End cover

| End cover |

| To remove |

| Important | ||

|

It is very important to observe great cleanliness when working on the gearbox. Dirt particles can seriously damage the function and service life of the gearbox. |

||

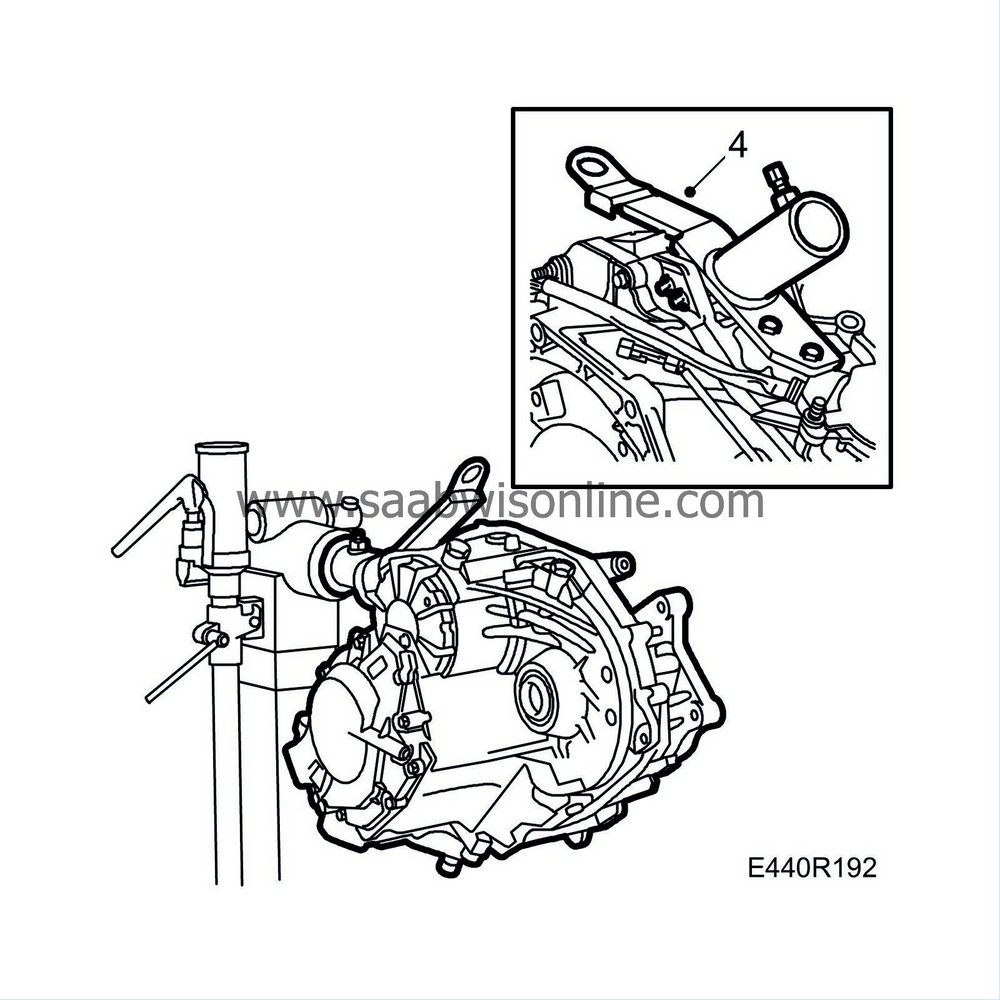

| 1. |

Drain the oil from the transmission in the car before starting removal. Remove the gearbox from the car. See adjustment/replacement, gearbox assembly. Fit the dipstick pipe.

