(210-2554 ed.3) Noise from the timing chain and oil sludge in the engine

Symptom: Rattling timing chain, abnormal whining, bellowing or knocking noise

from the engine or oil pressure lamp on. If none of the above symptoms is

present, no further diagnosis is to be performed.

|

TECHNICAL SERVICE BULLETIN

|

|

Bulletin Nbr:

|

210-2554 ed.3

|

|

Date:

...........

|

June 2006

|

|

Market:

|

US/CA

|

|

|

Noise from the timing chain and oil sludge in the engine

|

Saab 9-5 M98-03 with engine alternative B205 and B235

Saab 9-3 (9400) M99-03 with engine alternative B205 and B235

Various conditions can cause the formation of oil sludge in the engine

or a rattling noise from the timing chain.

In the case of customer complaint, the following procedure must be carried

out.

|

Note

|

|

If repair is to be covered under New Car Warranty or Special Policy,

prior authorization from Saab Field Representative is required.

|

Symptom description

Rattling timing chain, abnormal whining, bellowing or knocking noise

from the engine or oil pressure lamp on. If none of the above symptoms is

present, no further diagnosis is to be performed.

Checking

|

•

|

Check the oil level, fill as necessary. If more than 1 litre of

oil is added then run the engine for 15 minutes before the checking for noise.

|

Listen to the engine for noise. The engine must be run to operating

temperature! If the engine sounds normal and oil pressure lamp does not come

on, consult with the owner about performing more frequent oil and filter changes

and switching to full-synthetic oil.

|

I Procedure to determine extent of damage

|

|

1.

|

If the oil pressure lamp flashes or comes on

steady:

Check oil level, fill as necessary. Check the oil pressure in accordance

with WIS - Engine - Basic engine - Adjustment/Replacement - Measuring oil

pressure. If the pressure is in accordance with the specification, replace

the sensor. If not, continue with step 4.

|

|

2.

|

Checking in the event of noise:

|

|

|

2.a.

|

Check the oil level, fill as necessary. If more than 1 litre of

oil is added then run the engine for 15 minutes more before checking for noise.

|

|

|

2.c.

|

If a high-pitched whining noise is audible, particularly in a

cold engine, then it is most often from the oil filter or the check valve

in the oil filter adapter.

|

|

|

2.d.

|

If a low-pitched "bellowing" noise is audible at idling speed,

similar to the noise from a hydraulic pump, then this indicates a clogged

oil strainer.

|

|

|

2.e.

|

Lower-end knocking noise, bearing noise.

If either of the above noises are heard, proceed to step 4.

|

|

|

2.f.

|

If a timing or balance chain noise is heard, proceed with step

3.

|

|

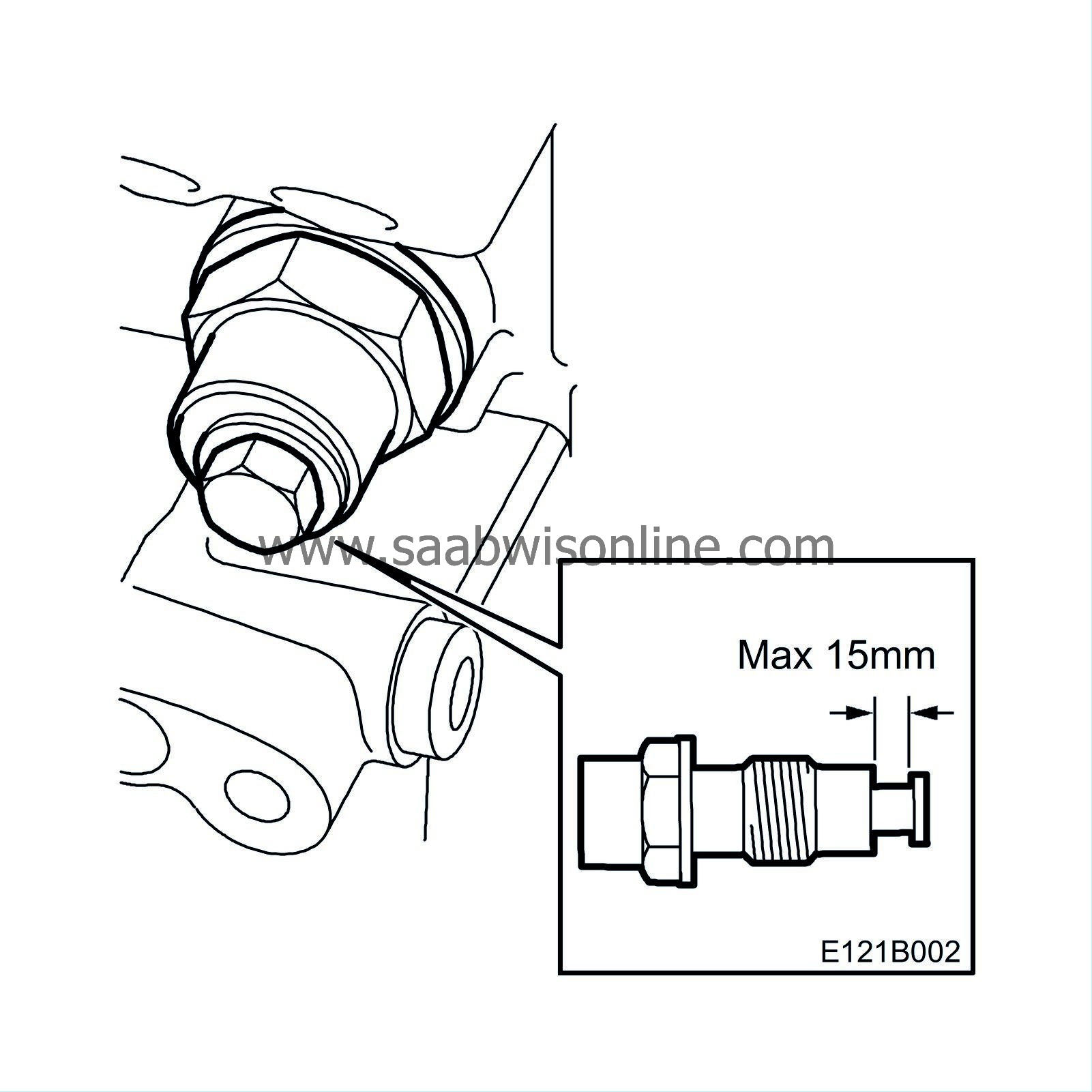

3.

|

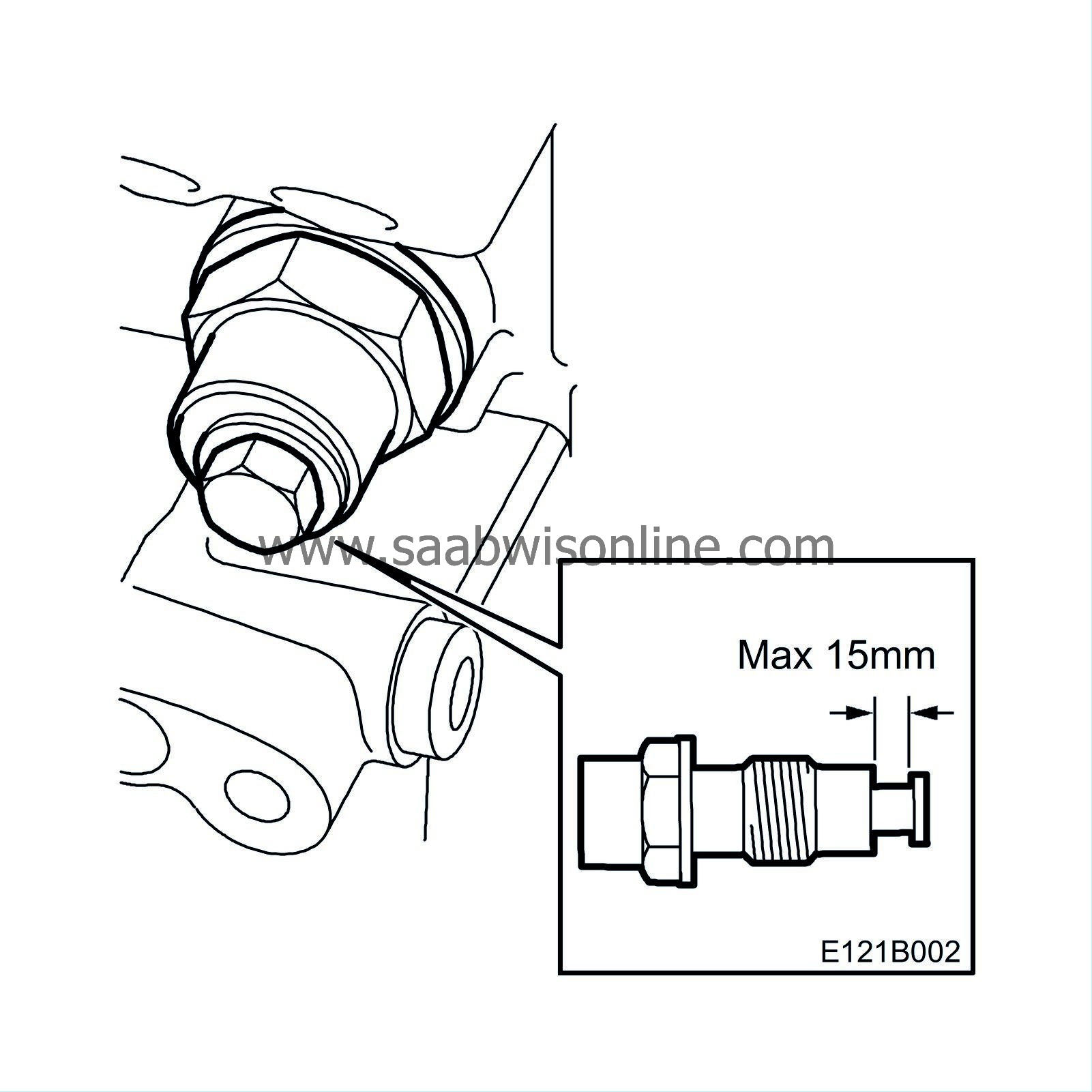

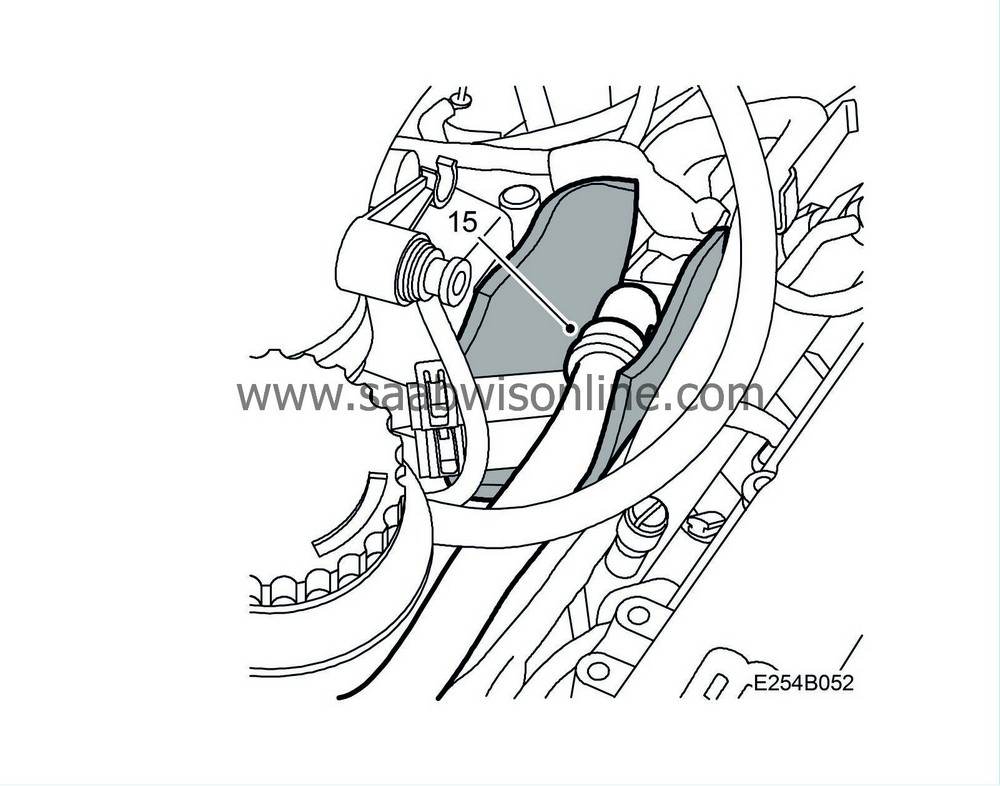

Checking Timing/Balance chain wear

If timing chain has excessive wear, the tensioner will protrude more

than 15 mm. If this has happened, the timing/balance chain and tensioners

must be replaced.

Use the following steps to determine chain wear:

|

|

|

3.a.

|

Remove small 12 mm hex bolt from end of tensioner so plunger does

not protrude further when removed.

|

|

|

3.b.

|

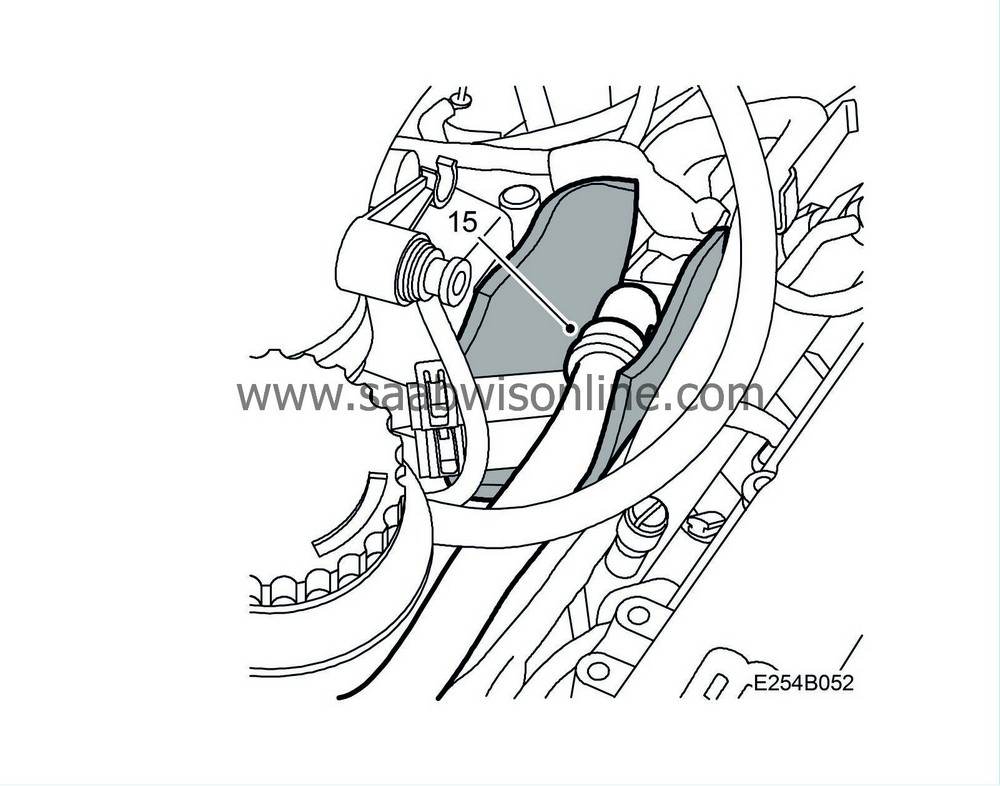

Remove tensioner from block and measure length, see pic.

|

|

|

3.c.

|

If timing chain tensioner length is greater than 15 mm, it will

be necessary to replace timing and balance chains as outlined in TSB 210-2480

ed. 2 (9-5), see WIS for this TSB. For 9-3, see WIS - Engine - Adjustment/Replacement

- Change of balance shaft chain B235 and B205. Before proceeding with chain

replacement, it must first be determined the extent of any further damage.

Continue with step 4.

Continue with step 4 to determine extent of damage before replacing

timing and/or balance chain and tensioner.

|

|

|

3.d.

|

If the timing chain tensioner length is less that 15mm, proceed

with step 4

|

|

4.

|

Determining extent of damage to engine lower

end

|

|

|

4.a.

|

Remove oil pan, refer to WIS-Engine-Basic engine-4-cyl petrol-Adjustment/Replacement-Oil

sump (in car).

|

|

|

4.b.

|

Inspect the main bearing and piston rod big end bearing on cylinder

1 and 4 with respect to abnormal wear or damage.

- Remove the main bearing caps and lower bearing half.

- Add a bead of Plasti-gauge. Type PG- 1 (green) must be used, p/n

30 06 558 or source locally.

- Fit the bearing caps with bearing shells (the marking figures on the

connecting rods turned to the same direction).

Tightening torque, with nut 20 Nm +70° (15 lbf ft +70°)

Tightening torque, with screw 25 Nm +100° (18 lbf ft +100°)

- Remove the bearing caps and bearing halves and measure the

Plastigauge strip. The bearing play must be between 0.014 - 0.062 mm.

|

|

|

4.c.

|

In the event of bearing damage, replace the short block assembly,

continue with cleaning of engine components.

|

|

|

4.d.

|

If the bearings are within the specification, continue with Cleaning

of engine components.

|

|

II Cleaning of engine components

|

To insure that engine does not return with additional subsequent damage

it is imperative that all components are cleaned before reassembly.

Cylinder head

If it is determined after inspection that the cylinder head must be

cleaned to a higher level than can be done while installed in the car, the

head is to be removed, completely disassembled and fully cleaned.

|

•

|

Remove the intake and exhaust manifolds and thermostat housing.

|

|

•

|

Remove camshaft bearing caps, camshafts, tappets, valve springs,

valves and valve seals.

|

|

•

|

Refit the bearing caps loosely.

|

|

•

|

Place cylinder head in an appropriate cleaning solution long enough

to fully remove all contamination.

|

|

•

|

Blow out all passages and cavities and check that all contamination

has been removed. Any residue must be removed with a stiff brush.

|

|

•

|

Reassemble with new valve seals, depending on condition it may

be necessary to dress valves prior to reassembly.

|

Oil Pan

|

•

|

Remove baffle plate, pickup tube and delivery pipe.

|

|

•

|

Clean all components in a suitable cleaning solution.

|

|

•

|

Upon reassembly, a new pickup tube (p/n 91 86 156) and o-ring

(p/n 91 38 009) must be used.

|

Oil filter Adapter Housing and Thermostat

|

•

|

Remove baffle plate, pickup tube and delivery pipe.

|

|

•

|

Remove the thermostat from the adaptor housing.

|

|

•

|

Wash both items in suitable cleaning solution.

|

Camshaft cover

|

•

|

Remove all gasket material and clean cover in suitable cleaning

solution.

|

|

•

|

Check the crankcase ventilation pipes in the camshaft cover.

Blow clean with compressed air or with a steel wire so that a free flow is

obtained.

|

|

•

|

In extreme cases, it may be necessary to replace the camshaft

cover if it cannot be properly and thoroughly cleaned.

|

|

•

|

Inspect all ventilation hoses with regard to condition and leakage

before fitting to new engine.

|

|

•

|

Carry out the procedure "Fitting renovation kit, crankcase ventilation",

Saab 9-5 and 9-3 (9400) respectively.

|

|

•

|

Replace oil filter element.

|

|

•

|

Fill engine with semi-synthetic oil.

|

|

•

|

Run the engine to the temperature that starts the radiator fan

and then for a further 5 minutes at 2000-3000 rpm.

|

|

•

|

Drain the oil and replace the oil filter.

|

|

•

|

Refill with FULL-SYNTHETIC oil.

