Fuel pump

| Fuel pump |

|

||||||||||||||||||||||

| To remove |

| Important | ||

|

The car should be parked on a level surface. If the tank is full and the car is jacked up at the rear when the pump is removed, it is very likely that fuel will run out. |

||

|

Place protective paper over the carpeting when the pump is removed as there is a risk of fuel spilling out. |

||

| 1. |

Raise the rear seat cushions and fold the carpeting out of the way.

|

|

| 2. |

Remove the fuel pump cover.

|

|

| 3. |

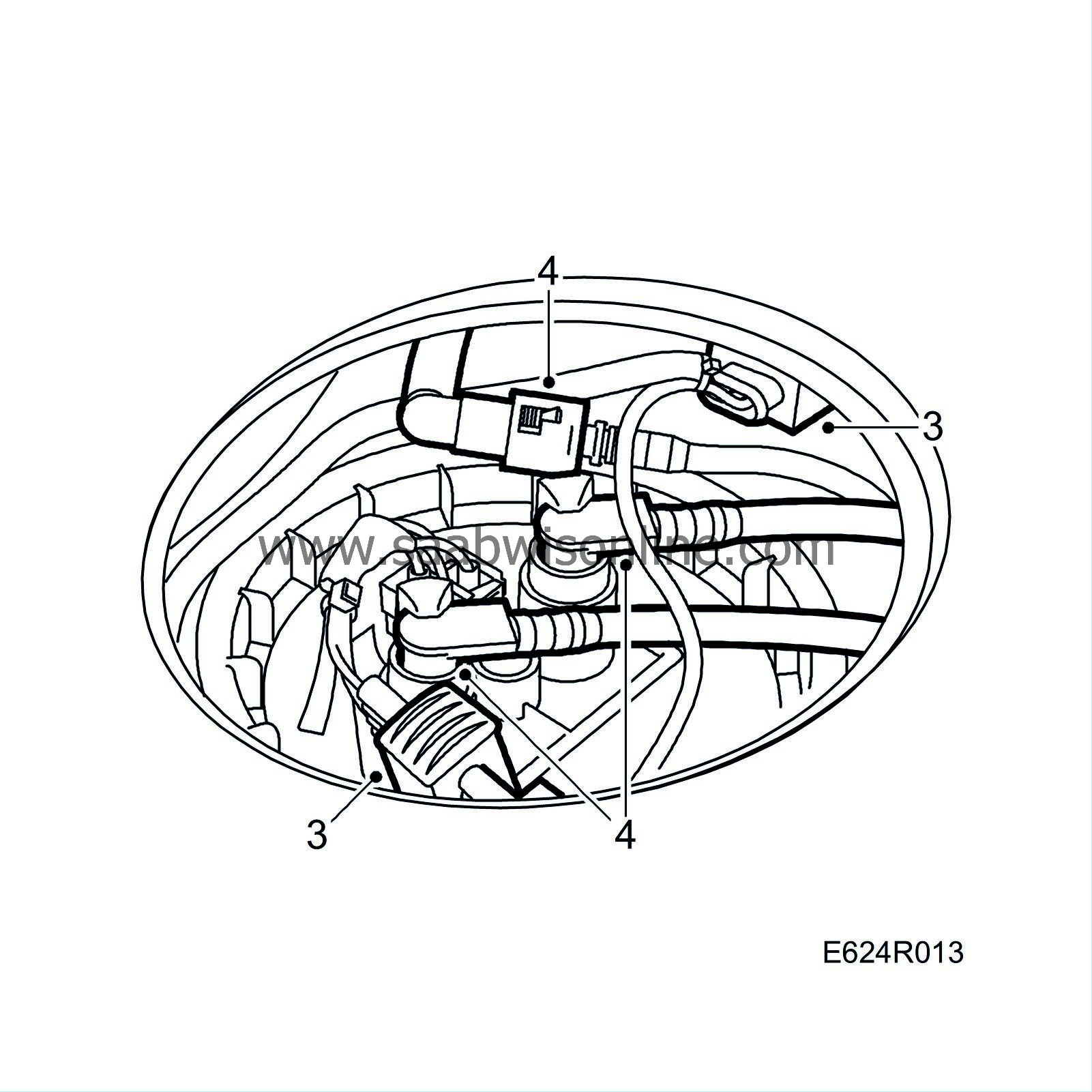

Undo the upper connector and the connector for the tank pressure sensor.

|

||||||||||

| 4. |

Carefully detach the non-return valve with fuel lines from the pump. The non-return valves are fastened to the pump with quick-release couplings.