|

|

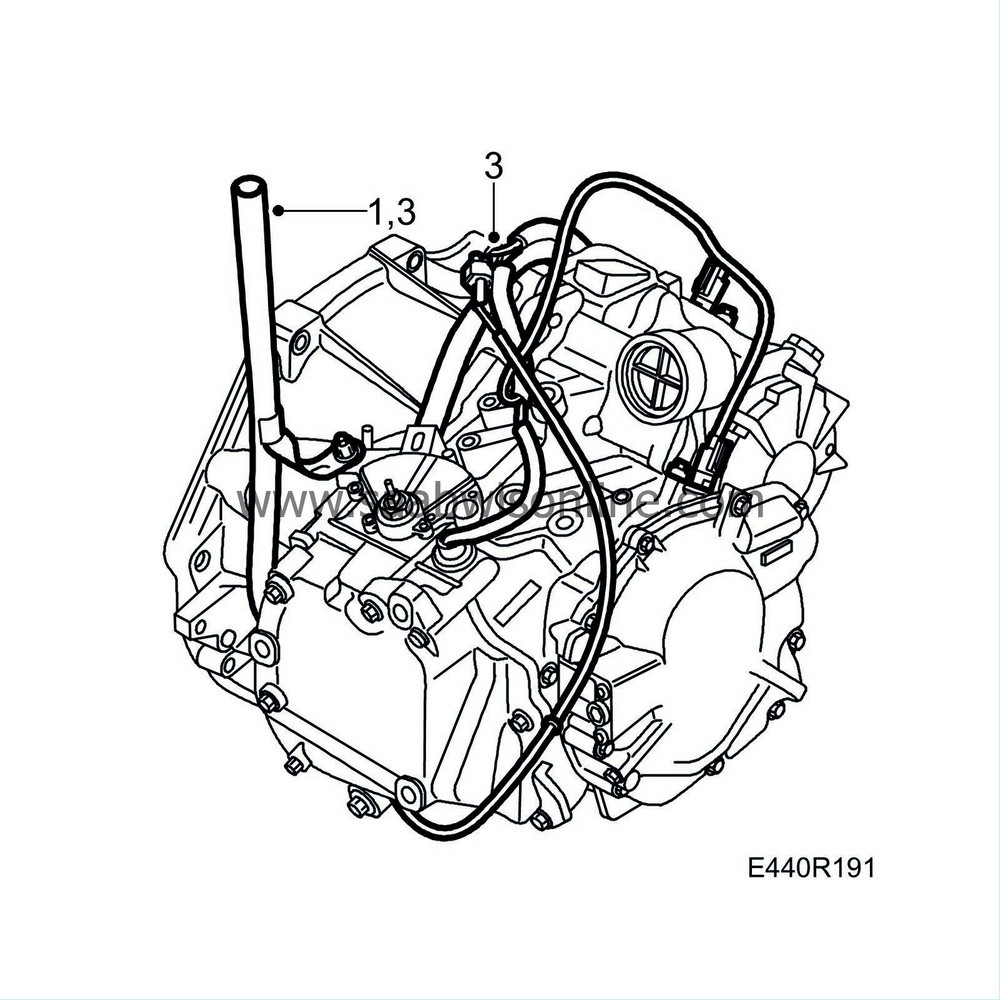

| 2. |

Plug the shaft openings and clean the exterior of the gearbox. Use plug 91 32 929, seals 91 32 937 and 87 92 665. Plug the vent pipe. |

|

| 3. |

Remove the dipstick pipe

|

|

| 5. |

Fit tool 87 91 766 into the torque converter. Remove holder 87 92 574. Remove the torque converter.

|

|

| 6. |

Turn the gearbox through 90° in the stand.

|

|

| 7. |

Remove the bolts securing the end cover. Knock loose the cover with a plastic mallet. Remove the four seals.

|

|

| 8. |

If necessary, remove the accumulator for C1 from the end cover with spring and plunger.

|

|

| 9. |

Remove any gasket remains from the gearcase and torque converter shell sealing surfaces. Use the gasket scraper with great care.

|

|

| Important | ||

|

The remains of old gaskets and other particles must under no circumstances fall into the oil ducts, openings or components. |

||

| Fitting |

| 1. |

Fit the accumulator for C1 in the end cover. Use new O-rings lubricated with petroleum jelly.

Tightening torque 10 Nm (7 lbf ft)

|

|

| 2. |

Fit the bearing race for the rear cover. Lubricate the bearing race with petroleum jelly. Lay the bearing race and the thrust bearing in the C1/C2 unit.

