Rear window 5D

| Rear window 5D |

| To remove |

| 1. |

Open the door windows so that there is no risk of the window being pressed out by the overpressure that would build in the passenger compartment if one of the doors would be closed.

|

|

| 2. |

Remove the wiper arm.

|

|

| 3. |

Open the tailgate.

|

|

| 4. |

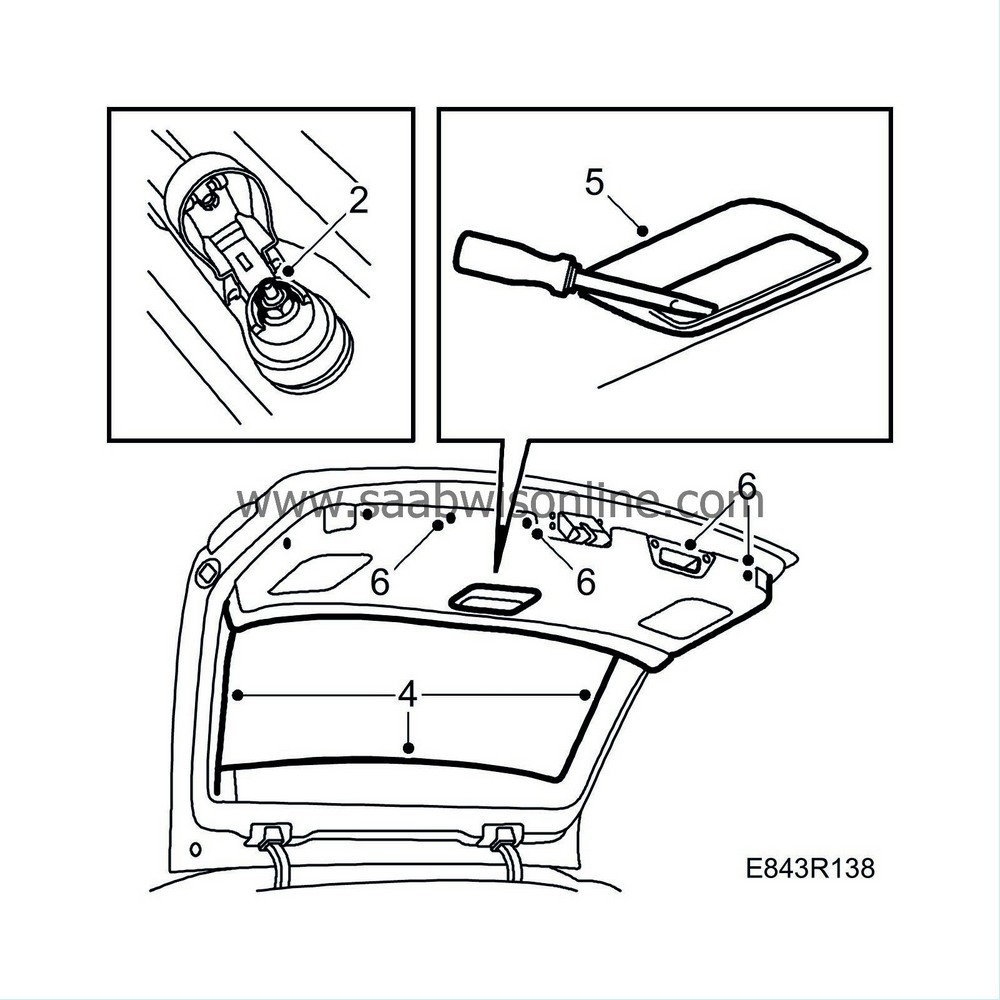

Remove the upper moulding by pulling it out so that the 6 clips release. Remove the side mouldings by pulling them outwards (fastened with clips).

|

|

| 5. |

Remove the frame round the inner tailgate handle by prying it up with a screwdriver in the three recesses. When the frame's clips have released, pull the frame downwards and bend it out.