When filling the oil for the second time, and for the extended special

policy to be valid, a fully synthetic long-life oil in accordance with Saab

Automobile's requirements specification is strongly recommended. This requirement

also applies for the engines where the previous recommendation was mineral

or synthetic based oil.

|

|

•

|

Test drive the car and check that the steering wheel stands straight

when driving on a straight road. Adjust as necessary.

|

|

•

|

Consult with owner concerning shorter maintenance intervals and

use of full synthetic, long-life oil.

|

Parts needed

55 561 200 Renovation kit, crankcase ventilation

Other parts, as per EPC

If needed

91 86 156 (CA: 55557225) Pickup tube/strainer

91 38 009 (CA: 30544347) O-ring

55 560 445 Hose to oil pan

55 560 463 Hose for camshaft cover

93 99 973 (CA: 30585634) Hose with check valve

Other parts, as per EPC

|

Fitting Renovation kit, crankcase ventilation, Saab 9-5

|

|

1.

|

Disconnect the battery's negative cable.

|

|

2.

|

Remove the upper engine cover.

|

|

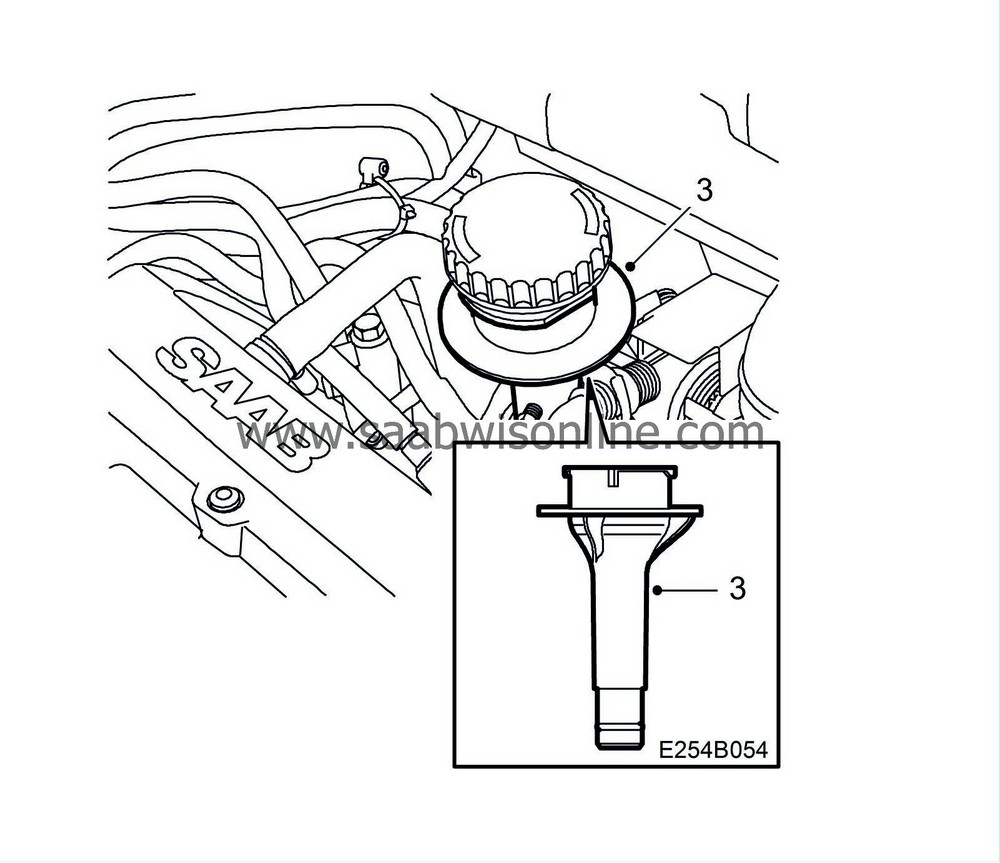

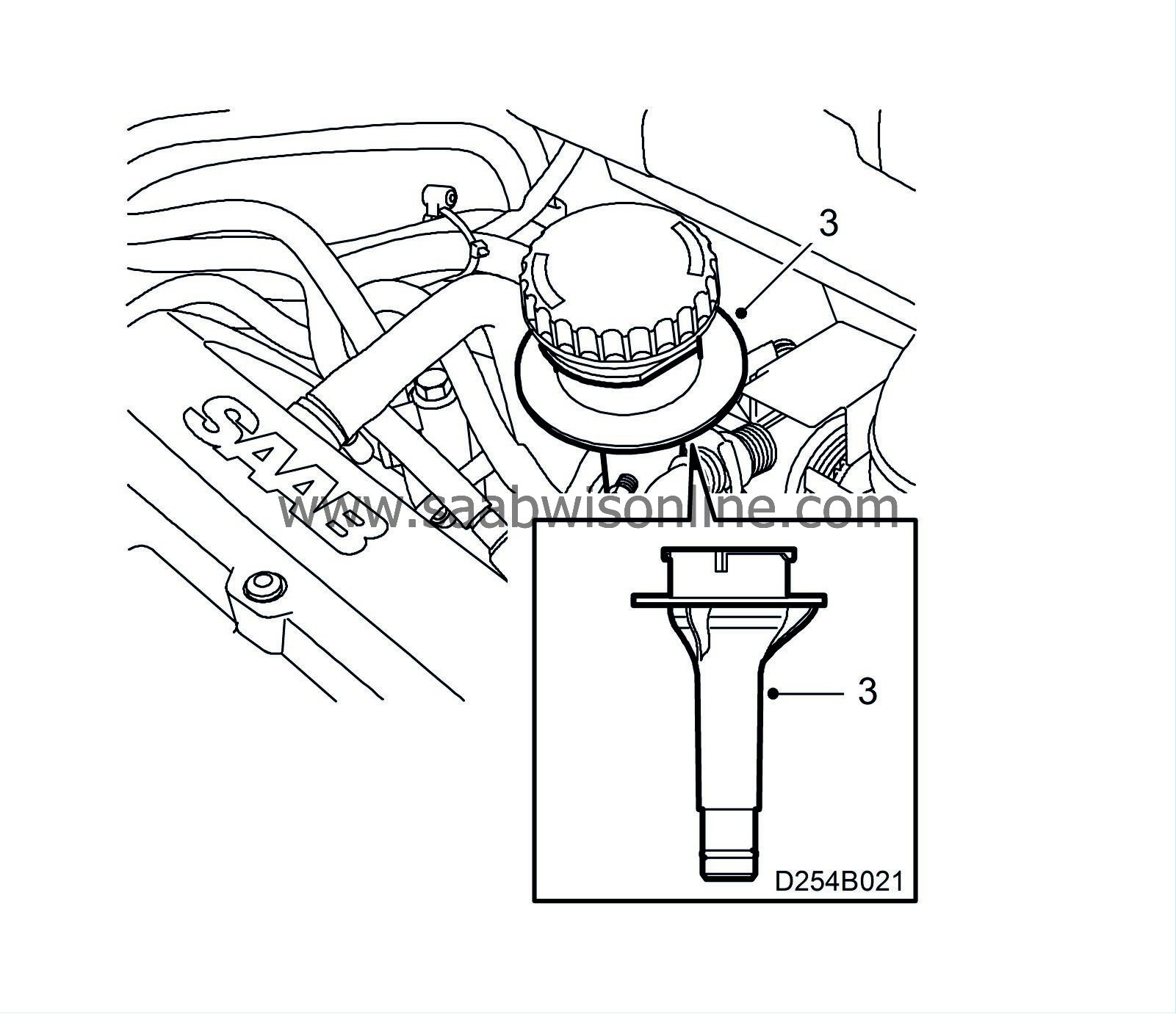

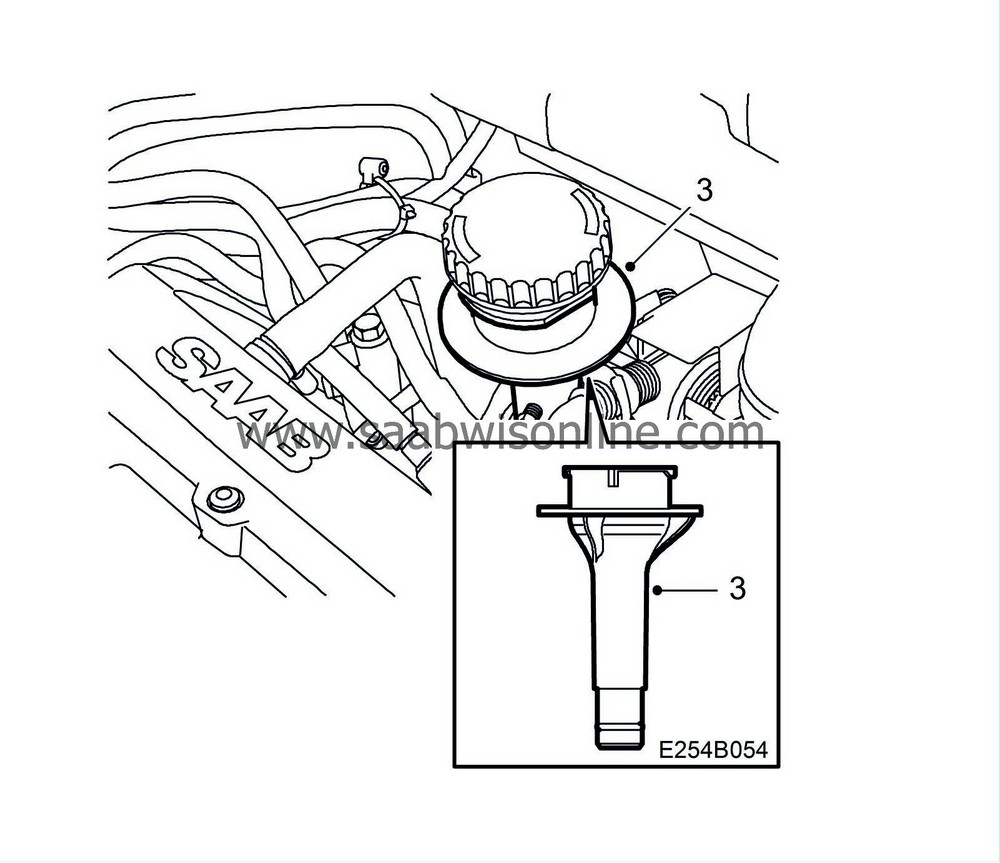

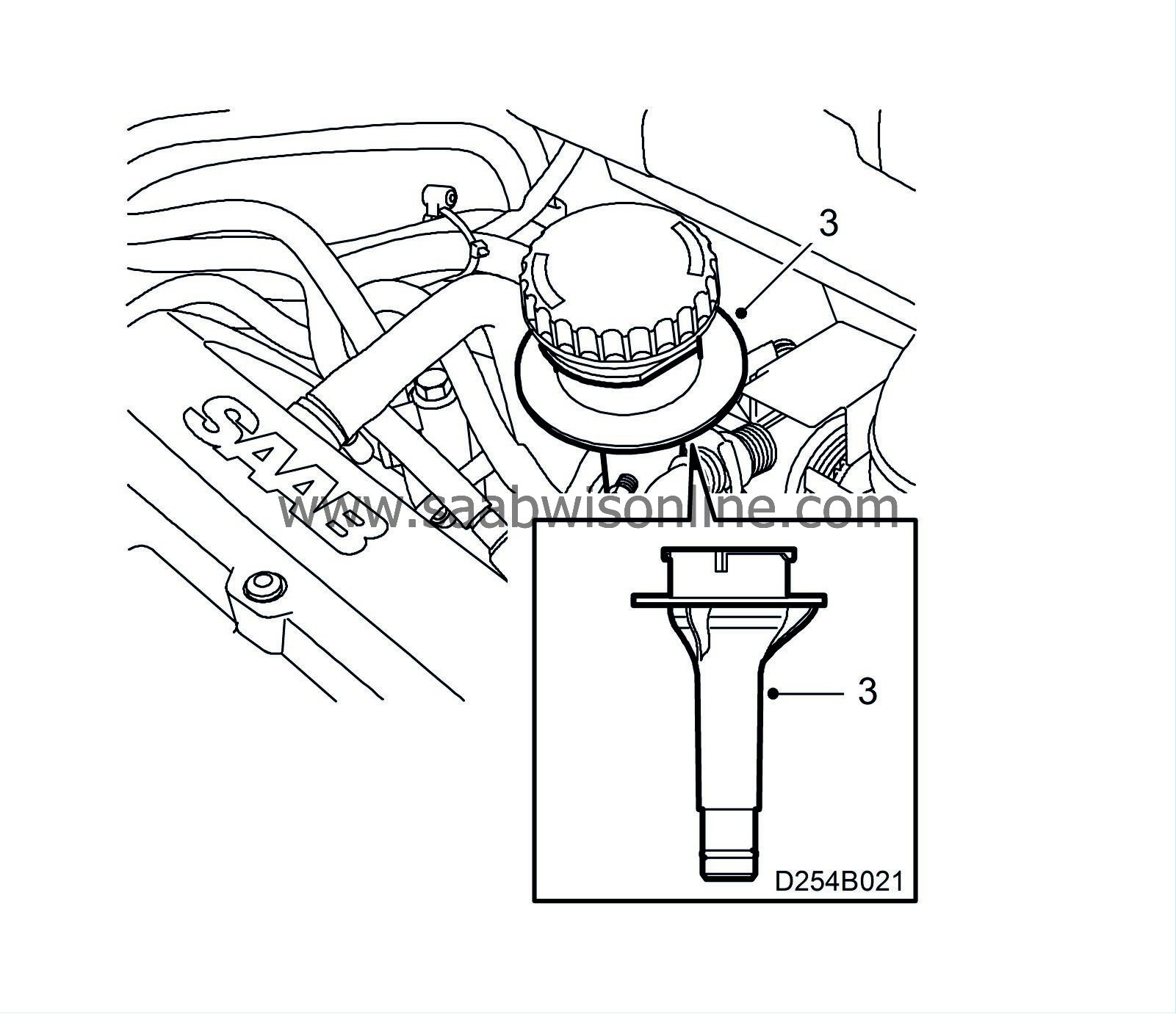

3.

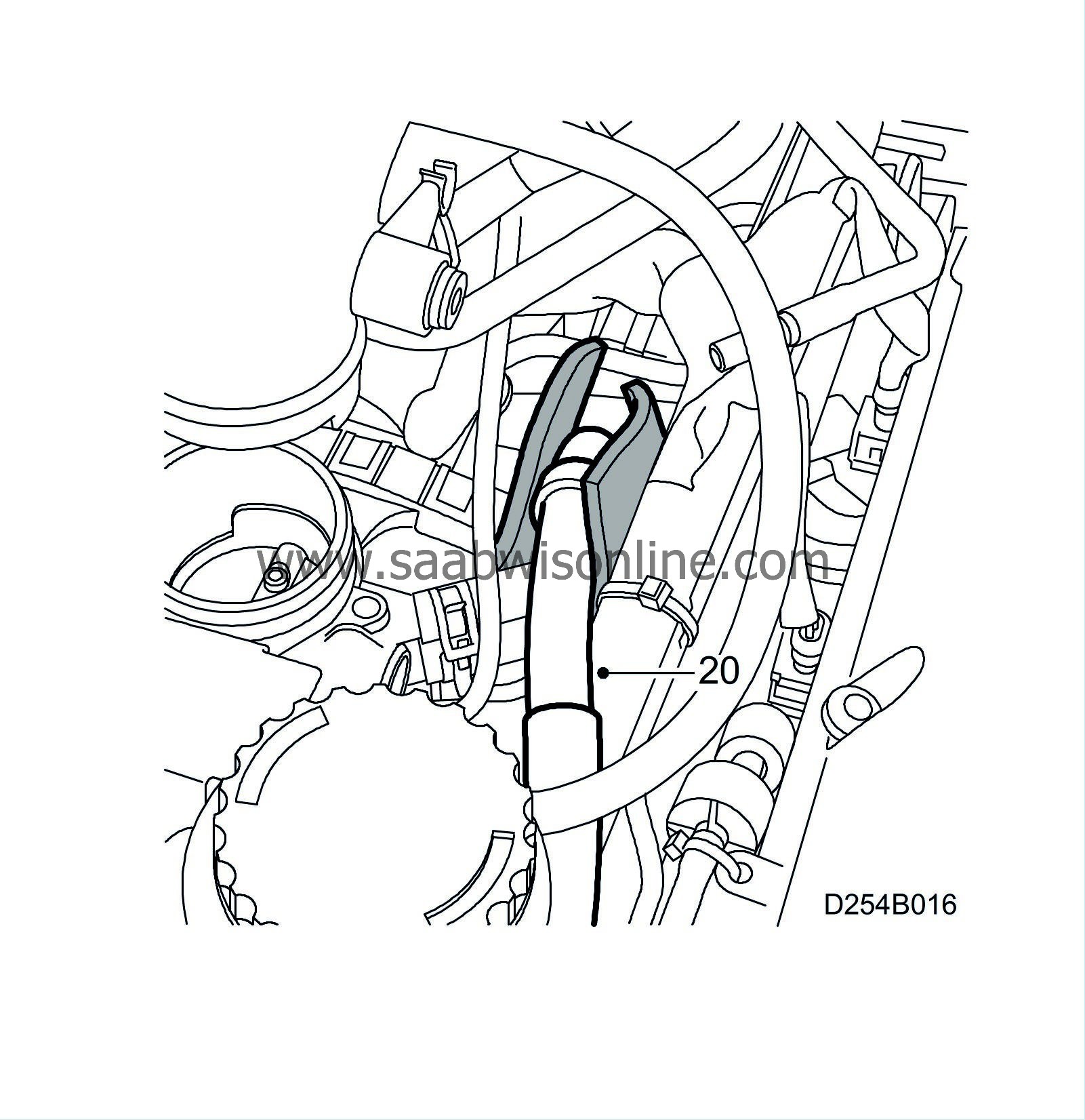

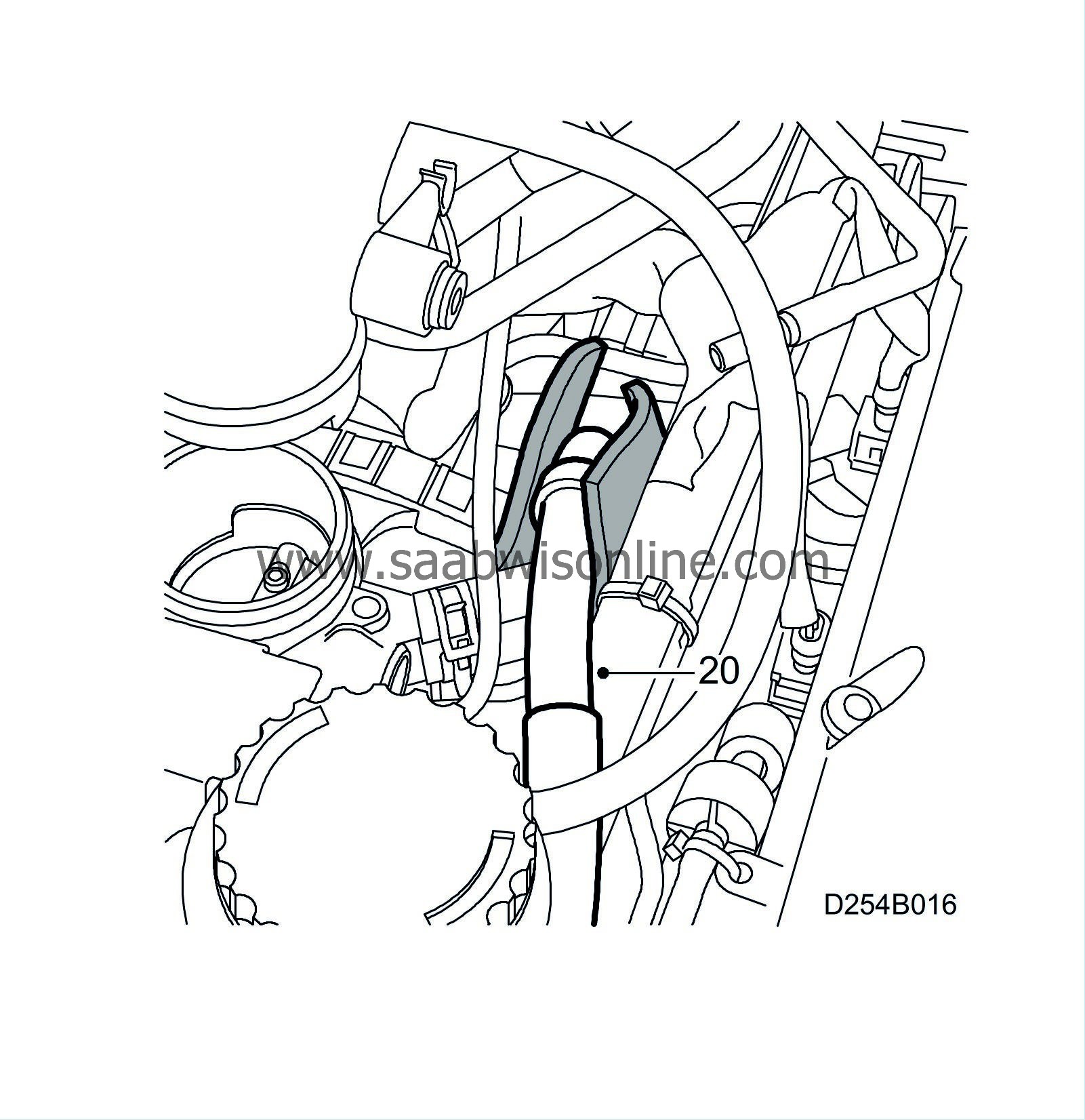

|

Install a new oil filler

pipe.

|

|

4.

|

Remove the hose from the pipe connection on the turbo's intake

manifold.

|

|

5.

|

Remove the hoses from the nipple in the camshaft cover. Check

the condition of the hoses, replace if necessary.

|

|

6.

|

Remove the old nipple and bushing from the camshaft cover and

install the new nipple and bushing.