Carefully move the purge hose out of the way. |

|

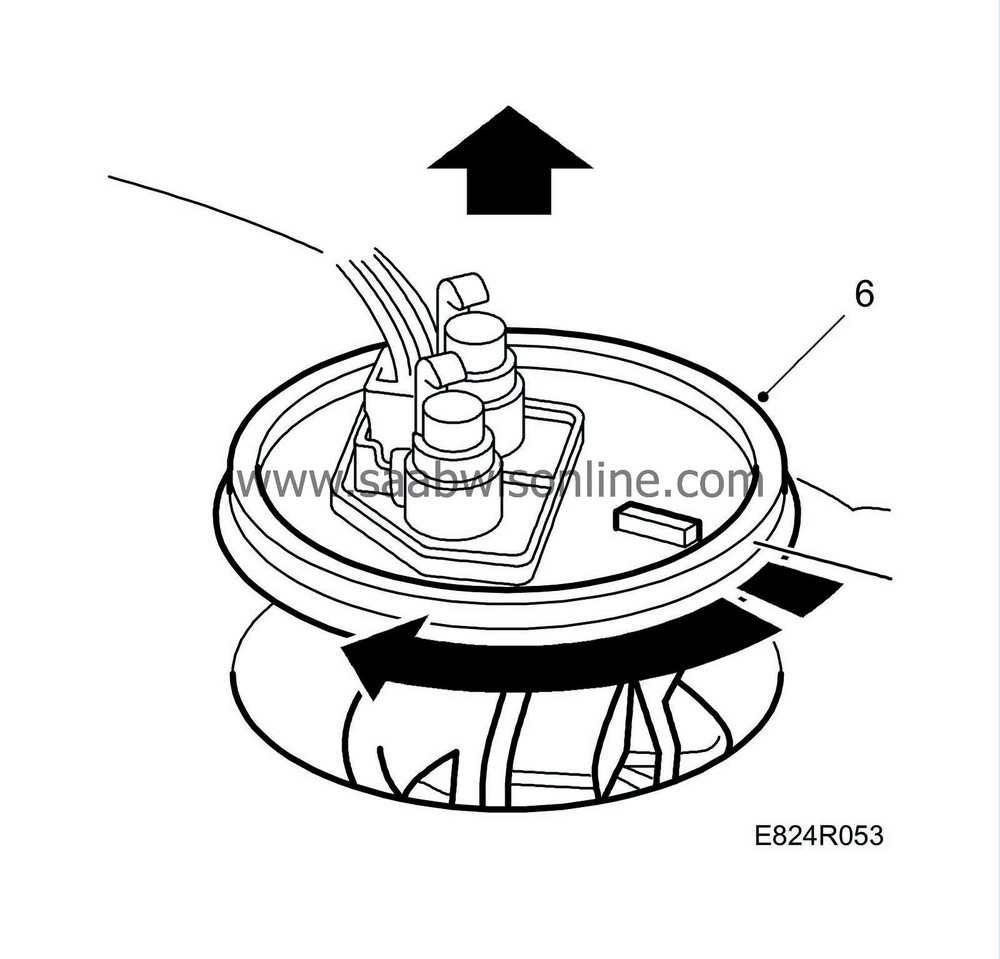

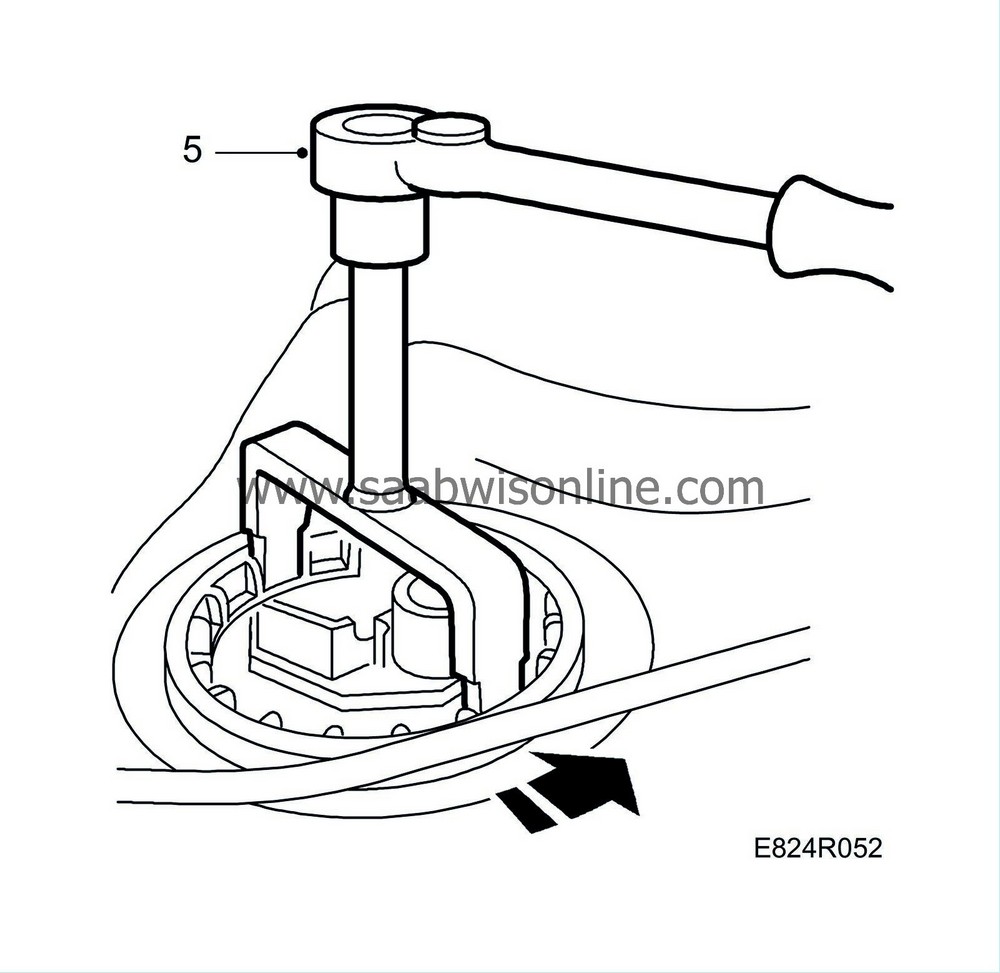

| 5. |

Remove the screw ring, using special tool 83 94 462.

