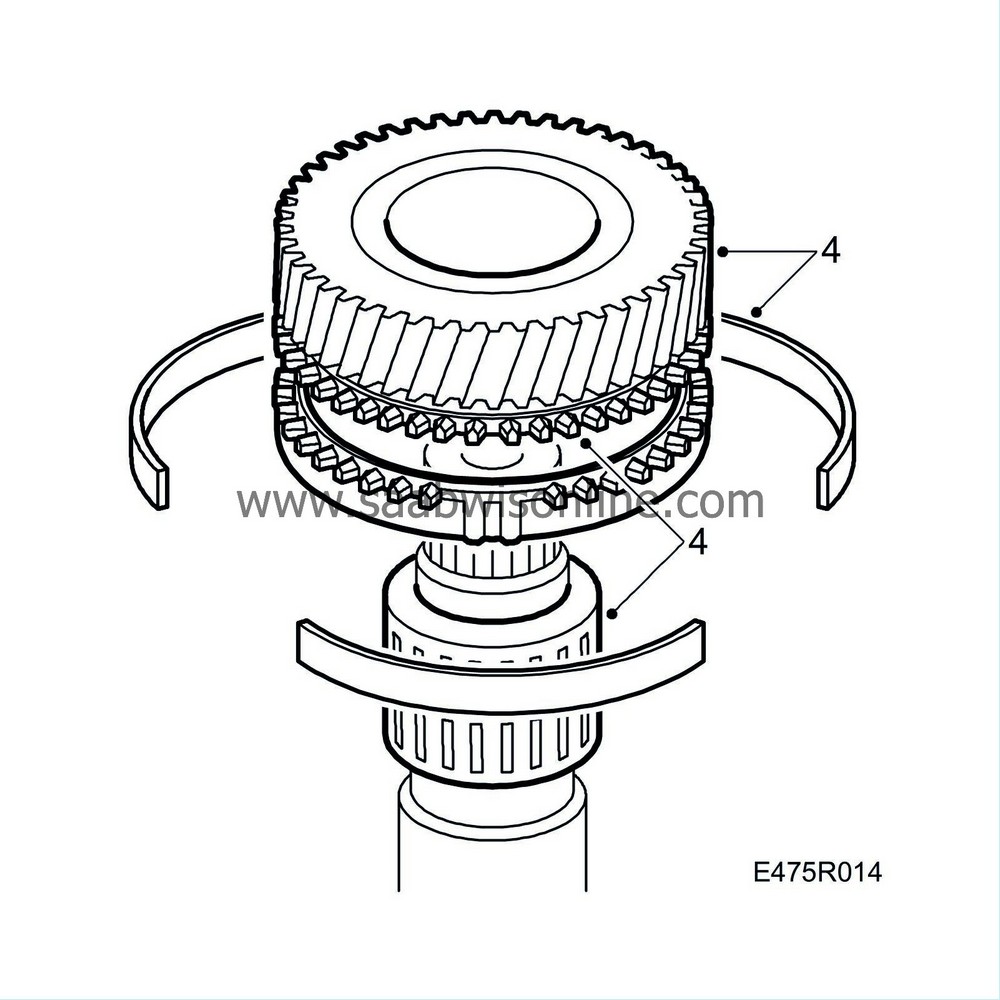

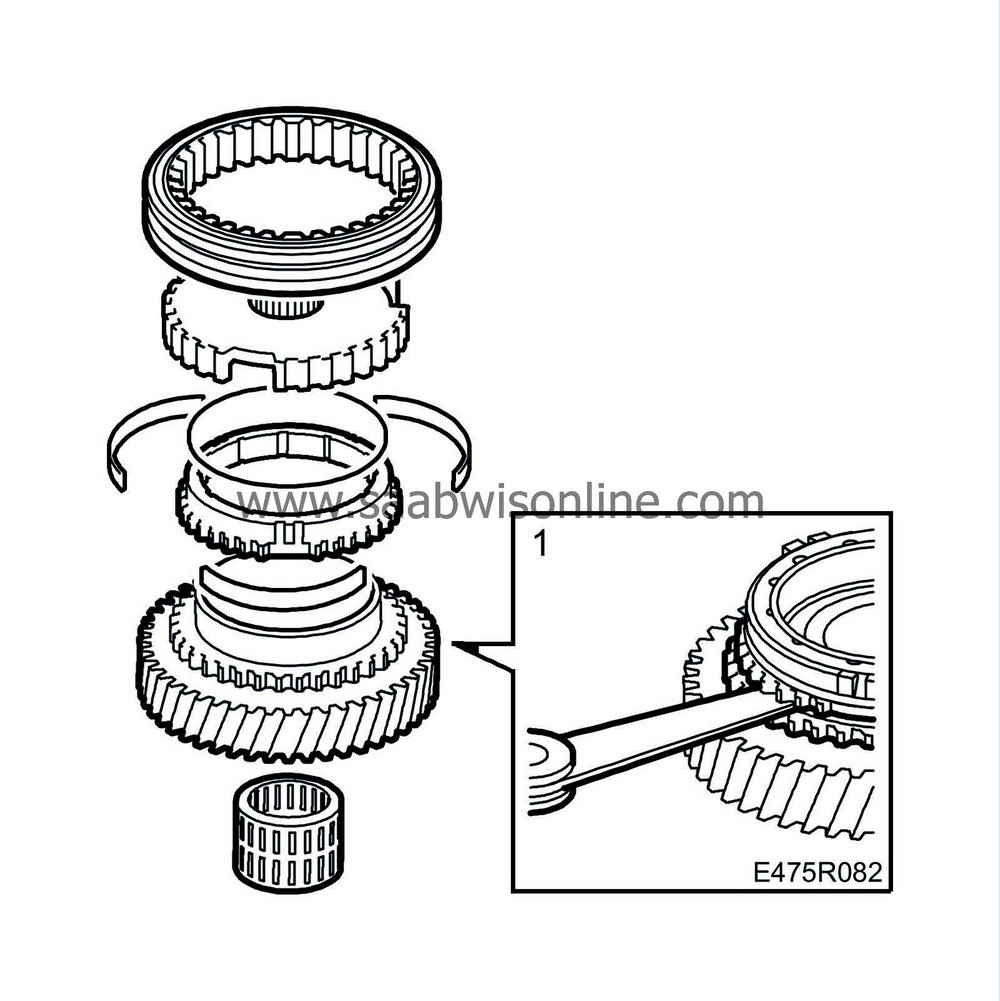

Lift off the 4th pinion, synchromesh and needle bearing. Keep the leaf springs in a safe place.

|

|

| 5. |

