Output shaft, pinion

| Output shaft, pinion |

| To remove |

| 1. |

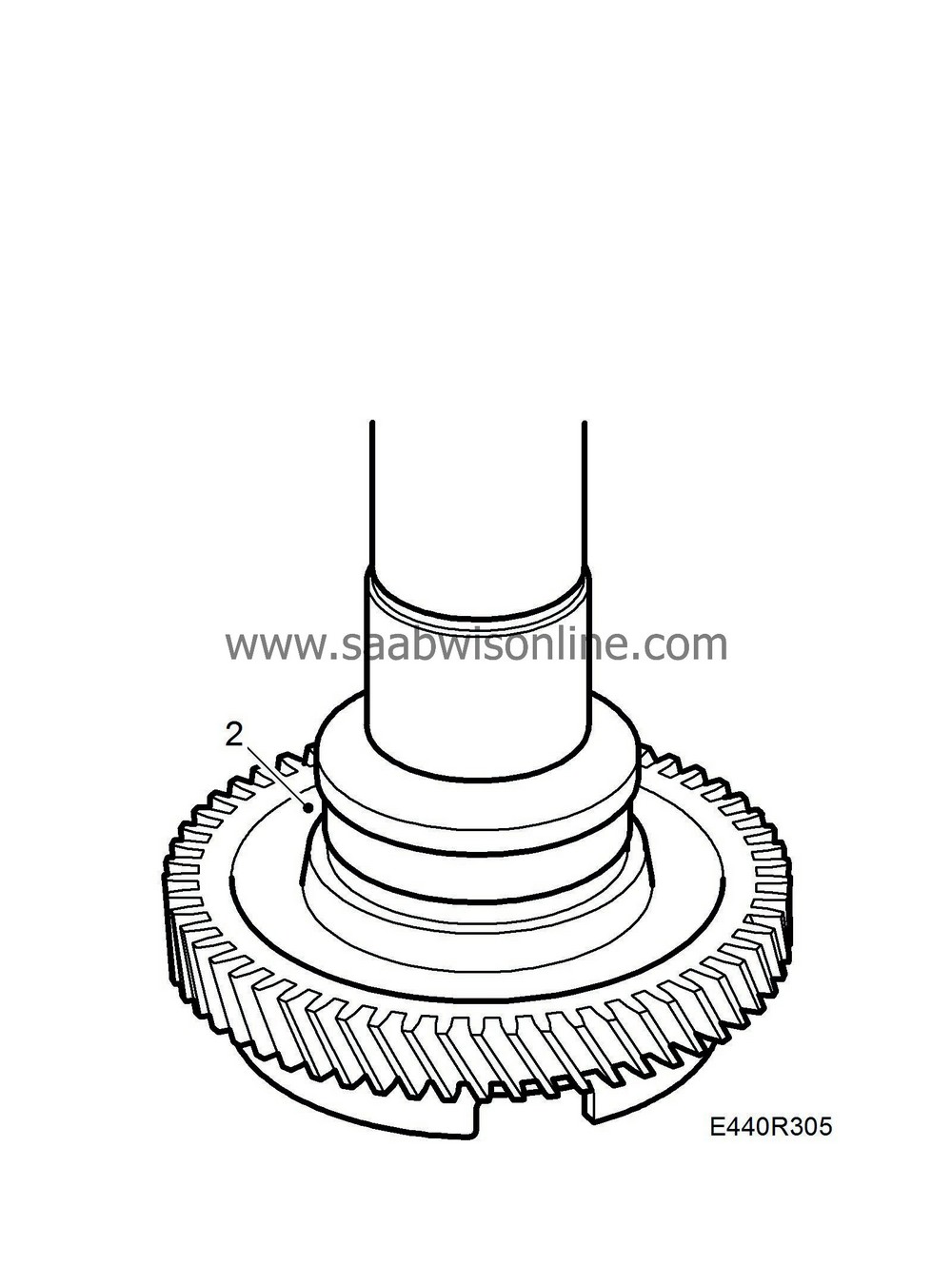

Undo the circlip and remove the ring gear. Use gloves so as not to hurt your hands on the teeth.

|

|

| 2. |

If the bearings on the idler gear are to be changed, measure the rolling torque as illustrated and make a note of this. Use

83 90 130 Dynamometer

and a piece of string.

