Grinding (turning) a brake disc, removed

|

|

Grinding (turning) a brake disc, removed

|

Lathe “VBG 600” and the “accessory 26” connecting plate were used in the development of this method.

|

1.

|

Remove the brake disc, see

To remove

for front wheels,

To remove

for rear wheels with fixed brake caliper, and

To remove

for rear wheels with swinging caliper.

|

|

2.

|

Check the brake disc dimensions, see

and

and

.

.

|

|

3.

|

Clean the mating surface.

|

|

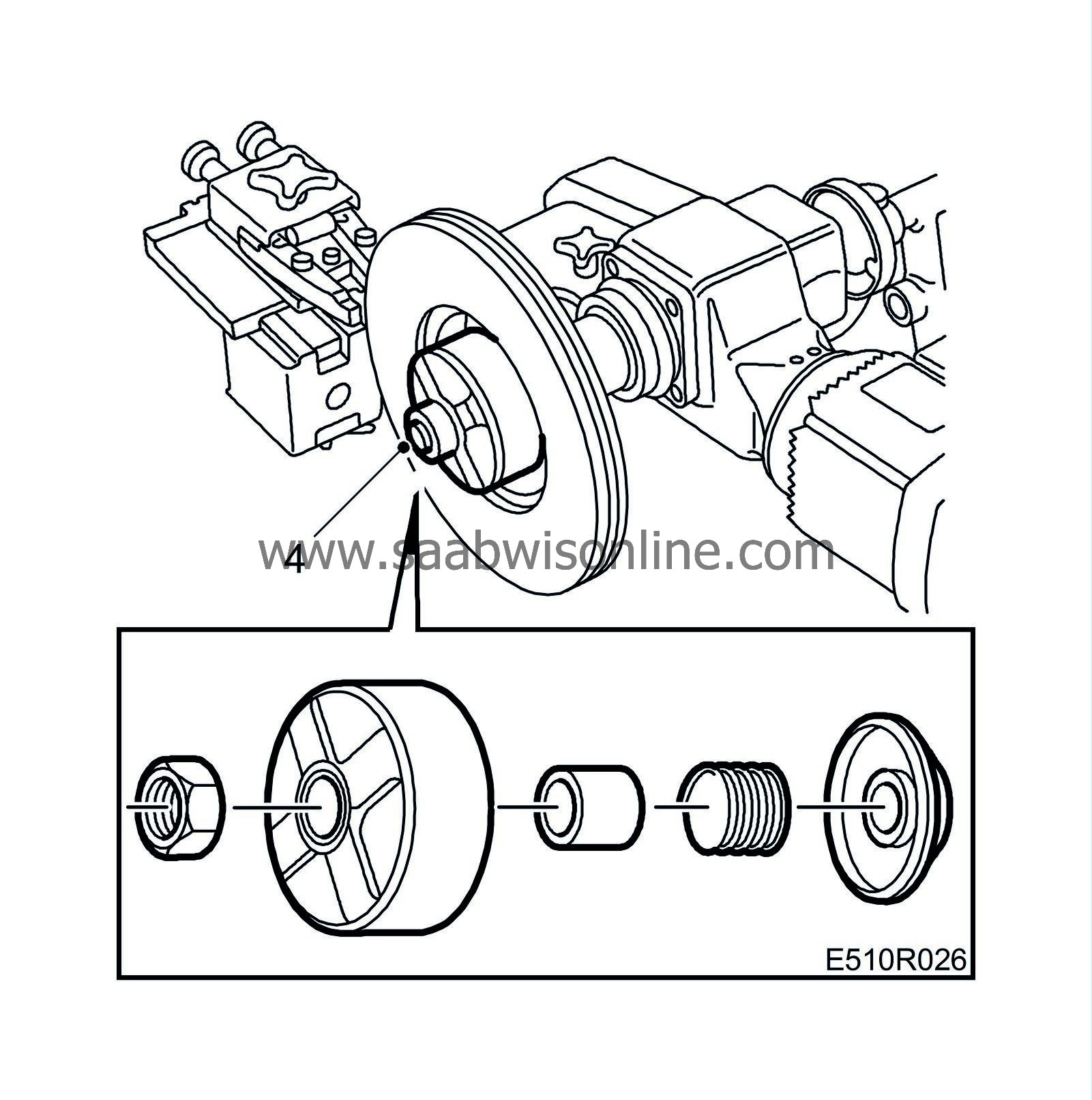

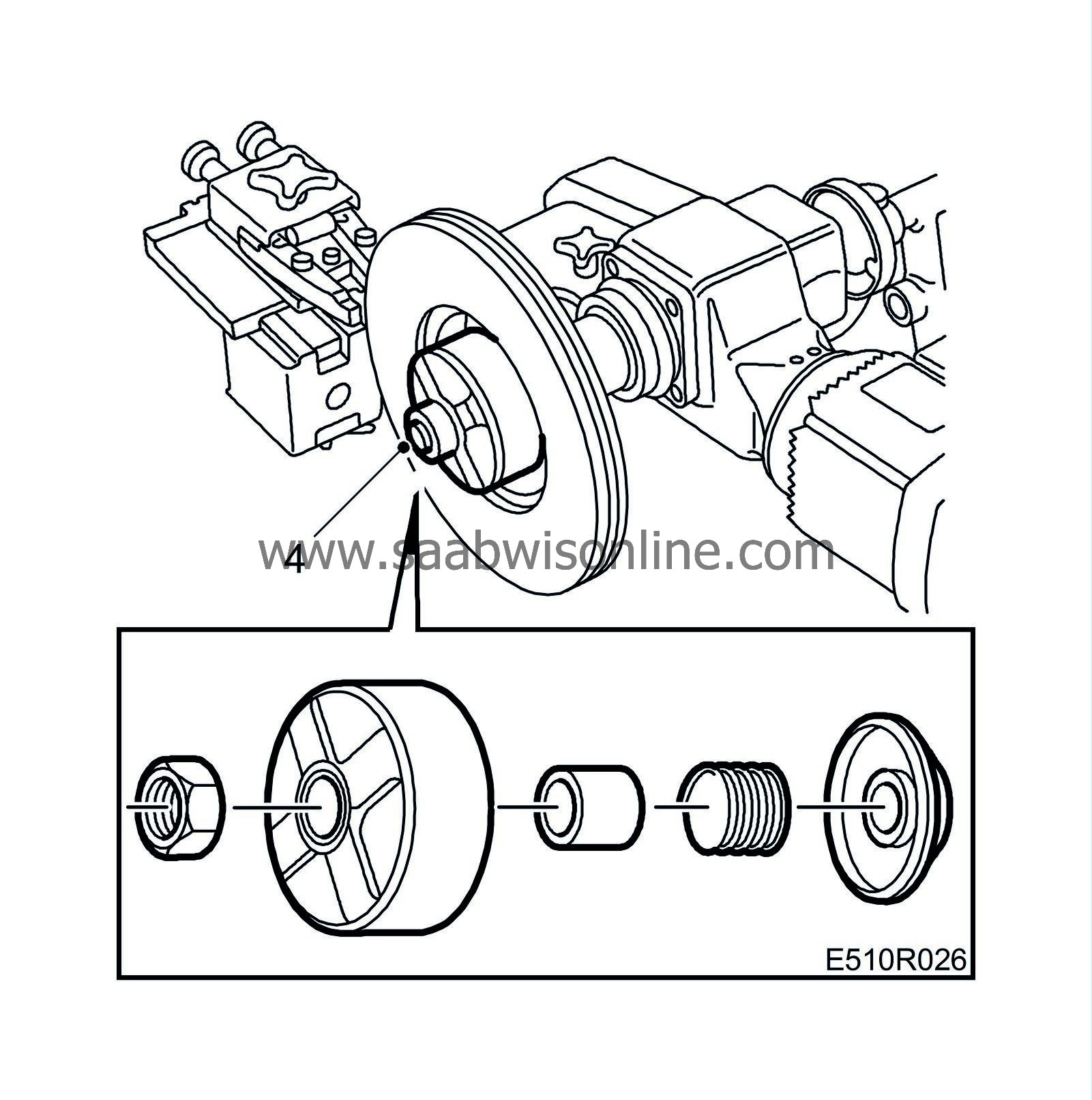

4.

|

Fit the connecting plate on the lathe.

