Roof 4D

| Roof 4D |

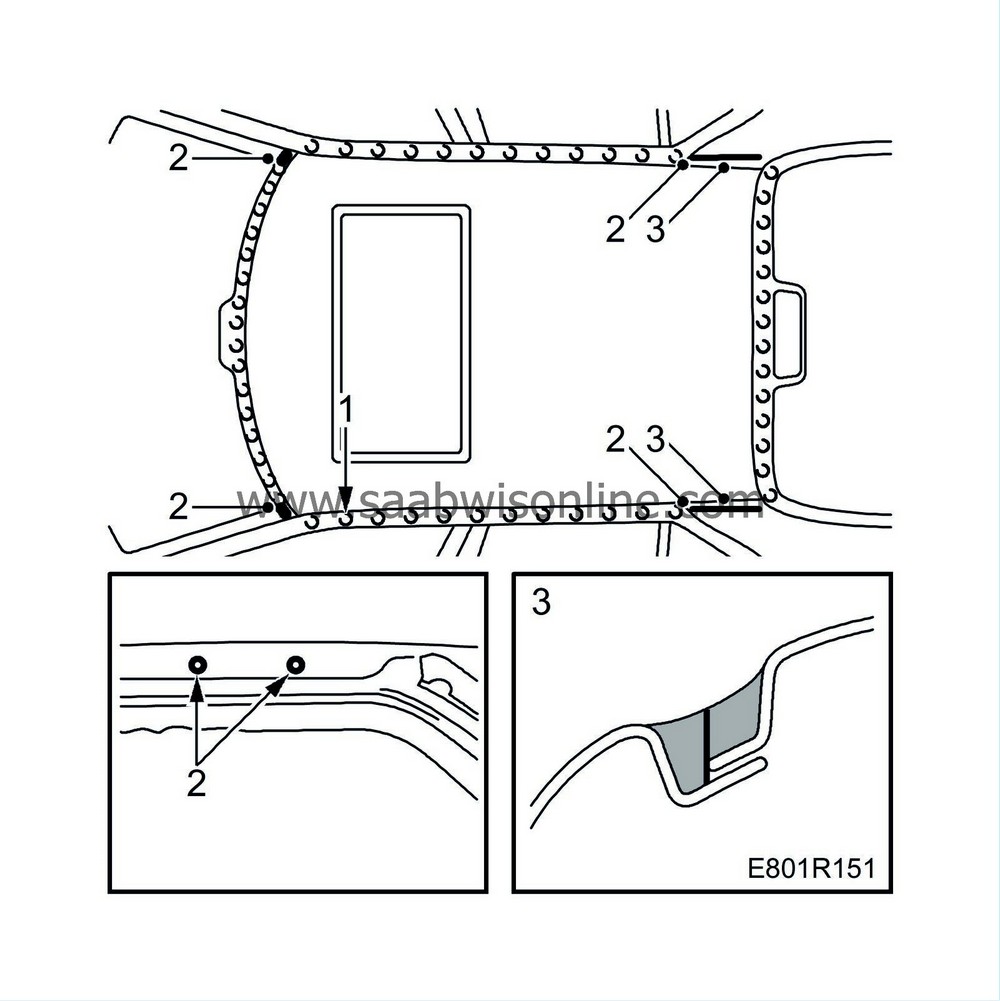

| 1. |

Drill out the spot-welds.

|

|

| 2. |

Grind down the welds holding the roof to the A and C pillars. Drill out or grind down the nuts for the carrier racks at the edge of the roof.

|

|

| 3. |

Make a cut in the middle of the adhesive string between the roof and the outer side panel.

|

|

| 4. |

Tap loose the roof and align any damaged sheet metal and panels.

|

|

| Fitting |

| Note | ||

|

Be careful not to damage the paintwork on the outer side panel when the seal string is adjusted. |