|

|

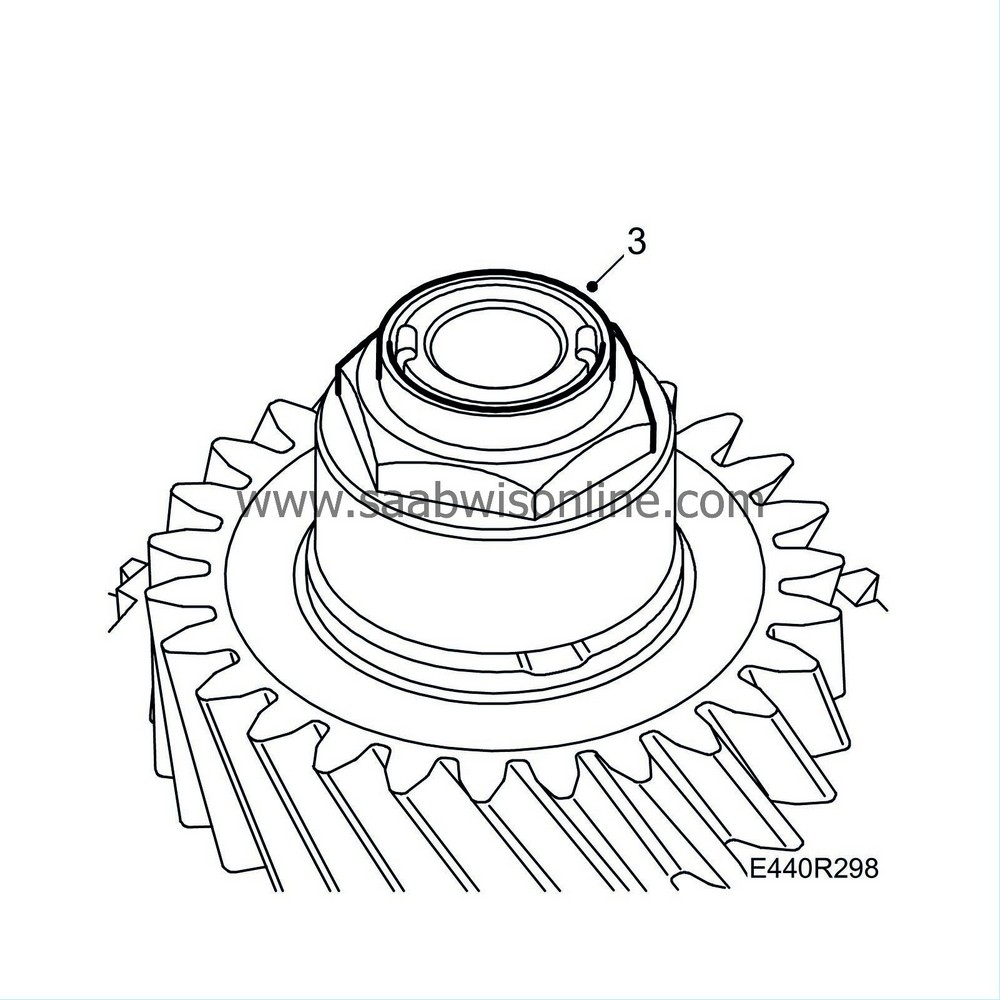

| 3. |

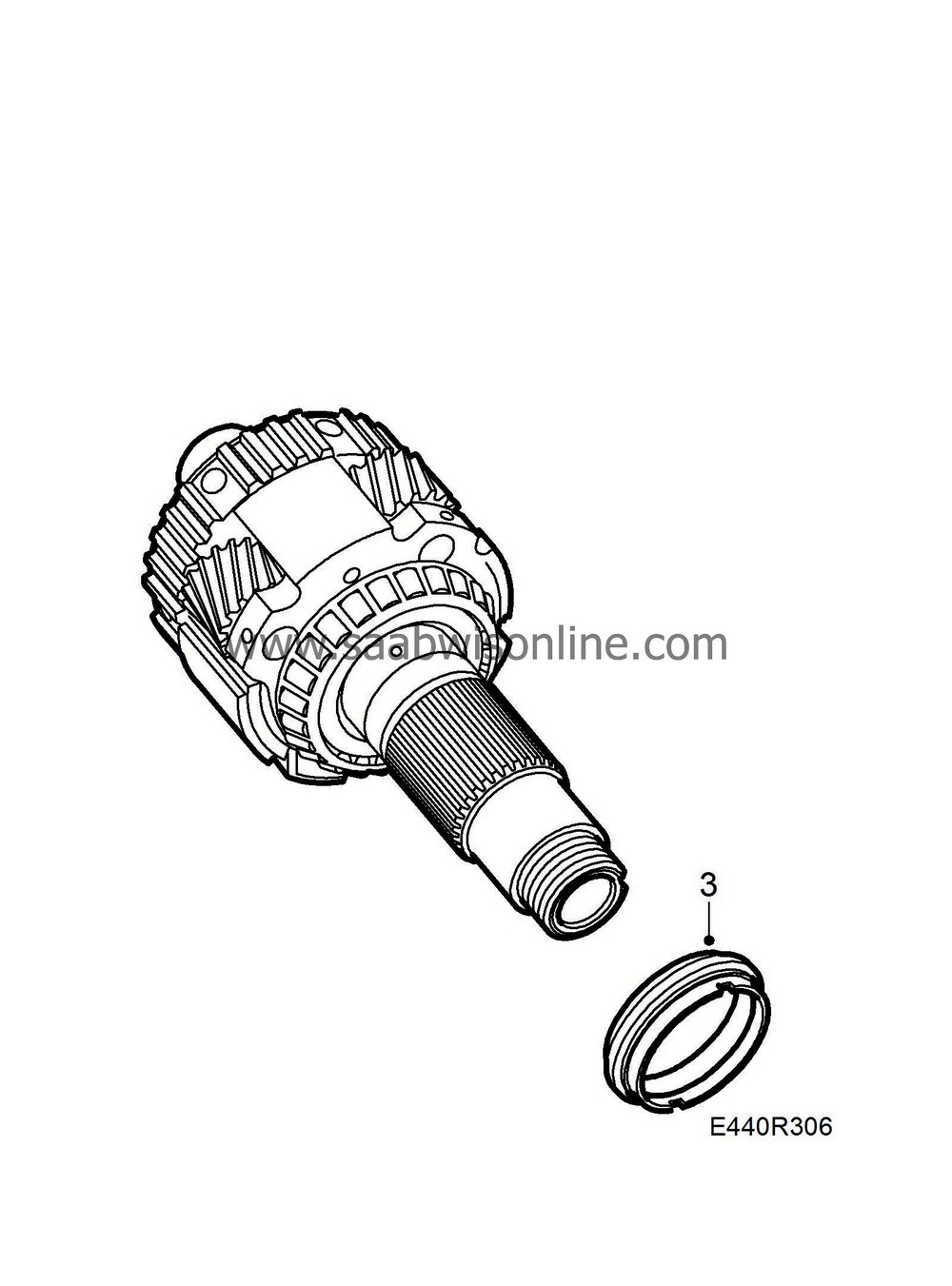

Tap out the lugs from the lock nut.