|

|

| 7. |

Transfer the pump to a suitable receptacle and pour off the fuel.

|

|

| To fit |

| 1. |

Clean sealing surfaces.

|

|

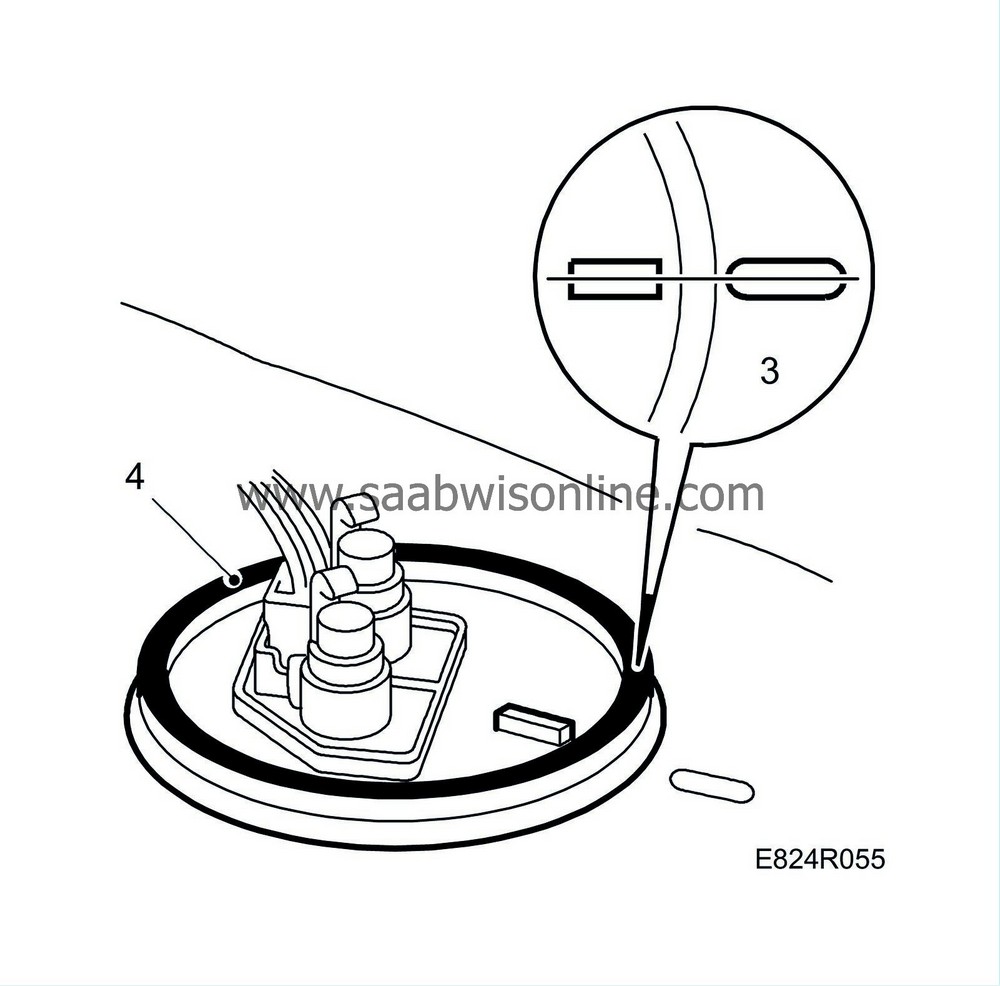

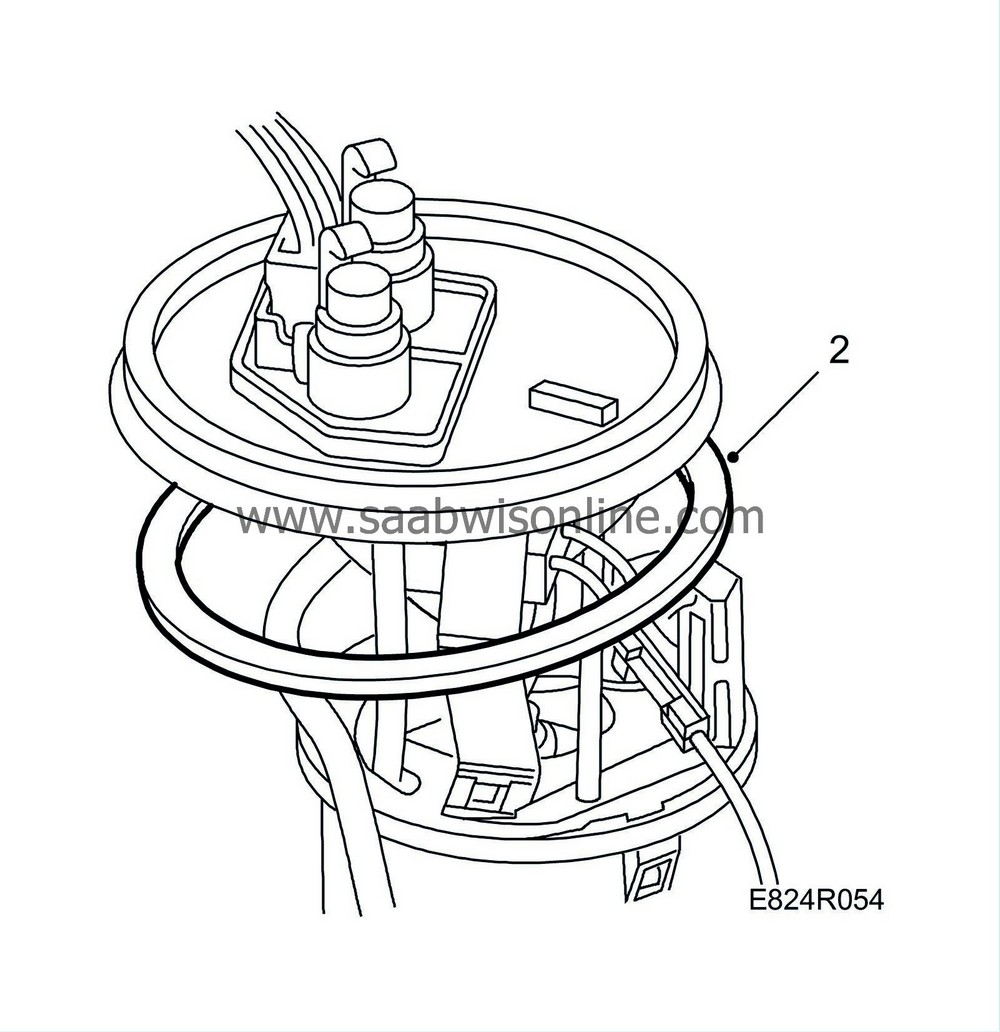

| 2. |

Fit a new O-ring in the groove in the tank.

|

|

| 4. |

Lubricate the threads on the pump lid and the top of the pump with non-acidic vaseline to prevent the pump from turning when the screw ring is tightened.

|

|

| 5. |

Fit the screw ring and tighten it, using tool 83 94 462.

Tightening torque: 75 Nm (55 lbf ft) |

|

| 6. |

Inspect and lubricate the O-rings on the fuel line connections with non-acidic vaseline and connect them to the pump.

|

|

| 7. |

Make sure that the yellow hooks have snapped in place over the connections.

|

|

| 8. |

Spray the connectors with Kontakt 61, part no. 30 04 520 and plug in them.

|

|

| 9. |

Check that the pump works properly and that it does not leak.

|

|

| 10. |

Fit the fuel pump cover, return the rear seat cushions to their places and fold back the carpeting.

|

|

| Checking the non-return valve |

| 1. |

Remove the engine cover.