|

|

| 6. |

Remove the inner tailgate trim by removing the door pull retaining screws and the plastic clips in the trim.

|

|

| 7. |

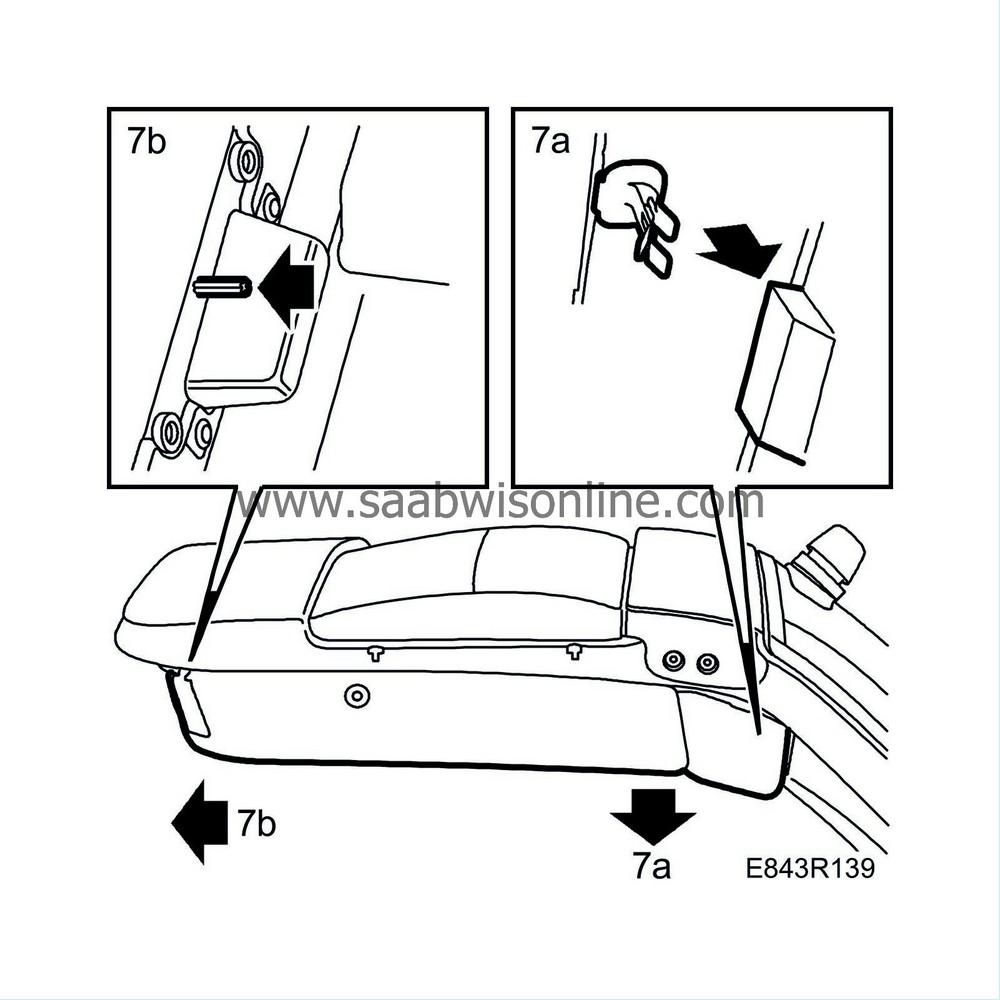

Lift off the tailgate trim as follows:

|

|

| 7.a. |

Pull down the top of the trim to release it from the clips.

|

| 7.b. |

Pull back on the trim to release the guide pin by the door pull without breaking it.

|

| 8. |

Unplug the connector for the electrically heated rear window and bend the flat pin connection against the window.

|

|

| 9. |

Unplug the wiper motor connector.

|

|

| 10. |

Remove the two screws and undo the nut securing the wiper motor.

|

|

| 11. |

Detach the washer hose and remove the wiper motor.