|

|

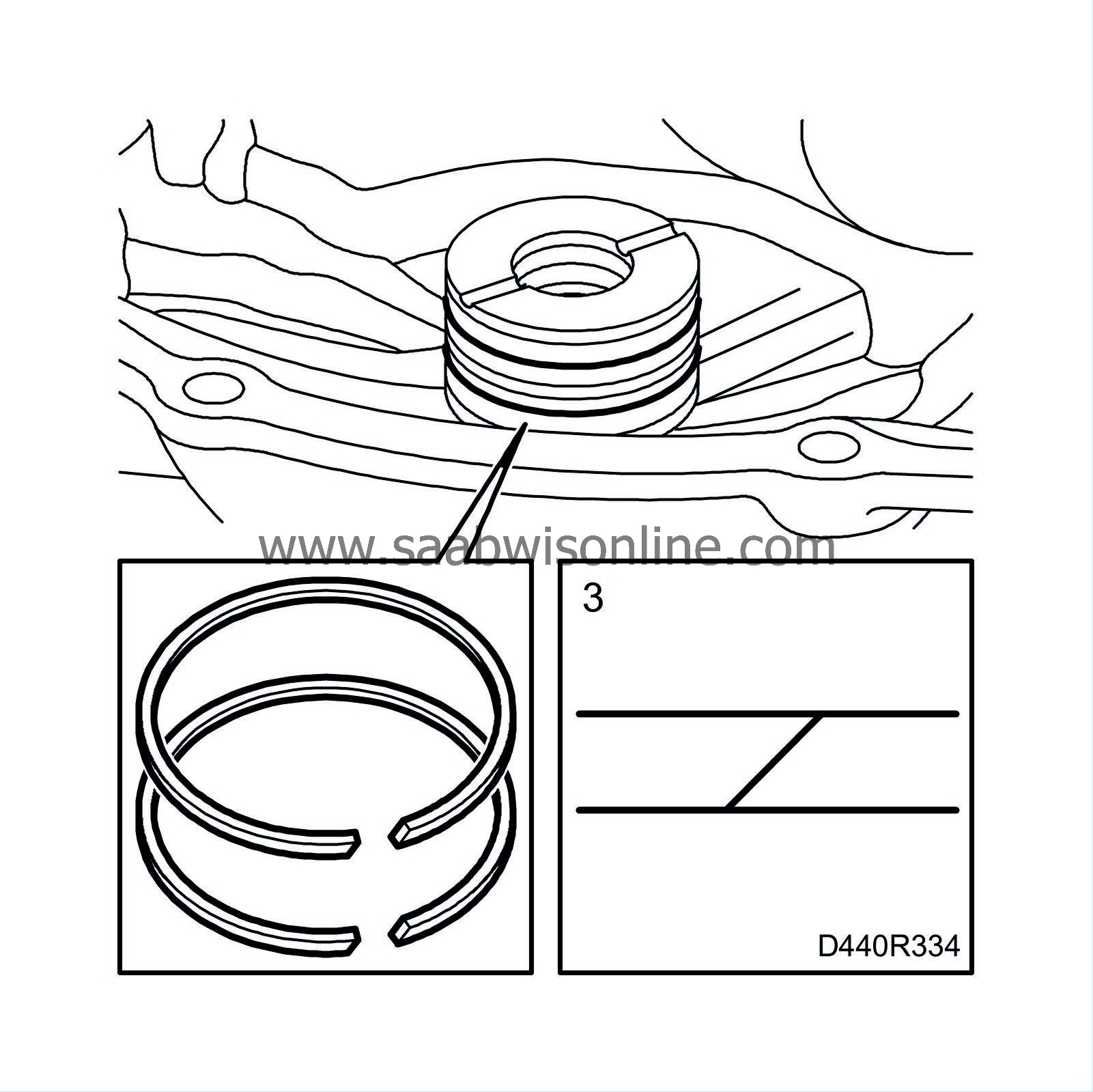

| 3. |

Fit sealing rings on the end cover bearing housing, do not bend them more than necessary.

|

|

| 4. |

Fit a new sealing ring on the C1/C2 shaft.

|

|

| 5. |

Clean the sealing surfaces with cleaning fluid 30 02 599.