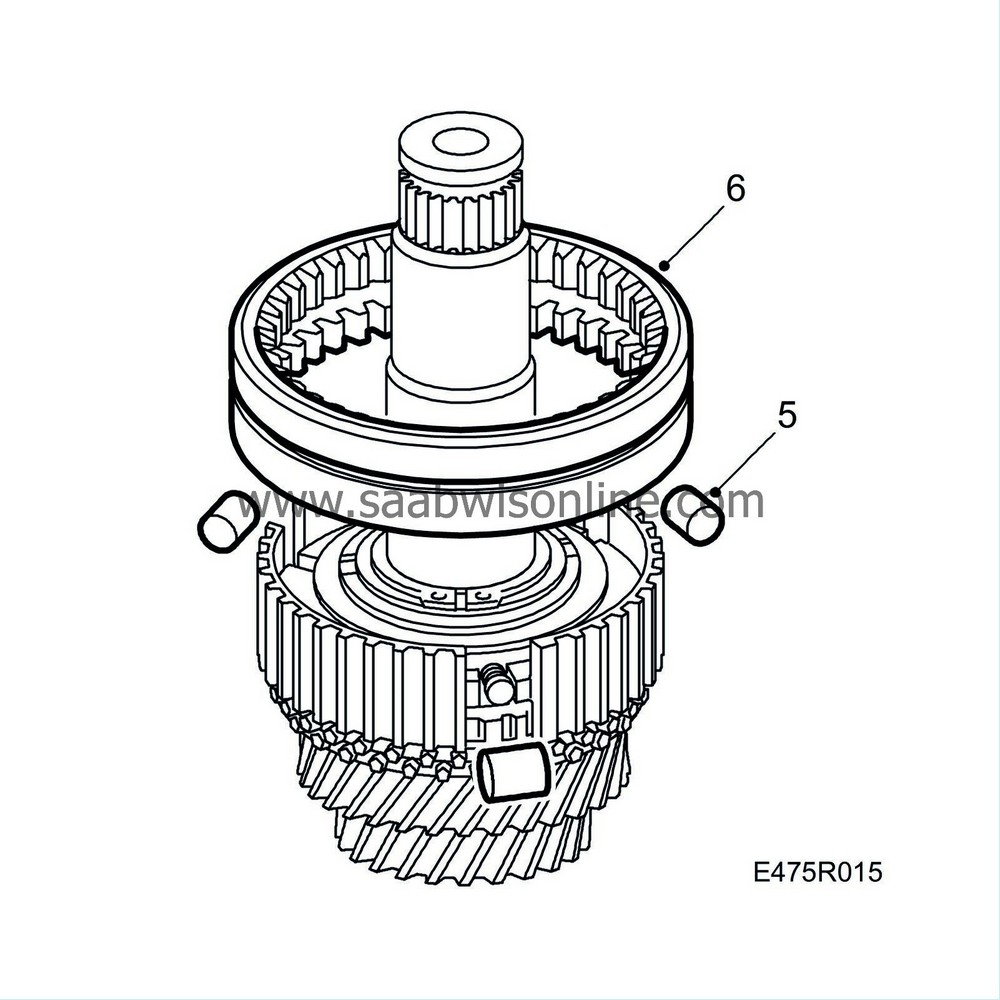

Slightly lift the synchromesh sleeve and hold with your hand so that the spring-loaded rollers do not come out. Keep the rollers in a safe place.

|

|

| 6. |

Lift off the synchromesh sleeve.