|

|

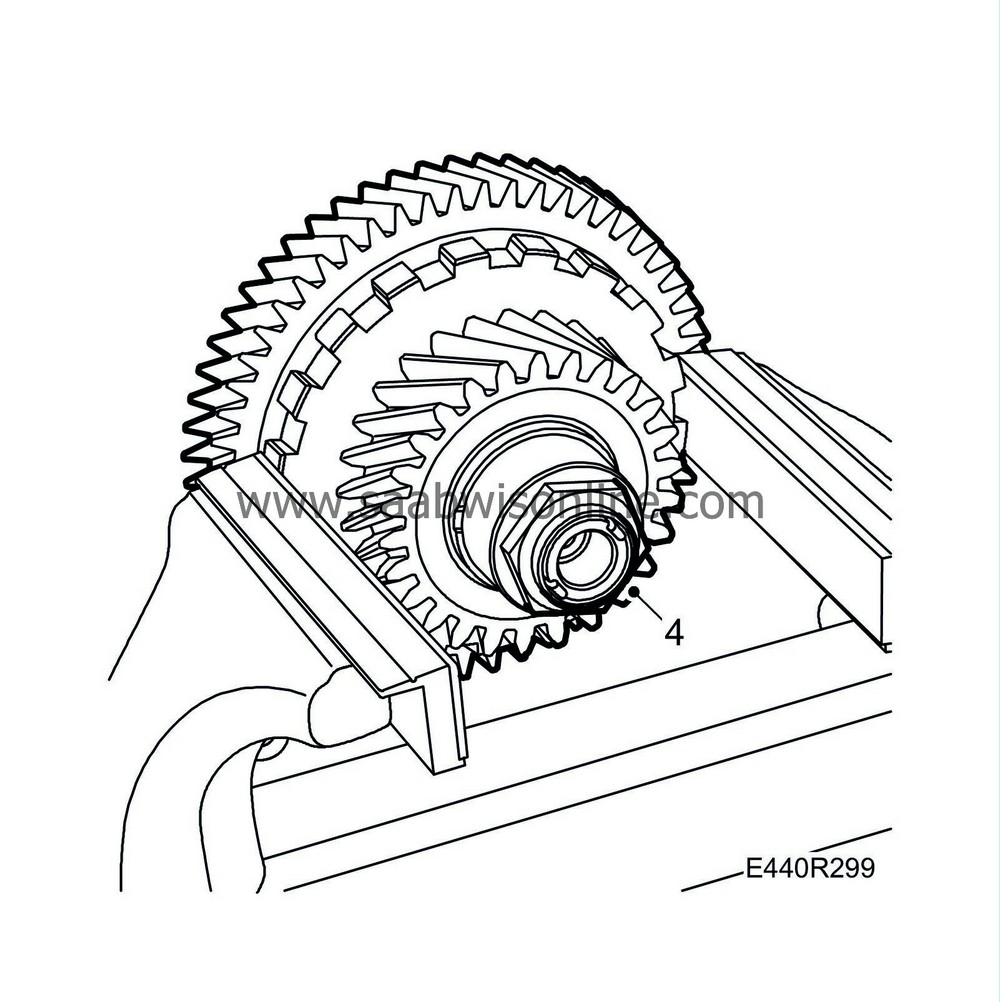

| 4. |

Fix the shaft in a padded vice and remove the nut.