|

|

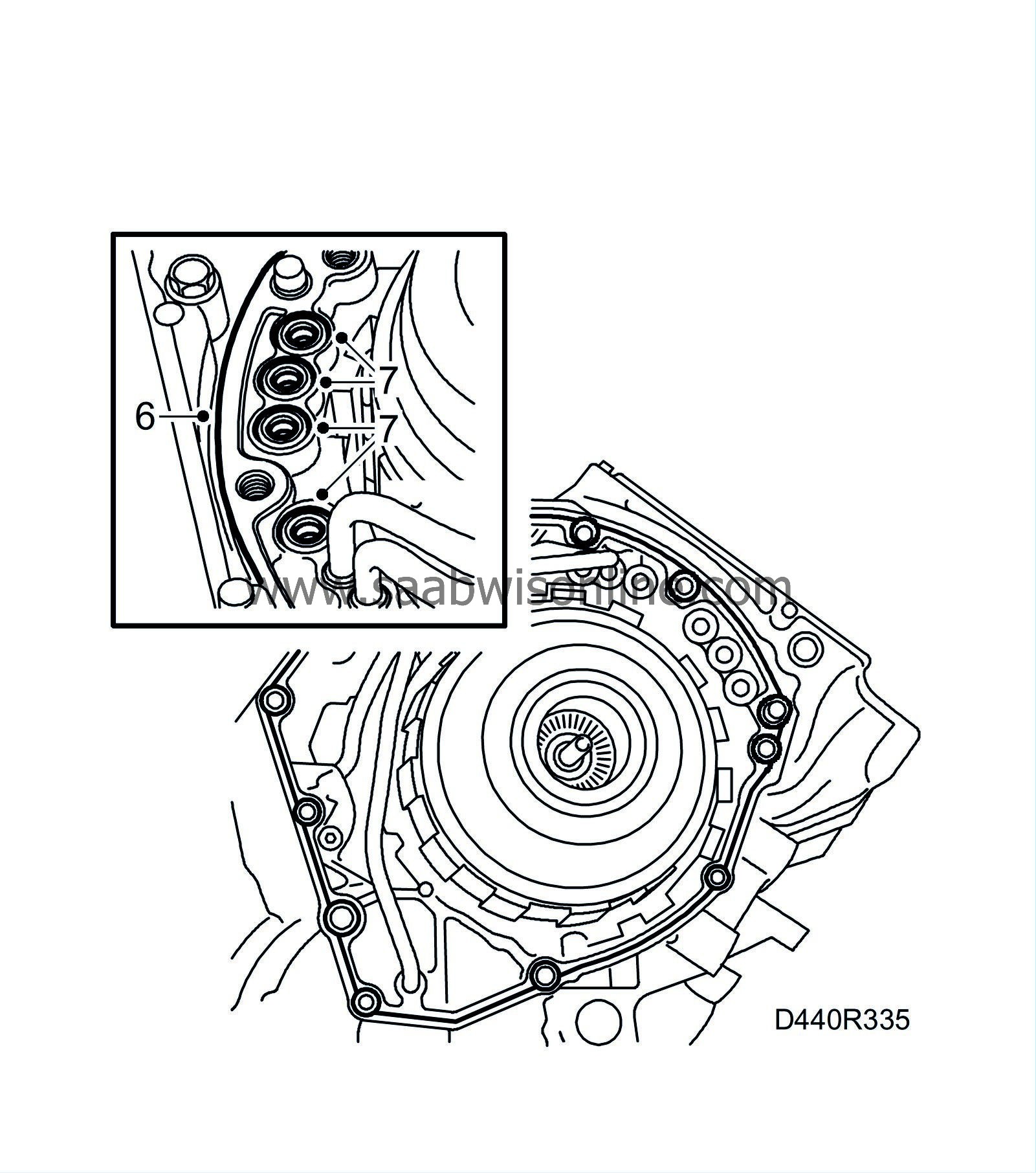

| 6. |

Apply a bead of flange sealant 93 21 795 approximately 1 mm thick on the end cover. Keep the sealing surfaces free from grease.

|

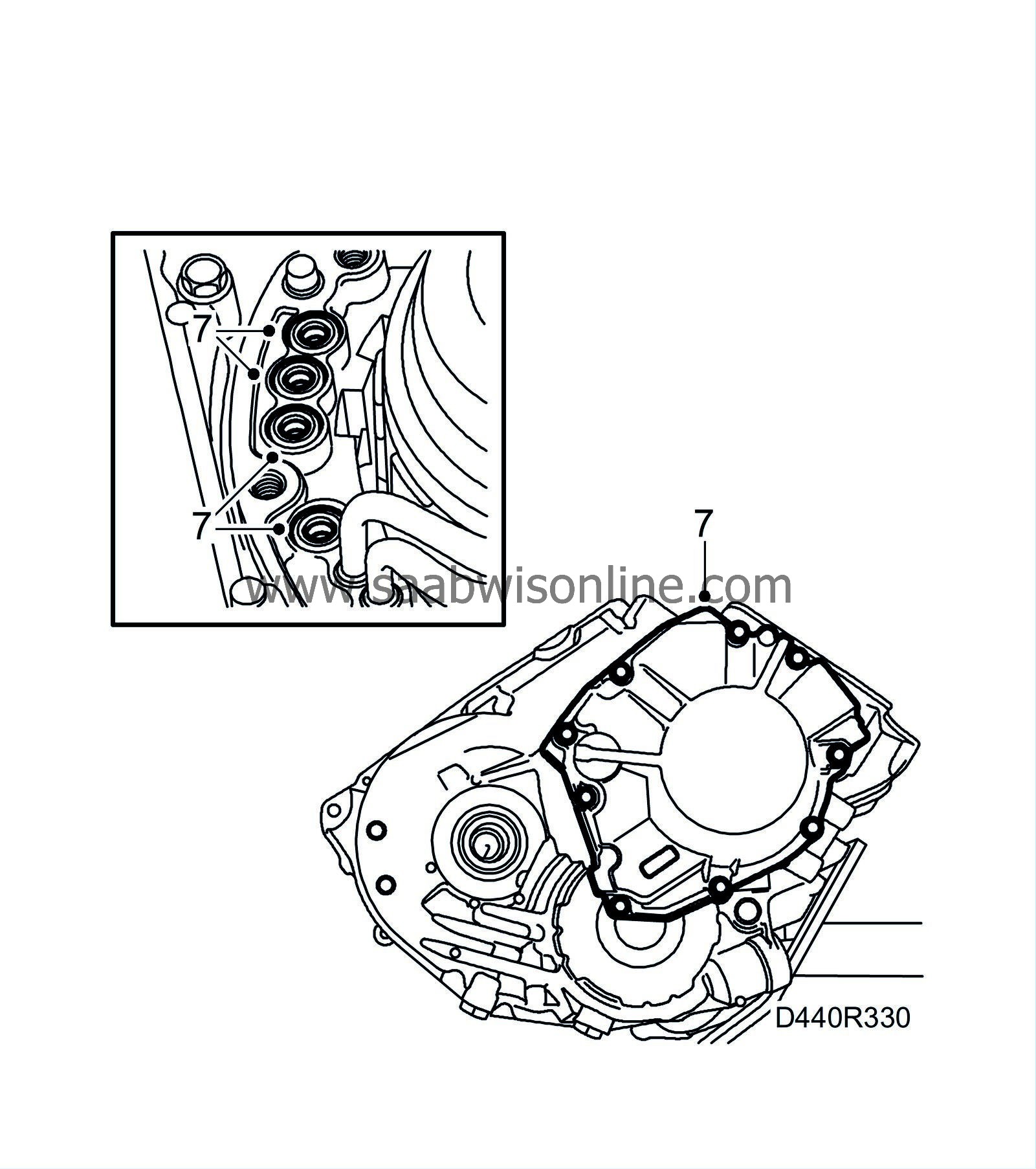

|

| 7. |

Lubricate four new sealing rings for the oil holes with petroleum jelly and fit them on the gearcase.