|

|

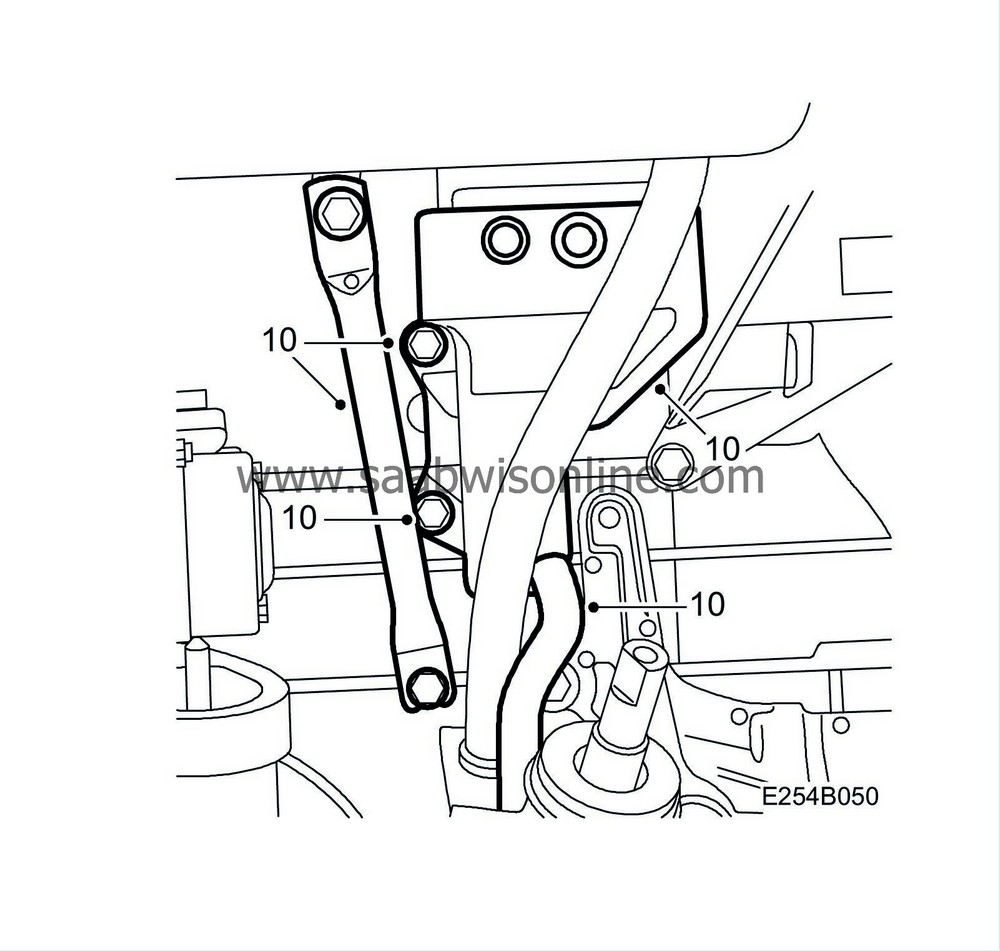

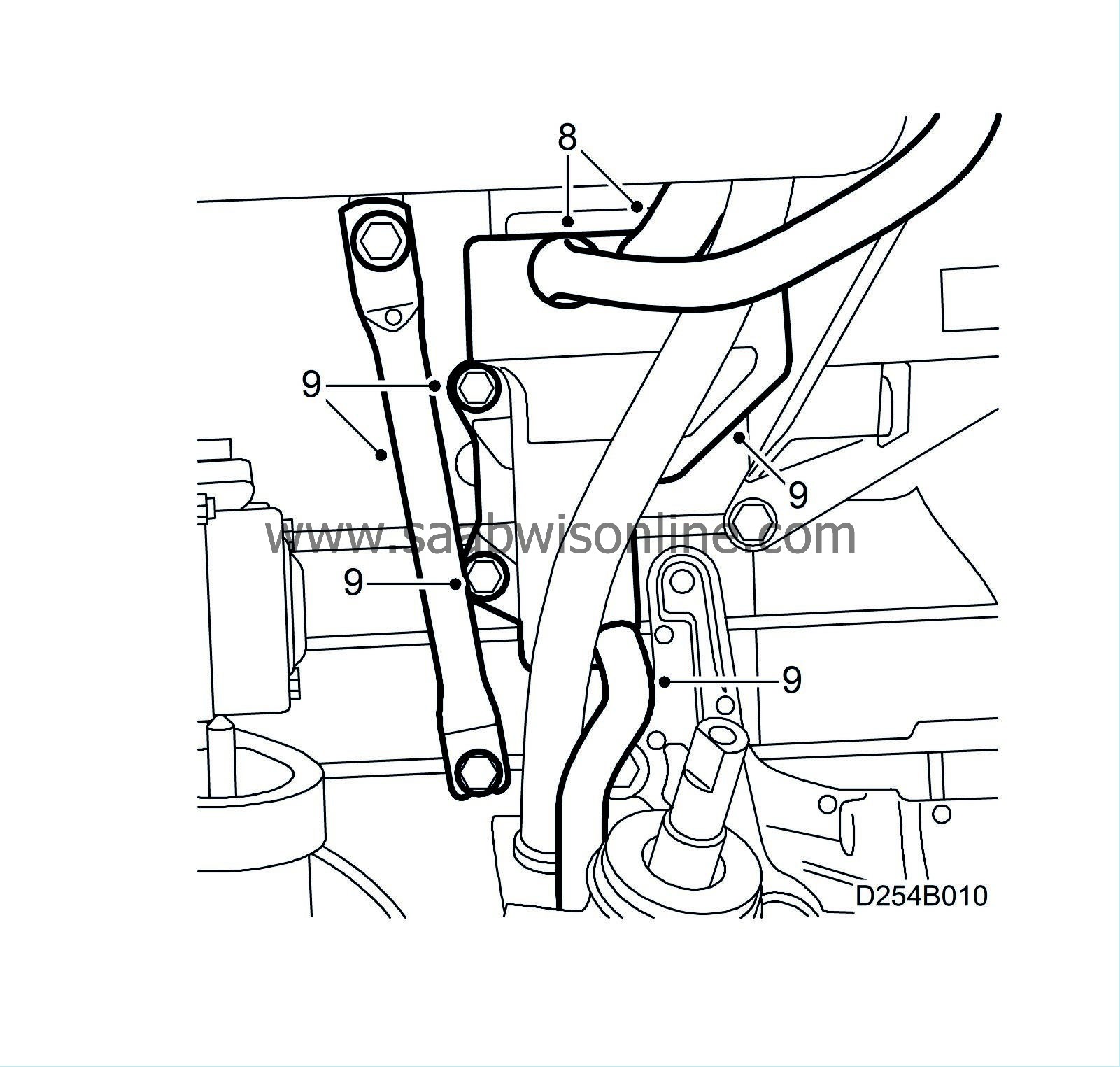

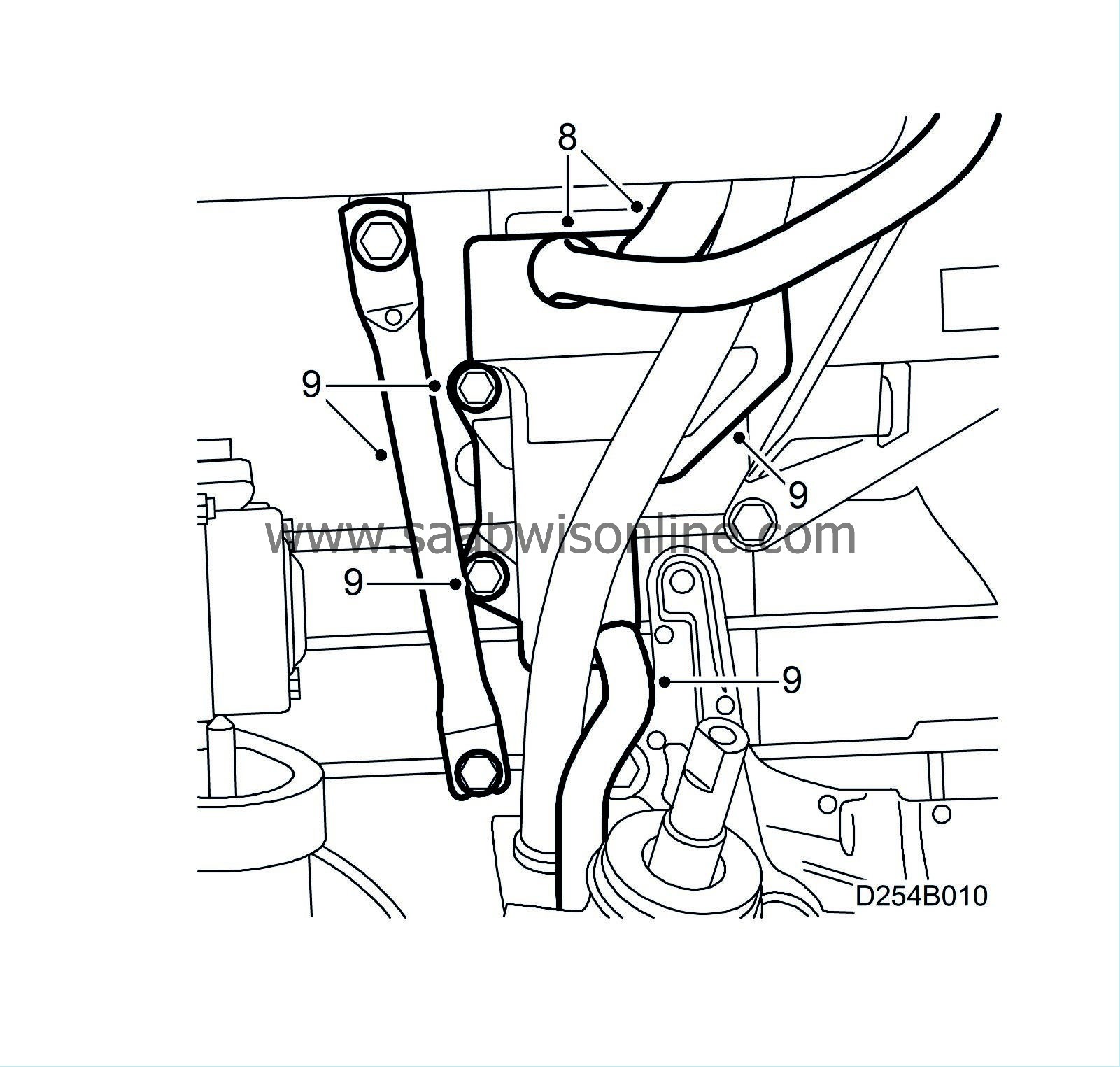

8.

|

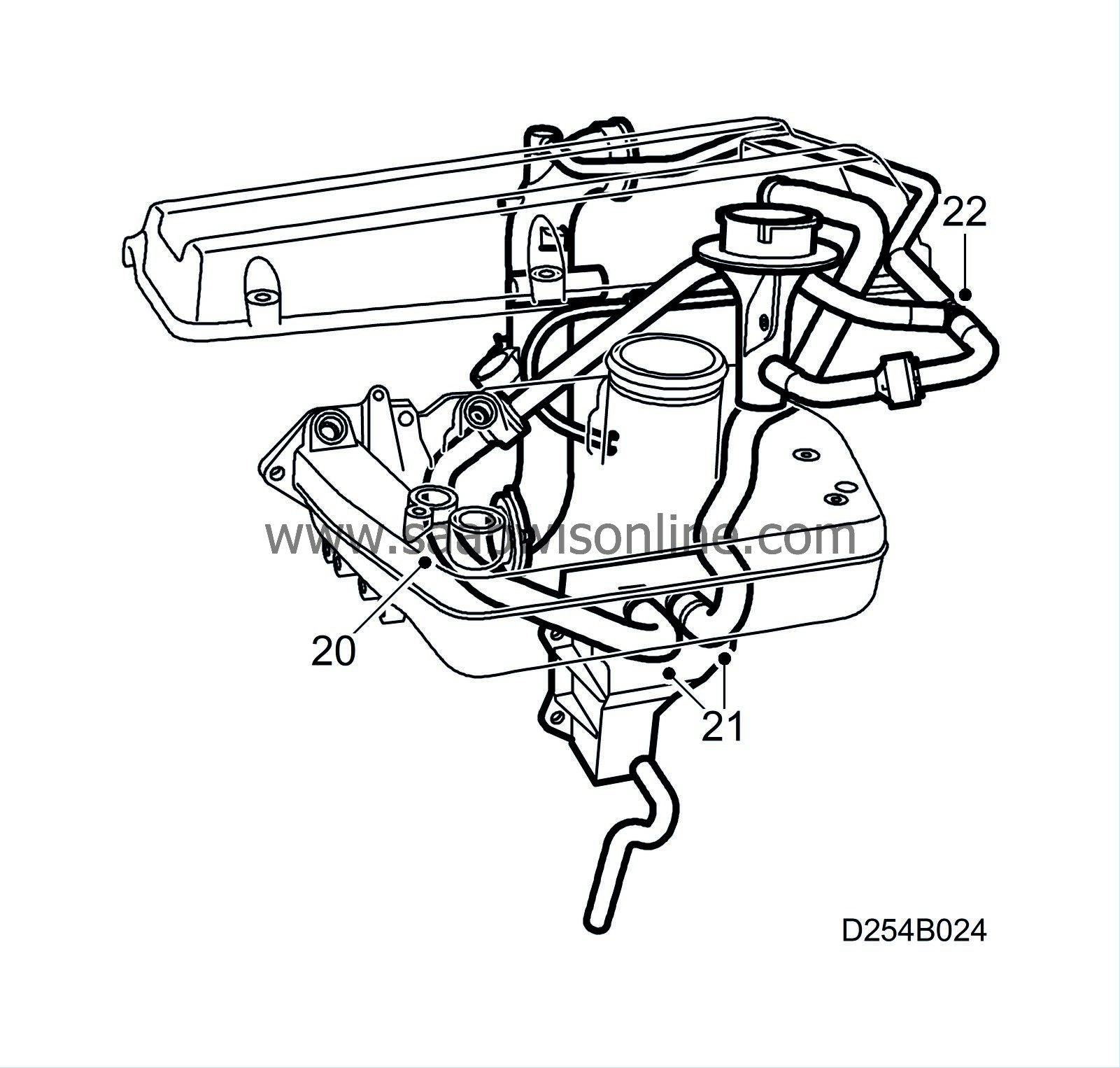

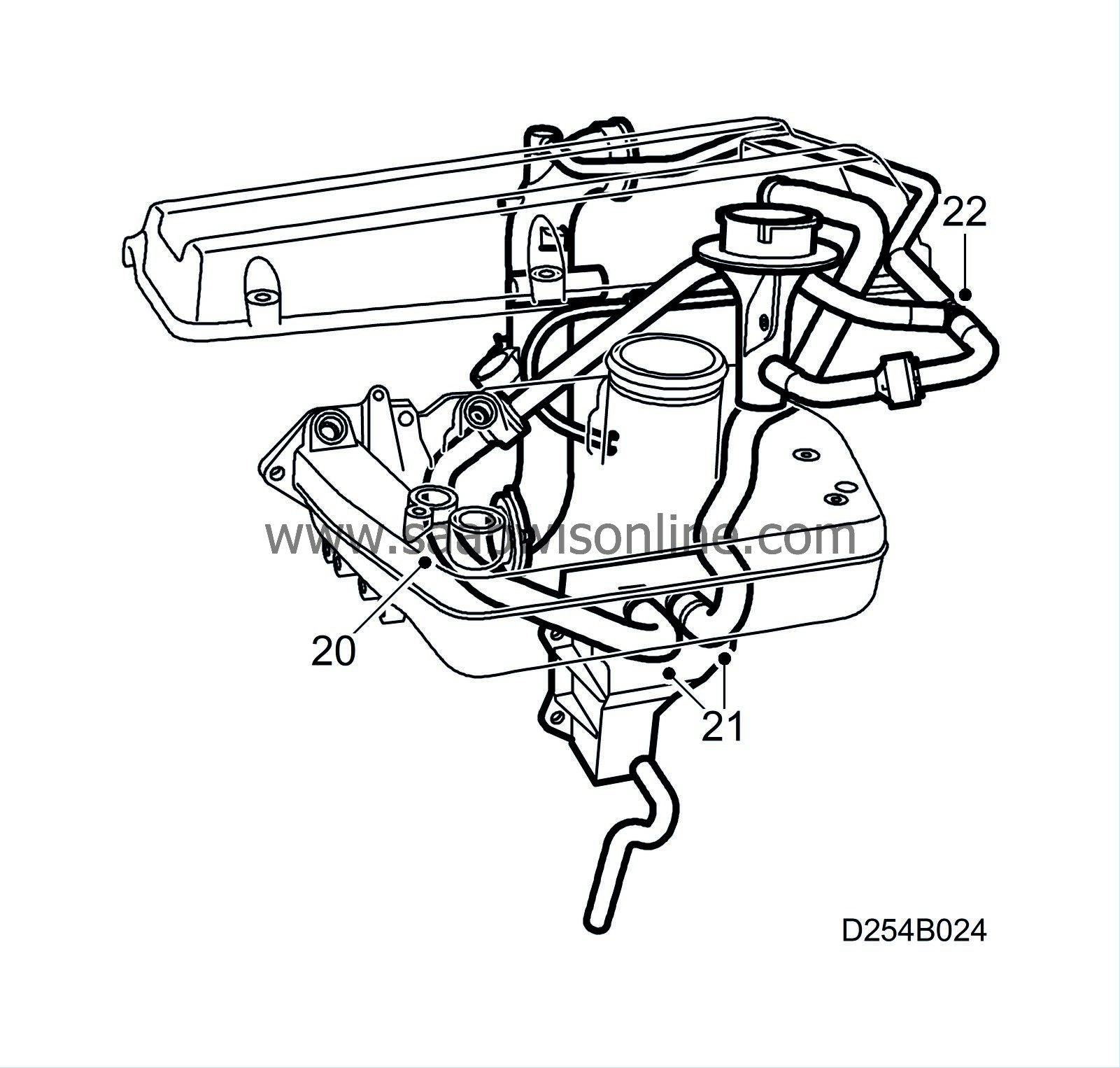

Remove the oil trap's

two upper hoses.

|

|

9.

|

Remove the lower hose to the oil trap. Remove the stay to the

intake manifold and the oil trap. If necessary, remove the generator positive

cable.