|

|

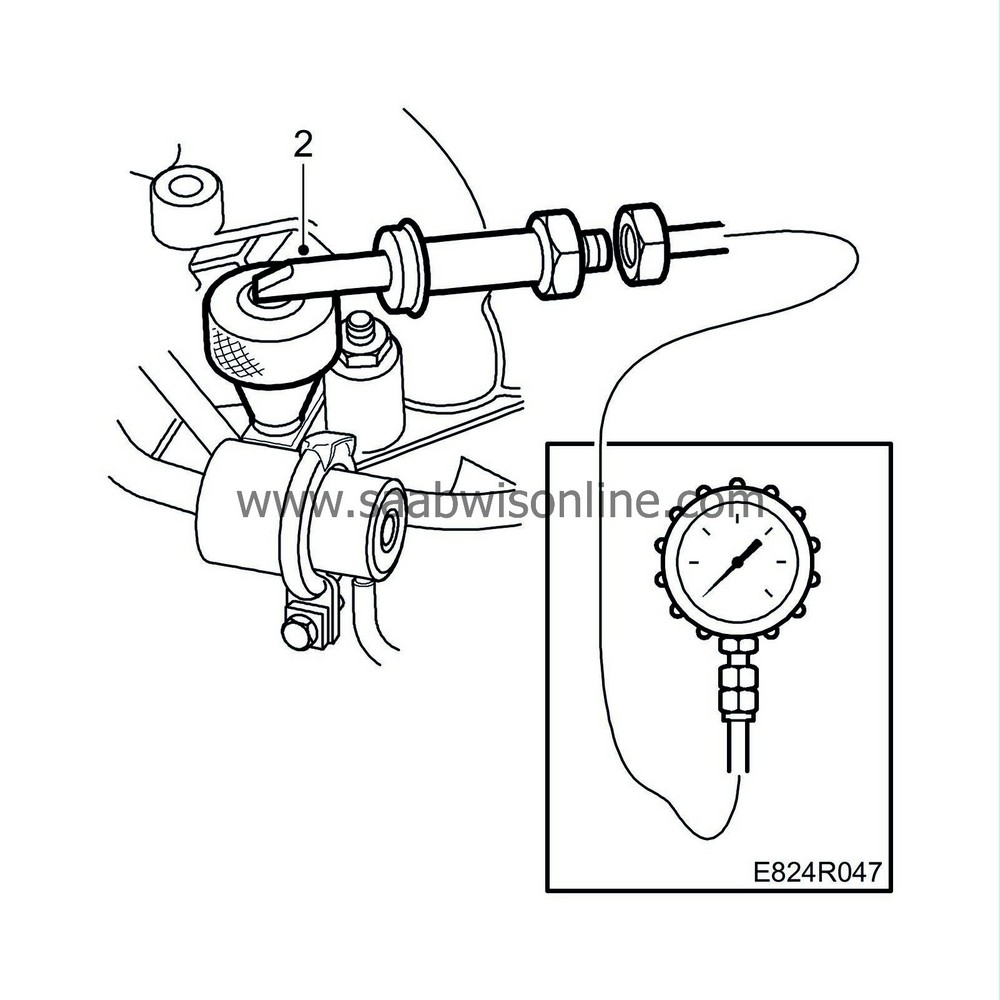

| 2. |

Remove the valve cap. Connect the pressure gauge (tool No. 83 93 852) and adapter (tool No. 83 94 744) to the fuel rail with the pressure gauge (tool no. 83 93 852) “safety” on. Use the tool with the “Safety” off.

|

|

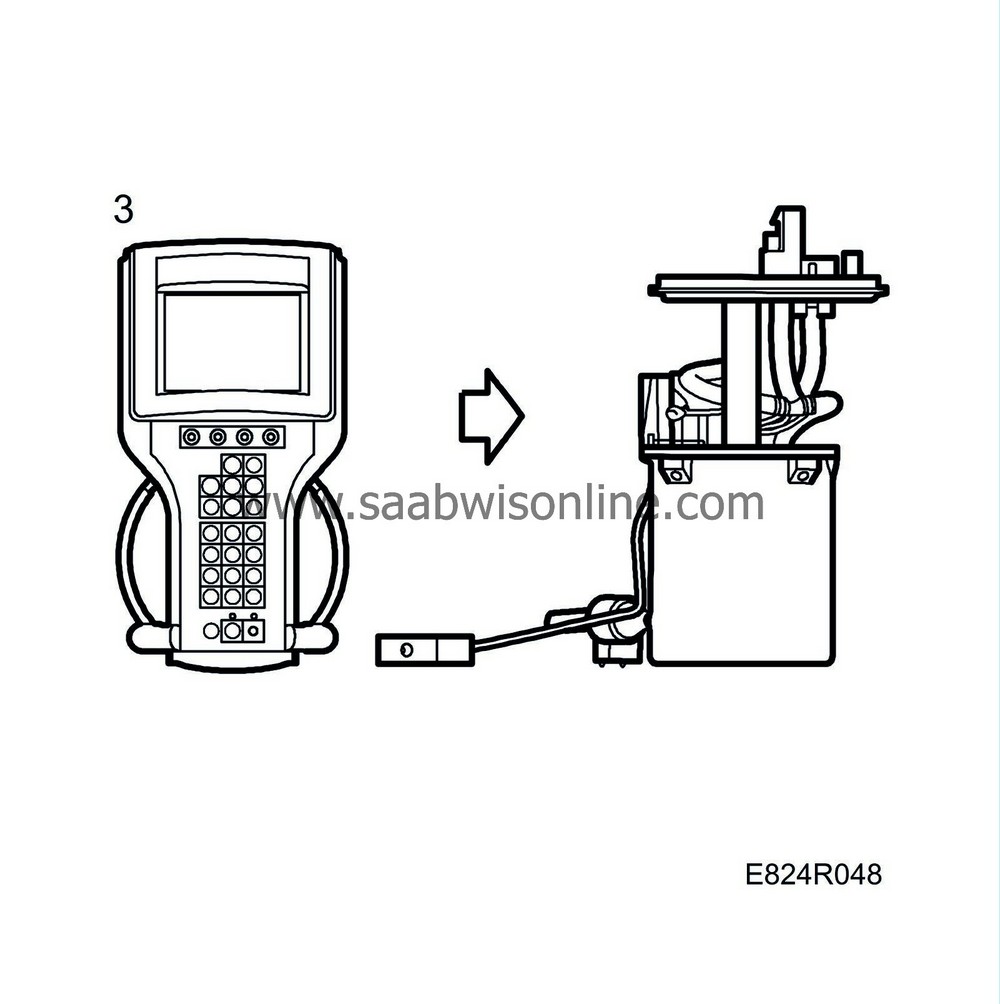

| 3. |

Activate the fuel pump with the diagnostic tool.

|

|

| 4. |

Run the pump manually until the pressure gauge stops rising.

|

|

| 5. |

Read the pressure gauge. Turn off the pump. The residual pressure after 20 min. should be at least 2.3 bar (33 psi).

|

|

| 6. |

If the residual pressure is too low then check the non-return valve by detaching it from the pump outlet to see if it is leaking.

|

|

| 7. |

Remove the tool (part No. 83 93 886).