|

|

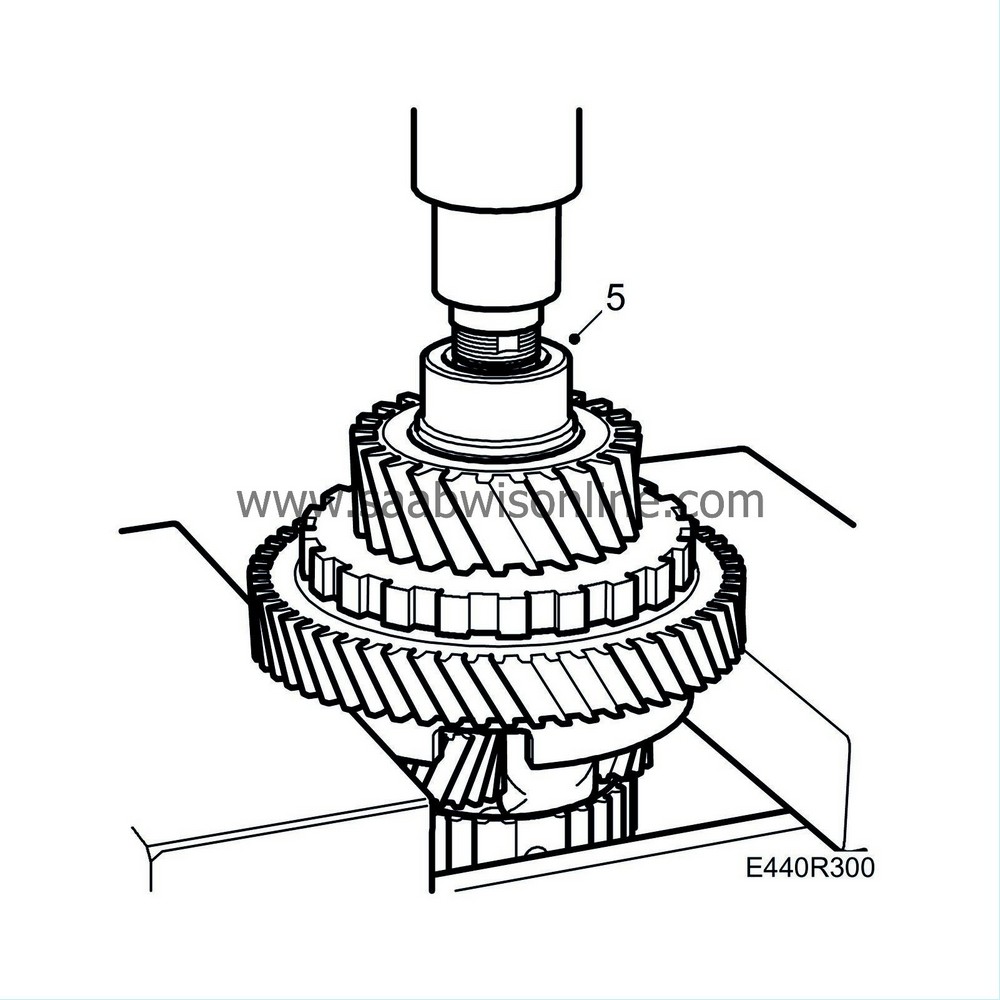

| 5. |

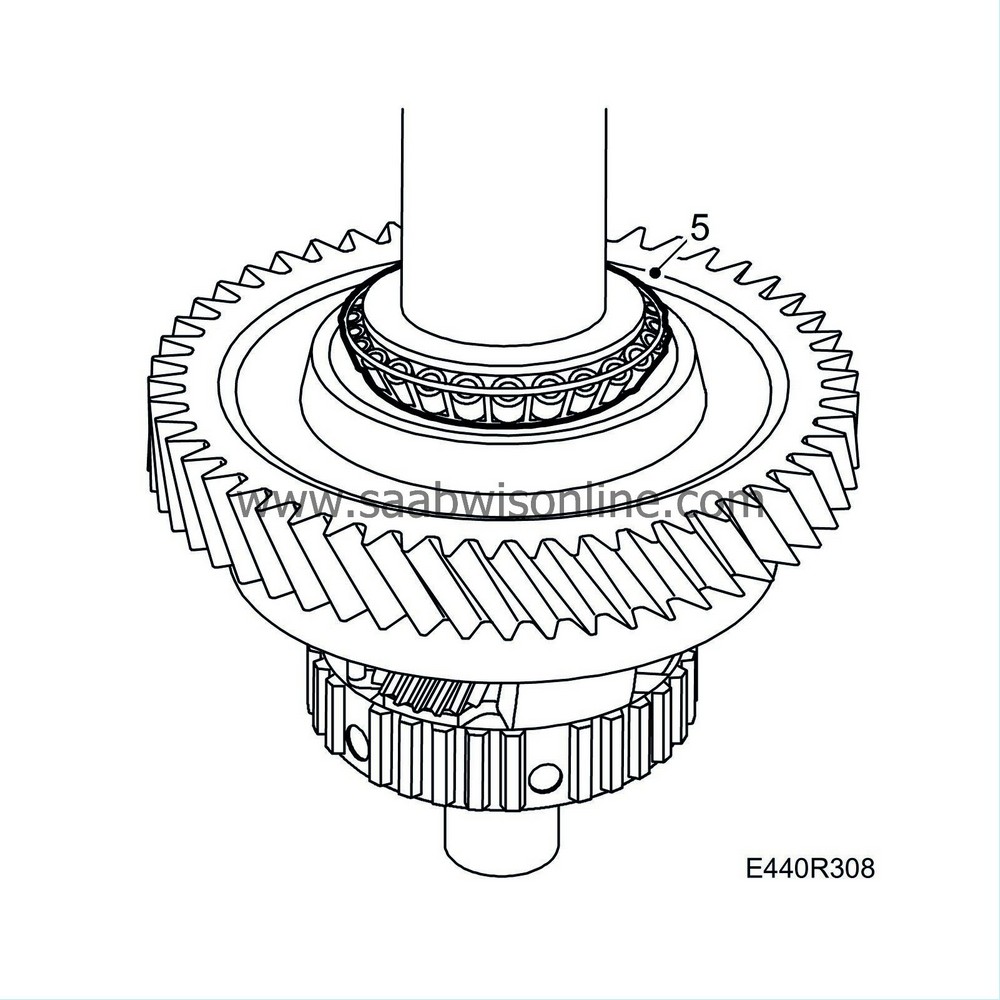

Press the output shaft out of the pinion using

87 92 210 Support, differential bearing

in a hydraulic press. Hold the shaft so that it does not fall to the ground. Mark the bearing race with a felt-tip marker so it can be refitted in the same position.