|

|

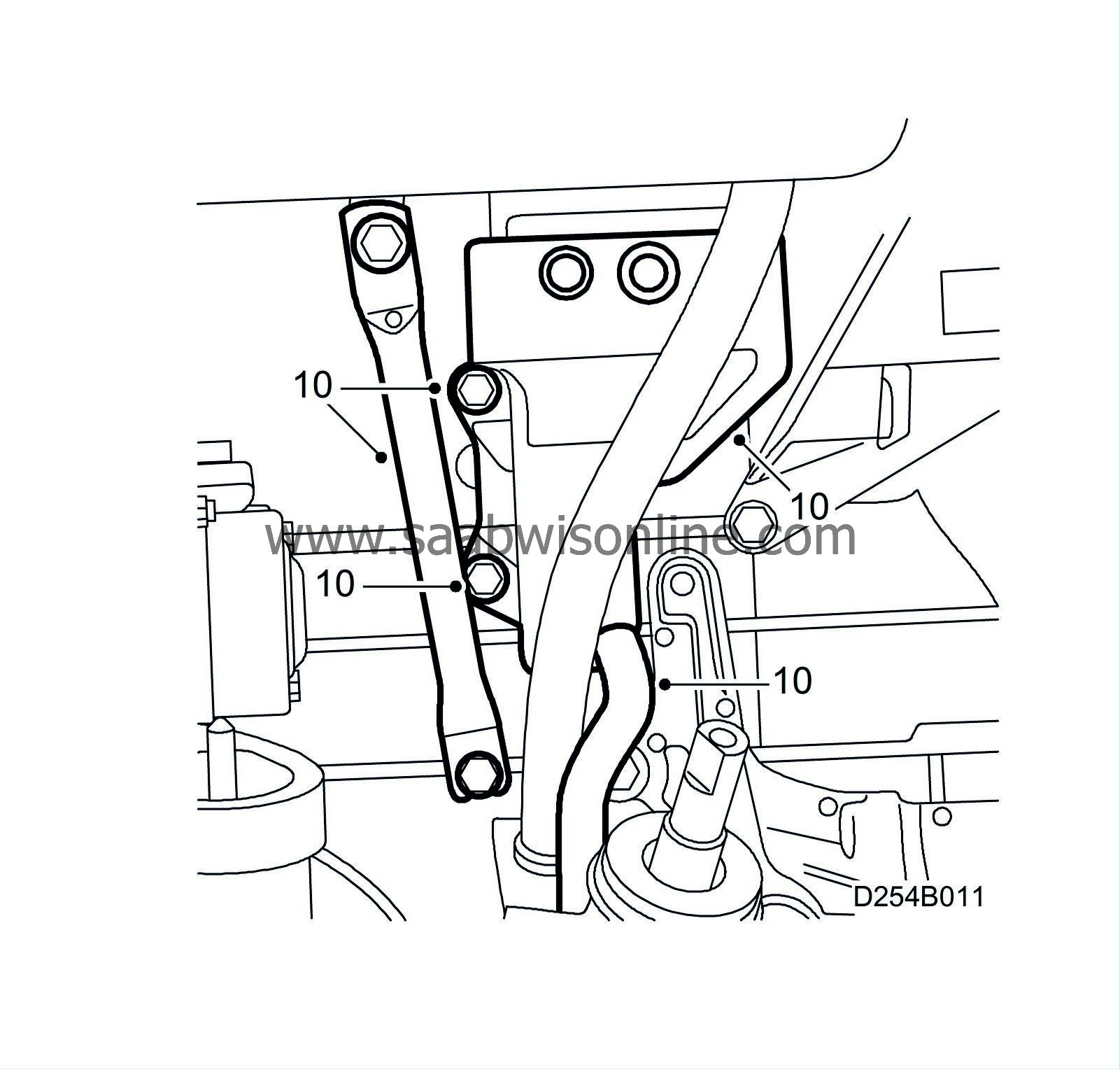

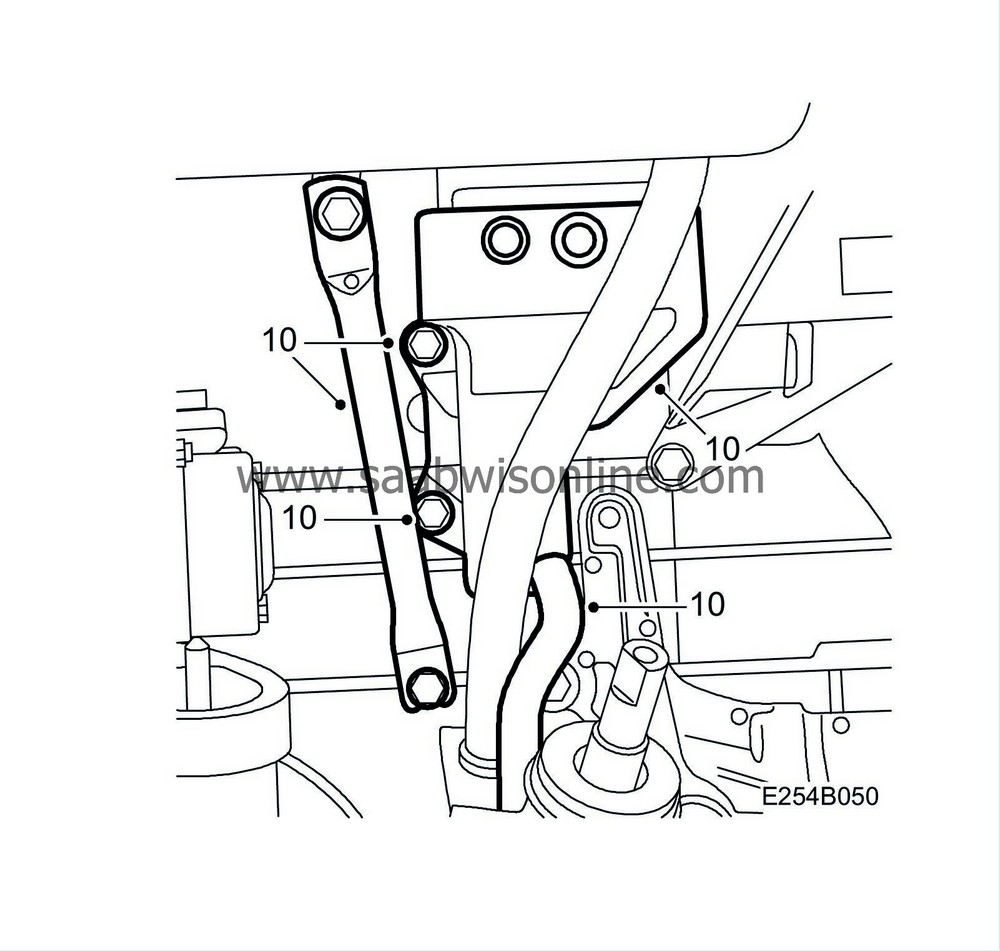

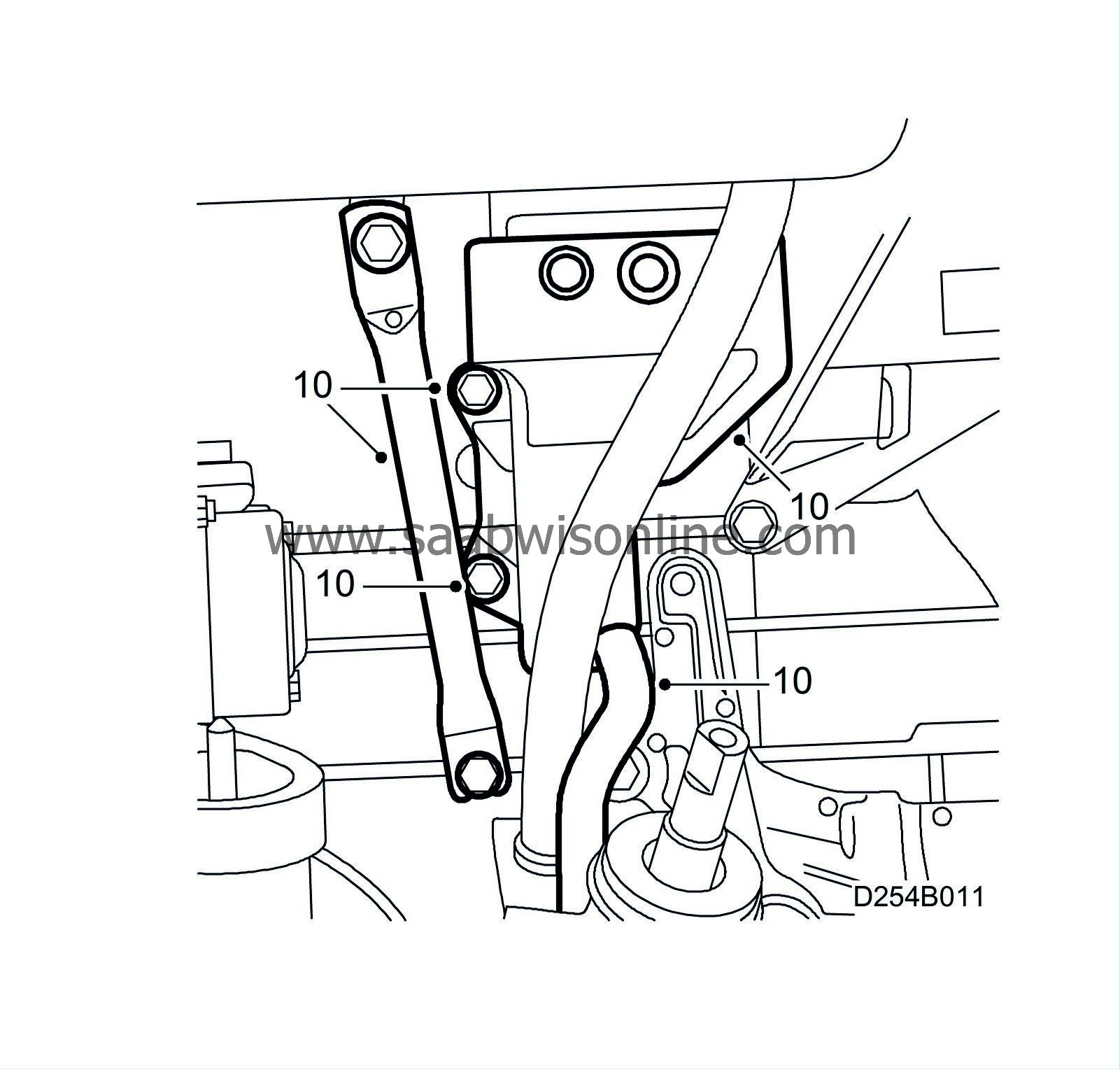

10.

|

Install the new oil trap,

the lower hose to the oil trap (replace hose if necessary) and the stay for

the intake manifold. If the positive cable was removed, connect it to the

generator.

|

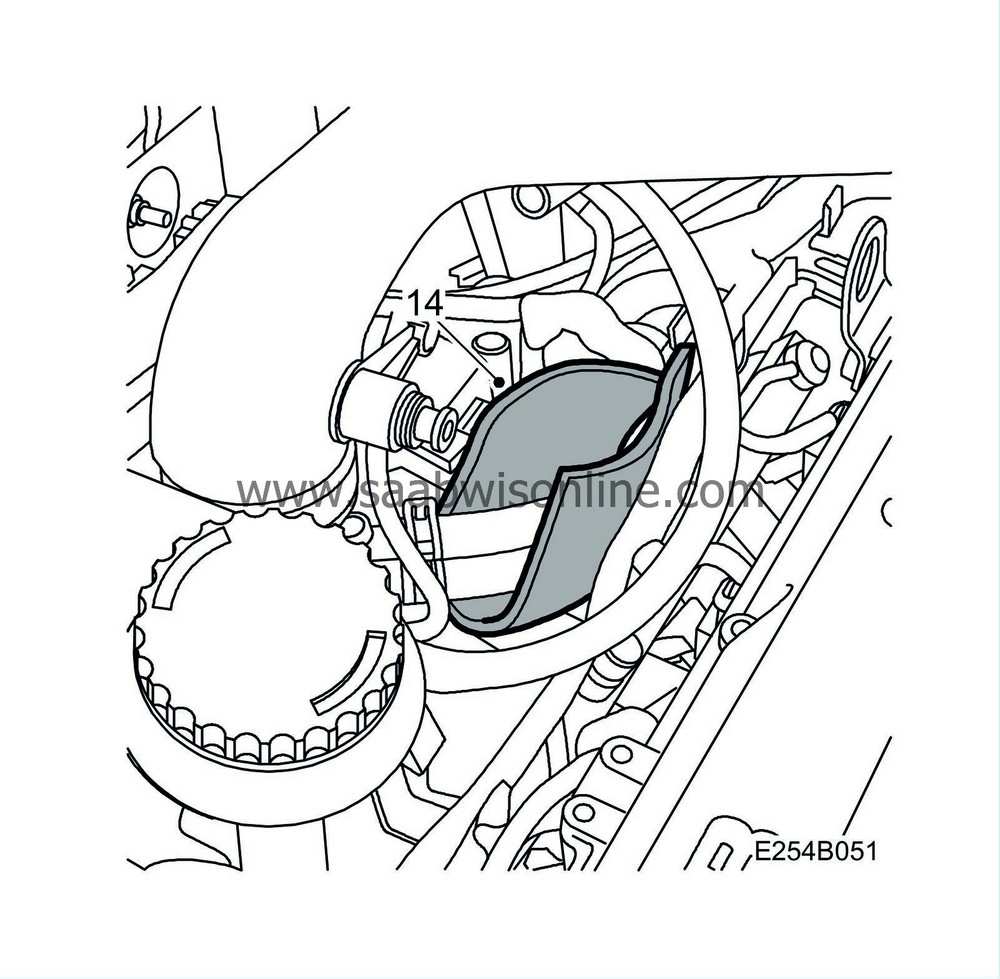

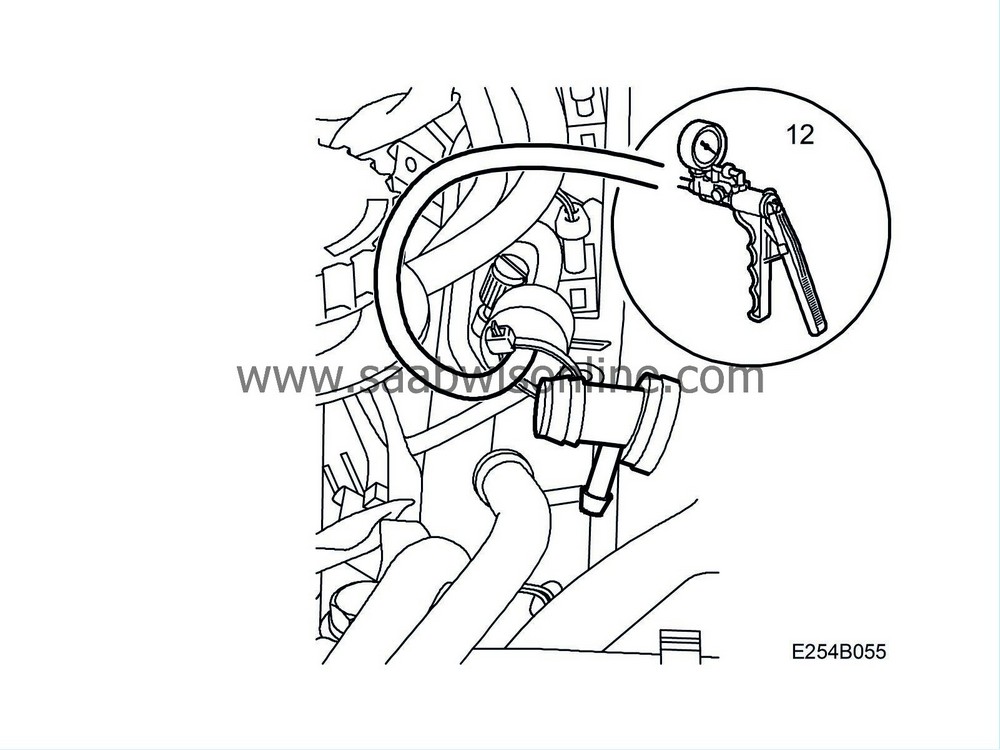

|

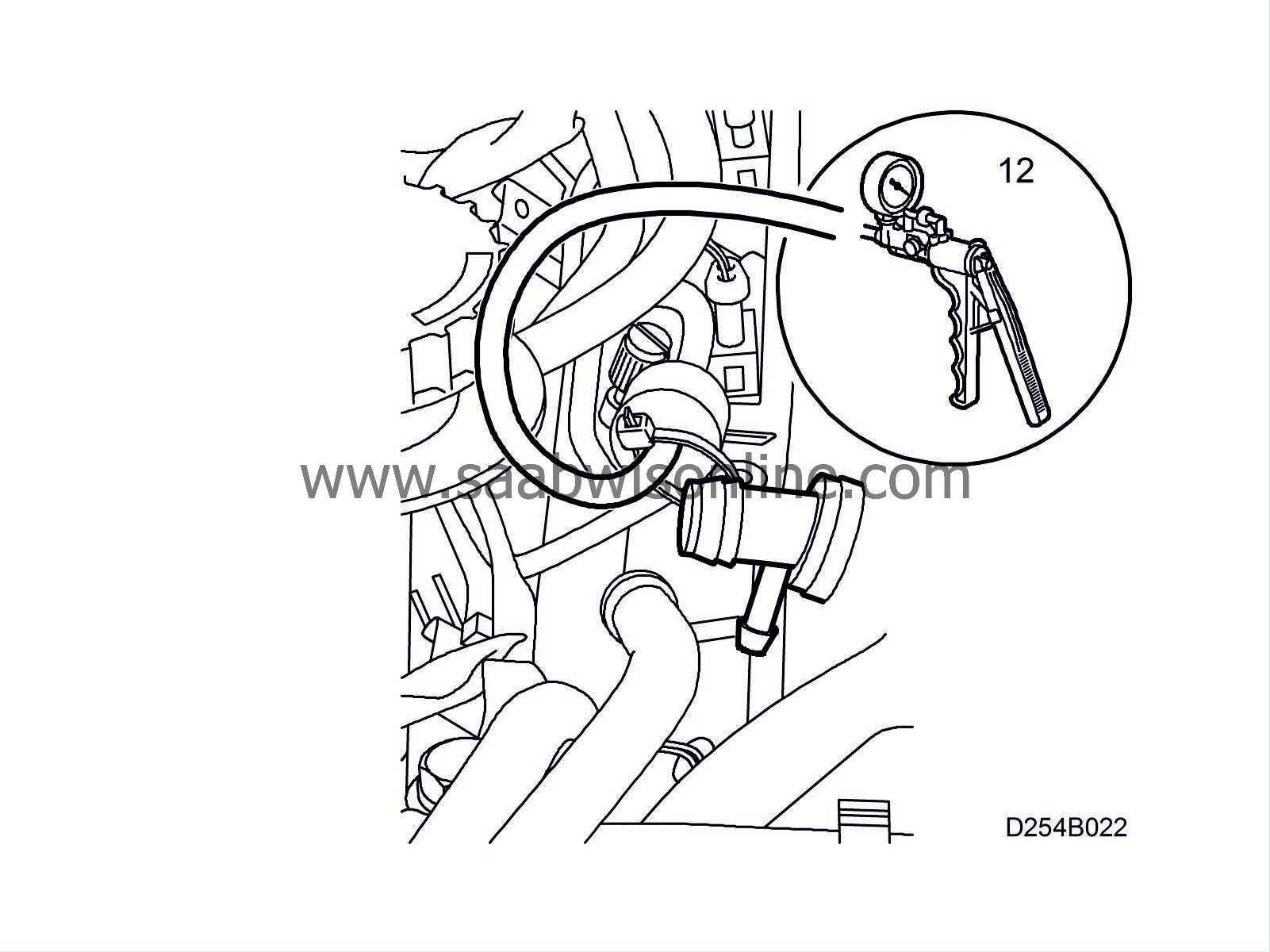

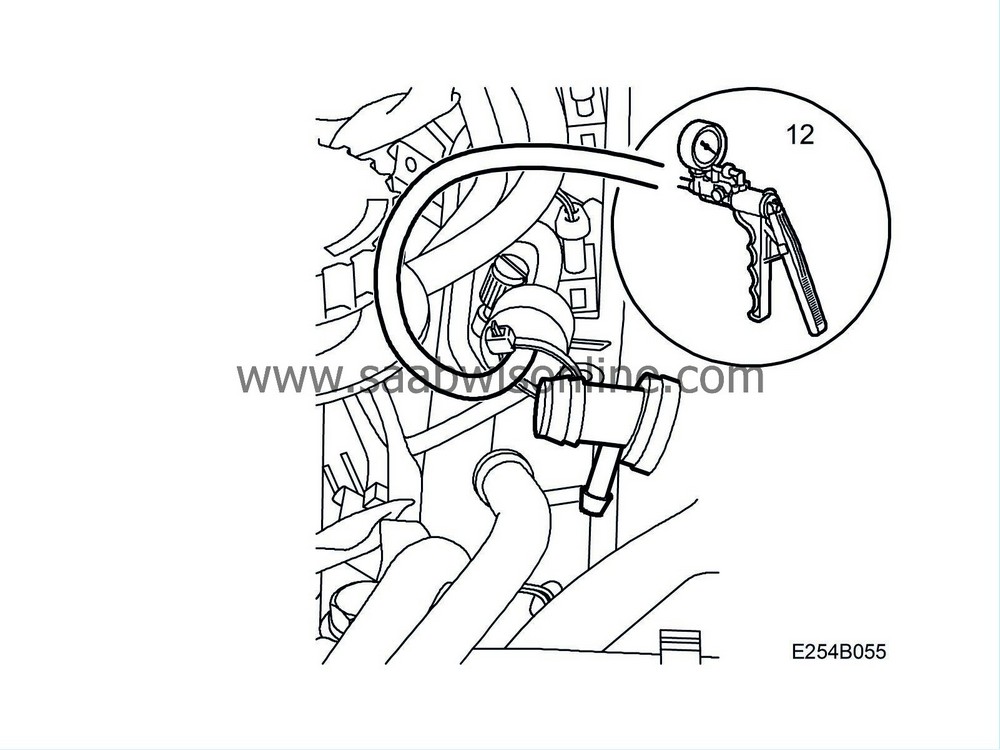

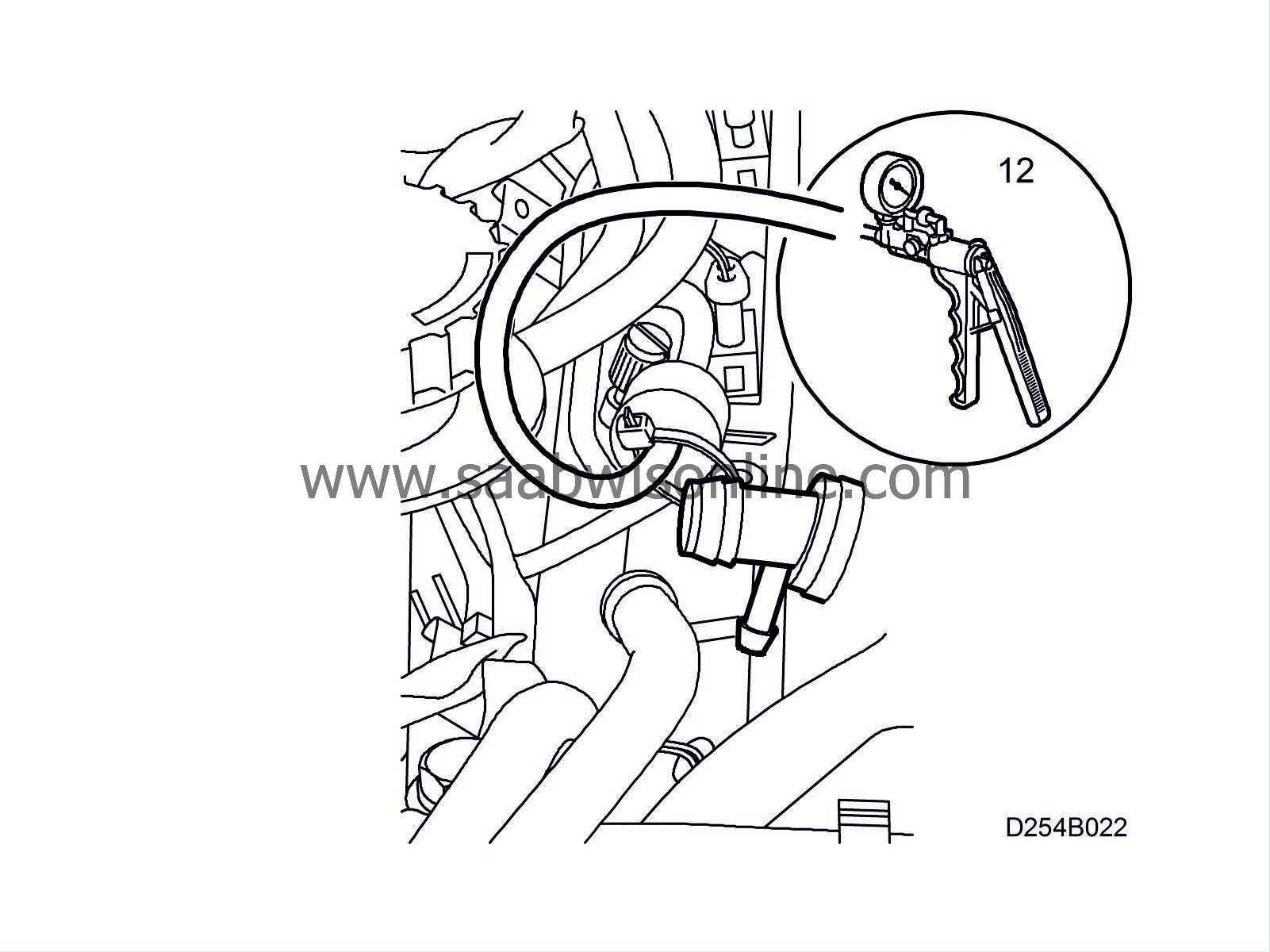

12.

|

Check the function of

the check valve on the small circuit with 30 14 883 Pressure/Vacuum pump,

replace if necessary. The arrow must point toward the throttle body.

|

Note

|

|

Arrow's direction on the check valve.

|

|

|

13.

|

Connect the new hose

kit (with T-connection) between the nipple on the oil filler pipe and the

connection on the turbo's intake manifold.

