Fuel pump

| Fuel pump |

|

||||||||||||||||||||||

| To remove |

| Important | ||

|

The car should be parked on a level surface. If the tank is full and the car is jacked up at the rear when the pump is removed, it is very likely that fuel will run out. |

||

|

Place protective paper over the carpeting when the pump is removed as there is a risk of fuel spilling out. |

||

| 1. |

Raise the rear seat cushions and fold the carpeting out of the way.

|

|

| 2. |

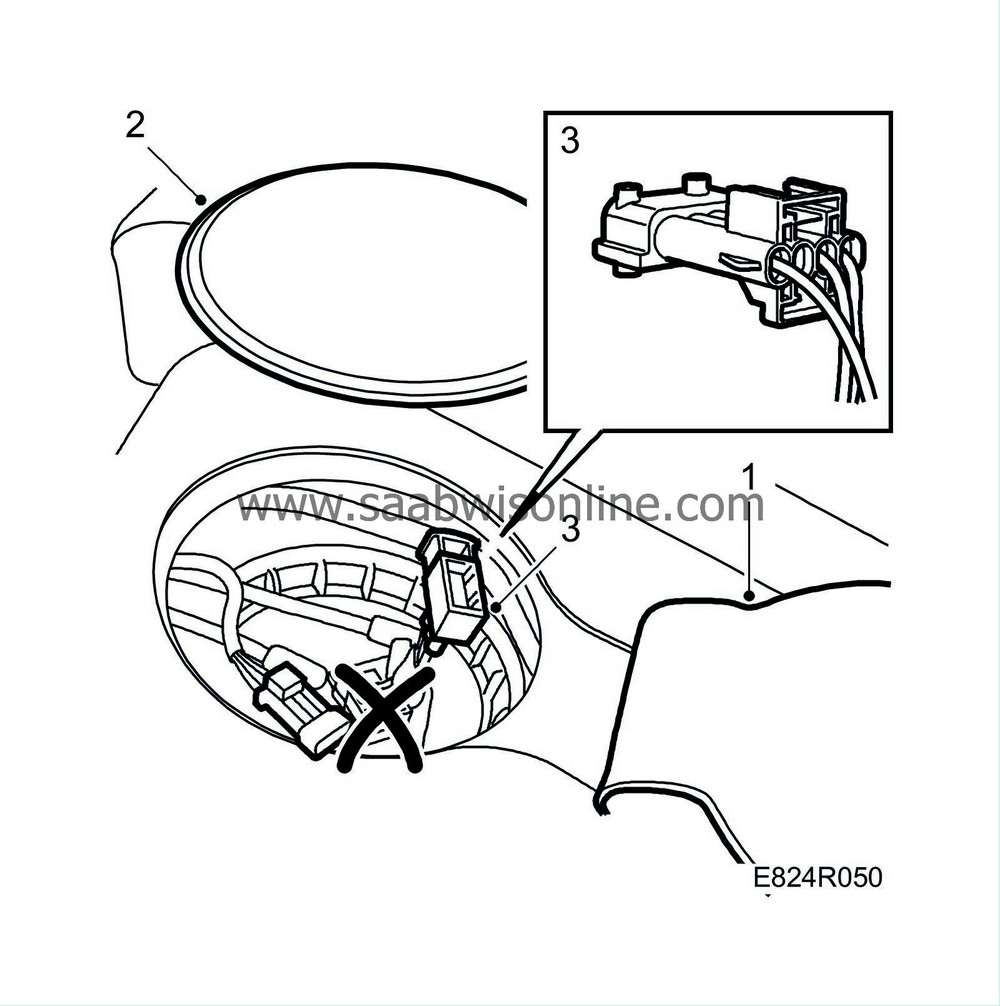

Remove the fuel pump cover.

|

|

| 3. |

Unplug the upper connector.

