Welding

| Welding |

|

|||||||||||||

| Symbols |

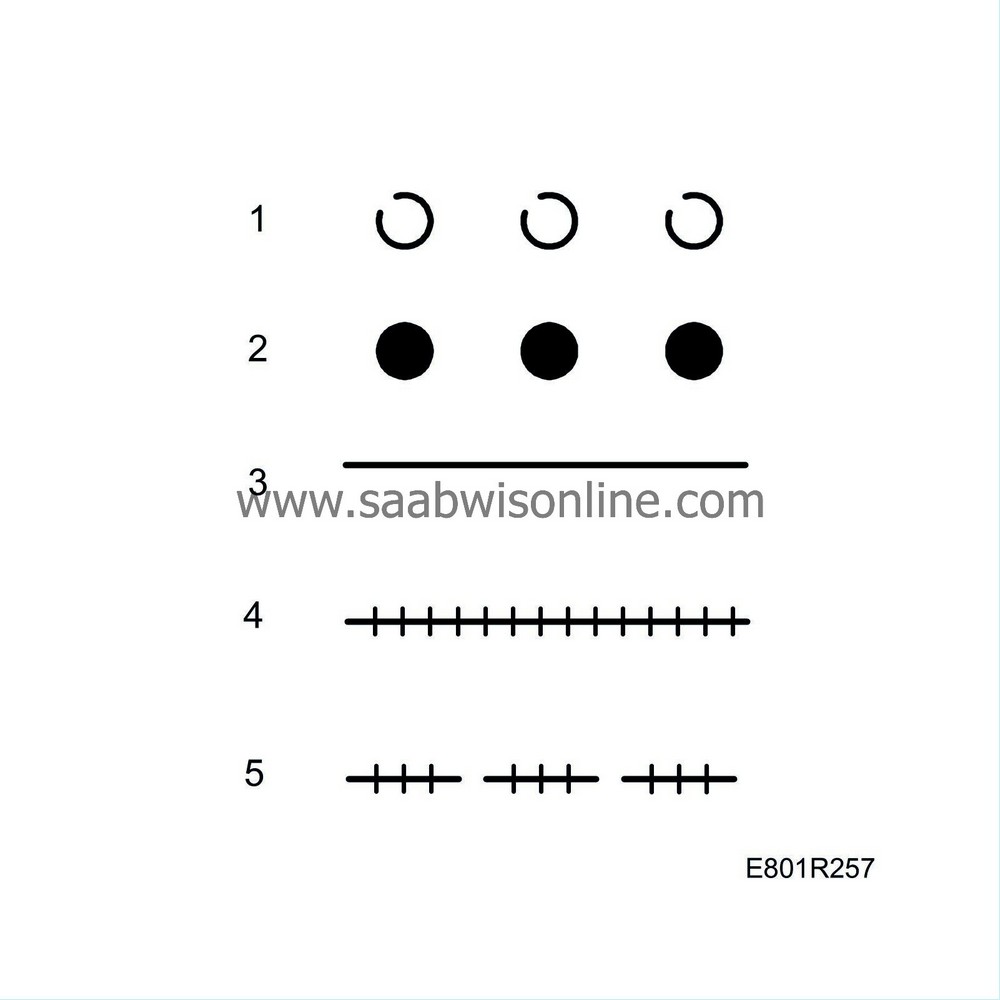

The following symbols have been used in the method description for the various tasks:

| 1. |

Spot-welding drill

|

|

| 2. |

Point or plug weld

|

|

| 3. |

Cutting

|

|

| 4. |

All-weld, continuous seam

|

|

| 5. |

Seam weld

|

|

| Grinding |

All surfaces to be welded must first be ground clean from paint. Use a belt grinder. When spot-welding galvanized metal, the paint must be removed with a wire brush and hot-air gun so that the galvanized surface is not damaged. All-welded and plug-welded details must be ground to an even and fine finish after welding.

| Important | ||

|

Be careful not to grind away too much metal. The strength of the material must for no reason be weakened. |

||

Use abrasive cloth 120 or finer on external surfaces. Coarser abrasive cloth leaves marks that will be visible after painting.

| Welding |

The characteristics of the body's deformation zones and cabin enclosure must not be changed or become deteriorated after repair. Therefore, it is important that all welding work is carried out in accordance with method descriptions and that the correct welding method is used in the correct places. Spot-weld rather than plug-weld if space allows. Always check the number of spot-welds and their location before removing the damaged part and use the same number and locations when fitting the spare part. When spot-welding, the diameter of the electrodes must not exceed 6 mm. The core of the spot-weld must be at least 5 mm in diameter to ensure high strength so that a screwdriver placed between to spot-welds can be hit with a hammer without breaking the join. To reduce the risk for corrosion, welding primer must always be applied between the sheets being spot-welded together. Use Teroson Zinkspray.

When carrying out MAG welding, make sure that the grounding of the welding unit is good and connect the ground cable as close as possible to the welding point. This is important, as it will enable welding work to be done without the need to remove all electronic units from the car.

| Important | ||

|

If good grounding is not ensured, electronic components can be damaged by current surges through the metal. |

||

| Welding galvanized sheet metal |

| • |

Use a wire brush and hot-air gun to remove any paint from the surface. A grinder can remove the galvanized surface and must not be used.

|

|||||||||||||

| • |

Galvanized sheet metal should be spot-welded. Weld using slightly higher temperature and pressure than for ordinary cold-rolled sheet metal. Apply a zinc-based primer between the surfaces that are to be welded together.

|

|

| • |

Use welding rod suitable for galvanized sheet, such as "Magsi 54", and an ordinary controlled atmosphere of mixed gas type for MIG welding.

|

|

| • |

For filling work, use special filler for galvanized sheet metal., for example, Top filler (10) 82 85 488 , with Standox hardener (10) 82 85 496.

|

|

| • |

Working with galvanized sheet metal requires a higher standard of protective equipment than ordinary cold-rolled sheet metal.

|

|

All new methods and materials can be used on cold-rolled sheet metal.

Warning

Warning