|

|

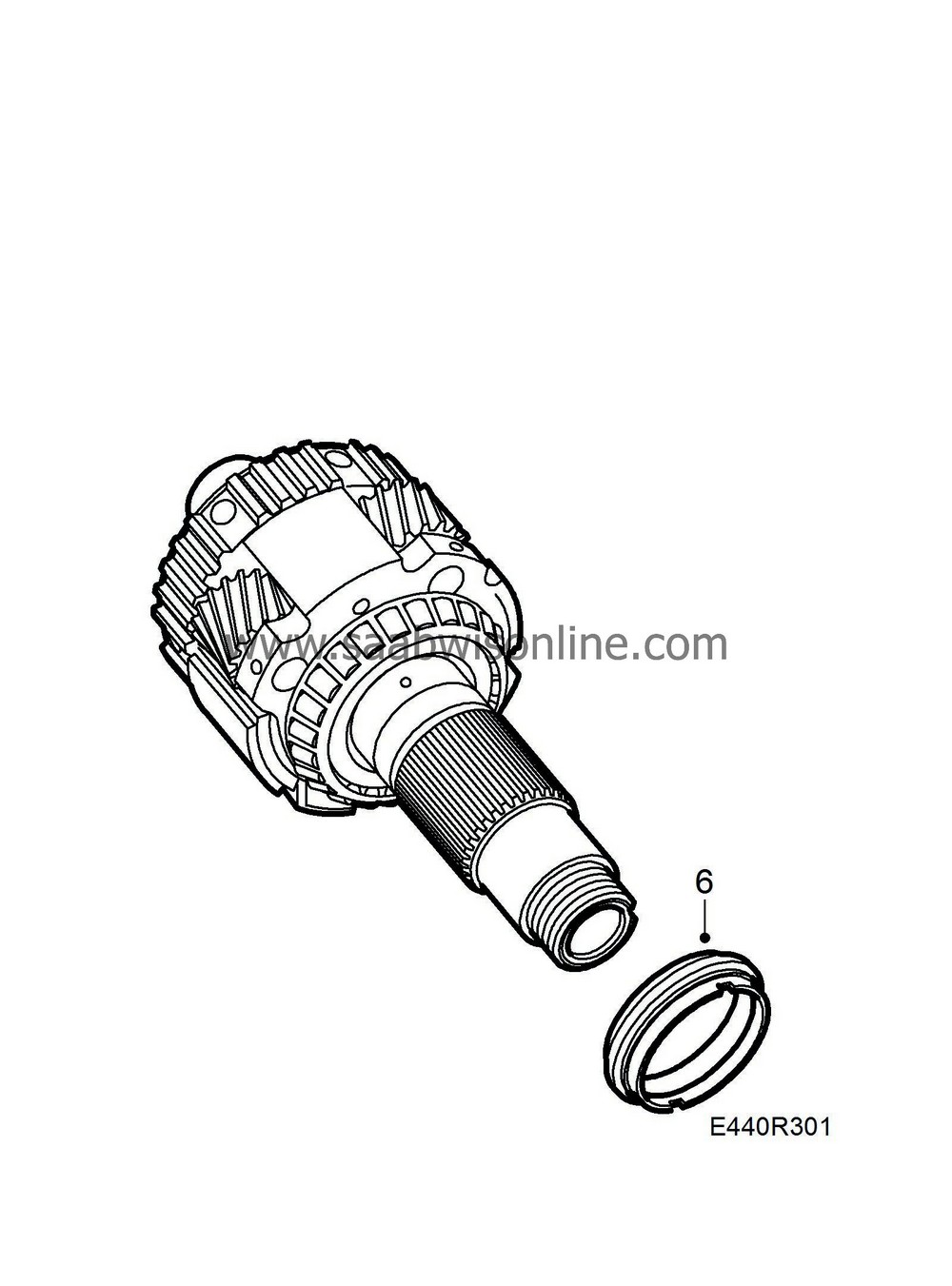

| 6. |

Remove the retaining sleeve.