|

|

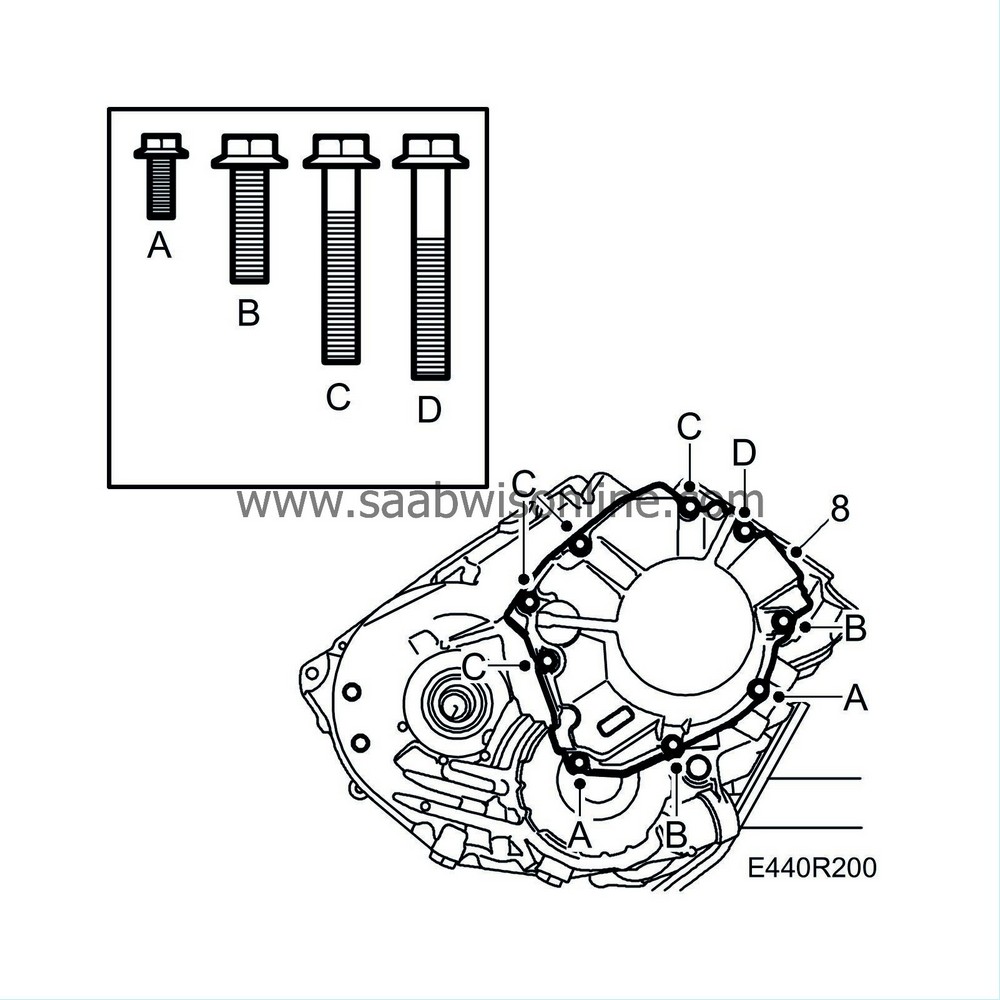

| 8. |

Fit the end cover on the gearcase. Apply thread locking compound 74 96 284 to the bolts and tighten. (Different lengths)

Tightening torque M6 10 Nm (7 lbf ft) Tightening torque M8 25 Nm (18 lbf ft)