|

||||||||||

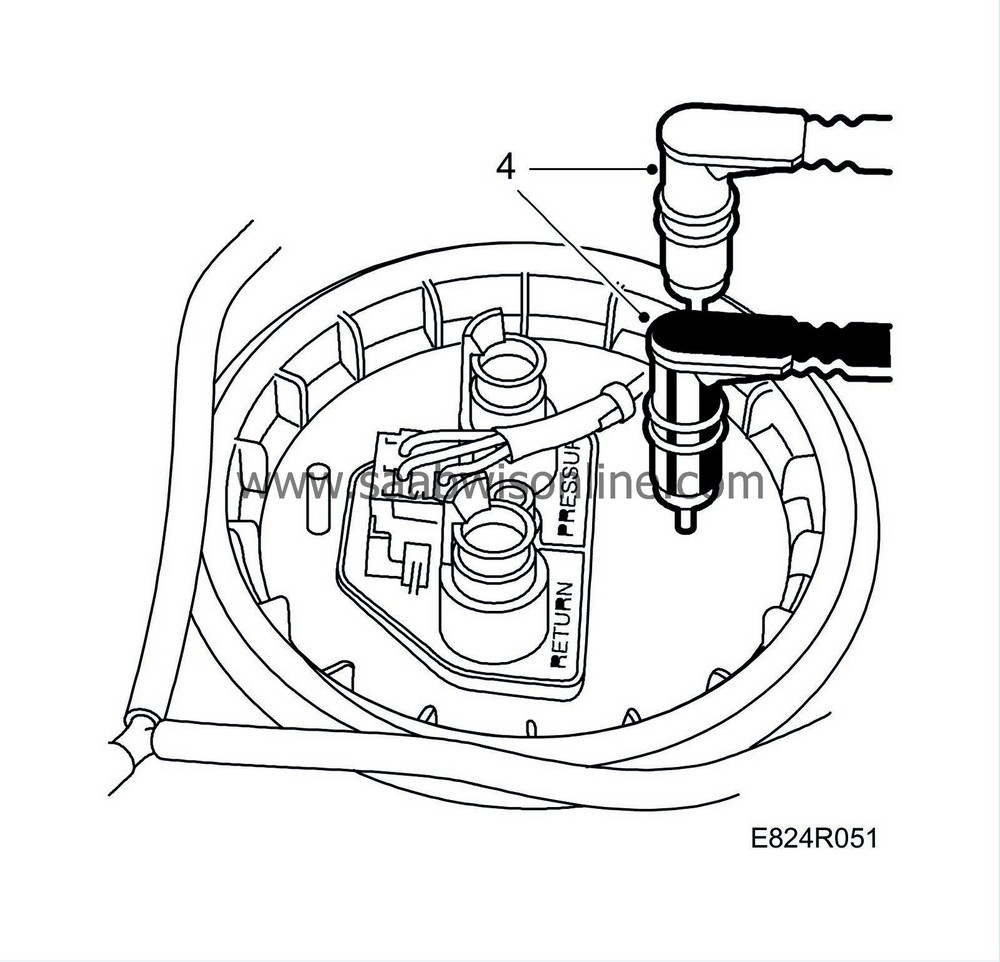

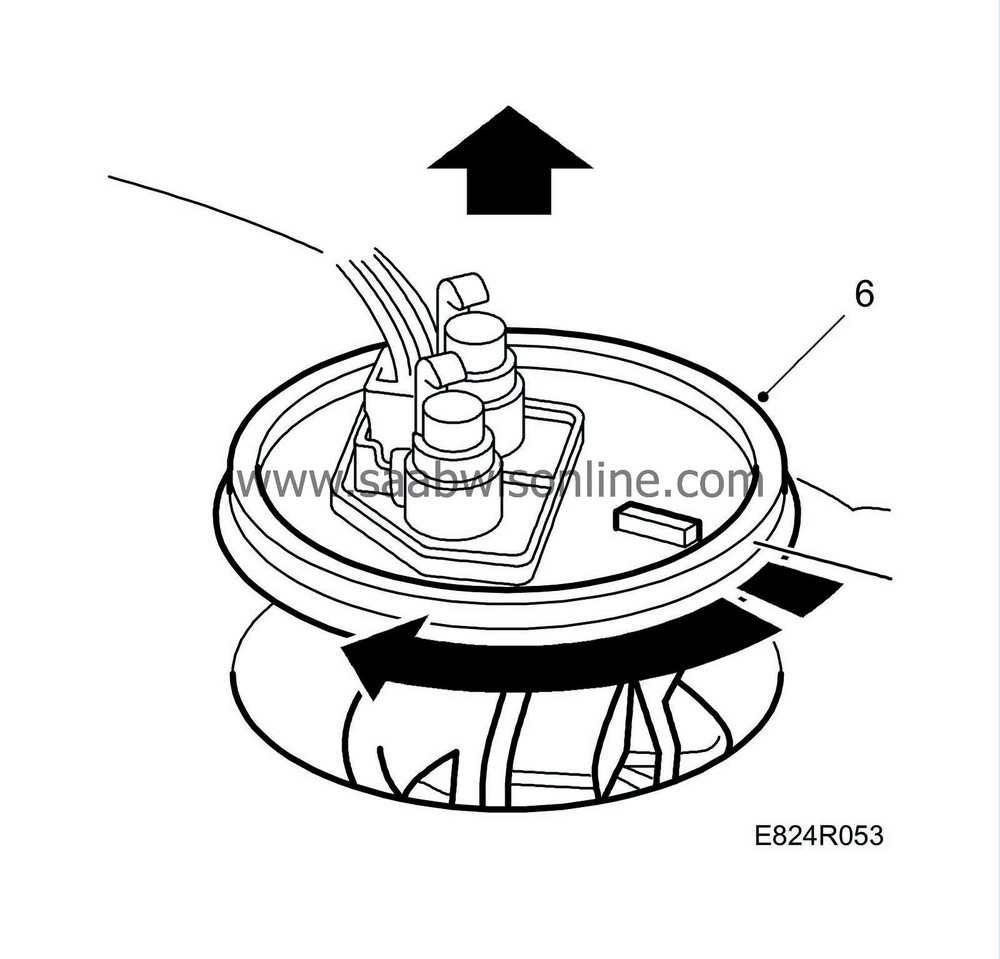

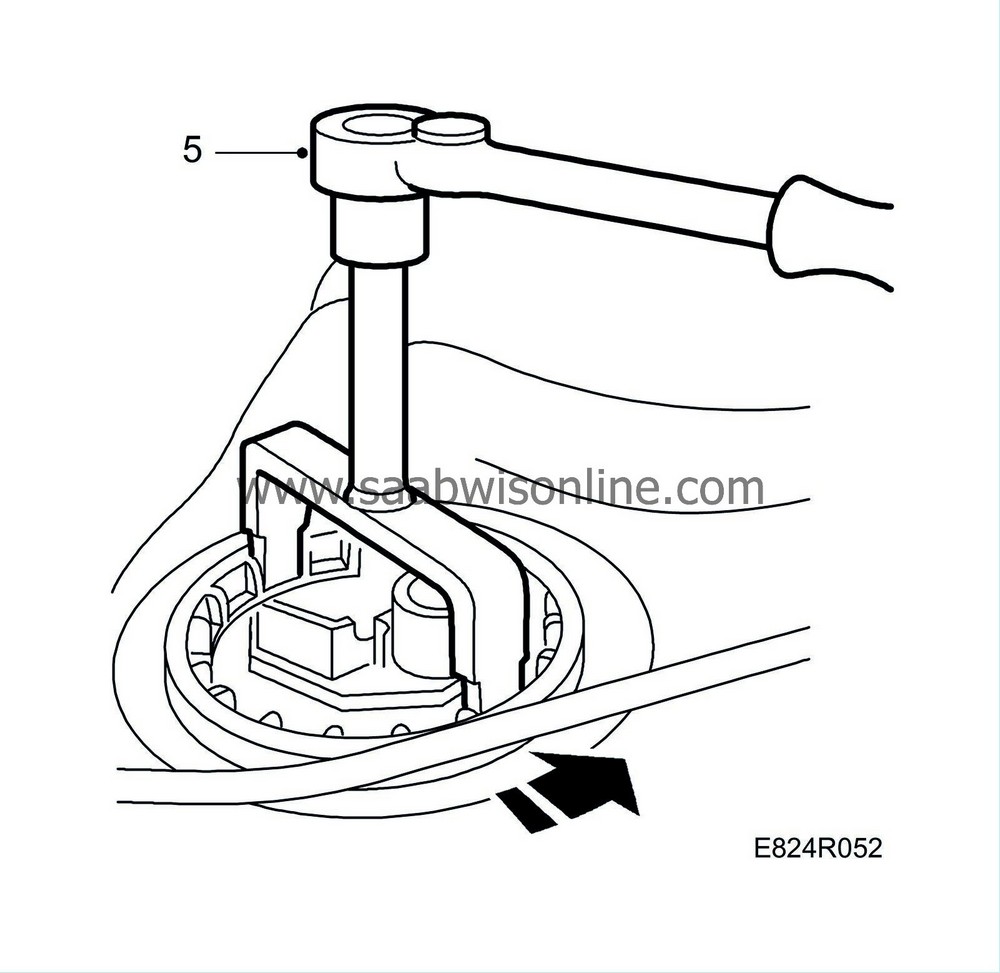

| 5. |

Remove the screw ring, using special tool 83 94 462.

|

|

| 7. |

Transfer the pump to a suitable receptacle and pour off the fuel.

|

|

| To fit |

| 1. |

Clean sealing surfaces.