|

|

| Changing the non-return valve |

| Important | ||

|

If the non-return valves on both the delivery line and the return line are changed then it is important to make sure they are fitted on the correct line. |

||

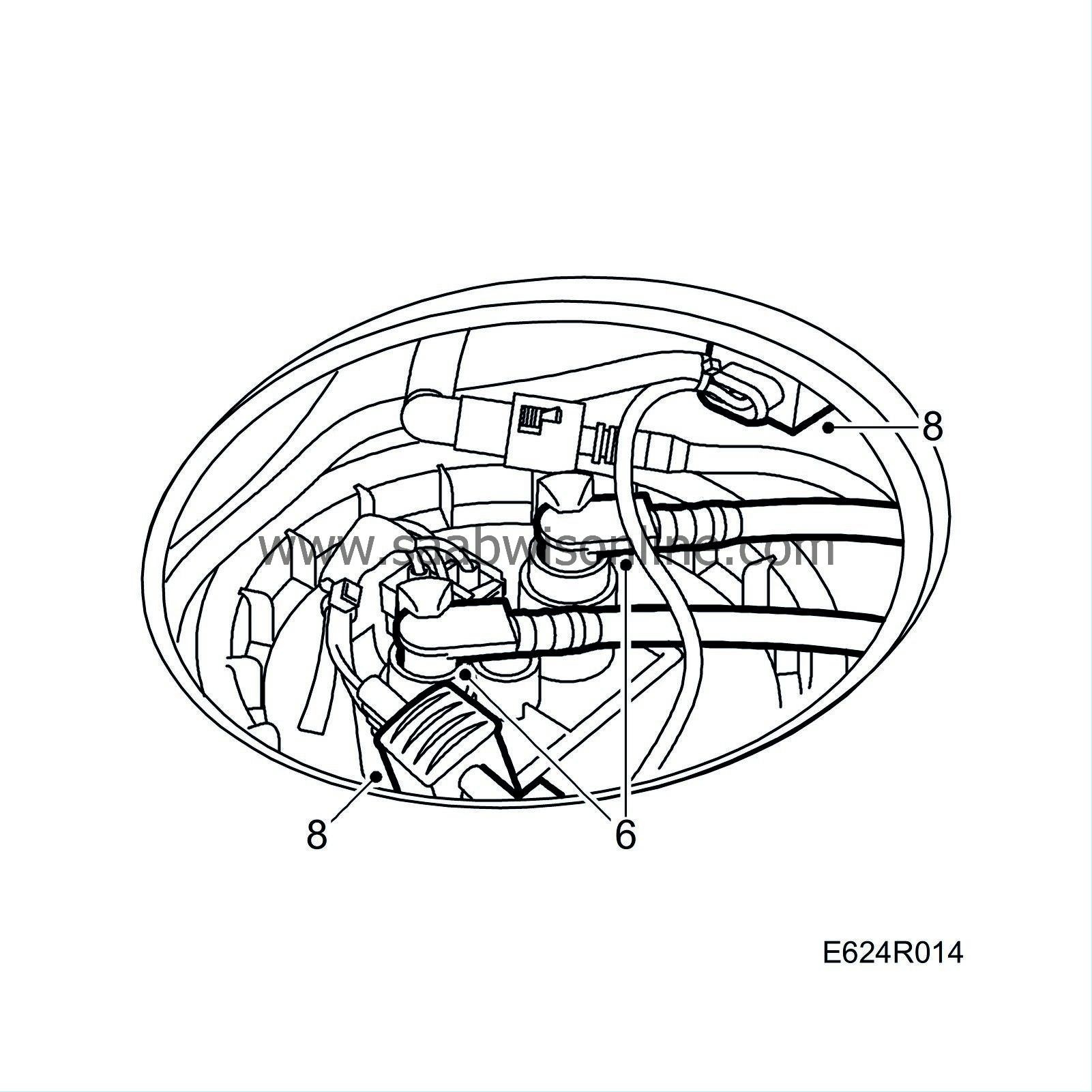

| 1. |

Expose the non-return valve.