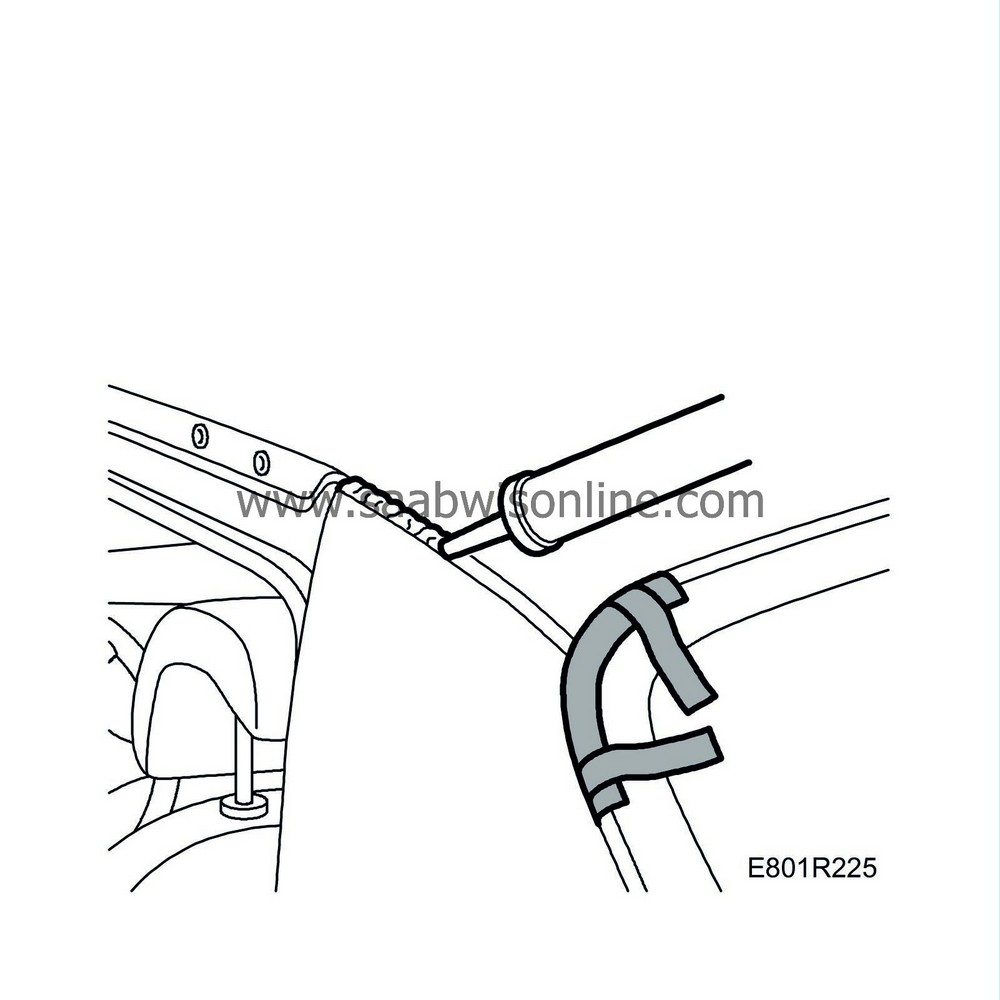

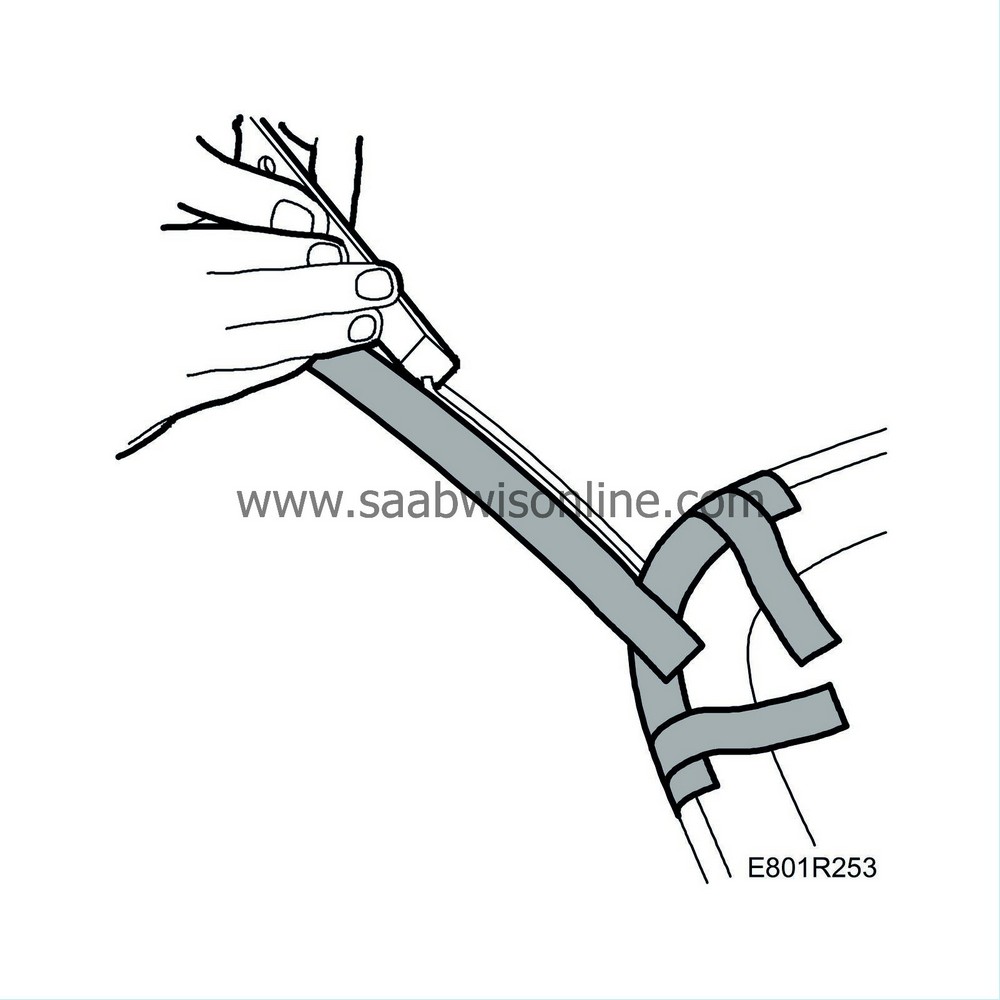

| 1. |

Mask off the outer side panel. Cut away the centre section of putty towards the edge of the side panel using

Cutting tool, roof joint 4D

.

Use 82 93 474 Removal tool to cut away the rest of the putty. Angling the putty knife will make it easier to remove the putty. Be sure to remove the putty at the bottom of the joint.

|

|

| 2. |

Grind all the surfaces that are to be welded.

|

|

| 3. |

Apply welding primer to the surfaces that are to be welded.

|

|

| 4. |

Fit the new roof and fixate with a few welding clamps.

|

|

| 5. |

Spot-weld the roof.

|

|

| 6. |

Seam weld the roof to the A and C pillars.

|

|

| 7. |

Grind the welds.

|

|

| 8. |

Remove any remaining welding primer. Welding primer reduces adhesion of paint, filler and sealant.

|

|

| 9. |

Apply etching primer to all surfaces that have been ground clean.

|

|

| 10. |

Wipe the seal joints clean with Teroson FL T875.

|

|

| 12. |

Then use the

plastic scraper

to remove excess material. Adjust the shape at the rear window flange and the roof moulding flanges.

|

|

| 13. |

Inspect the seal joint as regards quality and finish.

|

|

| 14. |

Allow the material to harden 2 hours at a minimum of 20° C (68°F).

|

|

| 15. |

After hardening inspect the joint as regards quality and finish.

|

|

| 16. |

Seal joints and seams with sealant.

|

|

| 17. |

Apply anti-corrosion agent to the edge of the roof after painting. Use Terotex HV 400 or Mercasol 1.