|

|

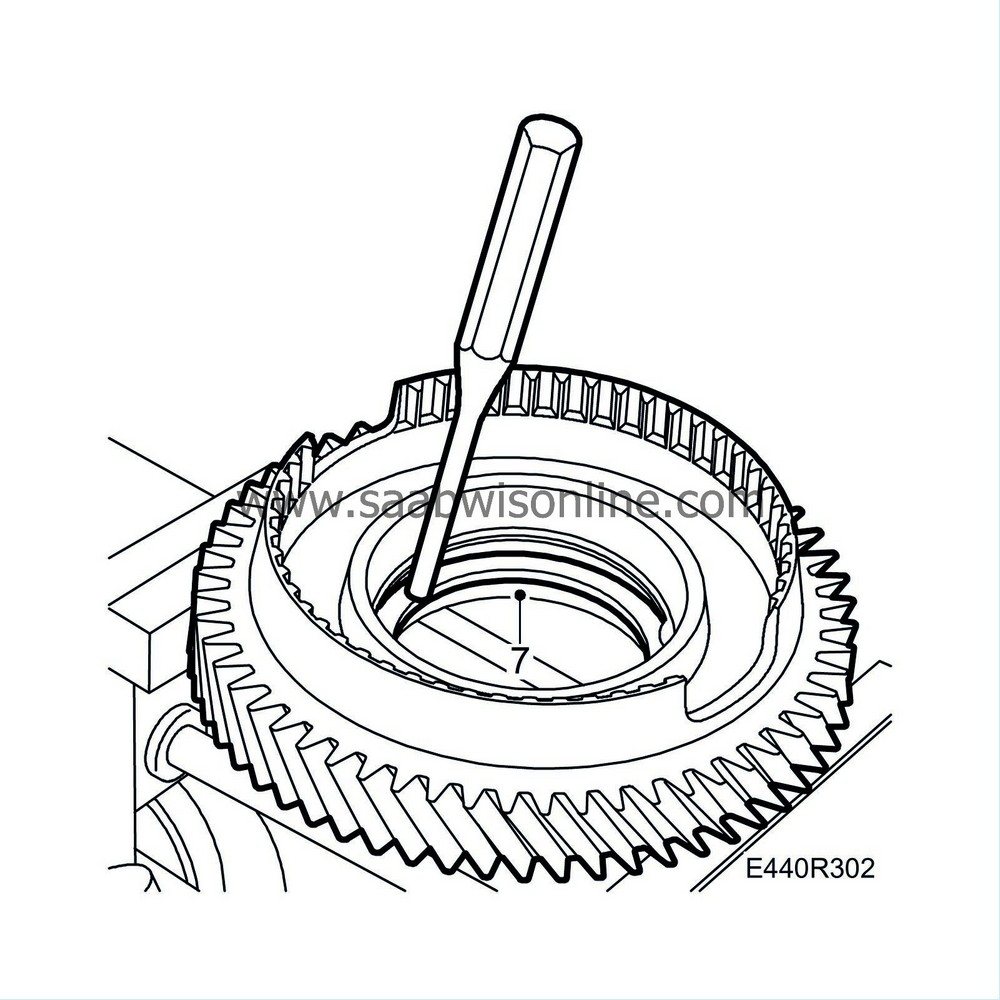

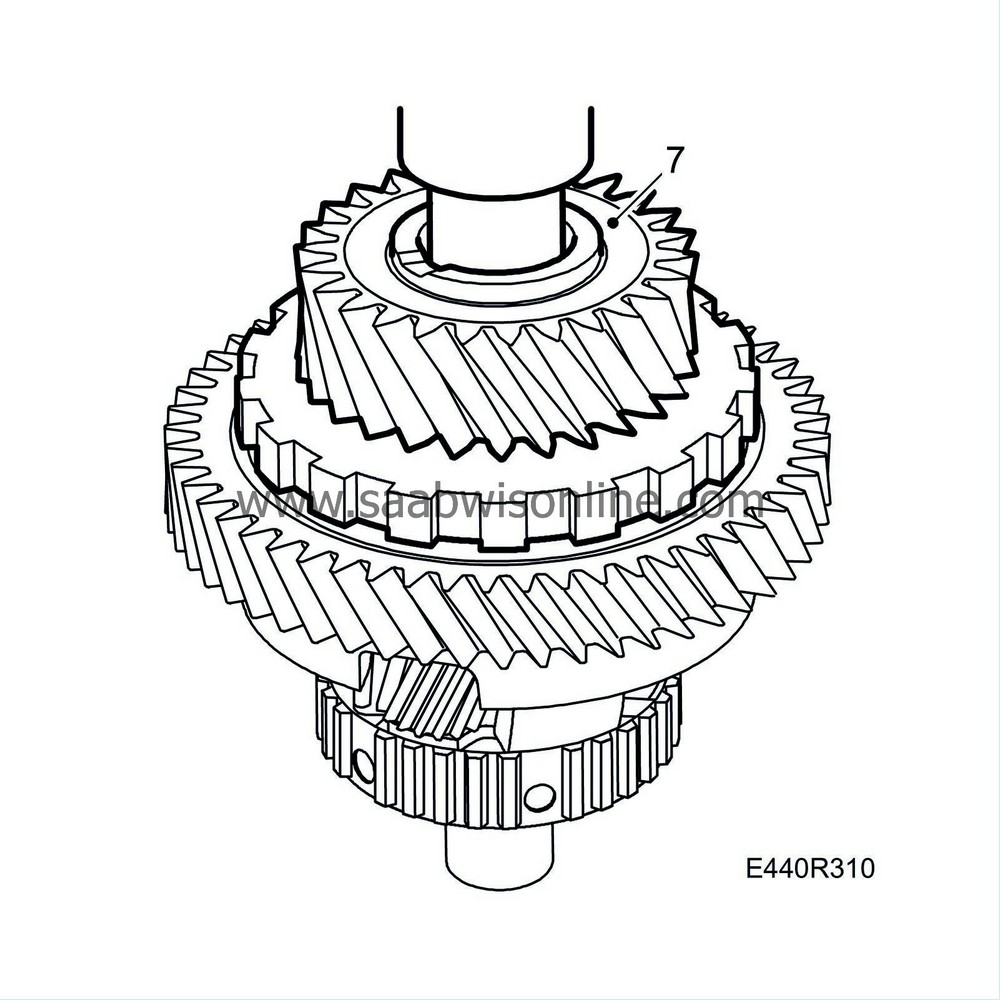

| 7. |

If necessary, tap the bearing races out of the idler gear using a hammer and drift.