|

|

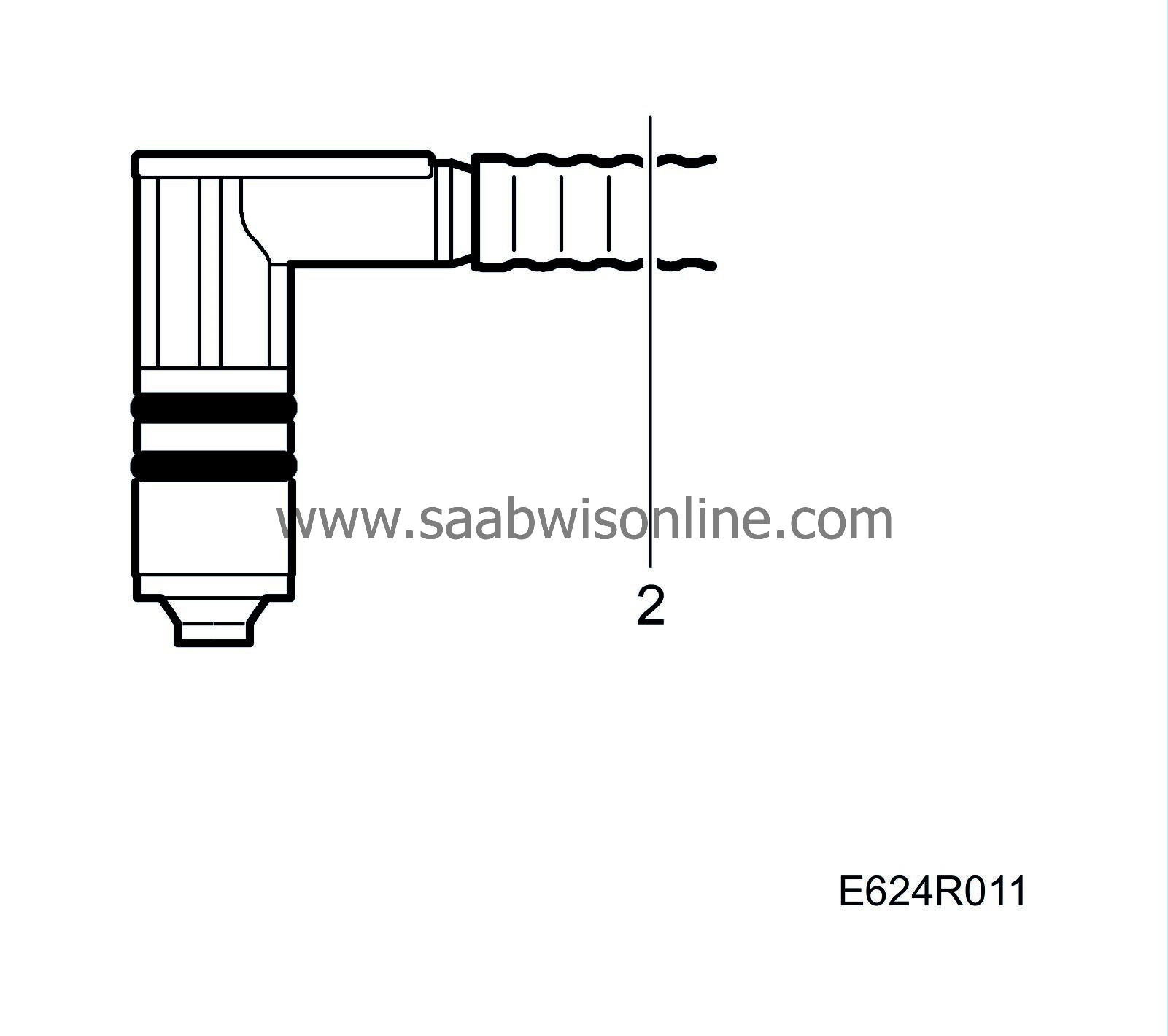

| 2. |

Cut the fuel line at the slight curve located just before where the non-return valve connector nipple ends.

|

|

| 3. |

Fit tool 83 95 329 onto the fuel line. The end of the fuel line should protrude slightly.

