P bus and I bus

| P bus and I bus |

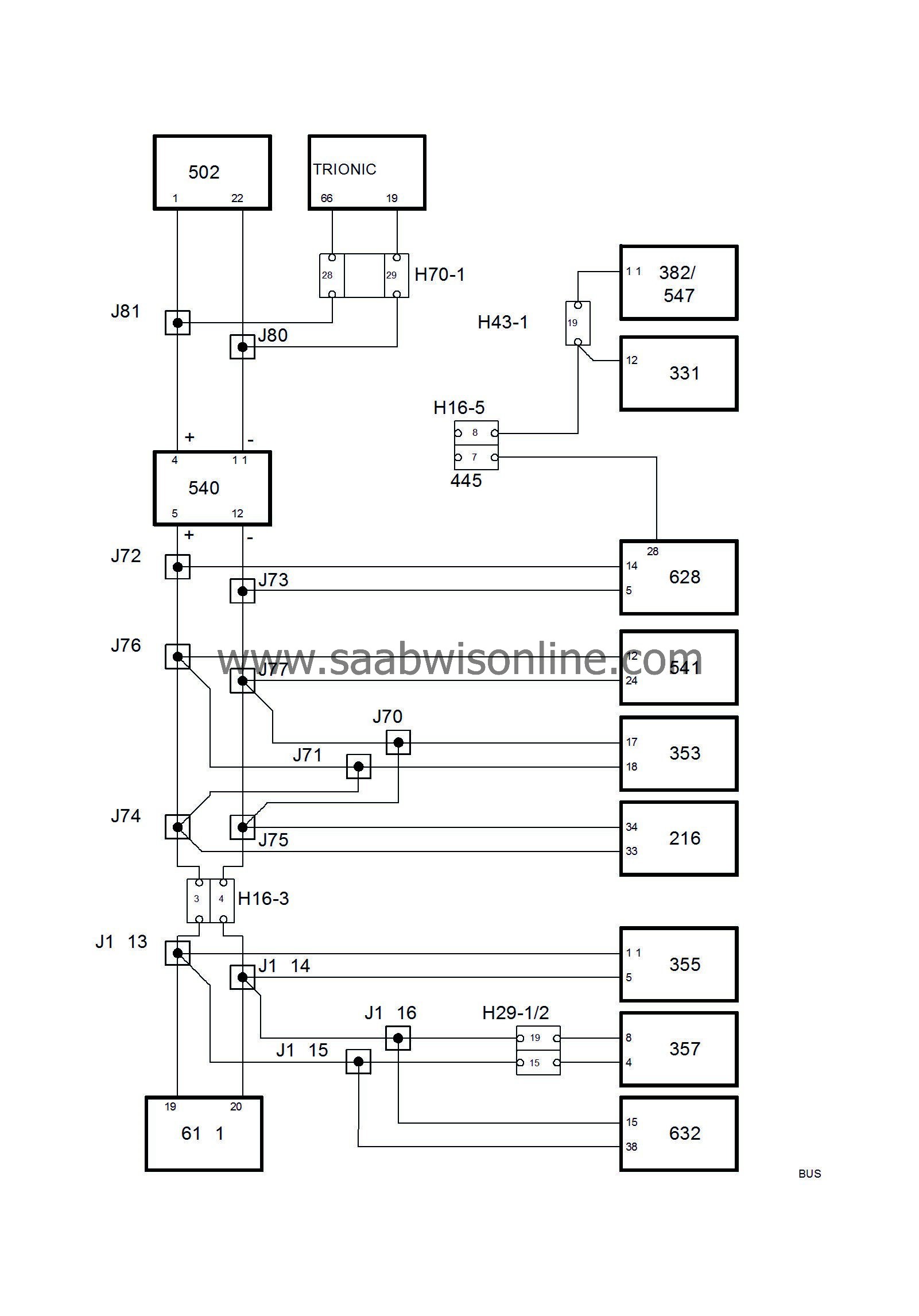

The buses are divided into the Powertrain bus (P-bus) and the Instrument bus (I-bus). Both buses are connected to the main instrument unit (MIU). The buses are electrically isolated from each other. The P-bus has a data transfer rate ten times higher than that of the I-bus.

All information sent out on a bus by a control module is available to all other control modules connected to the bus. The MIU ensures that the information that is available on one bus is also available on the other.

The control module sends out information on the bus at regular intervals. The time between two transmissions depends on which information is being transmitted and varies between 10 milliseconds (0.010 s) and 1 second. Information is also sent out by the control module whenever the information changes.