|

|

| 12. |

When replacing glued windows, use

82 93 714 Kit, window removal tool

. If the window is so damaged that the suction cups do not adhere, use

30 14 099 Handle for cutting wire

and saw out the window with the help of a co-worker.

|

|||||||||

| 13. |

Measure out 5,0 m cutting wire.

|

|

| 14. |

Insert the chisel from the inside of the window through the glue joint on the lower corner.

|

|

| 15. |

Hook the wire ends through the eyes of the chisel and bend the ends so that they do not come out.

|

|

| 16. |

Pull the chisel back through the glue joint into the passenger compartment. Pull in the wires about 0.7 m.

|

|

| 17. |

Unhook the cutting wires from the chisel. Straighten the wire ends so that they are at an obtuse angle. Put the chisel aside.

|

|

| 18. |

Place the wire under the moulding. Use the plastic tool of the kit to poke it in. Ensure that it lies around all corners. Pull in the wires and check their placement.

|

|

| 19. |

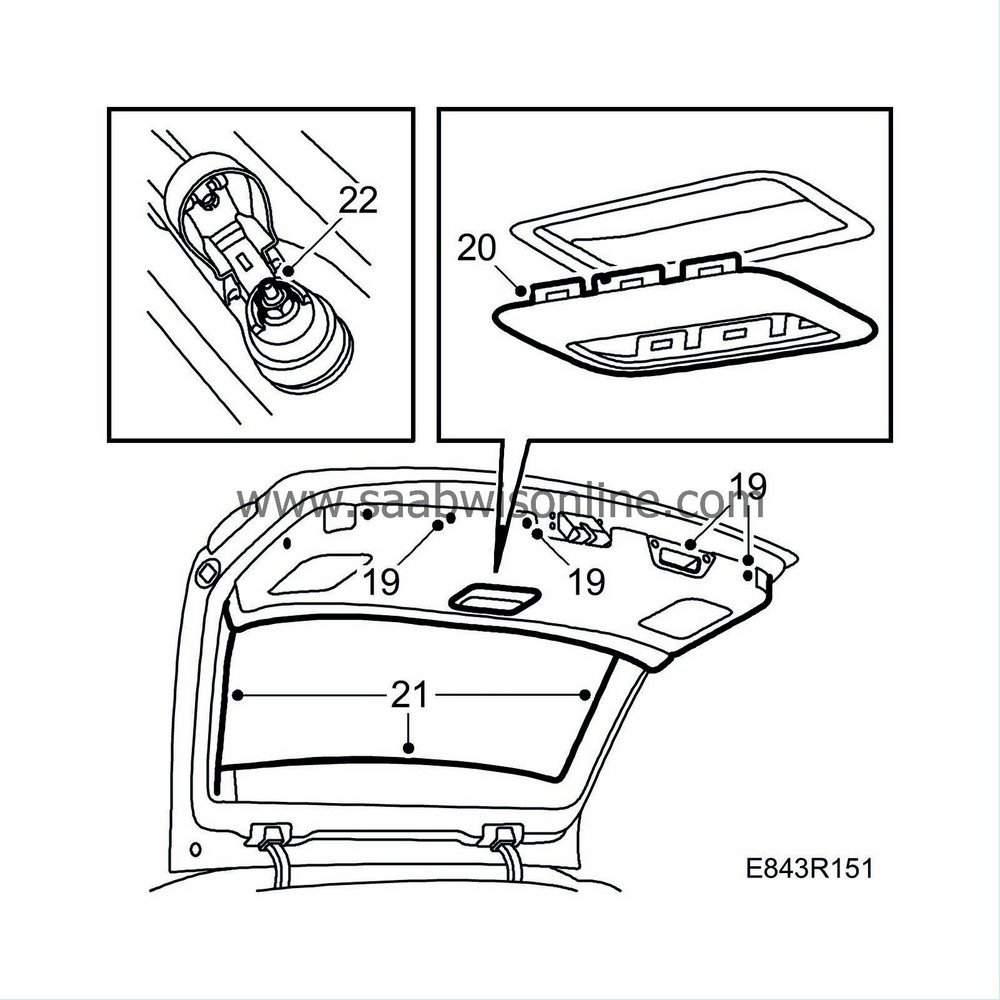

Fit the whimples on the inside of the window.