|

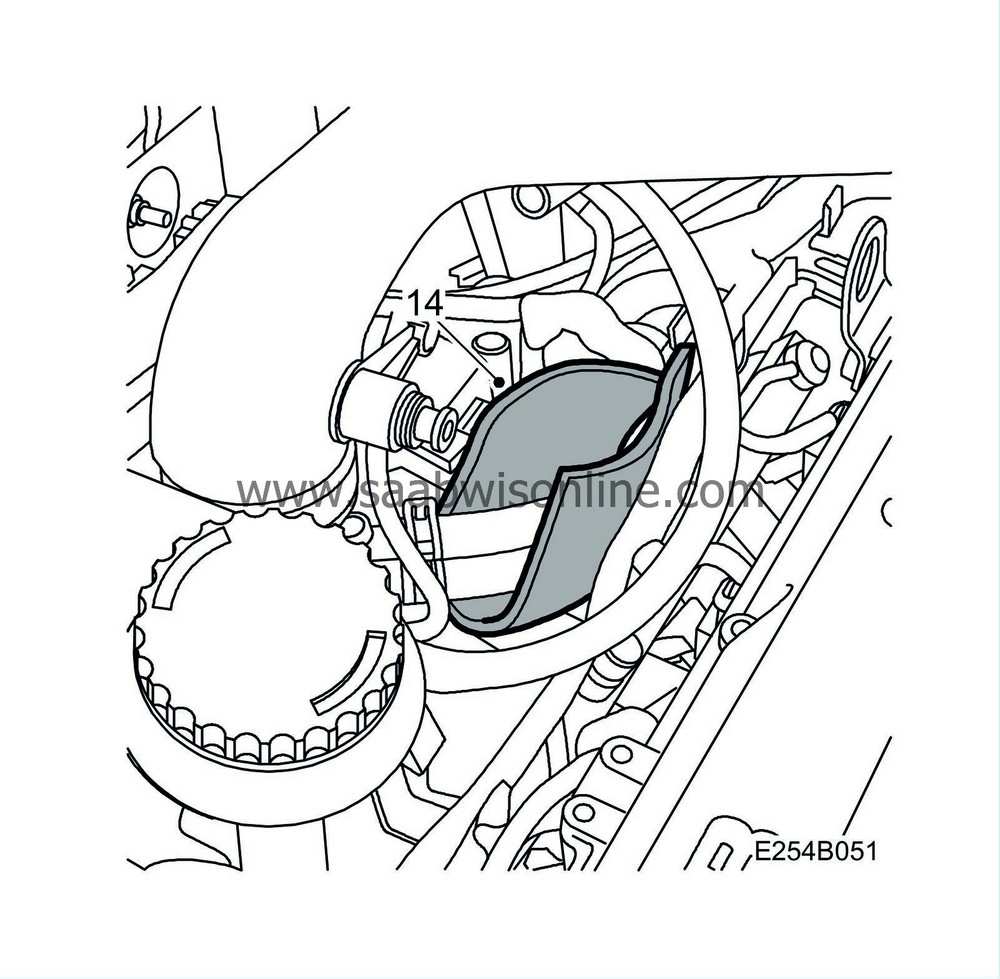

|

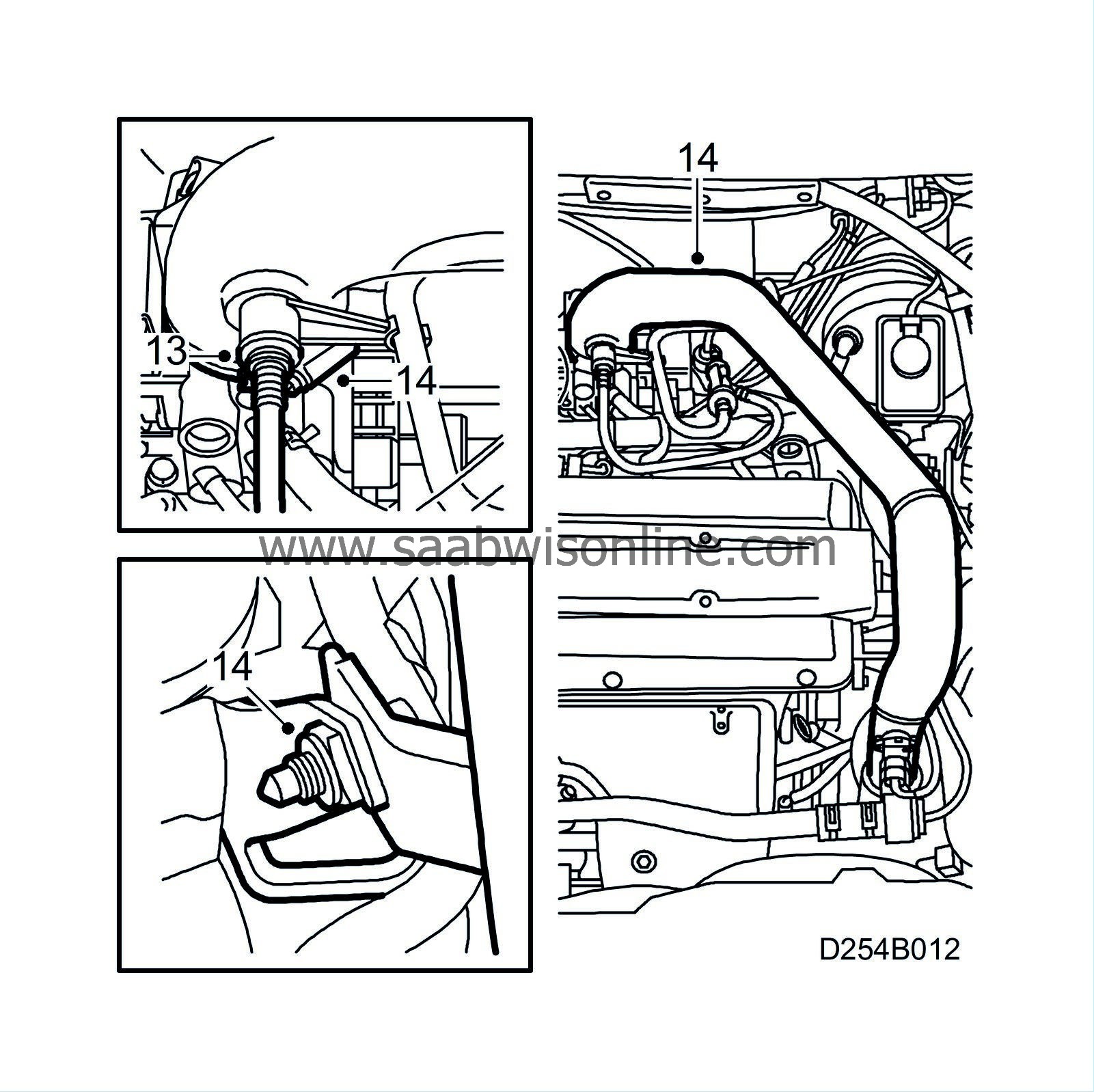

14.

|

Install the insulation

under the throttle body coolant hose so that the insulation's short sides

point upward.

|

|

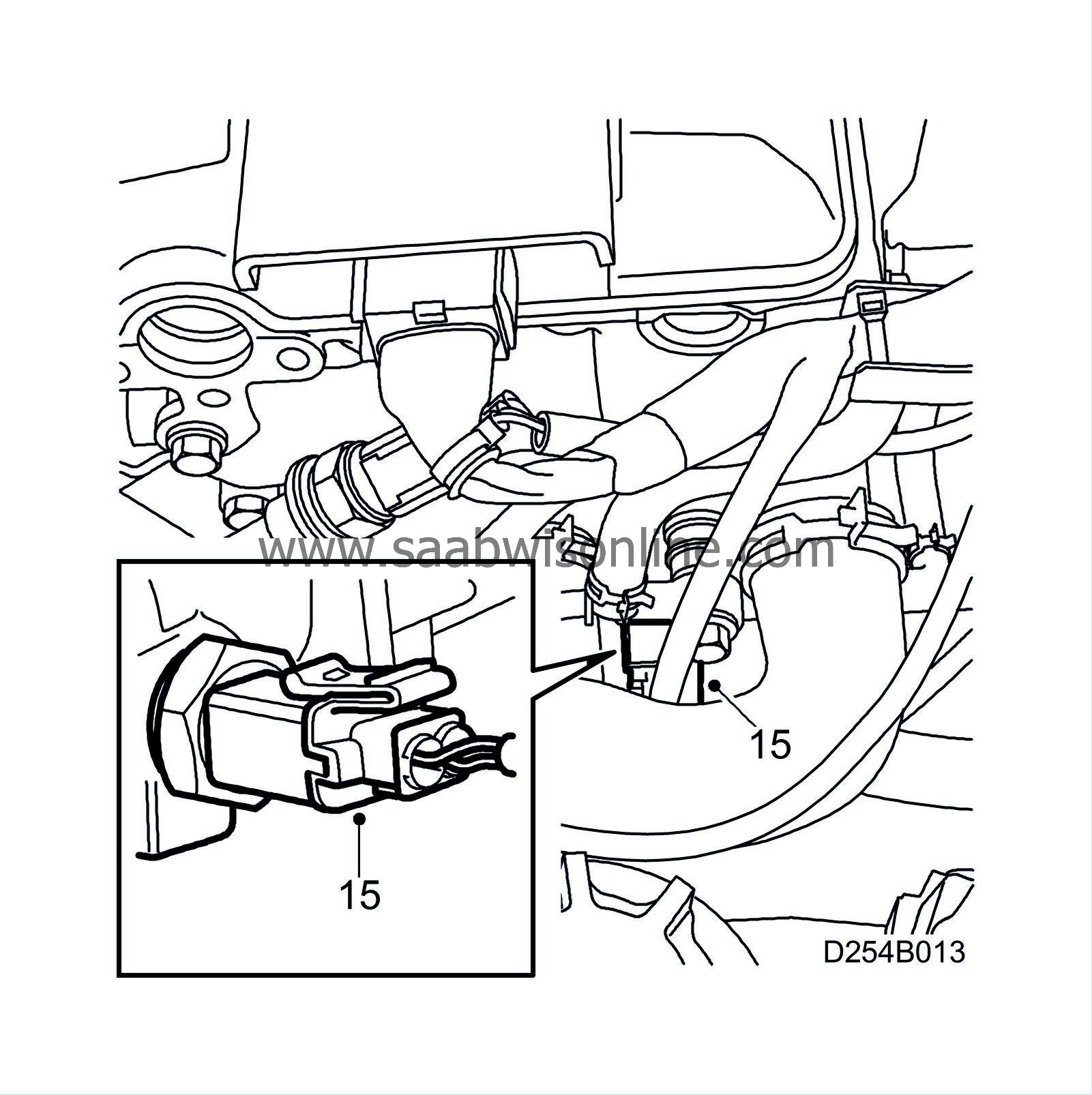

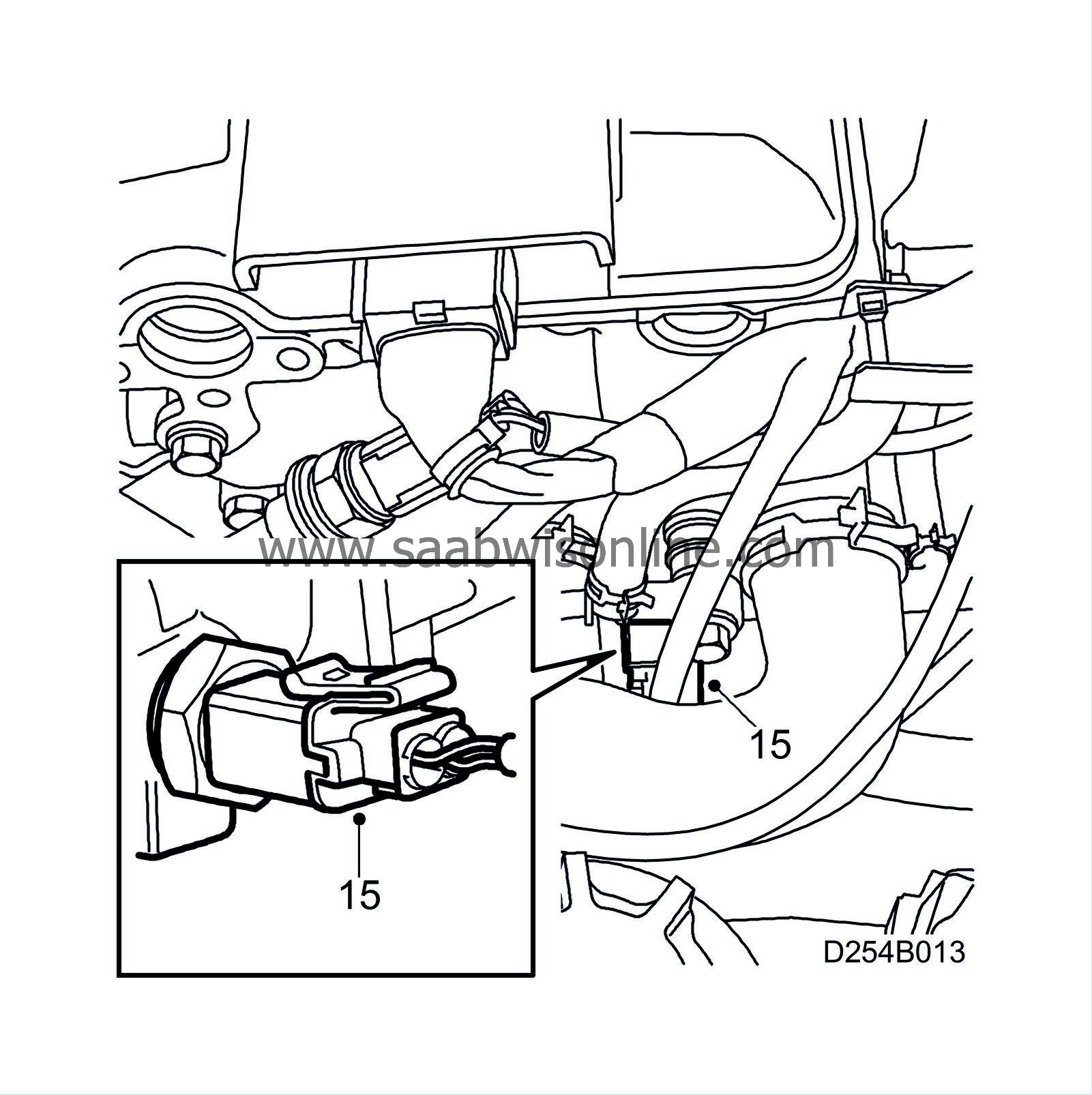

15.

|

Install the crankcase

ventilation hose so that the check valve is located above the coolant hoses.

The crankcase ventilation hose must follow the route of the lower coolant

hose through the intake manifold and then on to the oil trap.

|

|

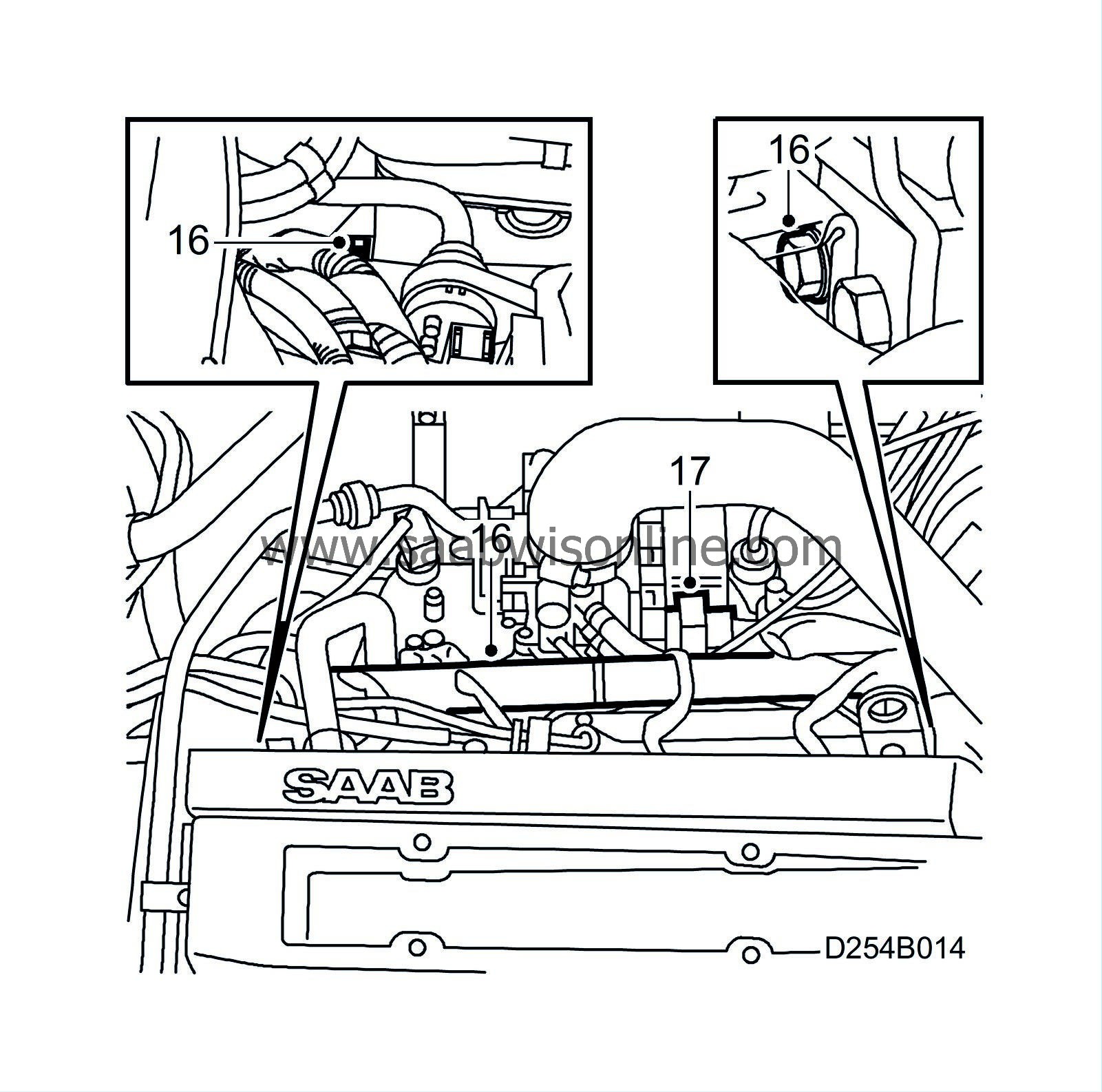

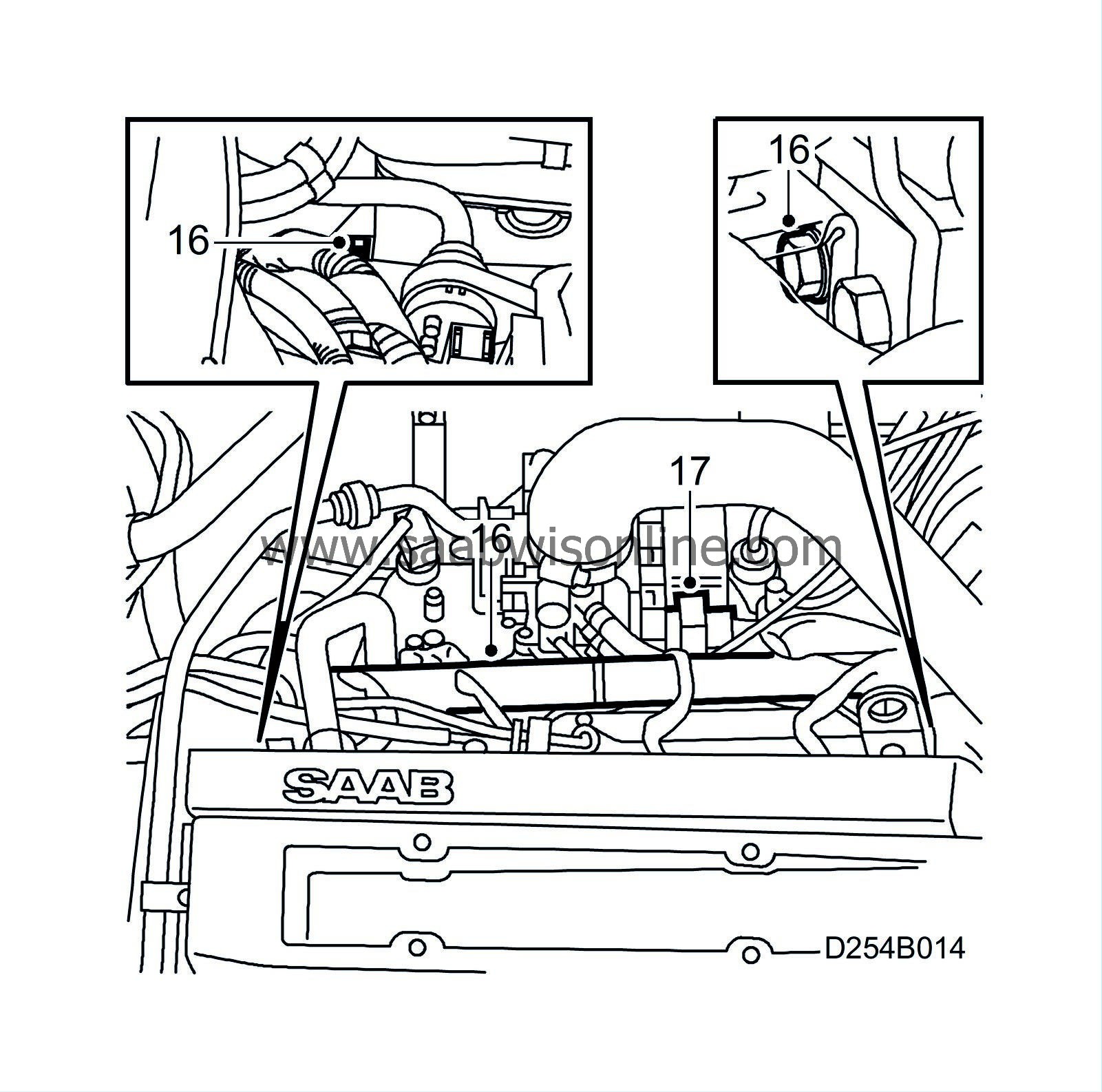

16.