|

|

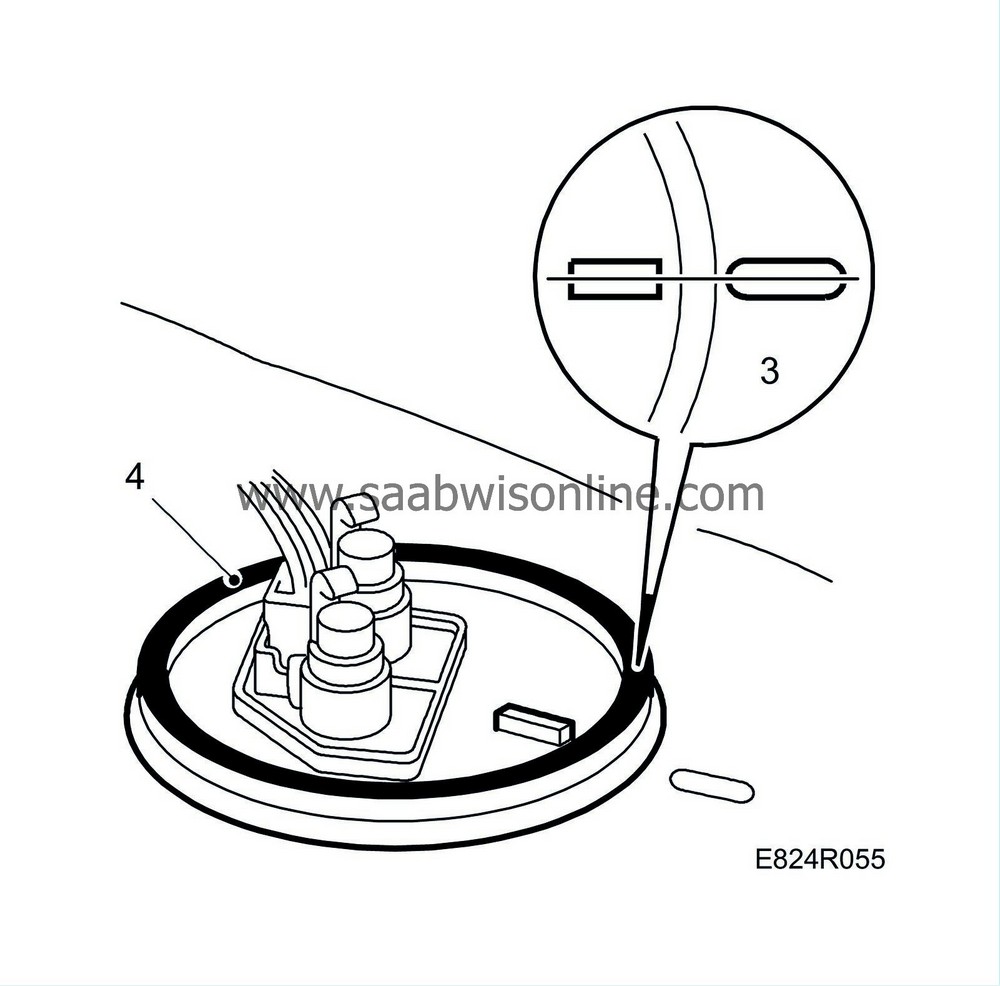

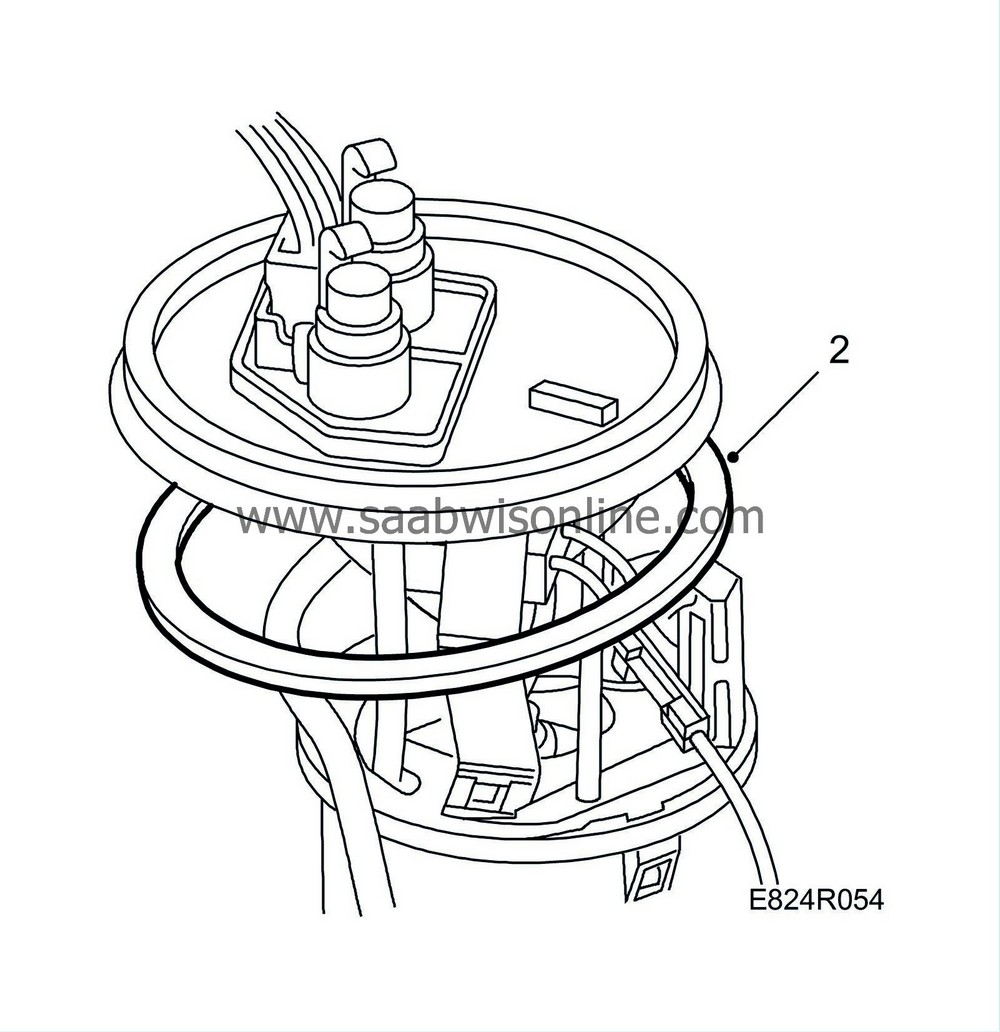

| 2. |

Fit a new O-ring in the groove in the tank.