|

||||||||||

| 7. |

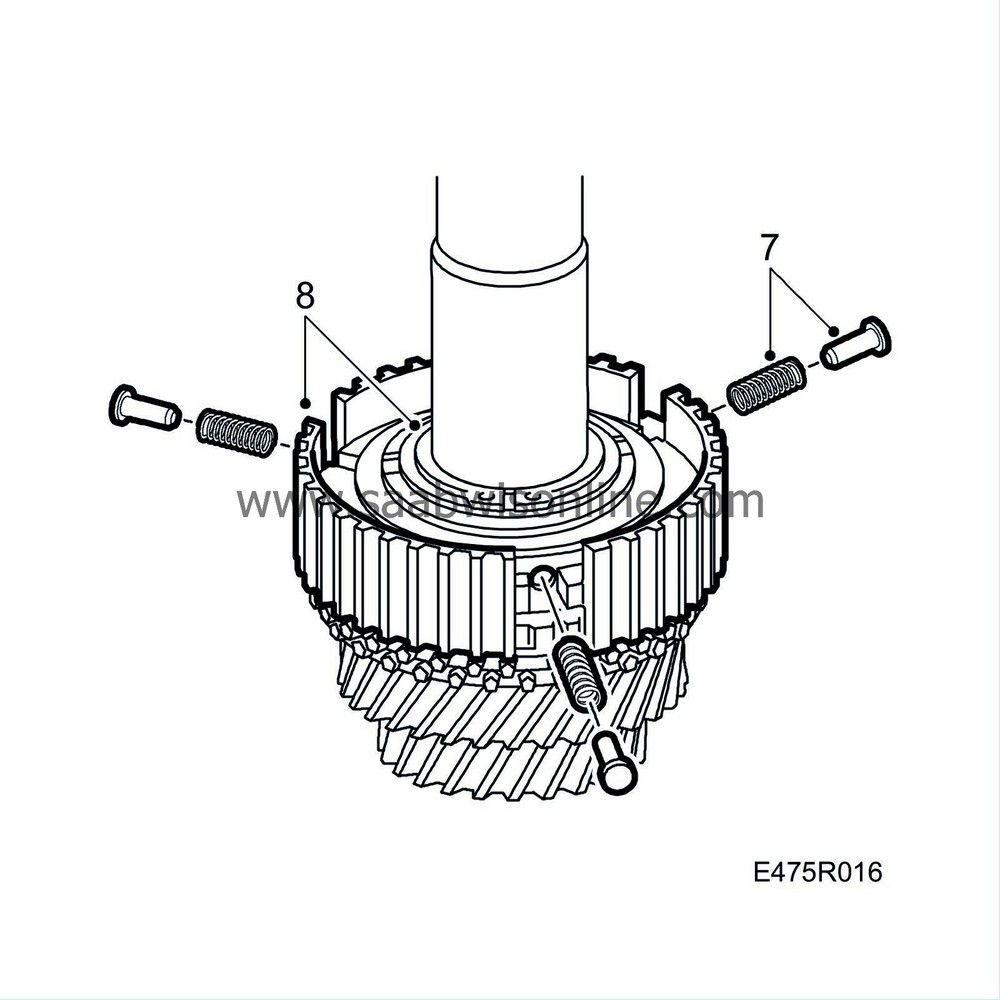

Keep springs and plungers.

|

|

| 8. |

Remove the washer and circlip which secure the synchromesh hub. Remove the hub and keep the leaf springs.