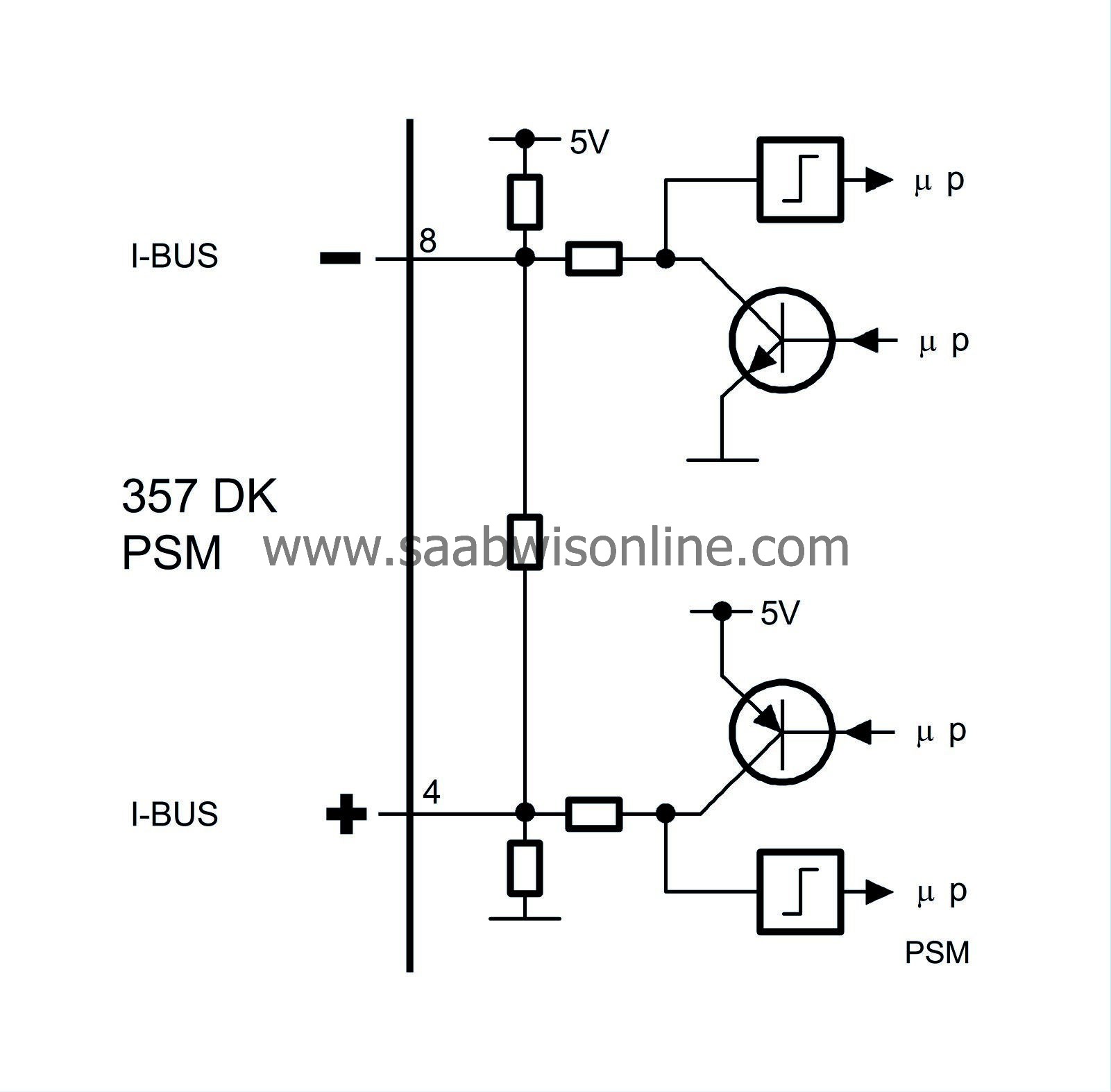

Information tr ansfer between control modules takes place via two leads, BUS+ (green lead) and BUS- (white lead). On the P-bus, the leads are twisted to reduce sensitivity to electrical interference.

| Diagnostics |

In a bus system, all the units must be able to communicate with each other. For example, the engine cannot be started if Trionic is unable to receive immobilizer information from TWICE.

Permanent bus fault

All Tech 2 communication with systems connected to the bus takes place through DICE. Irrespective of which system is contacted, Tech 2 first checks via DICE that all on-board systems connected to the bus are turned on and communicating. If any control module connected to the bus is missing, Tech 2 will show this. This means that all control modules connected to the bus are communicating correctly unless Tech 2 warns otherwise.Intermittent bus fault

The Trionic control module and the transmission control module (TCM) always check that all control modules from which they obtain information are communicating properly. If there is an intermittent fault in the bus communication, diagnostic trouble codes will be generated in the Trionic and TCM control modules. The cause of the fault may be that the control module concerned has lost power or one of the bus leads is disconnected.Incorrect values on the bus

A diagnostic trouble code is given in the Trionic and transmission control modules if any information they obtain from the bus has an incorrect value. The trouble code text indicates the system in which the fault has occurred.For further information on the bus, see Group 3, ”Bus and Diagnostic Communication”.

| PSM uses the following information: |

|

Incoming information

|

Sensor system

|

|

|

+54 circuit (On/Off)

|

DICE

|

DICE supplies PSM with information on the +54 circuit.

|

|

Diagnostics

|

DICE

|

PSM communicates with the diagnostic tool via DICE.

|

|

Driver's door (open/closed)

|

TWICE

|

TWICE sends information on whether the driver's door is open or closed.

|

|

Passenger door (open/closed)

|

TWICE

|

TWICE sends information on whether the passenger door is open or closed.

|

| PSM sends out the following information: |

|

Information Sent

|

User System

|

|

|

Sound signal (acoustic confirmation)

|

SID

|

SID receives information on whether a programming command has been performed and then gives an acoustic signal to indicate that the programming is complete.

|

|

Memory store button (On/Off)

|

PMM

|

PMM (Power Mirror Memory) uses the PSM memory function to store three settings for the electrically adjustable door mirrors.

|

|

Memory button (1, 2, 3)

|

PMM

|

PMM (Power Mirror Memory) uses the PSM memory function to store three settings for the electrically adjustable door mirrors.

|

|

Diagnostics

|

DICE

|

The diagnostic tool Tech 2 receives information from the PSM system via DICE.

|