|

|

| 4. |

Lubricate the threads on the pump lid and the top of the pump with non-acidic vaseline to prevent the pump from turning when the screw ring is tightened.

|

|

| 5. |

Fit the screw ring and tighten it, using tool 83 94 462.

Tightening torque: 75 Nm (55 lbf ft). |

|

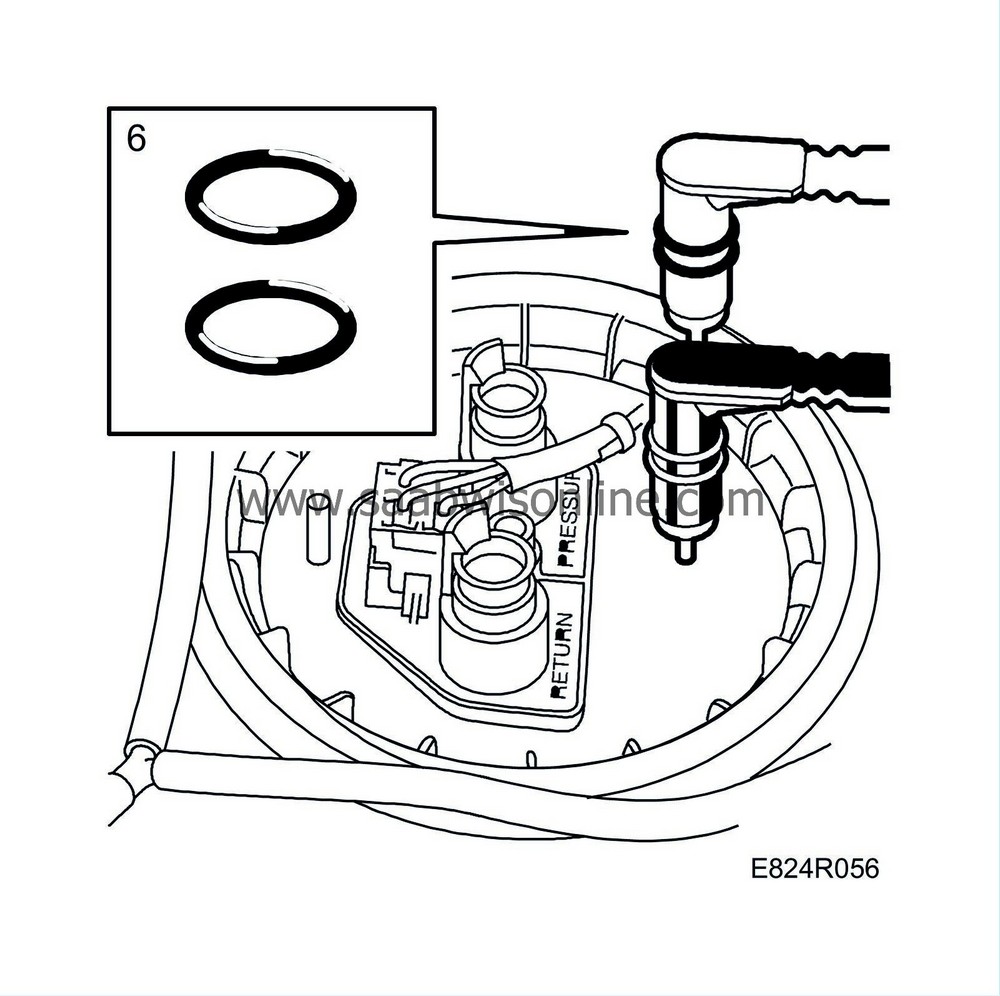

| 6. |

Inspect and lubricate the O-rings on the fuel line connections with non-acidic vaseline and connect them to the pump.