|

|

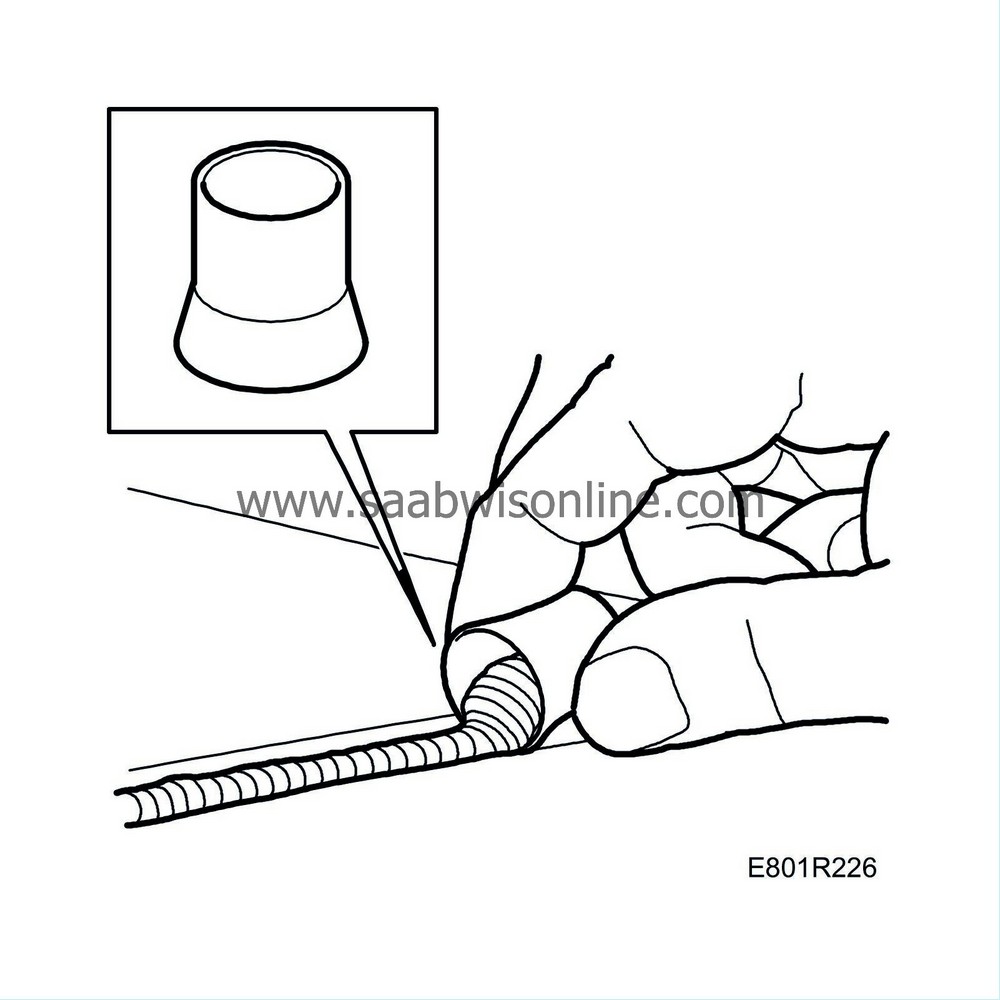

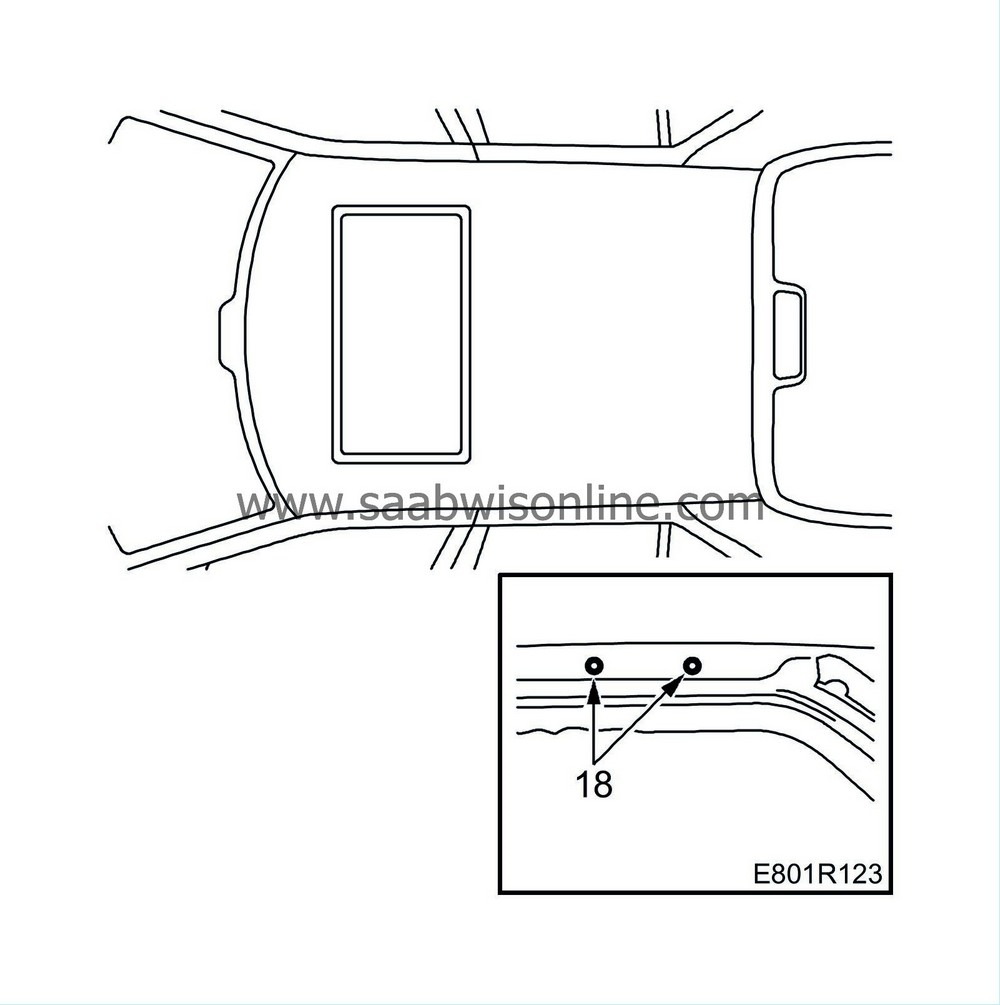

| 18. |

Apply anti-corrosion agent in the holes for the carrier rack and on the nuts.

|

|

| 19. |

Fit the carrier rack nuts on the edge of the roof.

|

||||||||||