|

|

| 20. |

Attach the wire ends in the coils of the whimples. Make sure that the wires do not cross. Use the groove in the whimple's suction cup as a pulley to get a good angle.

|

|

| 22. |

Lift off the window with the assistance of a co-worker.

|

|

| 23. |

Remove the cut guide pins and cut away the adhesive that is pressed down into the guide pin flanges.

|

||||||||||

| To fit |

| Important | ||

|

Betaseal X 2500 cures in 1 hour at 23°C and 50% relative humidity. To avoid the glass from coming loose or its position changing during the curing time, the car must not be subjected to jolts or blows. The doors, tailgate and bonnet must not be shut. The car must not be rocked or rolled. Neither must the glass be pressed in while the adhesive is curing. |

||

Use 32 025 039 Adhesive kit, window glass for bonding windows. To avoid confusion between the cleaner and primer, the tubes are different colours:

|

Betaclean 3300 (glass cleaner)

|

One wet and one dry cleaning cloth

|

|

Betawipe 4001 (for glass with plastic surround)

|

Blue

|

|

Betaprime 5061 (primer, glass and paintwork)

|

Green

|

The car should be standing with all four wheels on a level surface when the window is fitted. For the best possible results, it is extremely important for all surfaces that have been cleaned or primed to be kept free from dust and dirt while work is in progress. The same goes for the adhesive when it has been applied. Therefore, once work has started it should be continued without interruption until the window has been fitted and the adhesive has hardened. The adhesive begins to harden as soon as the contents of both tubes are mixed. The window should therefore be fitted into place within 5 minutes of the time that application of the bead of adhesive was first begun. Note that points 8-16 must without exception be carried out in the given order to ensure satisfactory results with maximum adhesion.

| 1. |

Cut down the bead of adhesive on the tailgate window to a height of no more than 2 mm. Use the cutting tool from the removal kit. If the old window is to be put back into place, the bead of adhesive on the window should also be cut to max. 2 mm. Old, well-bonded adhesive is a good foundation for the new bead. Remove any loose adhesive from the glass and metal.

|

|

| 2. |

Remove loose particles, dirt and remnants of the plastic moulding from the metal flange, using a vacuum cleaner.

|

|

| 3. |

Make good any damage to the paintwork.

|

|

| • |

Scrape off any loose flakes of paint with a knife.

|

| • |

Wash clean with Terosans Rengörare FL (Cleaner).

|

| • |

Apply primer. Use Standox 1K Füllprimer.

|

| • |

Apply the finish coat.

|

||||||||||

| 4. |

If there is no old adhesive, or if the adhesive is not intact, primer must be applied to the painted surfaces with which the adhesive will be in contact. Use Betaprime 5061

(green)

on any touched-up surfaces. Do not use body primer on old, well-cohered adhesive.

|

|

| 5. |

Close the tailgate.

|

|

| 6. |

Fit the lifting handle on the outside of the rear window and place the window inside up on a stand.