|

|

| 7. |

Make sure that the yellow hooks have snapped in place over the connections.

|

|

| 8. |

Plug in the connector and spray it with a contact cleaner like Kontakt 61 (part No. 30 04 520).

|

|

| 9. |

Check that the pump works properly and that it does not leak.

|

|

| 10. |

Fit the fuel pump cover, return the rear seat cushions to their places and fold back the carpeting.

|

|

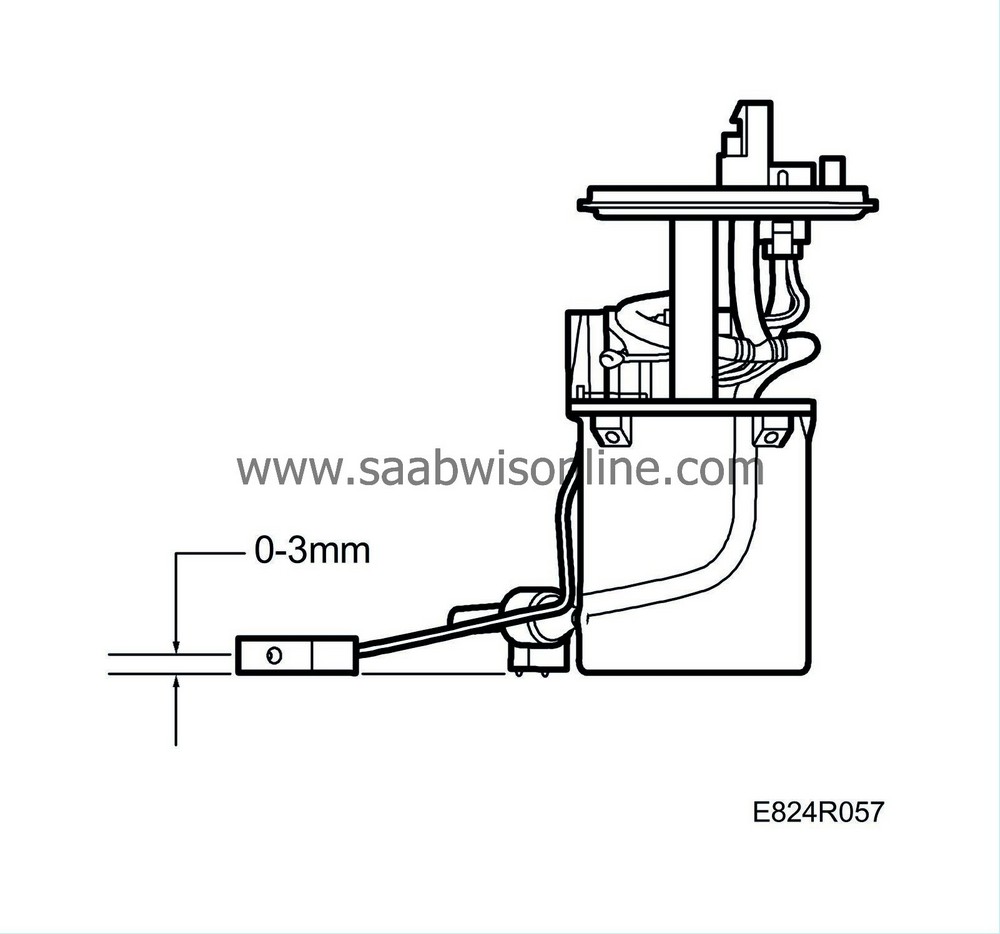

| Checking the fuel gauge float arm position |

With the pump placed on a level surface, the distance between the surface and the bottom of the float should be 0-3 mm.

The sensor resistance should be:

Empty tank, float at bottom: 50 ± 1.5 ohm

Full tank, float at top: 425 ± 6.5 ohm

Warning

Warning