|

|

| 9. |

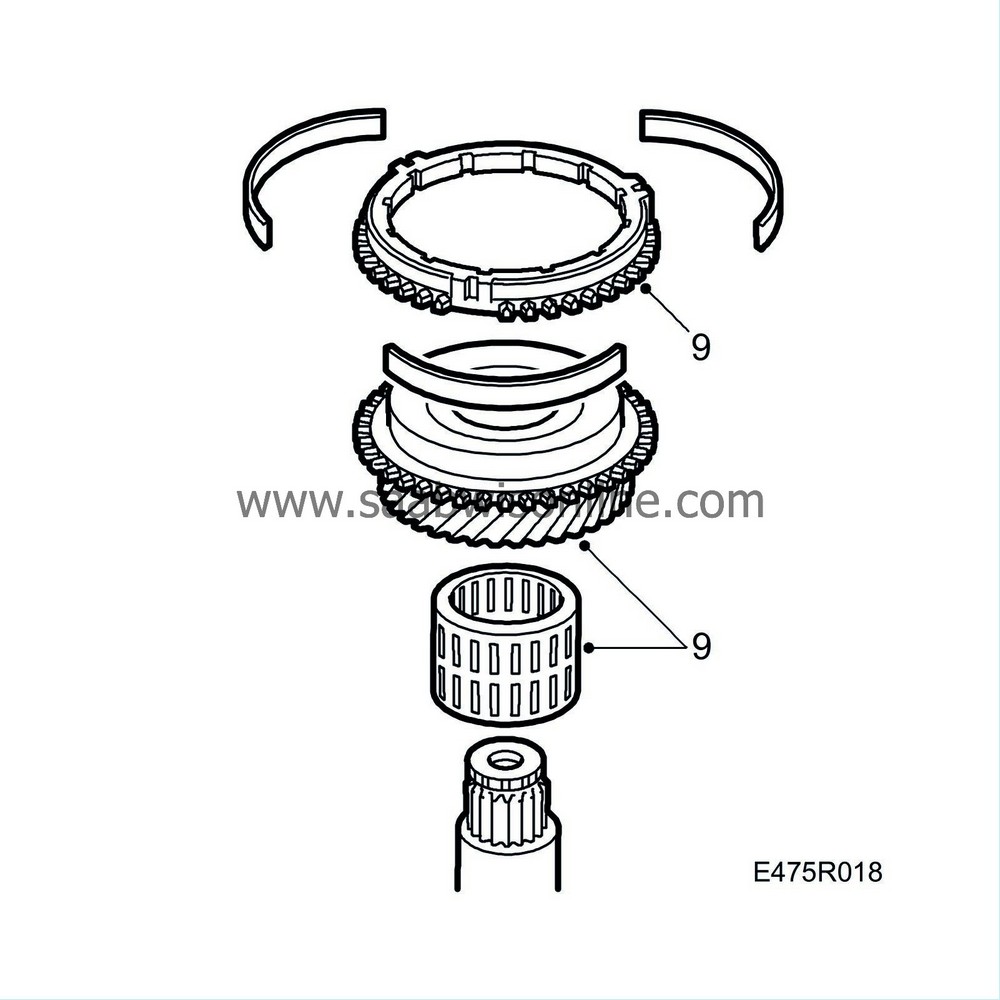

Lift off the 3rd synchromesh, pinion and needle bearing.

|

|

| 10. |

Check the condition of all parts as regards wear. Replace damaged or defective parts. Measure the wear on the synchromesh by fitting it in place. Measure with a feeler gauge in three places between the baulk ring and the pinion. Calculate an average of the readings. New synchromesh 0.8-1.1 mm. Min dimension is 0.5 mm. If the dimension is less, the synchromesh is worn out and must be replaced.

|

|

| To assemble |

All parts are fitted lubricated with Saab synthetic manual gearbox oil, see Technical data.

| 1. |

Mount the input shaft in a vice with protective jaws.

|

|

| 2. |

Fit the 3rd pinion with needle bearing and baulk ring.

|

|

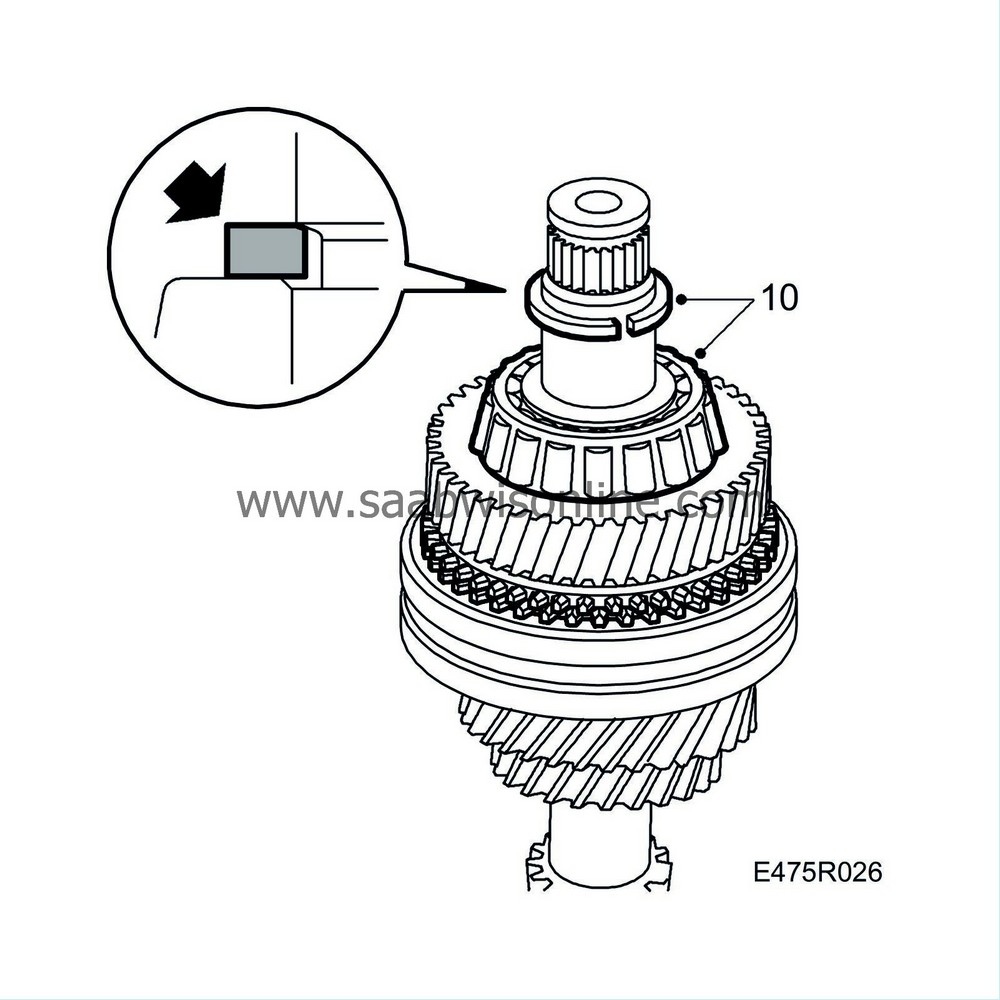

| 4. |

Fit the washer and a new circlip.