|

|

| 7. |

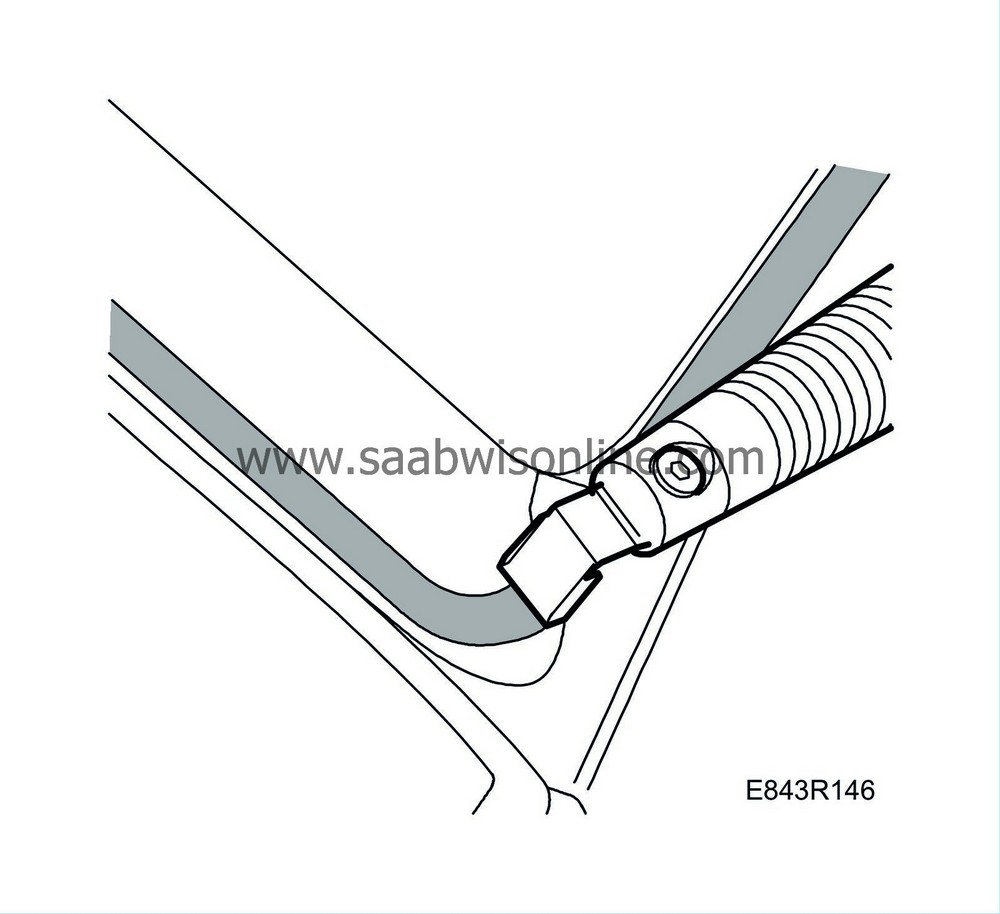

Refit the seal on the wiper motor. Check that the arrow on the seal sits against the marking on the window.

|

|||||||

| 8. |

Carefully wash the edges of the window with Betawipe 3300. Carefully wipe the edges using the wet cleaning cloth. Dry with the dry cleaning cloth provided in the adhesive kit. Avoid touching the cleaned surface.

|

||||||||||

| 9. |

Apply Betaprime 5061

(green cap)

to the cleaned surface. Allow the primer to dry for 10 minutes.

|

|

| 10. |

Avoid touching the primed surface.

|

|||||||

| 11. |

Apply the adhesive as follows:

|

|

| • |

Clip off the tip of the adhesive cartridge nozzle so as to provide a suitable shape to the bead of adhesive.

|

| • |

Hold the gun perpendicular to the surface of the glass and apply a bead of adhesive to the primed surface. Start at the bottom edge of the glass. Check that there are no voids in the bead of adhesive.

|

| 12. |

Put the new window in place with the assistance of a co-worker. Begin with the guide pins in the top edge.

Follow points 13 - 15 if the old window, which does not have guide pins, shall be remounted.