|

|

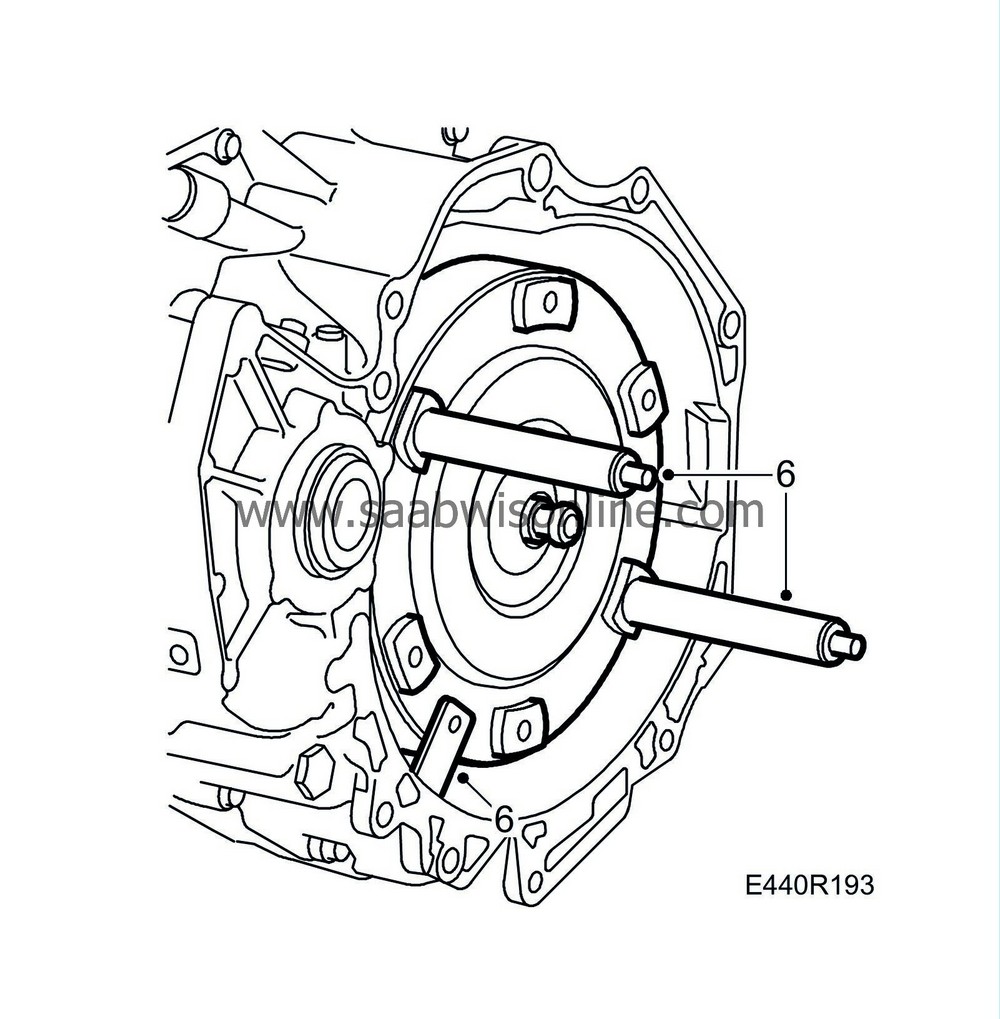

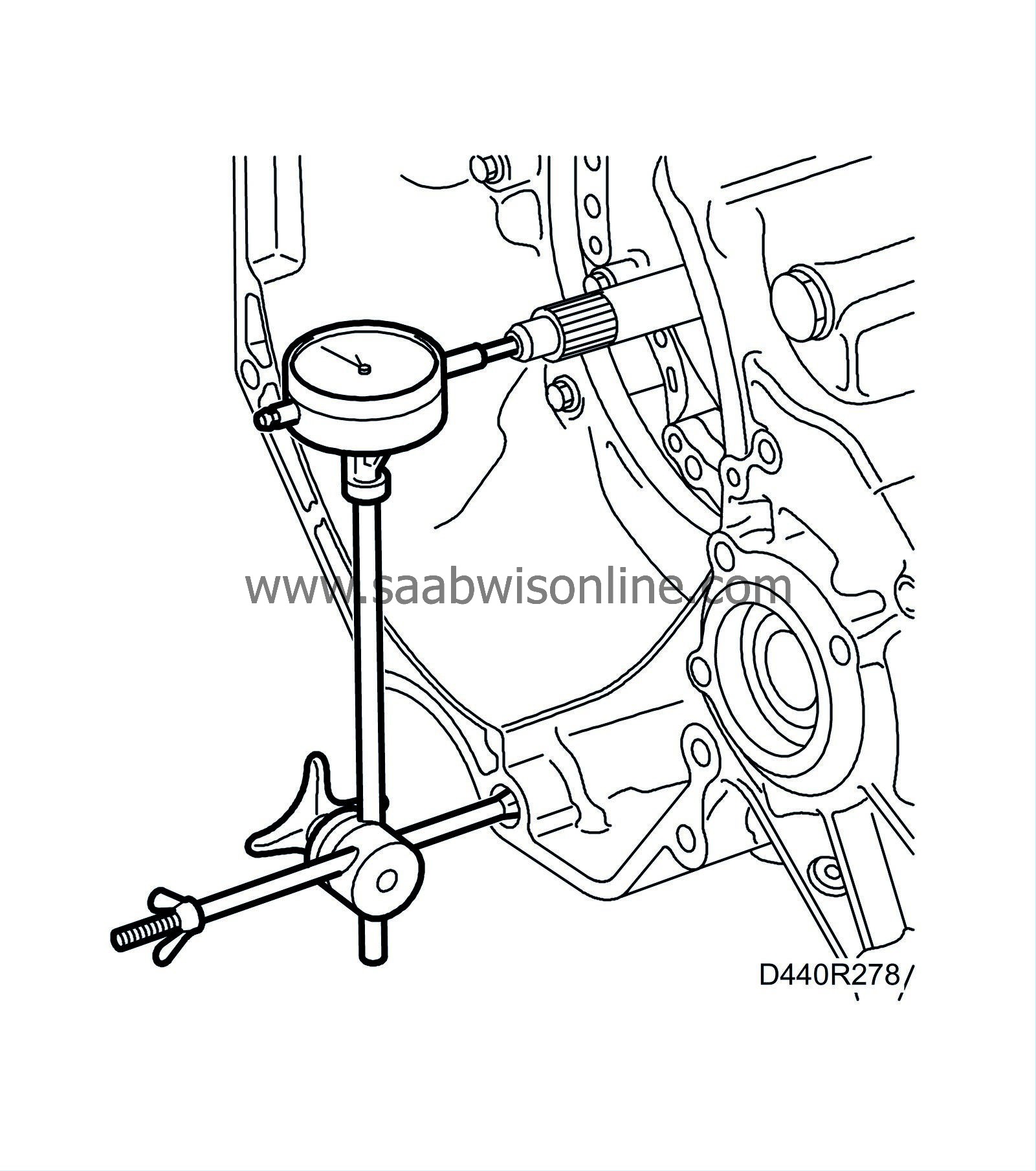

| 9. |

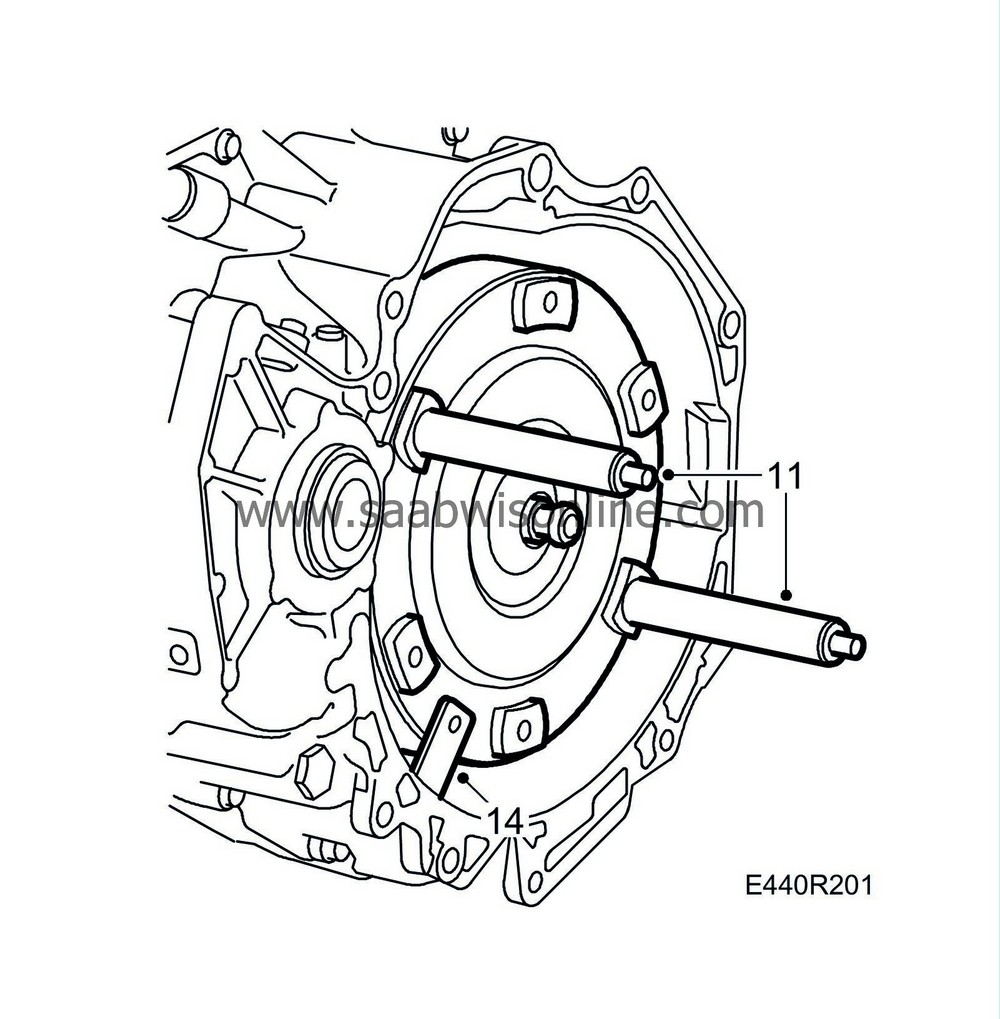

Make sure the turbine shaft has an axial clearance of 0.37 - 0.9 mm. Use dial gauge 78 40 622 and stand 87 90 727 as illustrated.