Lock washer inner, sharp edges directed towards the circlip. |

|

| 5. |

Check the axial clearance between the 2nd and 3rd gear pinions. The clearance should be between 0.05-0.40 mm.

|

|

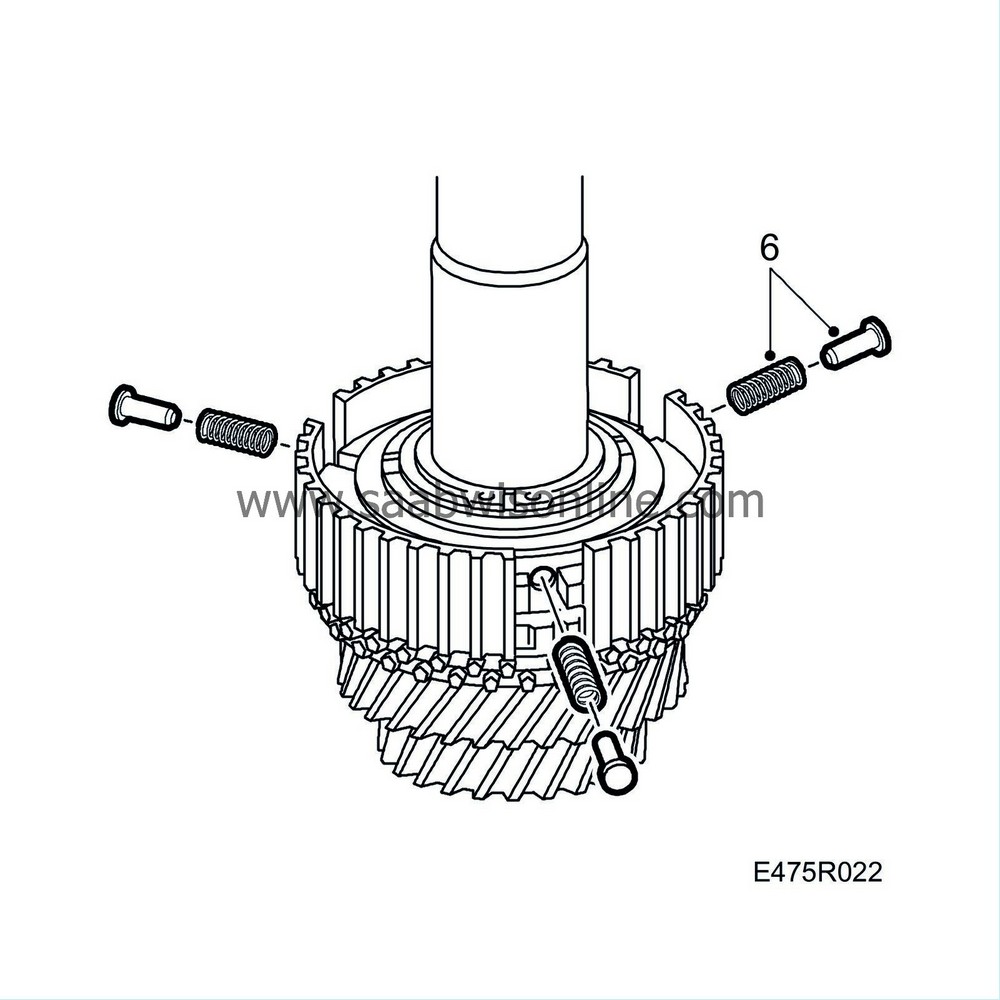

| 6. |

Fit the springs and plungers.