|

|

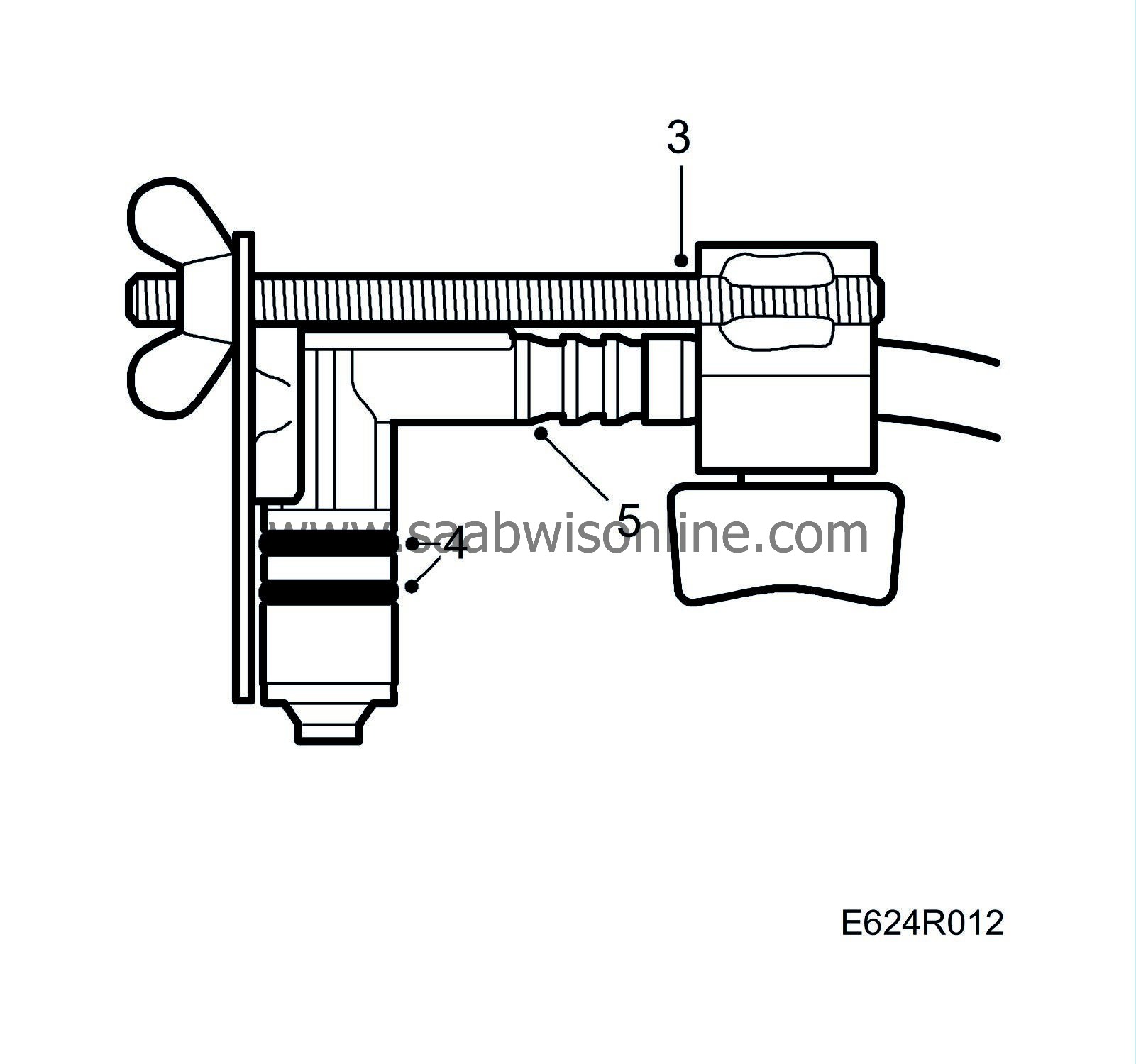

| 4. |

Fit the O-rings on the non-return valve. Lubricate the non-return valve with non-acidic vaseline and press it in the fuel line facing the right way, this is important because the valve cannot be turned round when it is fitted and the hose is also too stiff to turn.

|

|

| 5. |

Press the non-return valve in the fuel line using the tool. Move the tool little by little, making sure that there is always a small distance between the tool and the non-return valve's connector nipple.