|

|

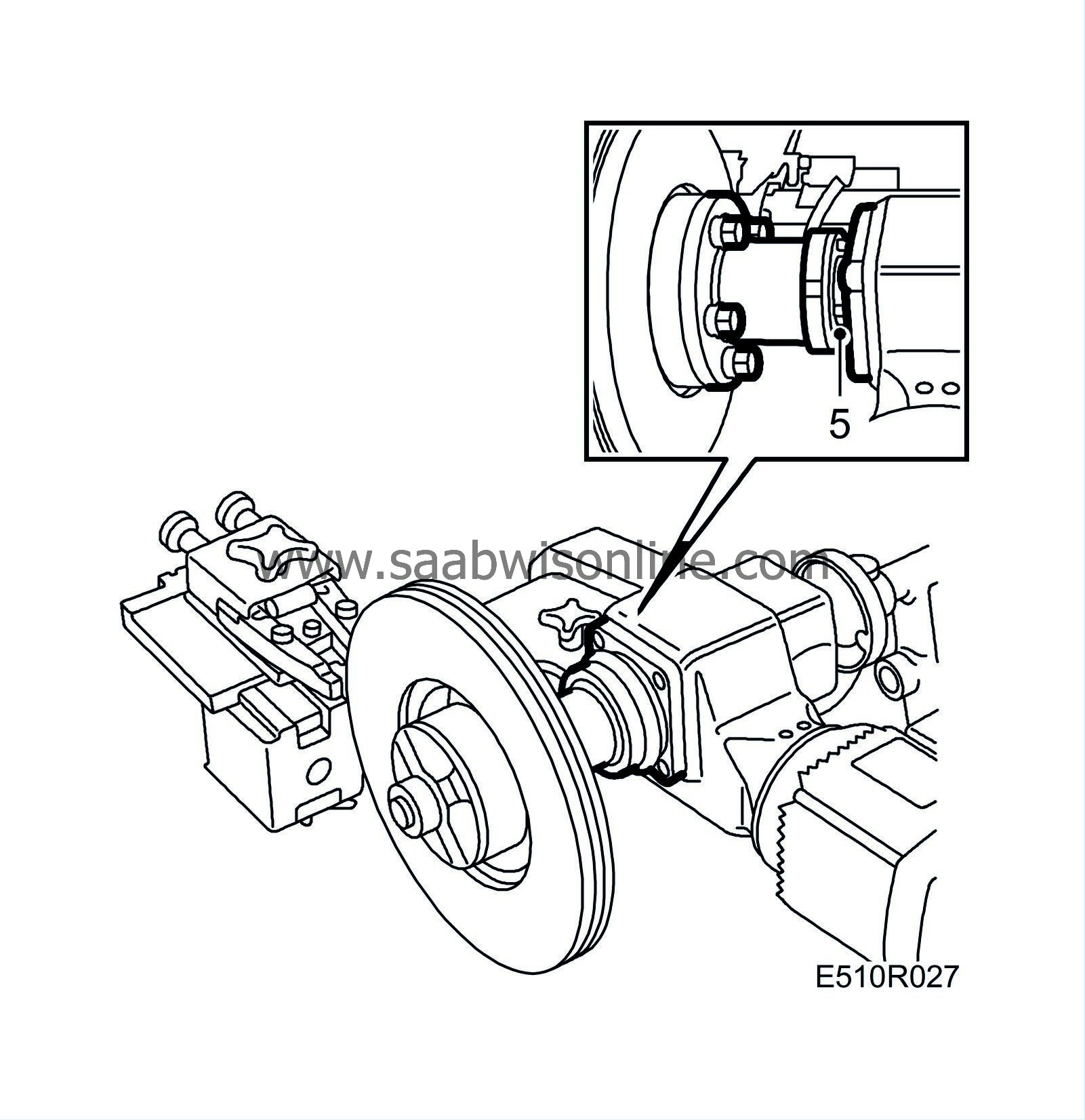

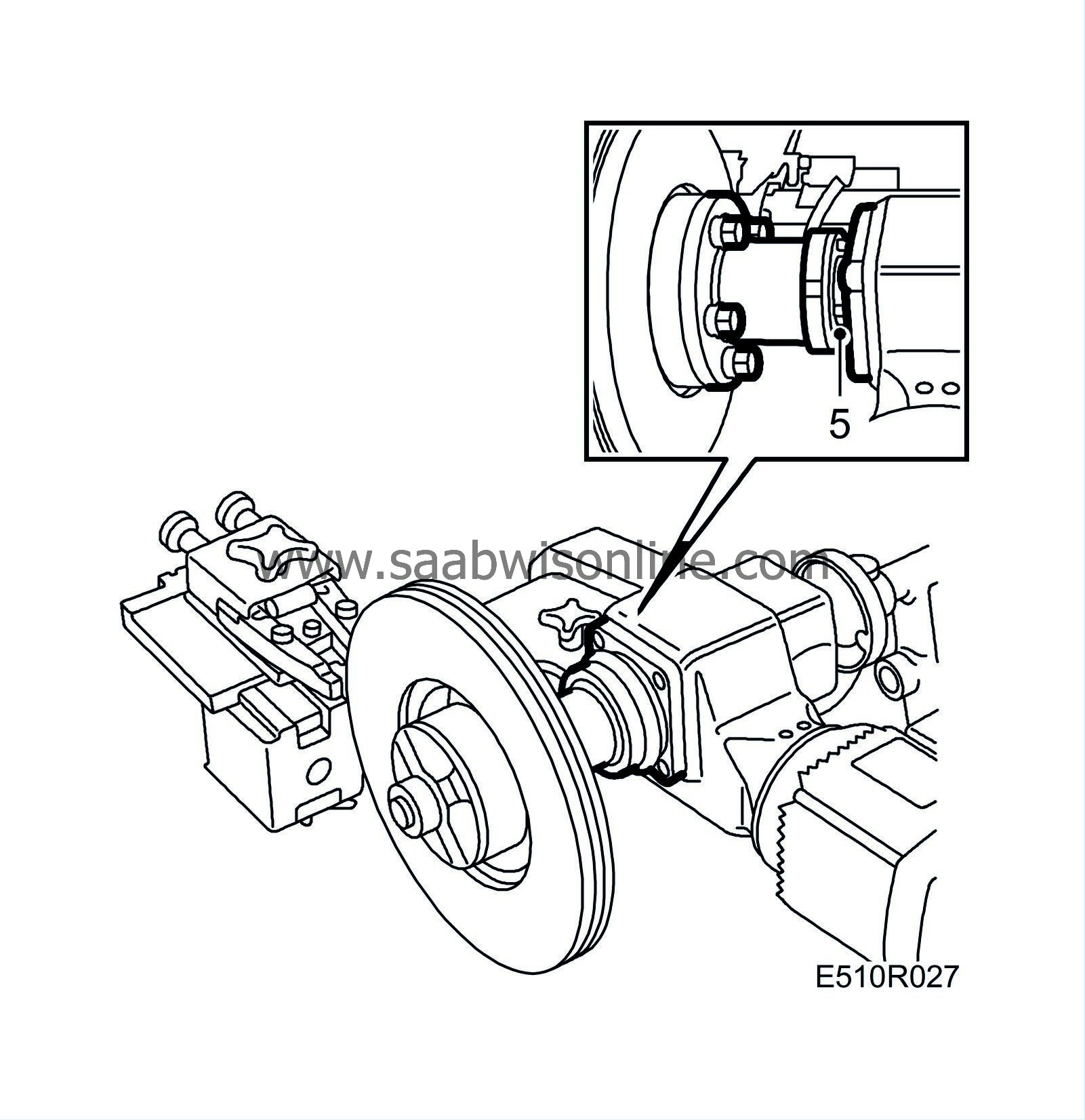

5.

|

Back off the adjusting screws.

Clean the connecting surface and fit the brake disc to the connecting plate, connect the lathe.

|

|

6.

|

Adjust the turning tools against the disc with the tool holder. Remove the locking screw and move the holder.

|

|

7.

|

Set the automatic stop.

|

|

8.

|

Feed out the tool holder and manually grind off the outer and inner rusty edges.

|

|

9.

|

Set the turning depth and switch on automatic operation.

|

|

10.

|

Check the brake disc.

|

|

11.

|

Remove the brake disc from the lathe.

|

|

12.

|

Remove the from the lathe and fit it into the car. Refer to

To fit

for front wheels,

To fit

for rear wheels with fixed brake caliper, and

To fit

for rear wheels with swinging caliper.

|

|

13.

|

Fit the brake caliper, see Adjustment/replacement, “Hydraulic body, front wheel, changing (33)” and Adjustment/replacement, “Fixed brake caliper, rear wheel, changing (44)”.

|

and

and

.

.