|

|

| 10. |

Change the torque converter seal. See adjustment/replacement, torque converter seal.

|

|

| 11. |

Fit the torque converter. Use holder 87 91 766.

|

|

| 12. |

Make sure the torque converter has been fitted in the correct position by laying a steel rule on the mating face of the torque converter and measure the distance between the mating face and the drive plate contact surface on the torque converter. The distance must be at least 15 mm.

|

|

| 13. |

Remove holder 87 91 766.

|

|

| 14. |

Fit torque converter holder 87 92 574.

|

|

| 15. |

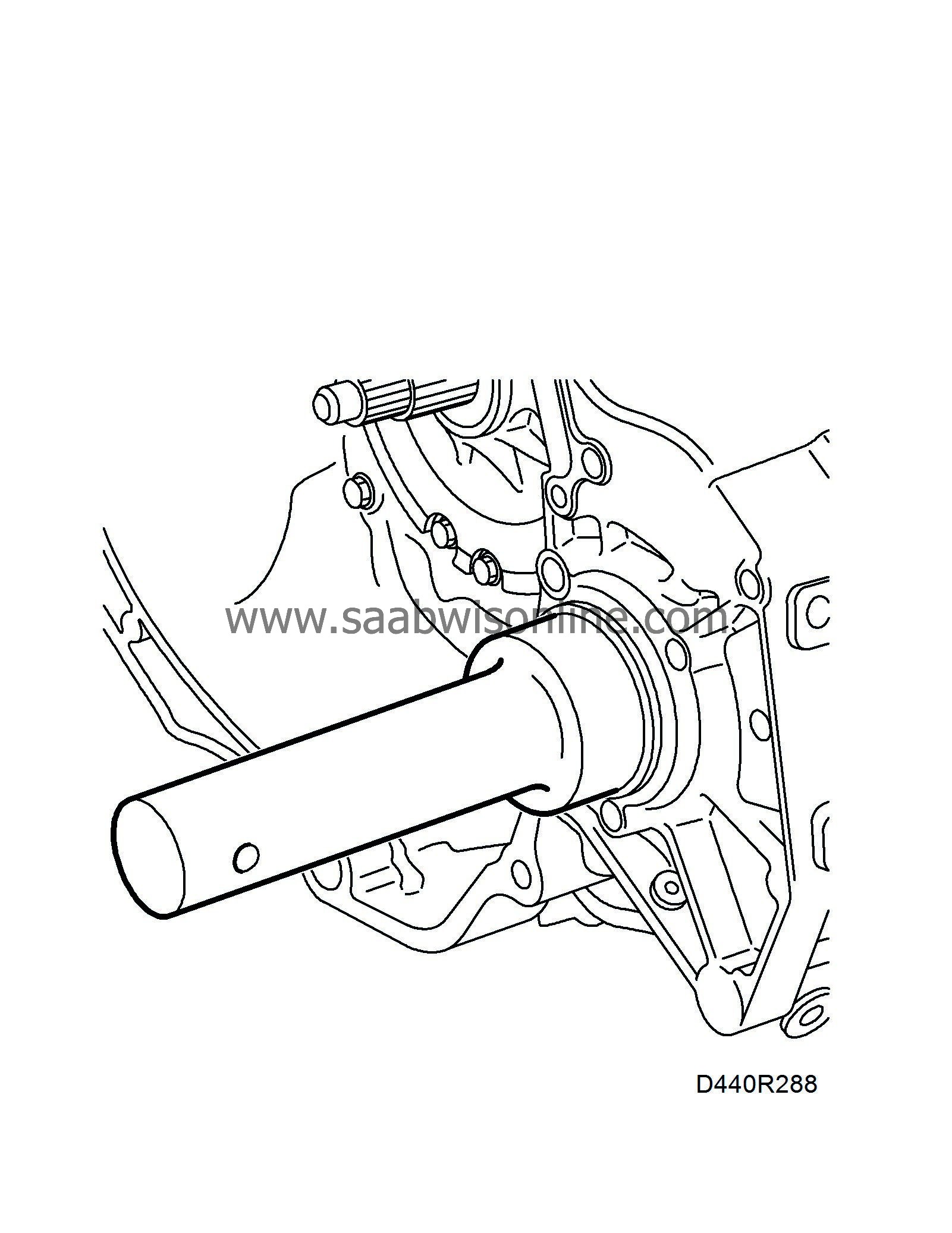

Change to new drive shaft seals. Use drift 83 90 122.

|

|

| 16. |

Lift down the gearbox.

|

|

| 17. |

Remove holder 87 92 392

|

|

| 18. |

Fit the attachment for the gear shift cable.

|

|

| 19. |

Fit the gearbox in the car. See adjustment/replacement, fitting gearbox assembly.

|

|