|

Connect the oil trap's

upper hoses. If the hose with part no. 55 560 463 is replaced then the nipple

enclosed with the hose must not be used. Use the nipple enclosed with the

spare parts kit.

|

|

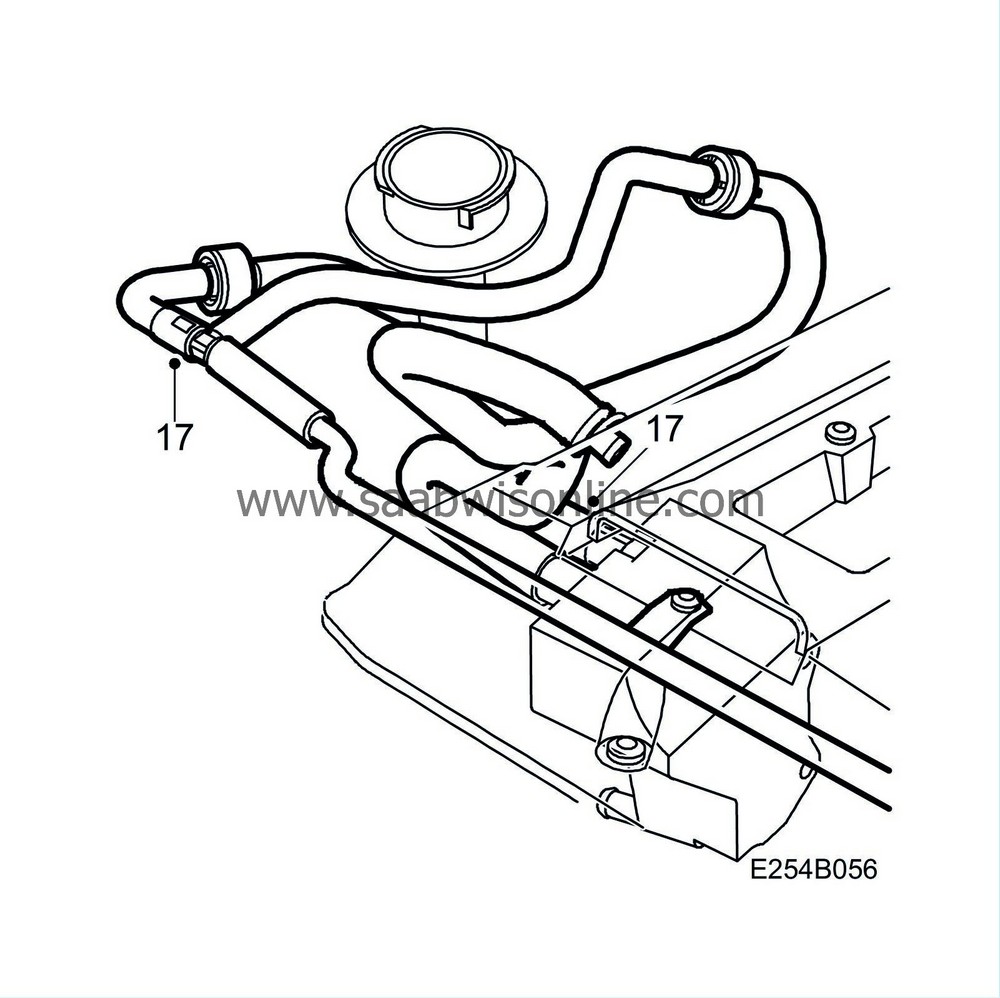

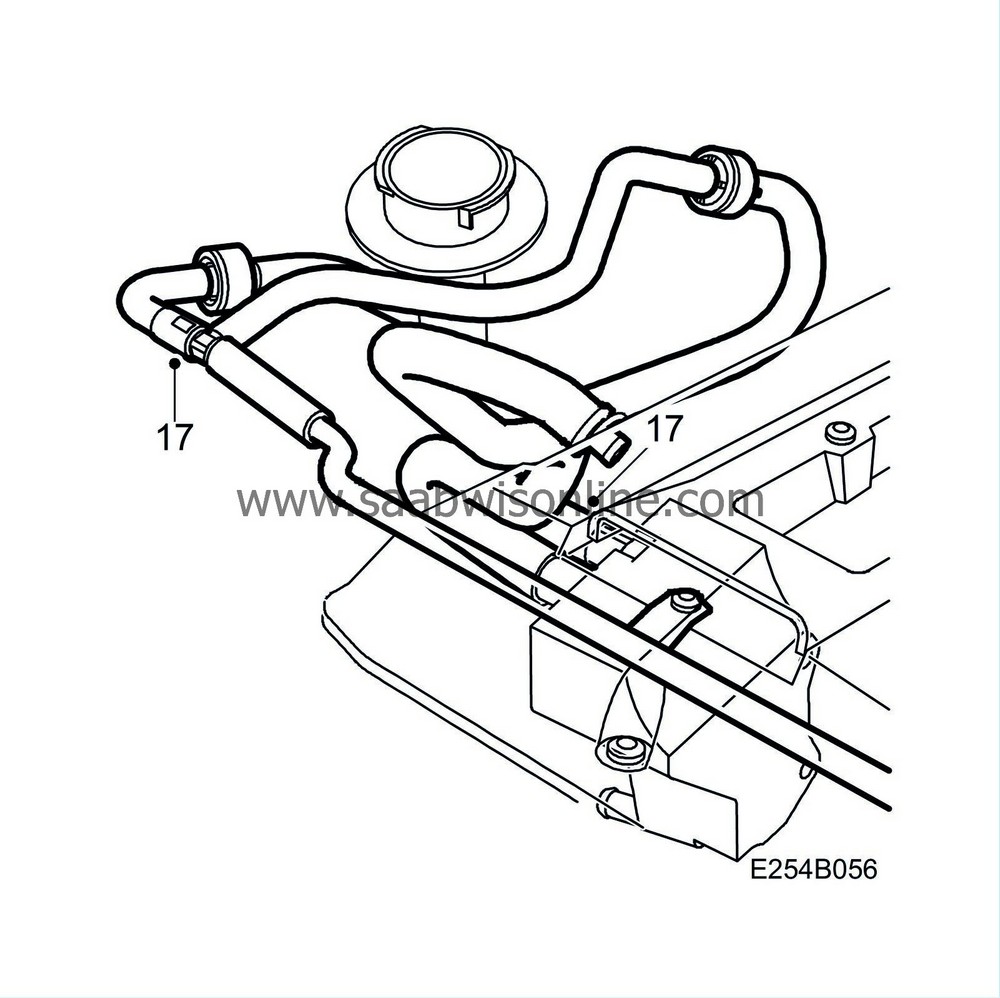

17.

|

Connect the new hose kit together at the T-connection.

|

|

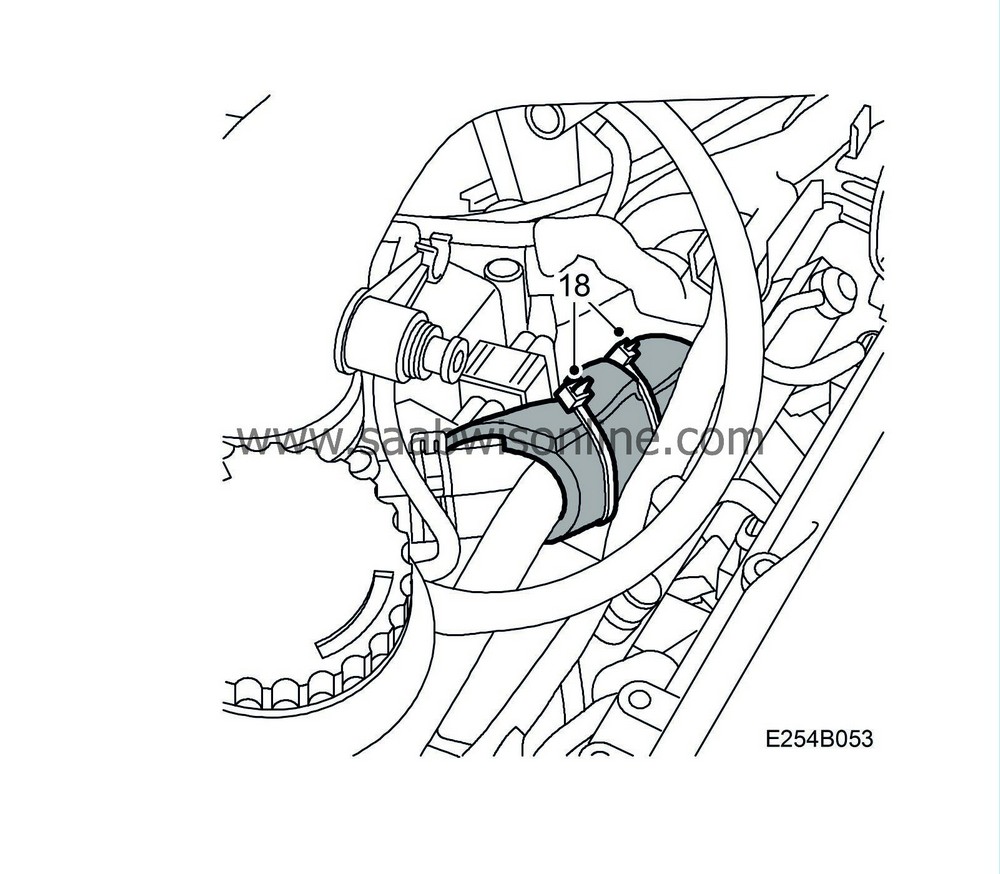

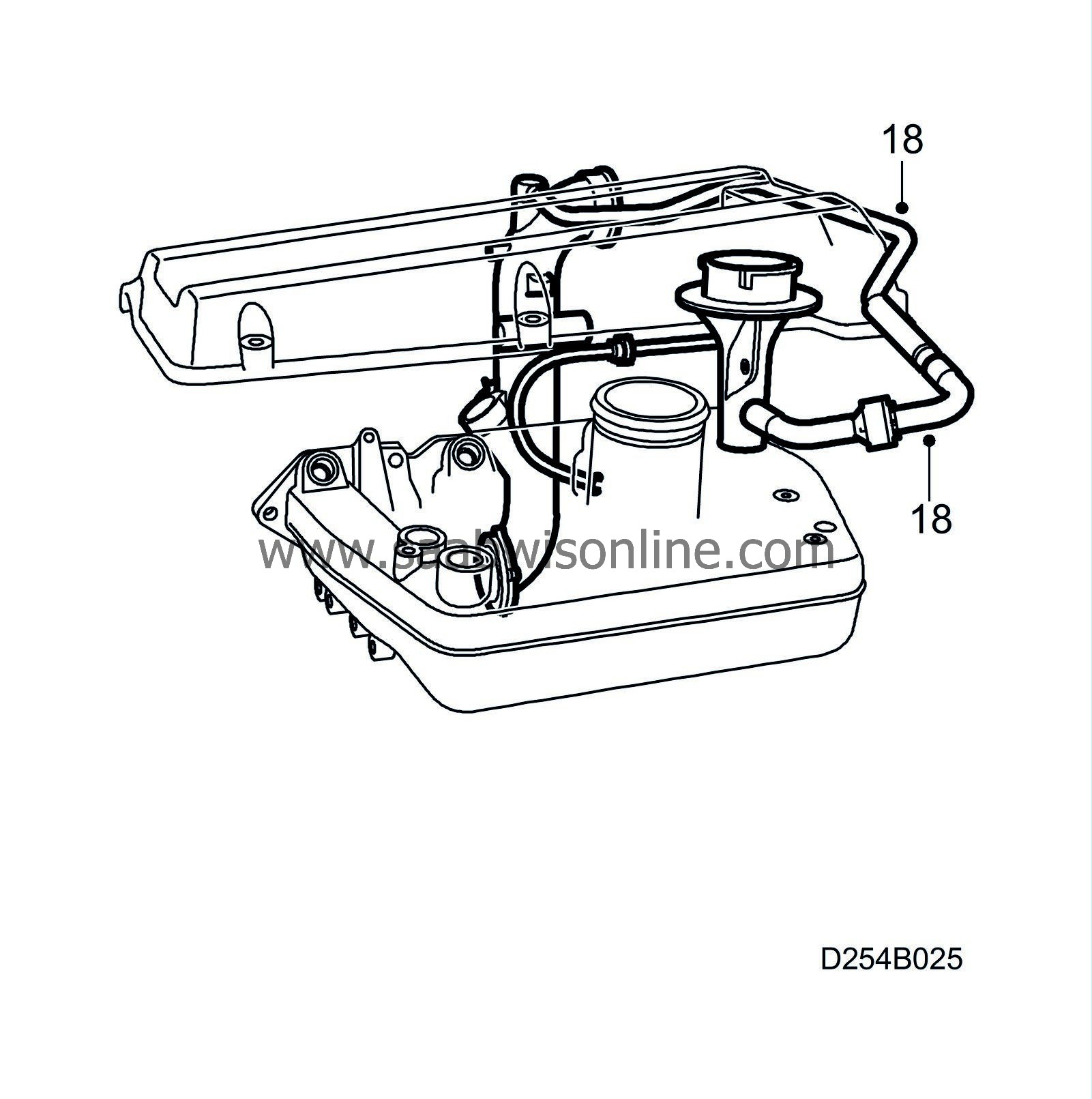

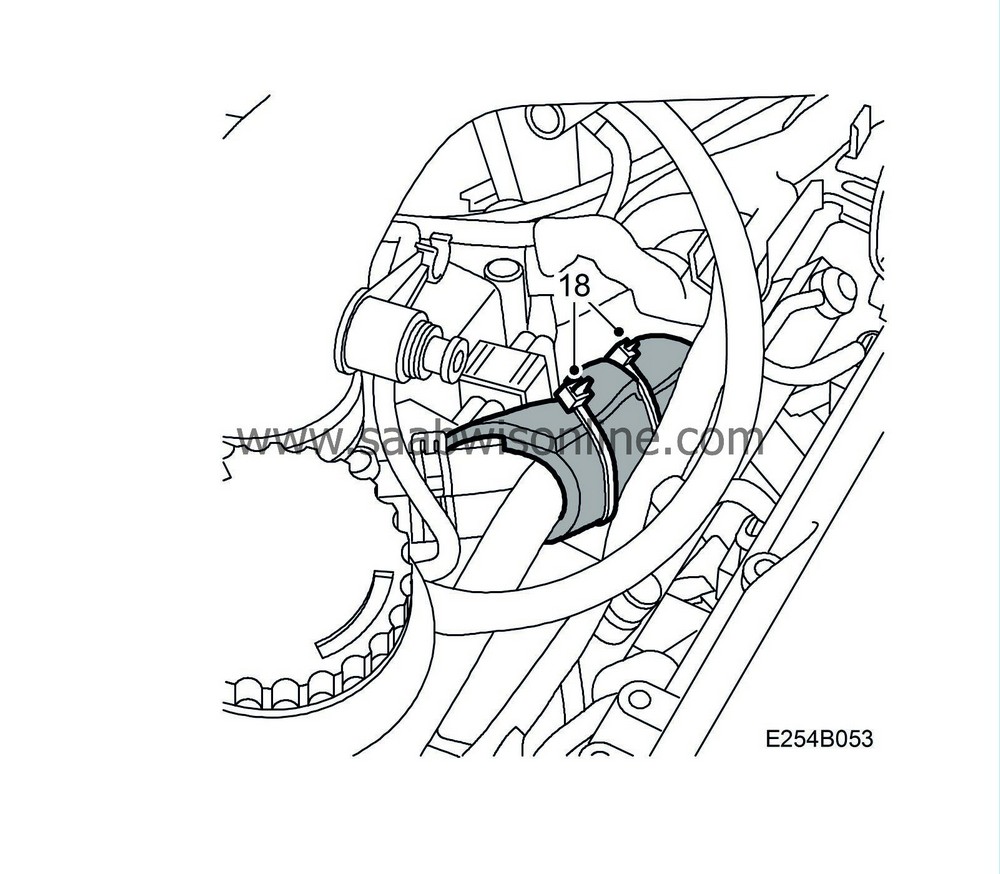

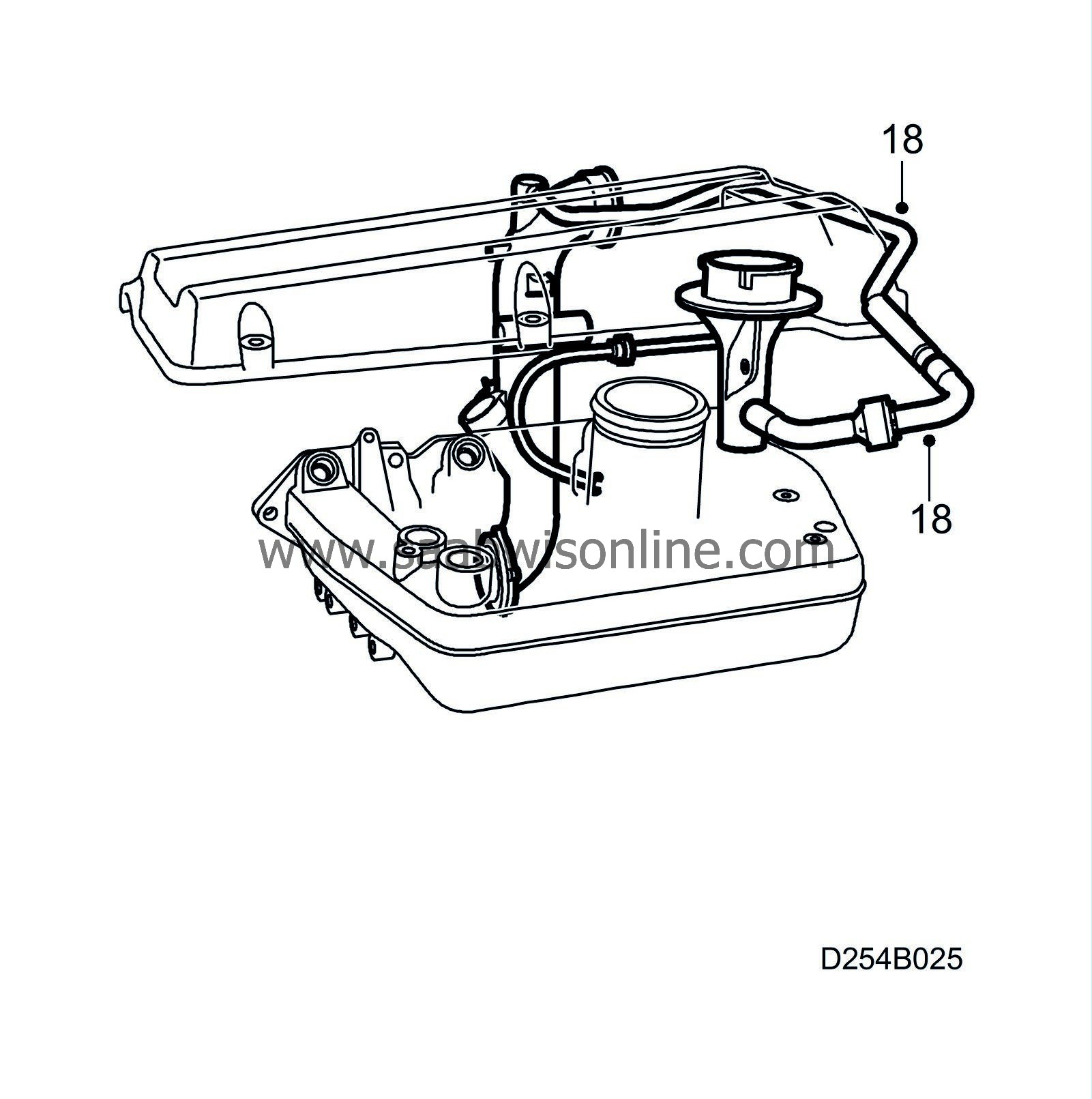

18.

|

Make sure that the check

valve has good contact with both coolant hoses. Affix a cable tie around the

insulation on each side of the check valve.