|

|

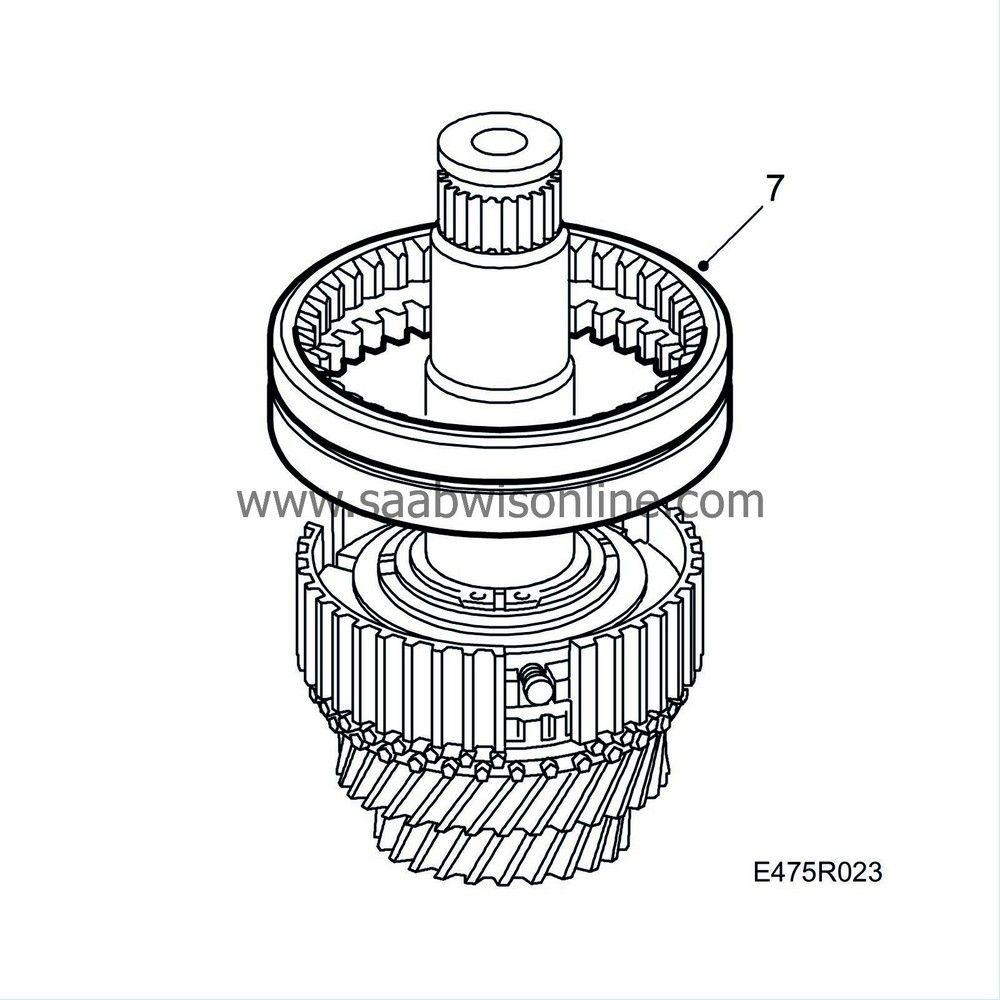

| 7. |

Fit the synchromesh sleeve.

|

||||||||||

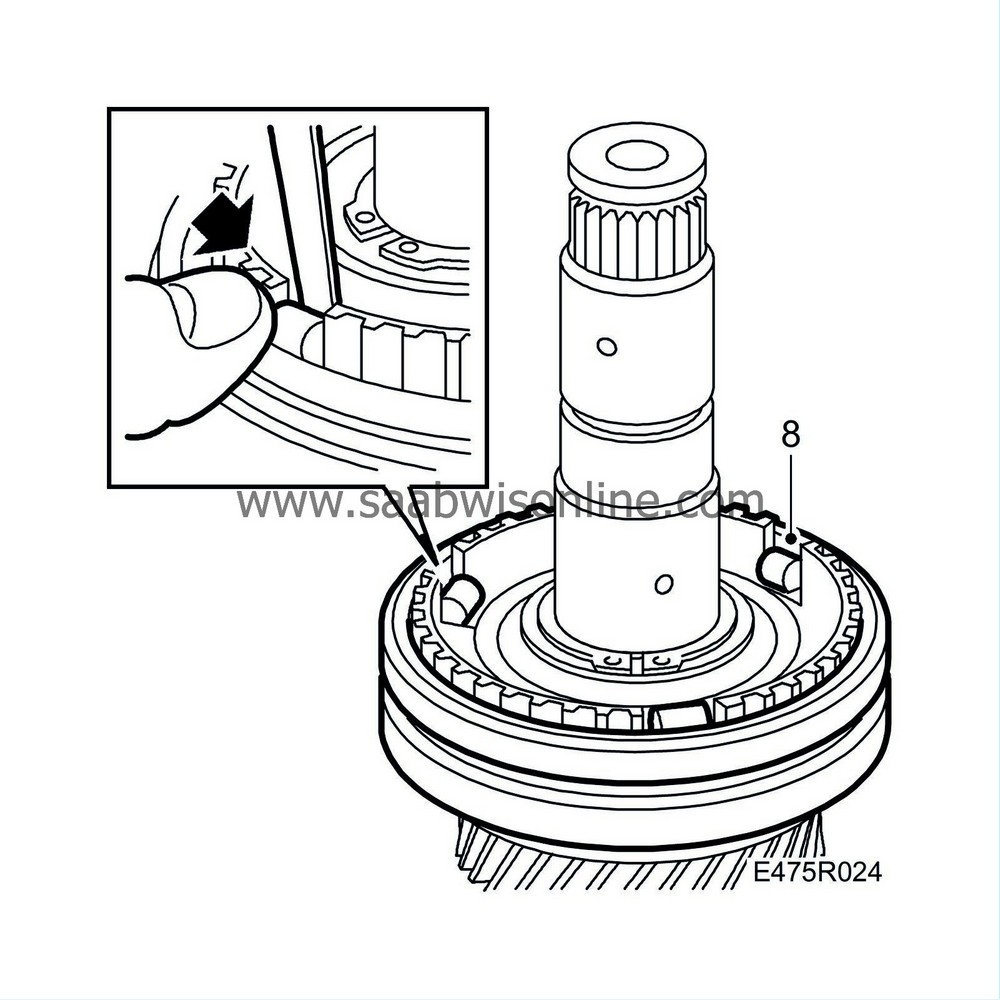

| 8. |

Fit the rollers. The rollers are fitted by pressing in the springs. For example, use a small screwdriver to press in the springs.

|

|

| 9. |

Fit the 4th baulk ring, leaf springs, needle bearing and pinion.