|

|

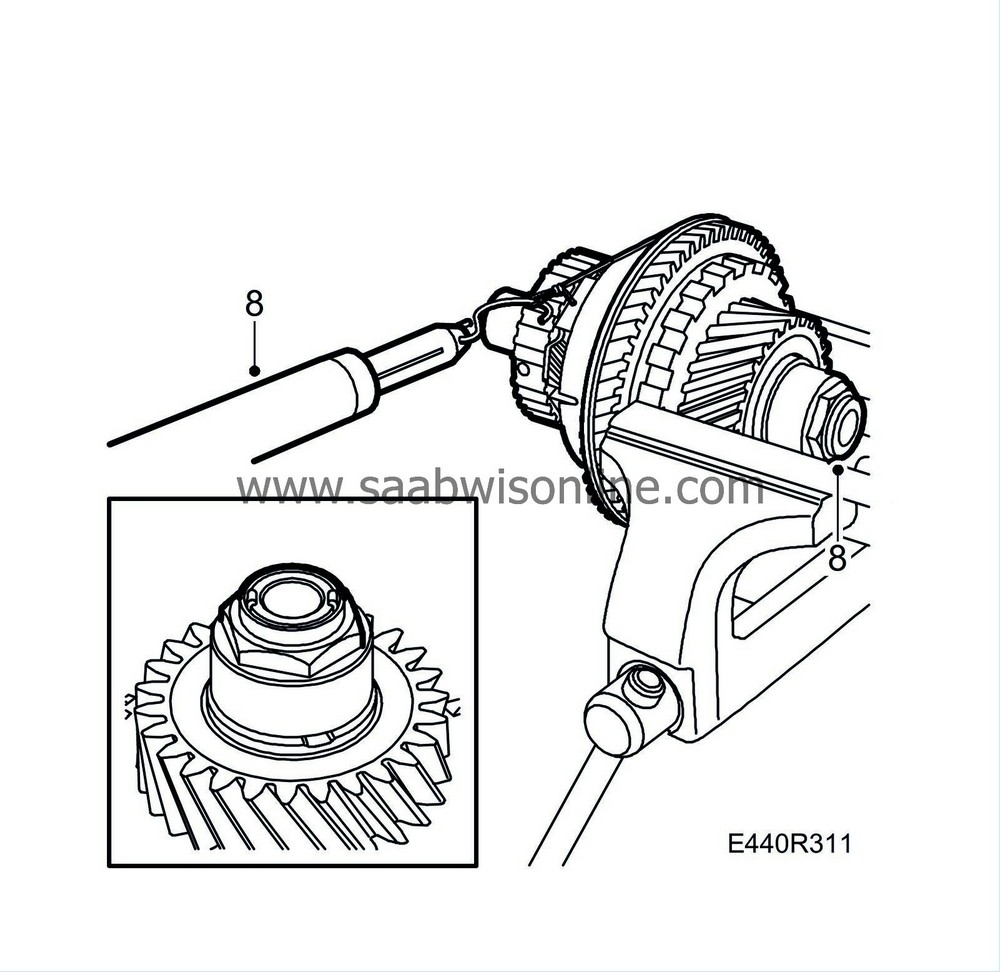

| 8. |

Remove the inner conical roller bearing using

87 91 832 Puller, internal Ø= 63 mm

. Rotate the shaft a number of times while tightening the tool. Fit

87 91 642 Basic tool

and use an M10 nut as support. Clean all parts thoroughly.

|

|

| Fitting |

| 1. |

Press bearing onto the pinion shaft. Lubricate with automatic transmission fluid. Use

87 91 204 Sleeve, bearing race

.