|

|

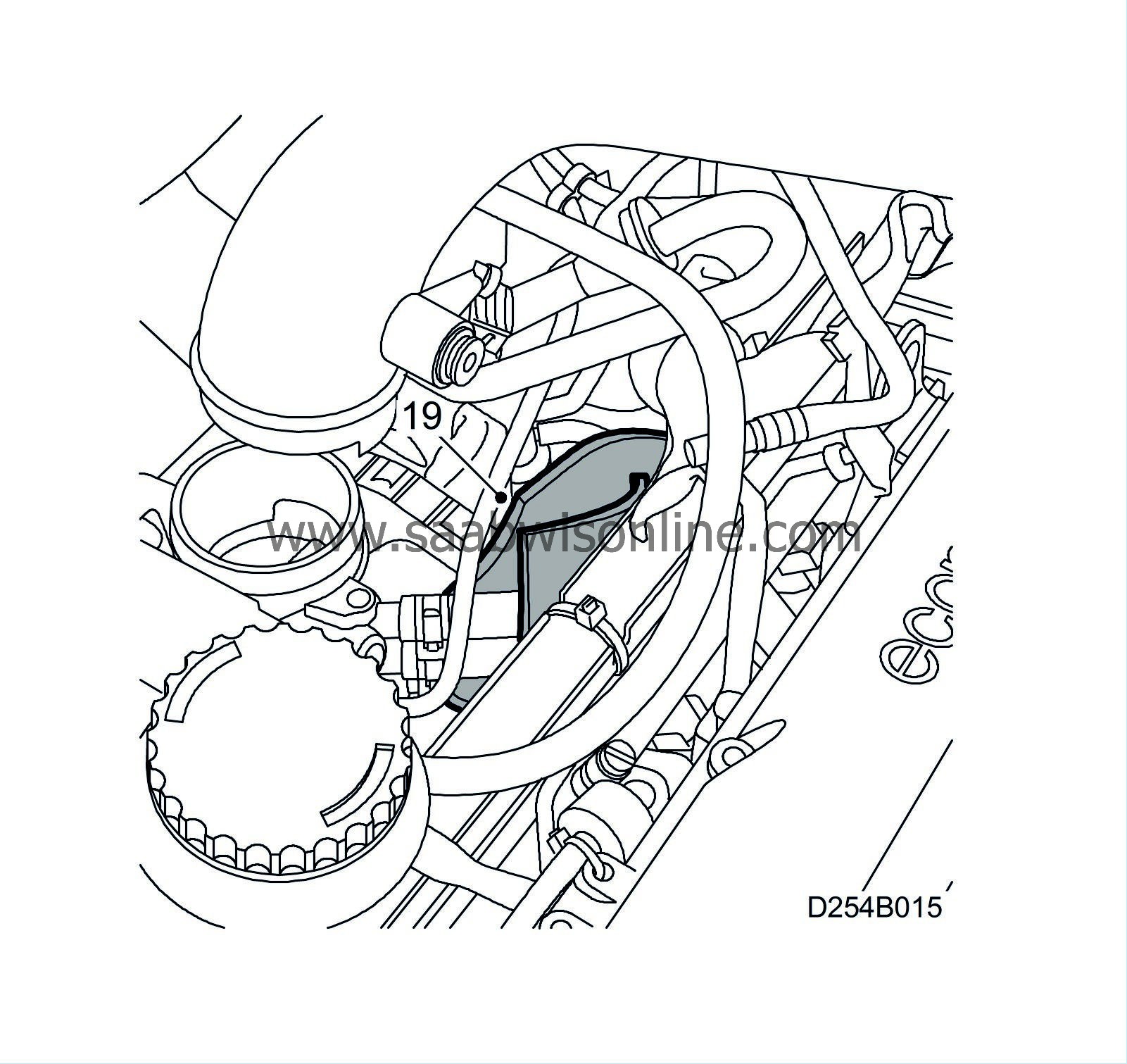

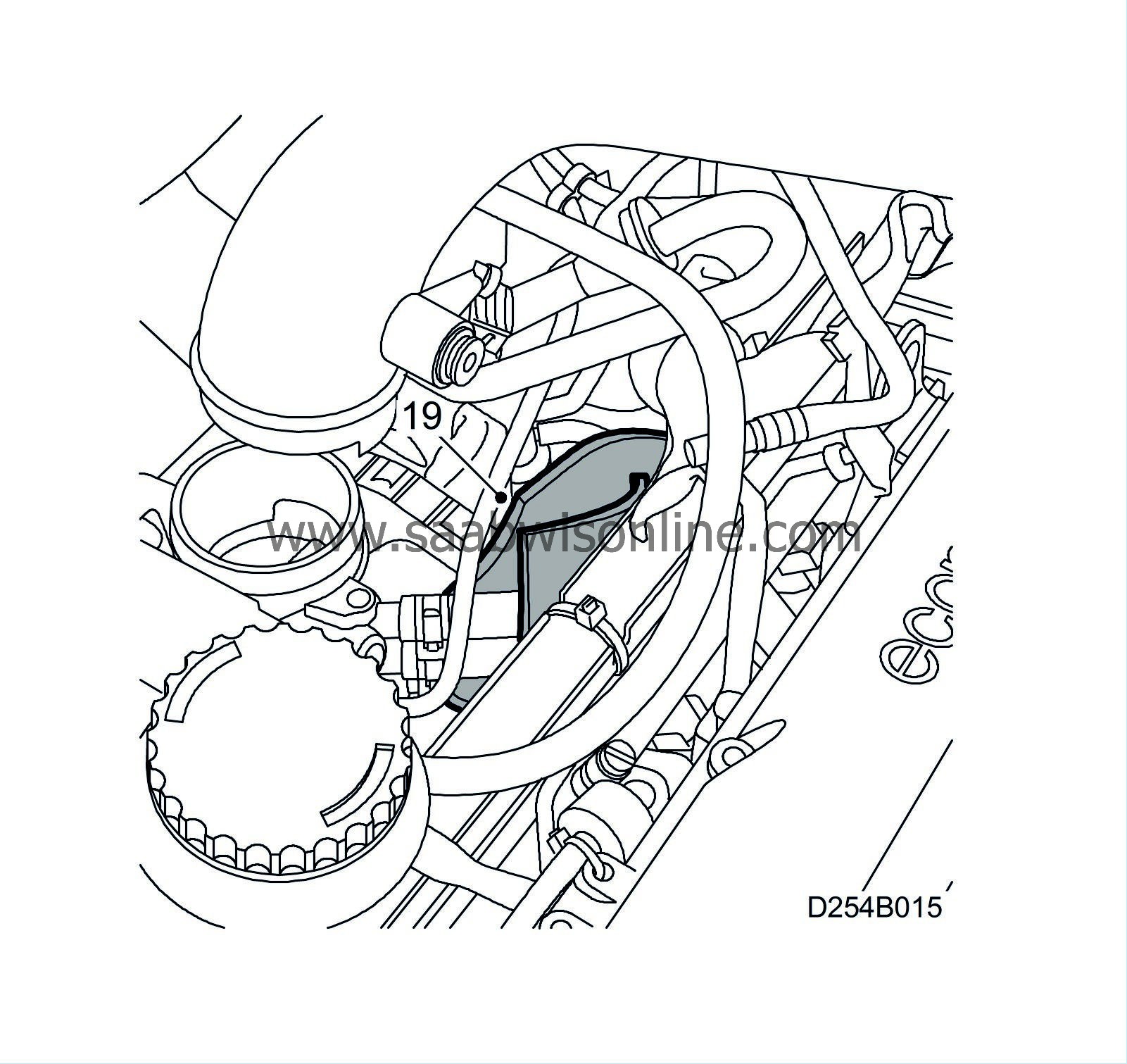

19.

|

Connect the hoses to the nipple on the camshaft cover.

|

|

20.

|

Install the upper engine cover.

|

|

21.

|

Connect the cable to the battery's negative terminal.

|

|

22.

|

Set the correct time and date in SID.

|

|

Fitting Renovation kit, crankcase ventilation, Saab 9-3 (9400)

|

|

1.

|

Disconnect the battery's negative cable.

|

|

2.

|

Remove the upper engine cover.

|

|

3.

|

Install a new oil filler

pipe.

|

|

4.

|

Remove the hose from the pipe connection on the turbo's intake

manifold.

|

|

5.

|

Remove the hoses from the nipple in the camshaft cover. Check

the condition of the hoses, replace if necessary.

|

|

6.

|

Remove the old nipple and bushing from the camshaft cover and

install the new nipple and bushing.

|

|

8.

|

Remove the oil trap's

two upper hoses.

|

|

9.

|

Remove the lower hose to the oil trap. Remove the stay to the

intake manifold and the oil trap. If necessary, remove the generator positive

cable.

|

|

10.

|

Install the new oil trap,

the lower hose to the oil trap (replace hose if necessary) and the stay for

the intake manifold. If the positive cable was removed, connect it to the

generator.

|

|

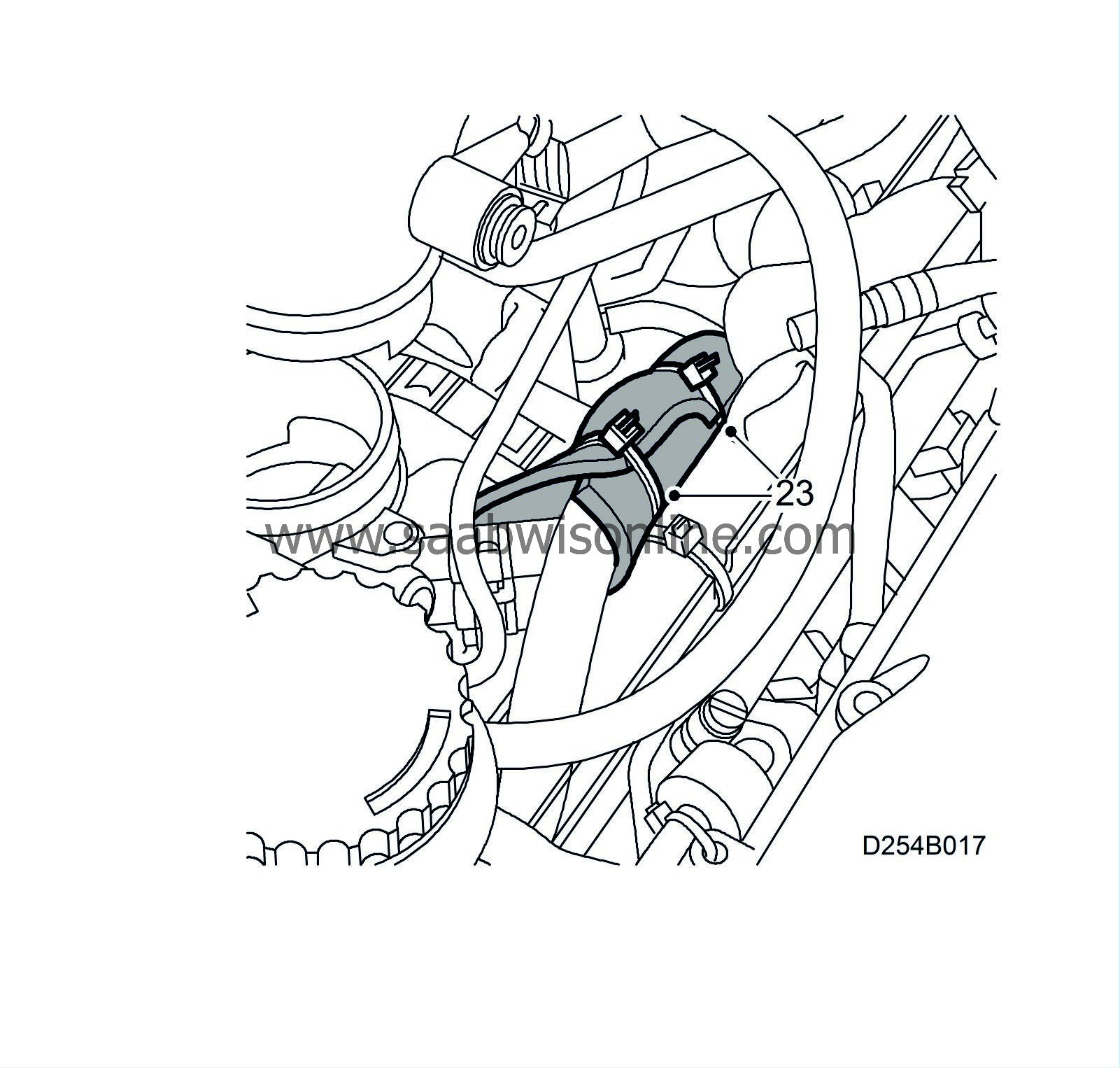

12.

|

Check the function of

the check valve on the small circuit with 30 14 883 Pressure/Vacuum pump,

replace if necessary. The arrow must point toward the throttle body.

|

Note

|

|

Arrow's direction on the check valve.

|

|

|

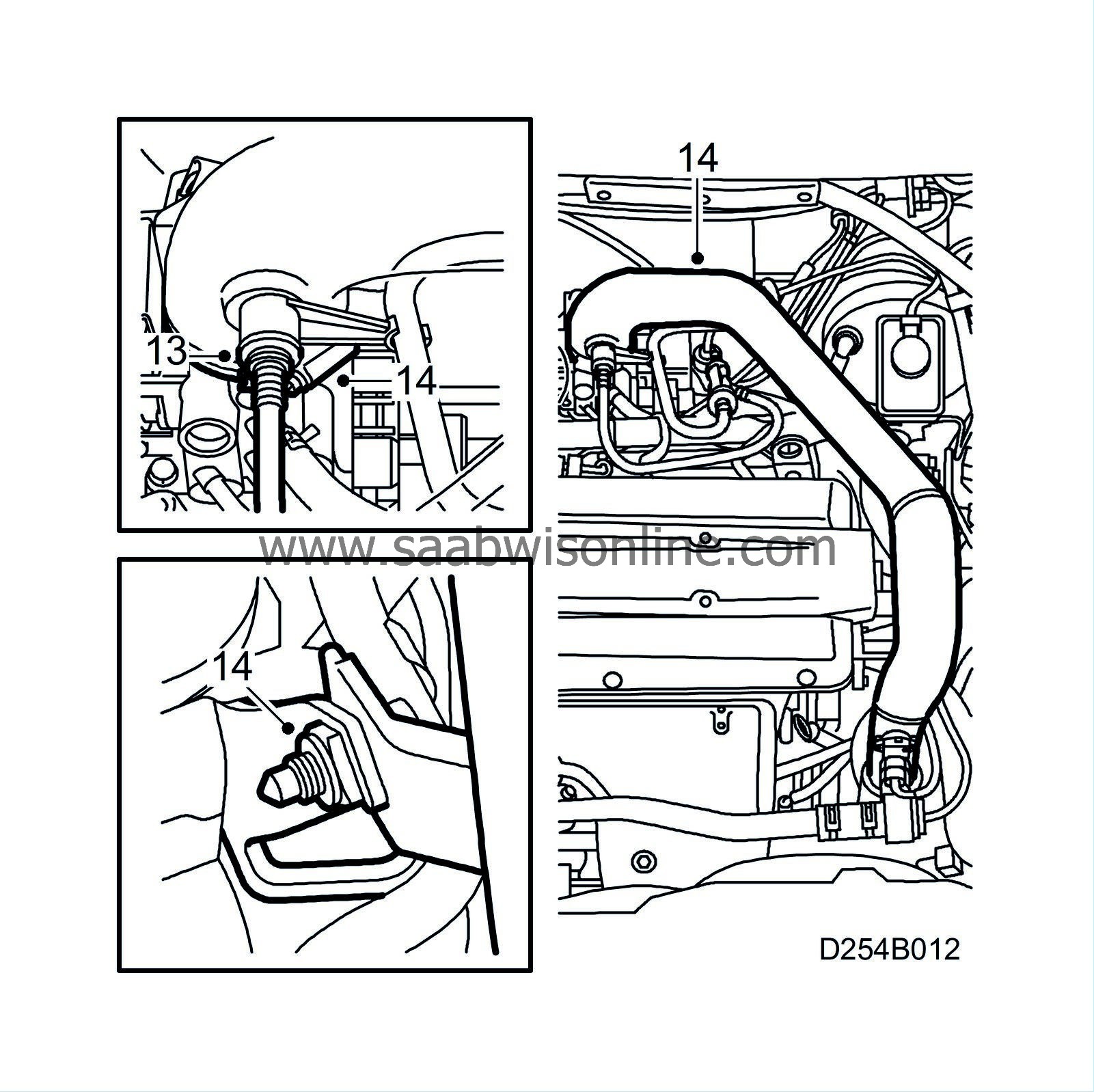

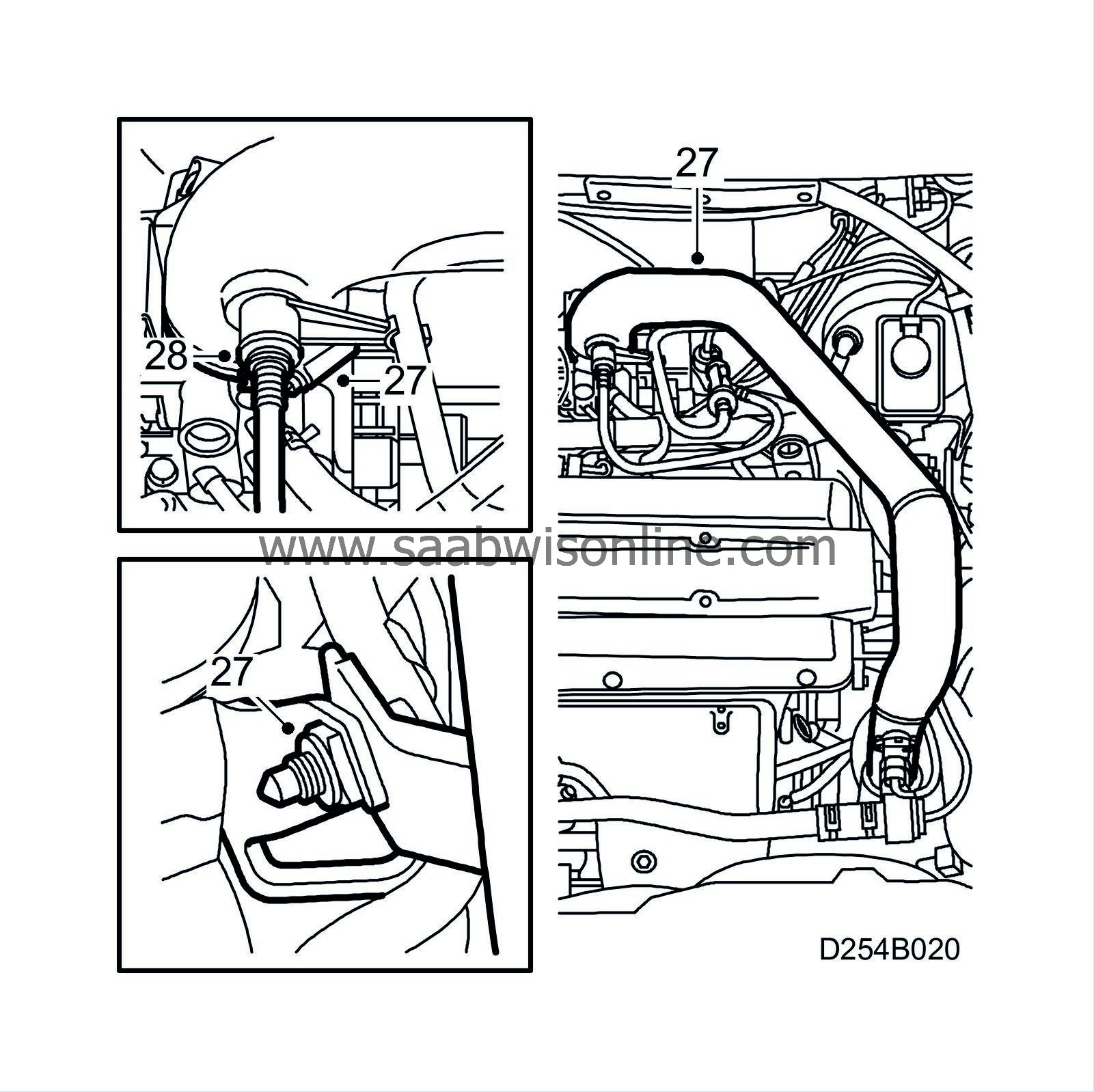

13.

|

Man:

Remove the vacuum pipe from the

turbocharger delivery pipe.

|

|

14.

|

Remove the upper turbocharger

delivery pipe from the throttle body and cylinder head. Move the turbocharger

delivery pipe aside.

|

|

15.

|

Unplug the temperature

sensor connector.

|

|

16.

|

Detach and move aside

the cable duct from the cylinder head.

|

|

17.

|

Unplug the throttle body connector.

|

|

18.

|

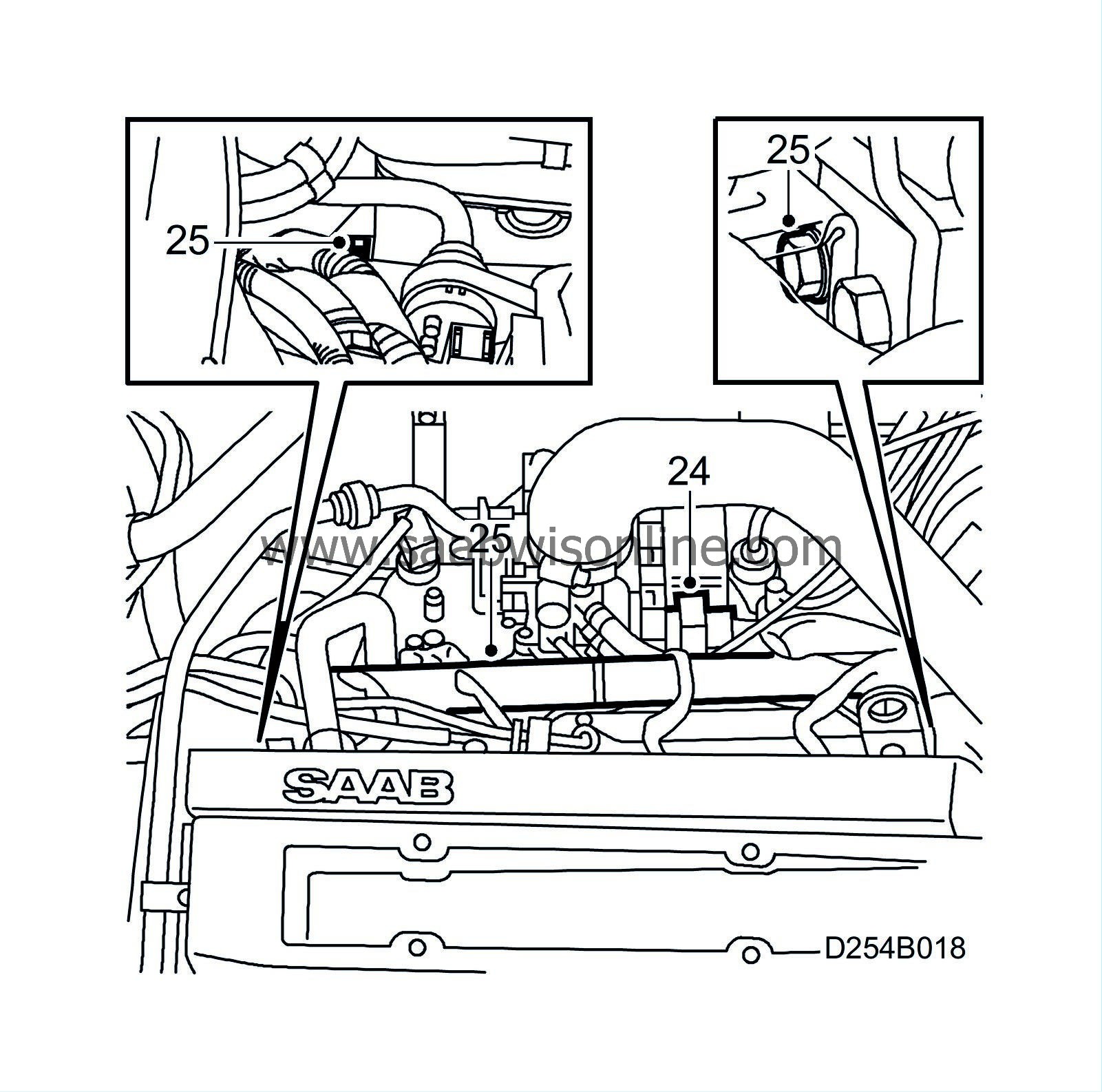

Connect the new hose

kit (with T-connection) between the nipple on the oil filler pipe and the

connection on the turbo's intake manifold.