|

|

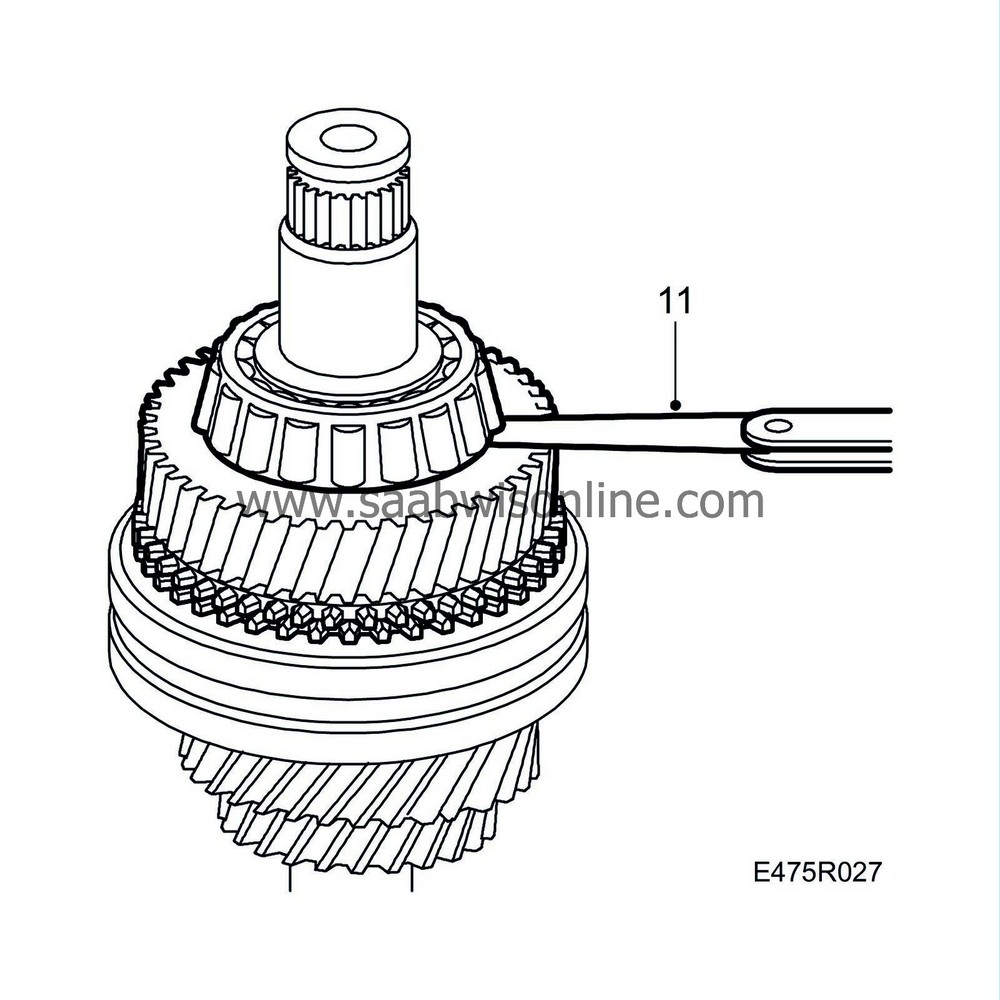

| 11. |

Check the play between bearing and 4th pinion to ensure that the input shaft is correctly fitted. Play should be 0.05-0.40 mm.