|

||||||||||

| 6. |

Plug in the connector and spray it with Kontakt 61 contact cleaner (part No. 30 21 763). Connect the fuel lines.

|

|

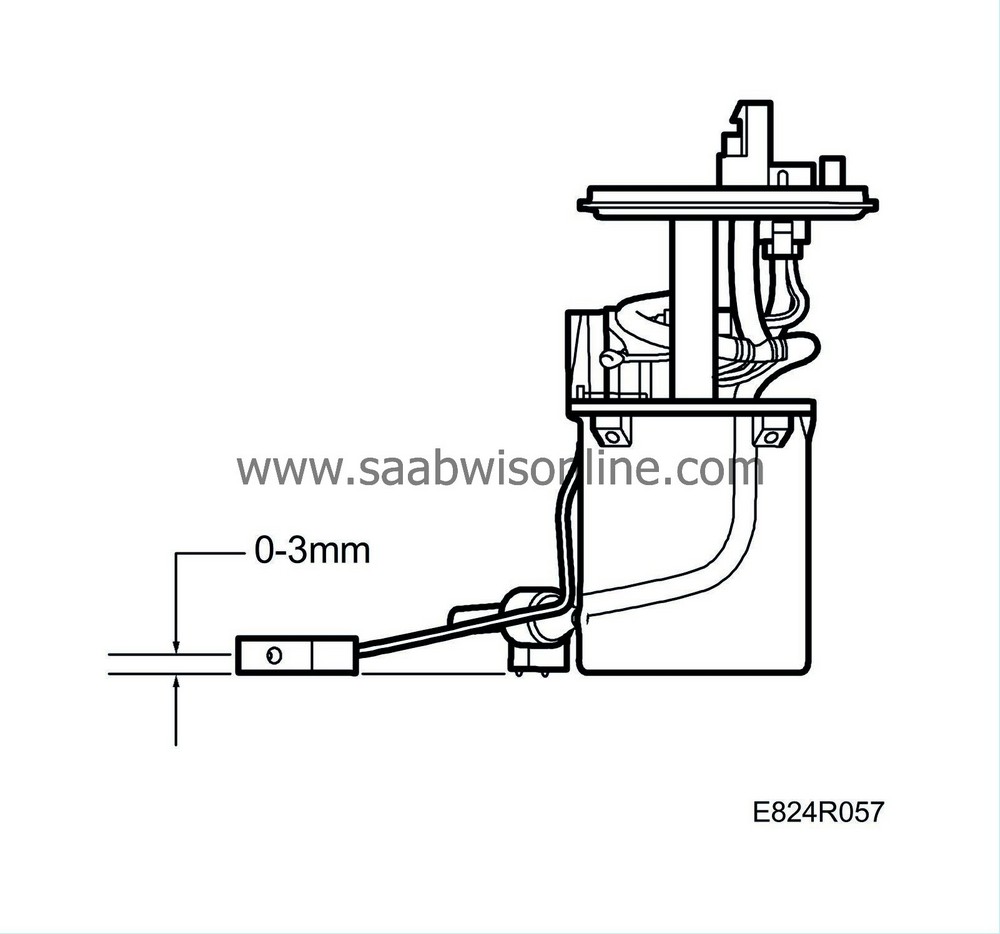

| Checking the fuel gauge float arm position |

With the pump placed on a level surface, the distance between the surface and the bottom of the float should be 0-3 mm.

The sensor resistance should be:

Empty tank, float at bottom: 50 ± 1.5 ohm

Full tank, float at top: 425 ± 6.5 ohm

Warning

Warning