|

|

| 13. |

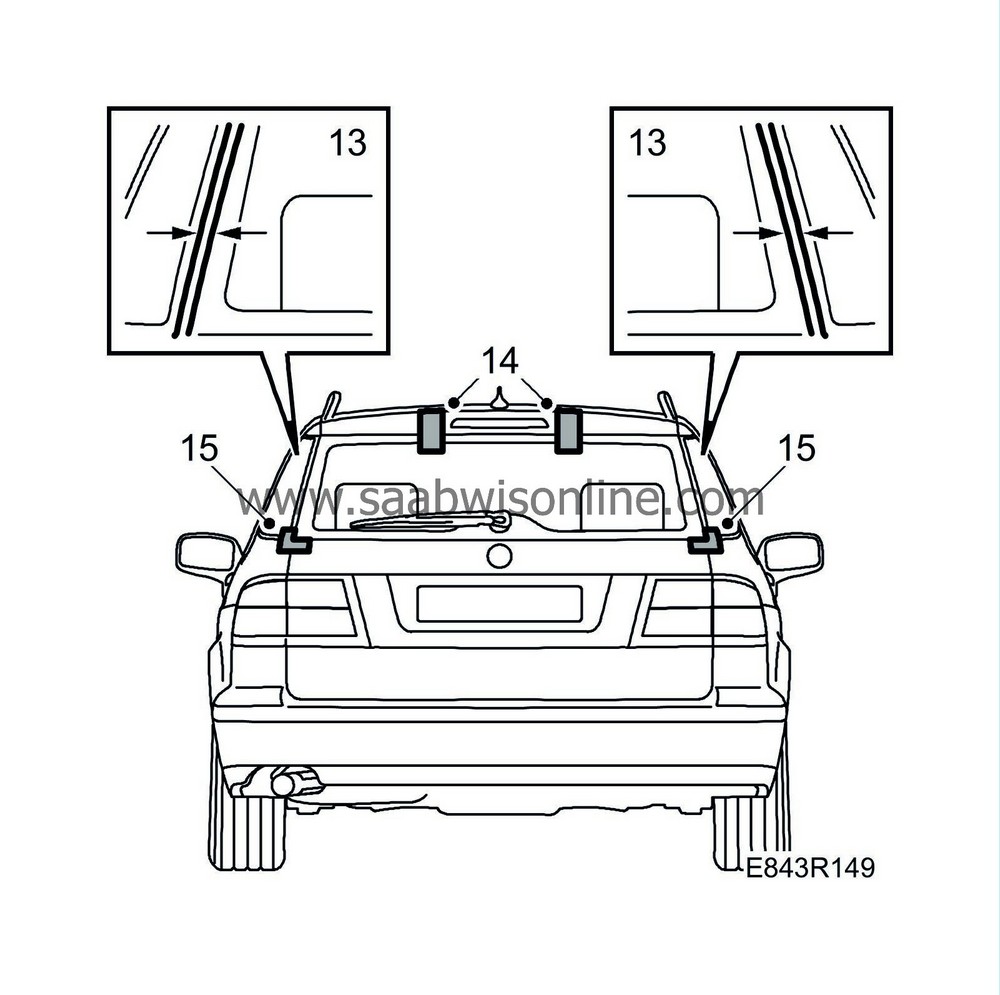

Adjust the glass so that it fits against the rear side windows.

|

|

| 14. |

Secure the windscreen with tape or straps so that it is held against the edge of the roof.

|

|

| 15. |

Place a counterstay (a piece of cardboard about 1 mm thick, for instance) at the bottom to prevent the glass from sliding down against the edge of the sheet metal.

|

|

| 16. |

Allow the adhesive to cure before continuing. Betaseal X 2500 cures in 1 hour at 23°C and 50% relative humidity.

|

|

| 17. |

Fit the wiper motor and attach the connector and washer hose.

|

|

| 18. |

Plug in the connector for the electrically heated rear window. Bend the taps so that they are covered by the side covers.

|

|

| 19. |

Fit the inner trim by inserting the guide pin at the door pull and fastening with the clips at the edge of the window. Screw in the two door pull screws. Fasten the remaining clips around the trim.

|

|

| 20. |

Fit the frame round the inner handle.

|

|

| 21. |

Fit the trim mouldings on the glass.

|

|

| 22. |

Close the tailgate and fit the wiper arm.

|

|

| 23. |

Check the function of the washer and wiper. Clean the window both inside and out.

|

|

Warning

Warning