|

|

| Replacement of bearing closest to 1st gear pinion on input shaft |

To remove

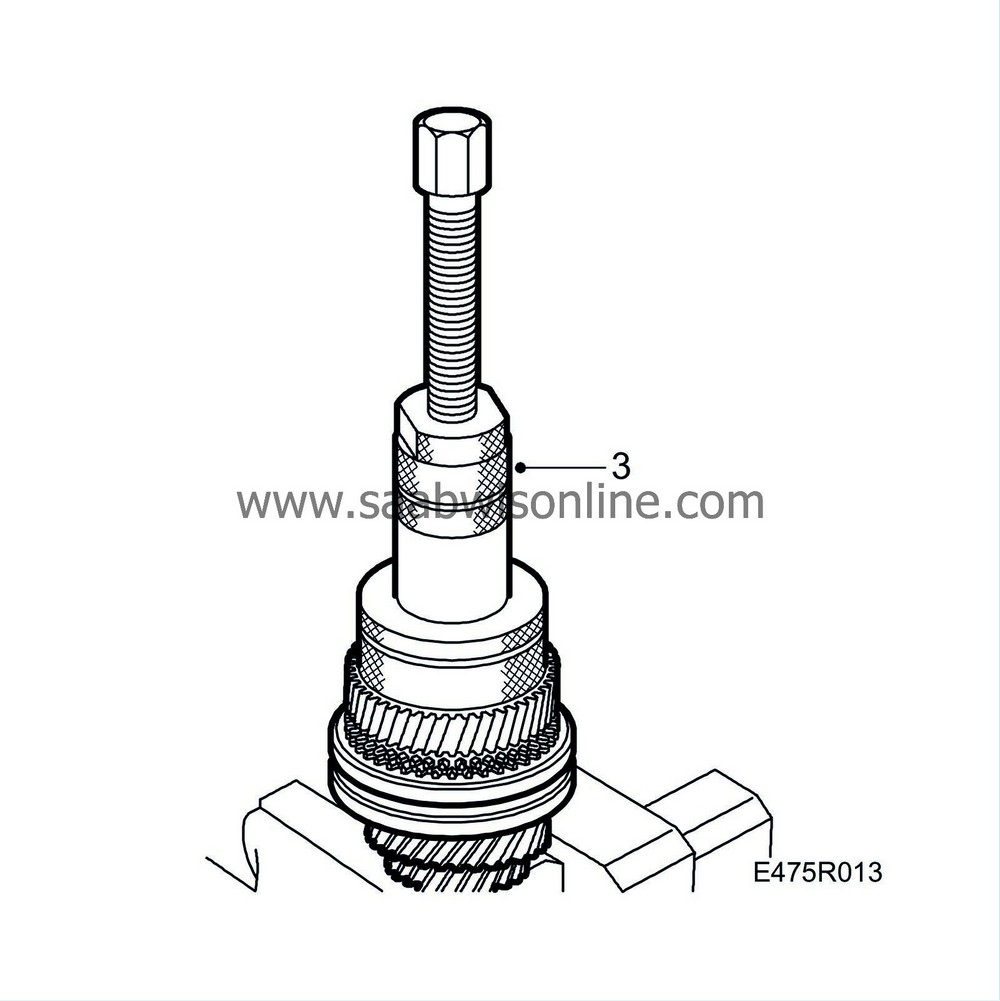

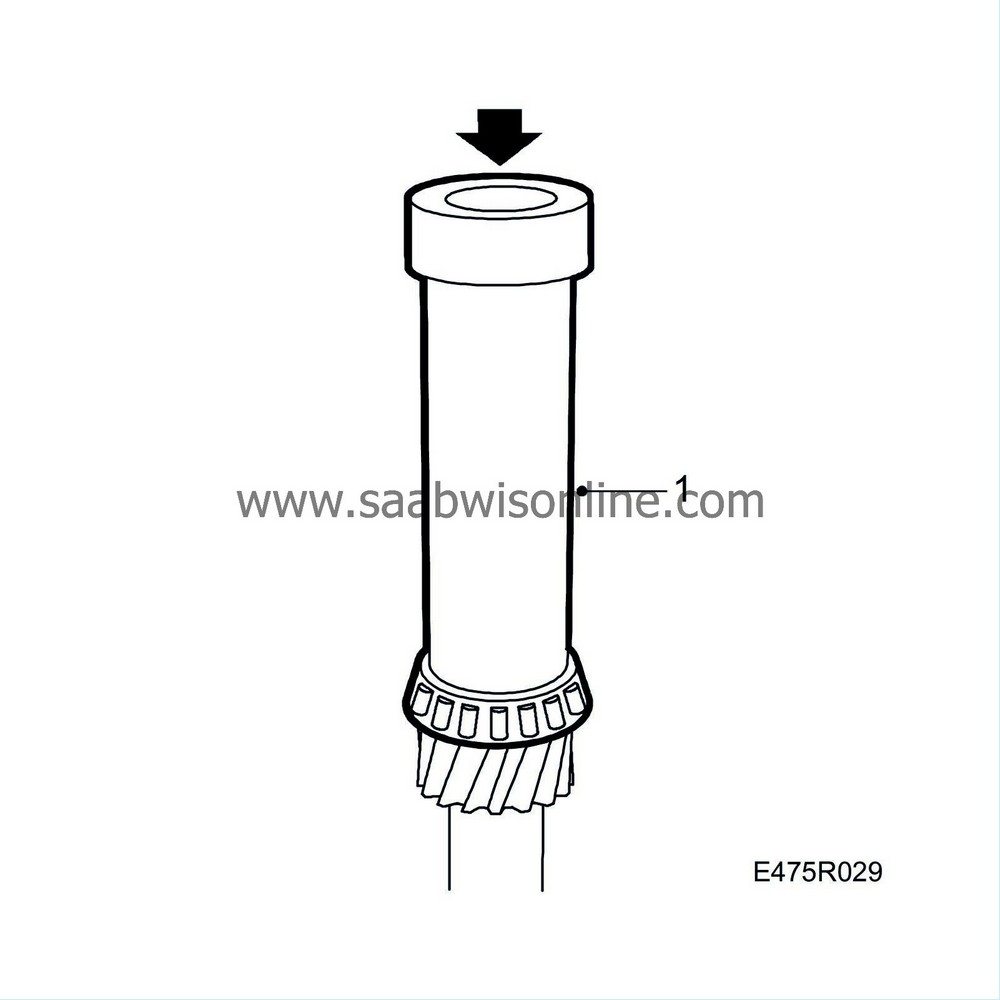

| 1. |

Mount the shaft in a press with puller ring 87 91 121

and fixture (parent tool 87 90 636).

and fixture (parent tool 87 90 636).

|

|

| 2. |

Press the bearing off the shaft.

|

|

To fit

| 1. |

Fit a new bearing. Make sure that the bearing faces the correct way. Press the bearing until it stops with the sleeve from puller 87 91 261.

|

||||||||||

| Checking 5th gear baulk ring |

| 1. |

Check synchromesh wear by placing it on the 5th pinion. Use a feeler gauge to measure at three points and calculate an average. If the average value is less than 0.5 mm, the synchromesh should be replaced.

|

|