|

|

19.

|

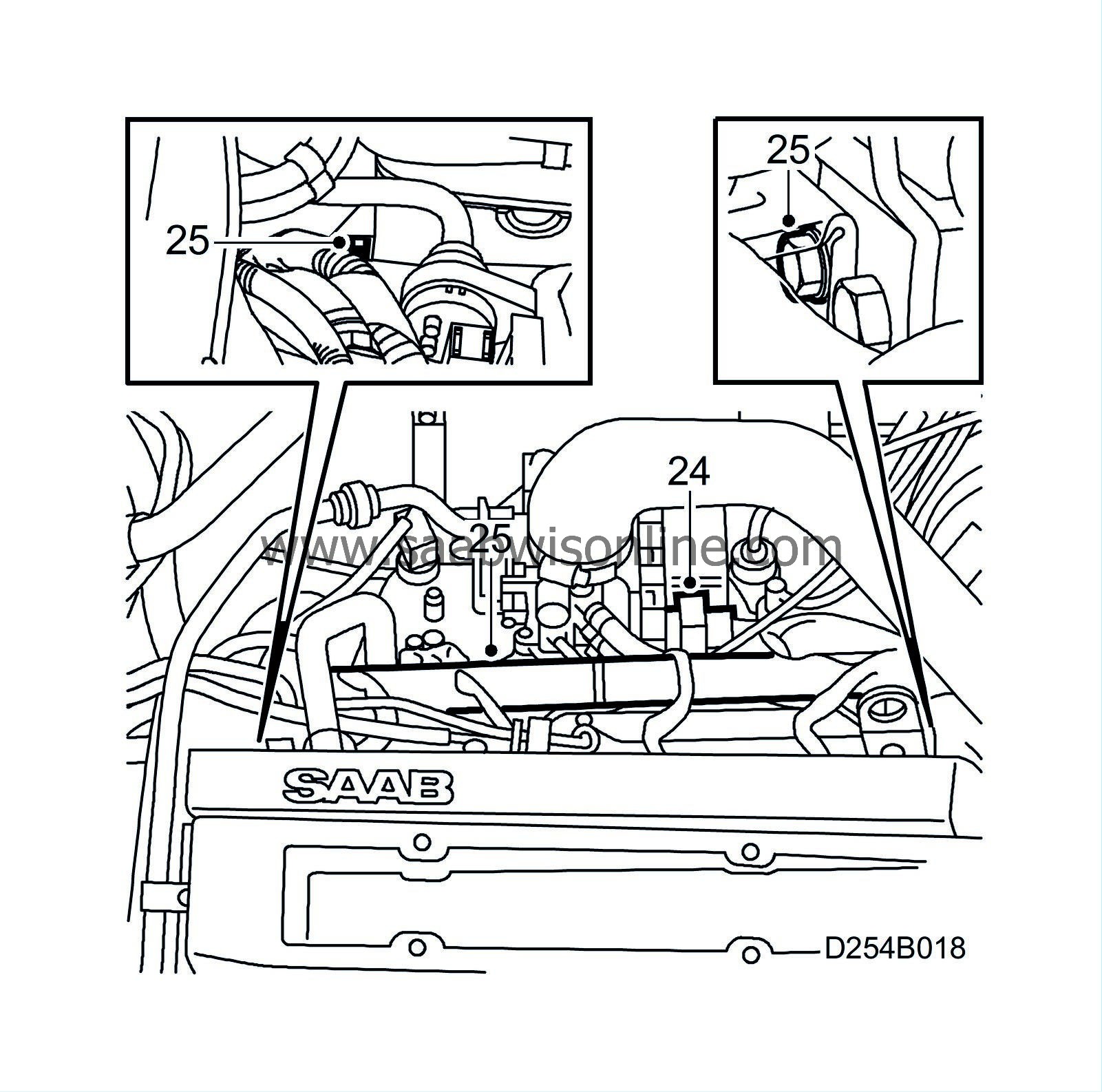

Install the insulation

under the throttle body coolant hose so that the insulation's short sides

point upward.

|

|

20.

|

Install the crankcase

ventilation hose in so that the check valve is located above the coolant hoses.

The crankcase ventilation hose must follow the route of the lower coolant

hose through the intake manifold and then on to the oil trap.

|

|

21.

|

Connect the oil trap's

upper hoses. If the hose with part no. 55 560 463 is replaced then the nipple

enclosed with the hose must not be used. Use the nipple enclosed with the

spare parts kit

|

|

22.

|

Connect the new hose kit together at the T-connection.

|

|

23.

|

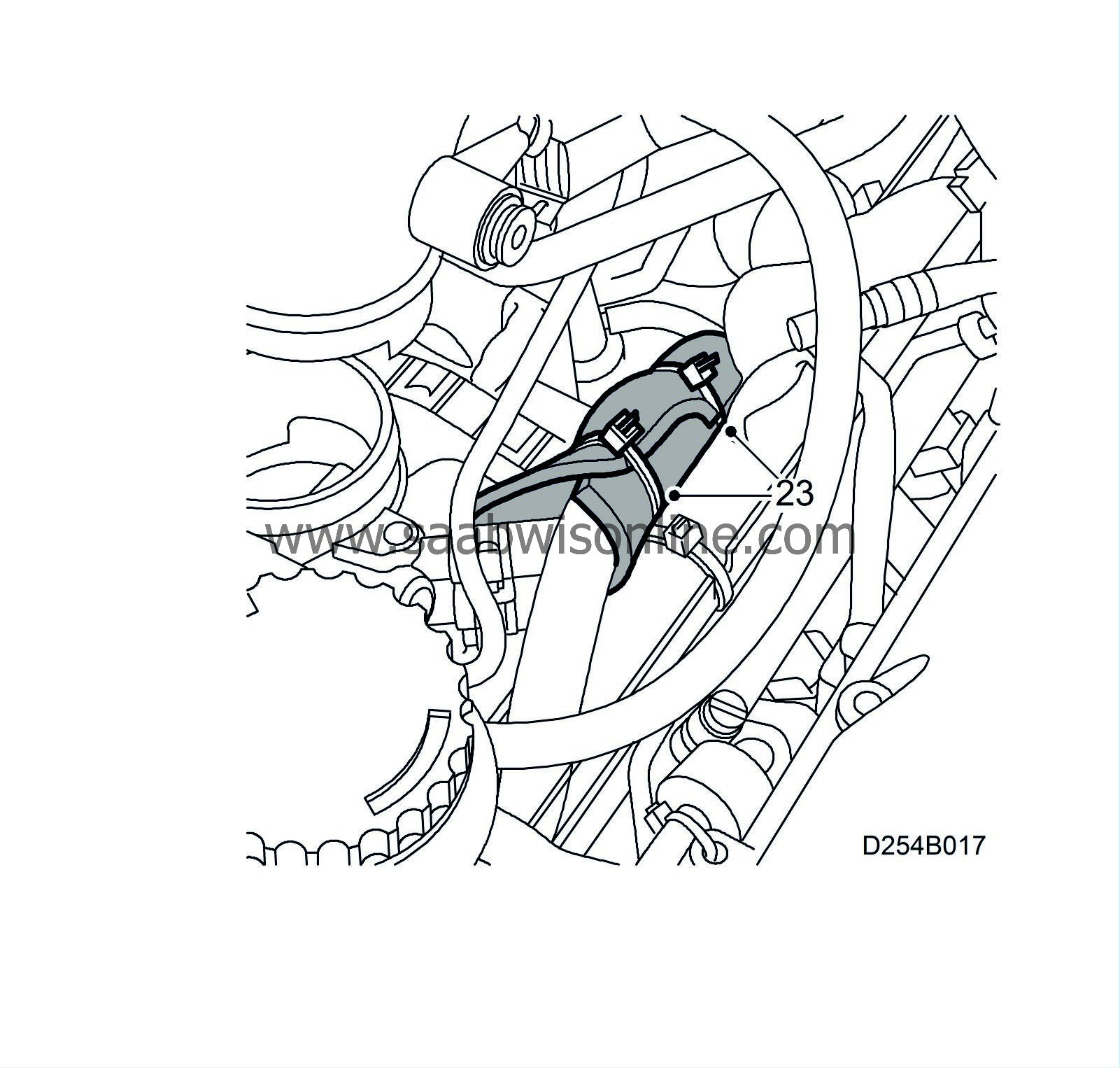

Make sure that the check

valve has good contact with both coolant hoses. Affix a cable tie around the

insulation on each side of the check valve.

|

|

24.

|

Plug the connector into

the throttle body.

|

|

25.

|

Fit the cable duct to the cylinder head.

|

|

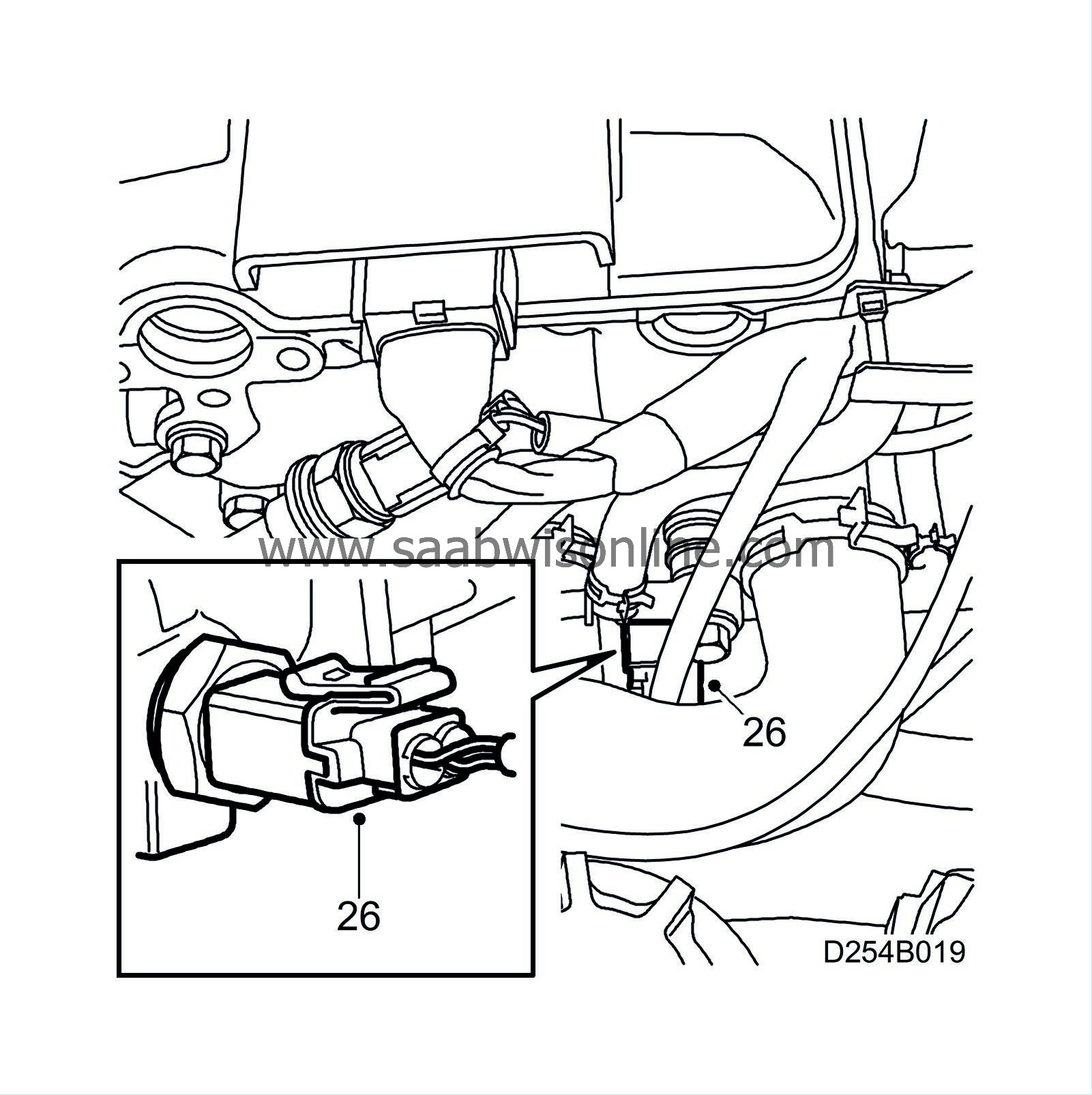

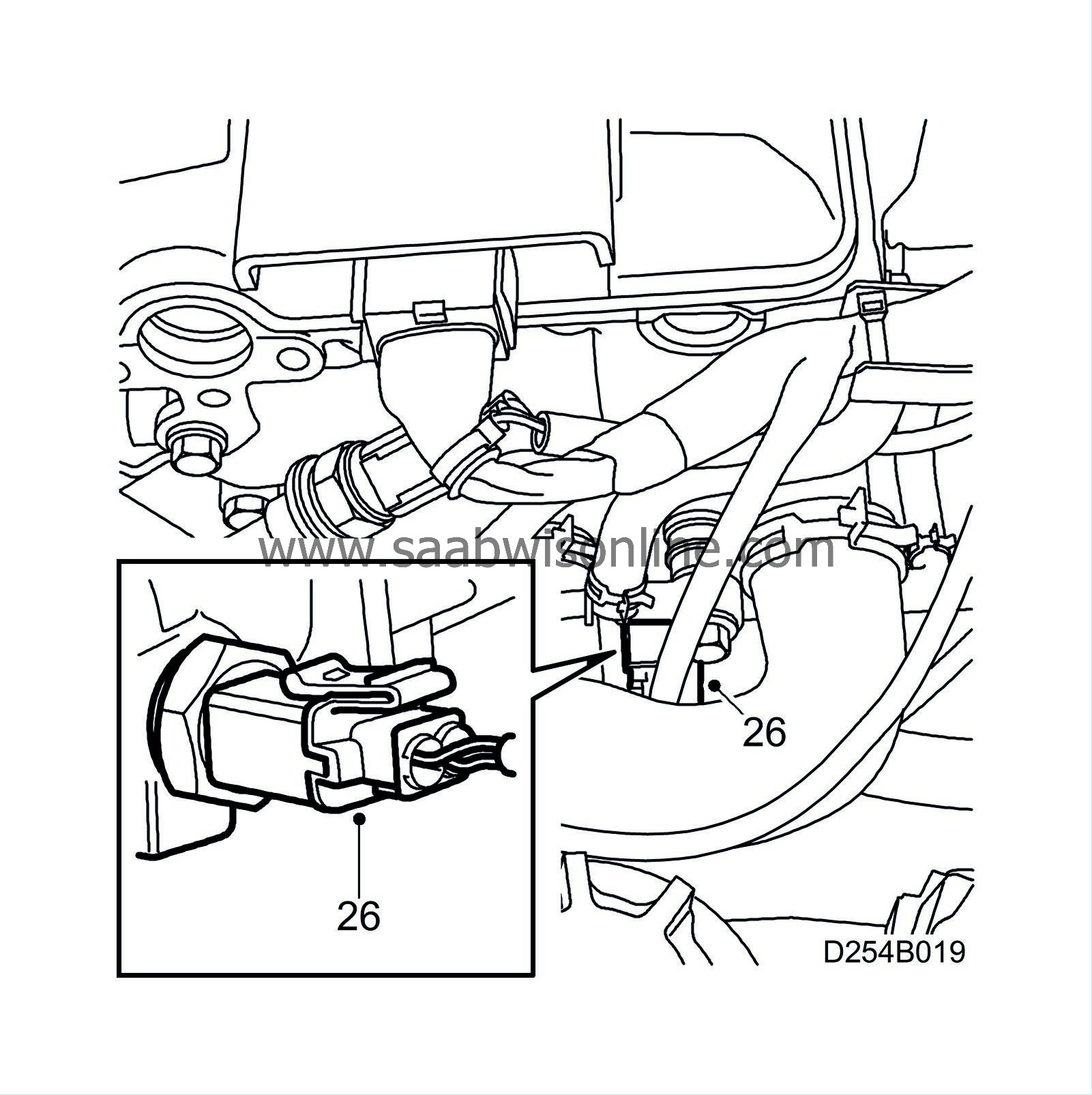

26.

|

Plug the connector into

the temperature sensor

|

|

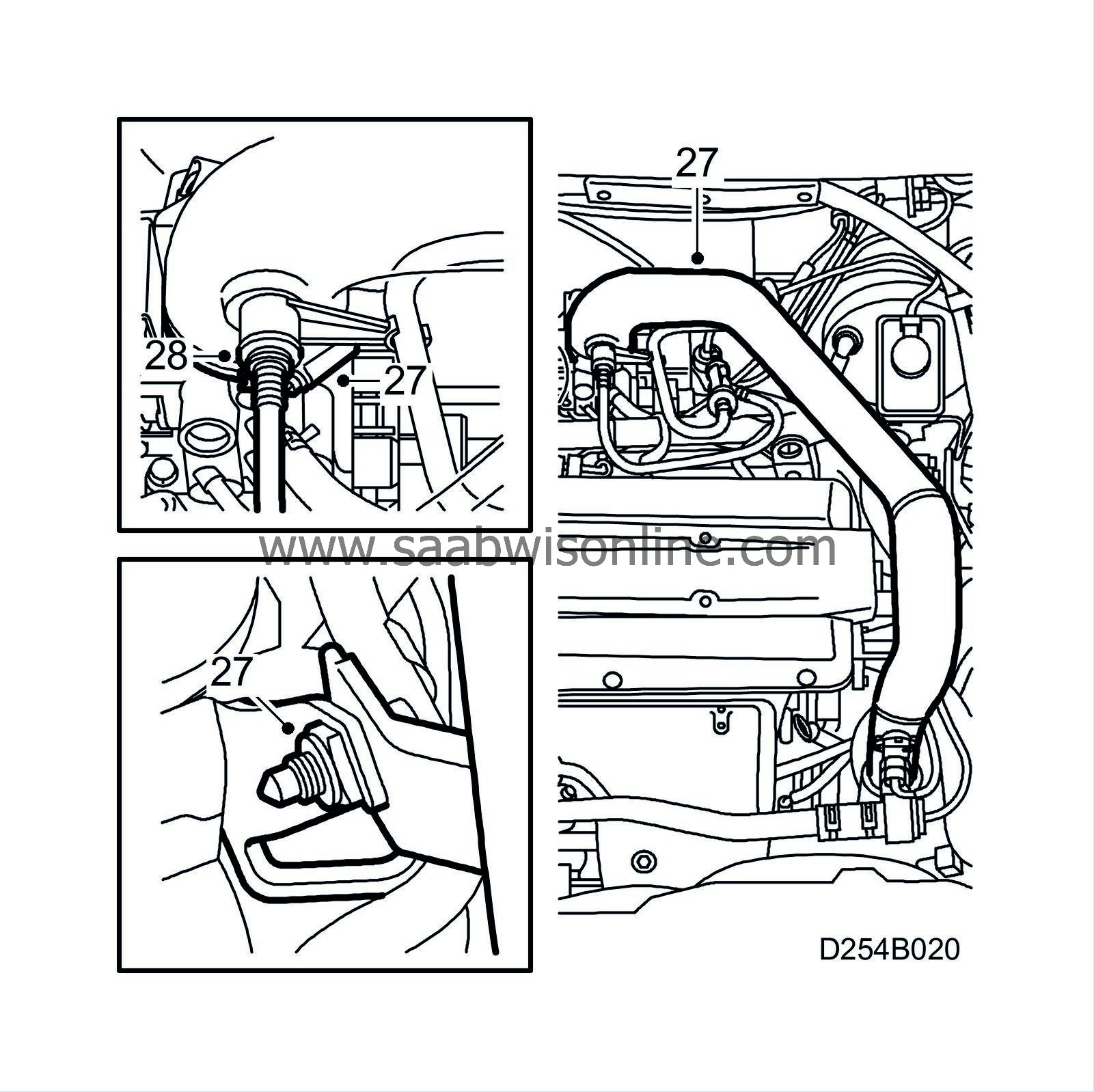

27.

|

Install the turbocharger

delivery pipe. If necessary, replace the throttle body O-ring.

|

|

28.

|

Man:

Install the vacuum pipe.

|

|

29.

|

Connect the hoses to the nipple on the camshaft cover.

|

|

30.

|

Install the upper engine cover.

|

|

31.

|

Connect the cable to the battery's negative terminal.

|

|

32.

|

Set the correct time and date in SID.

|

|

Warranty/Time Information

|

Note: Saab field representative authorization required prior to beginning

repairs

Failed Object: 19052

Fault/Reason code: 74

Warranty Type (US):

(01) During New Car Warranty period

(11) Beyond New Car Warranty but within 8 years

For Location Codes, Repair/Action codes, Labor operations and times:

Refer to the Oil sludge Diagnostics Repair Matrix included in this TSB.

Note: Labor operations are not to be combined. The operations are designed

to stand along according to the repair/action performed.