|

|

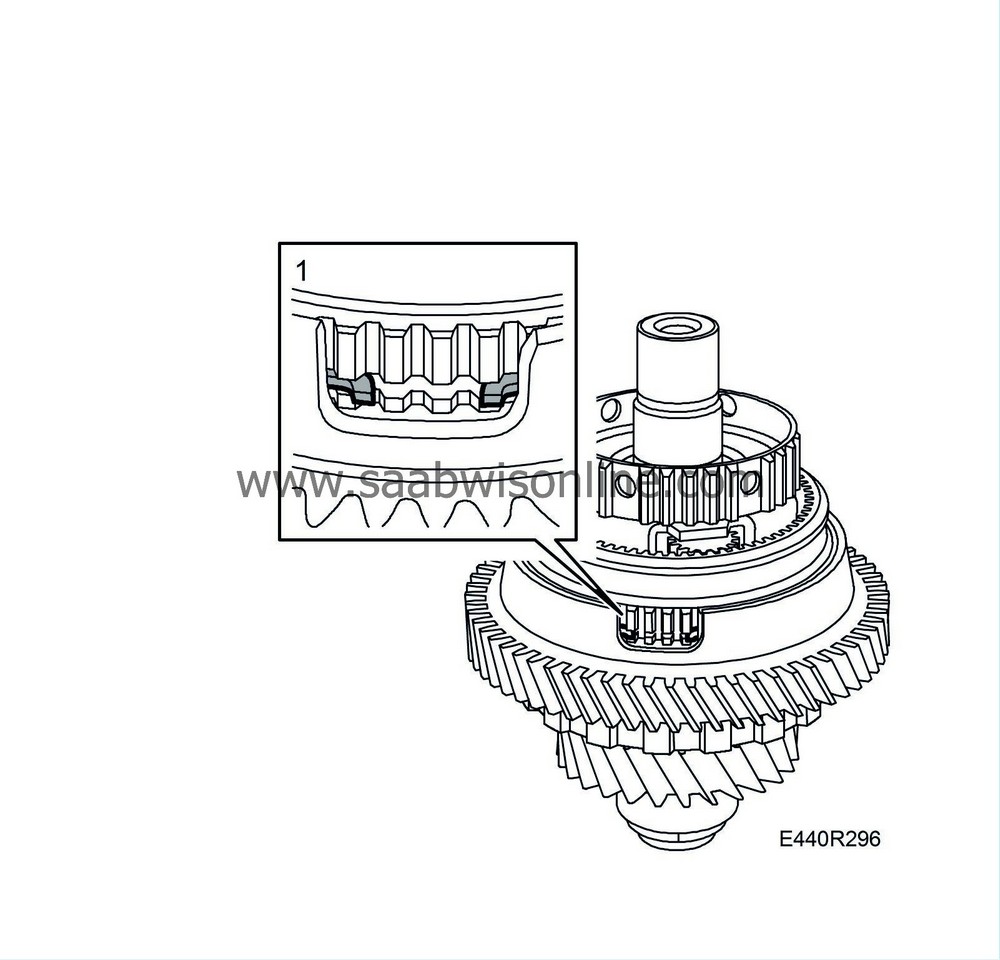

| 2. |

Press in the bearing race on one side of the idler gear towards the inner circlip. Use

87 91 204 Sleeve, bearing race

and the old bearing race in between. Press in the other bearing race in the same way.

|

|

| 3. |

Fit a new retaining sleeve.

|

|

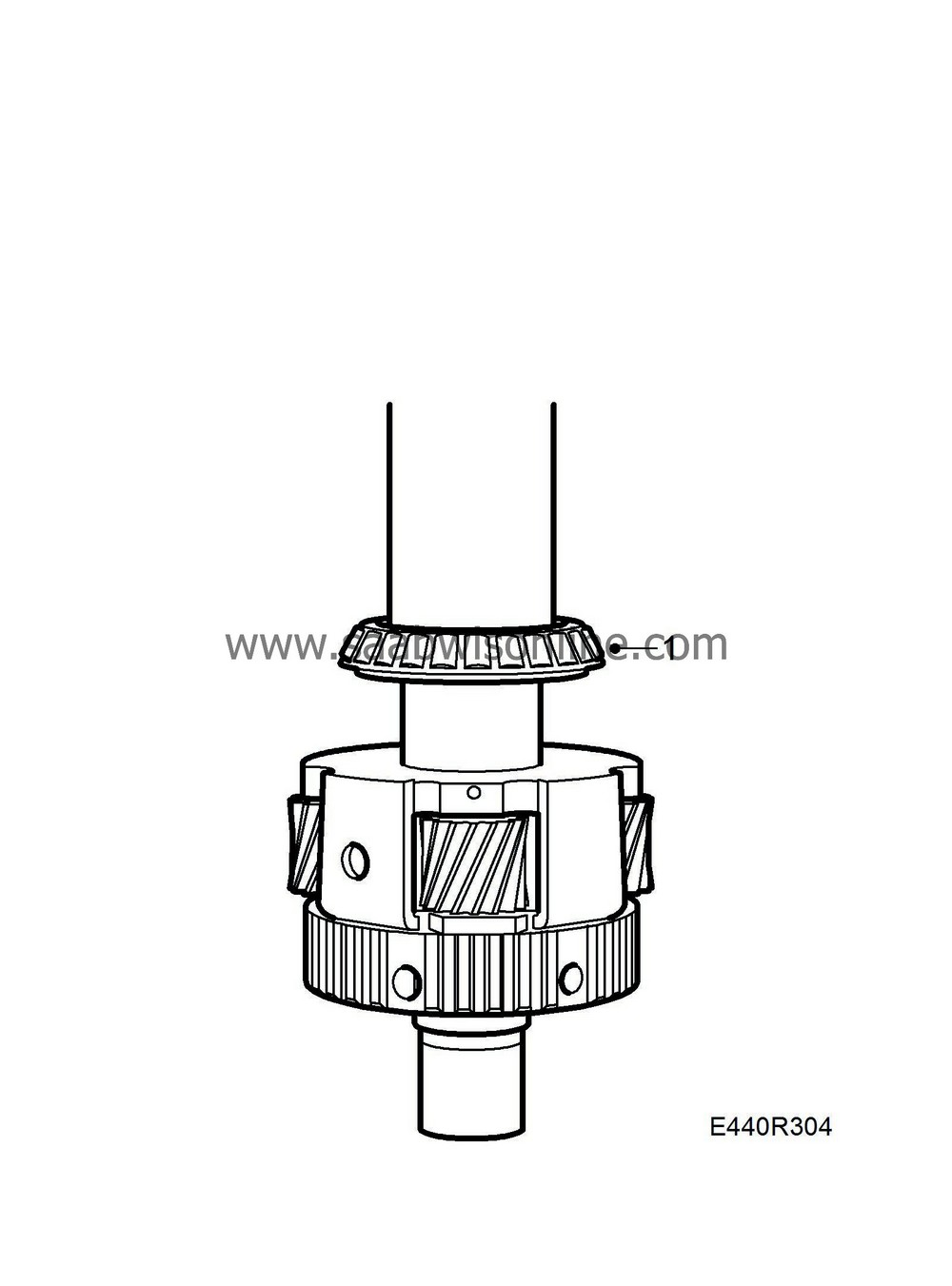

| 4. |

Fit the idler gear. Lubricate the bearings with ATF.

|

|

| 5. |

Fit the conical bearing by carefully moving it towards the spacer ring. Use

87 91 204 Sleeve, bearing race

.

|

|

| 6. |

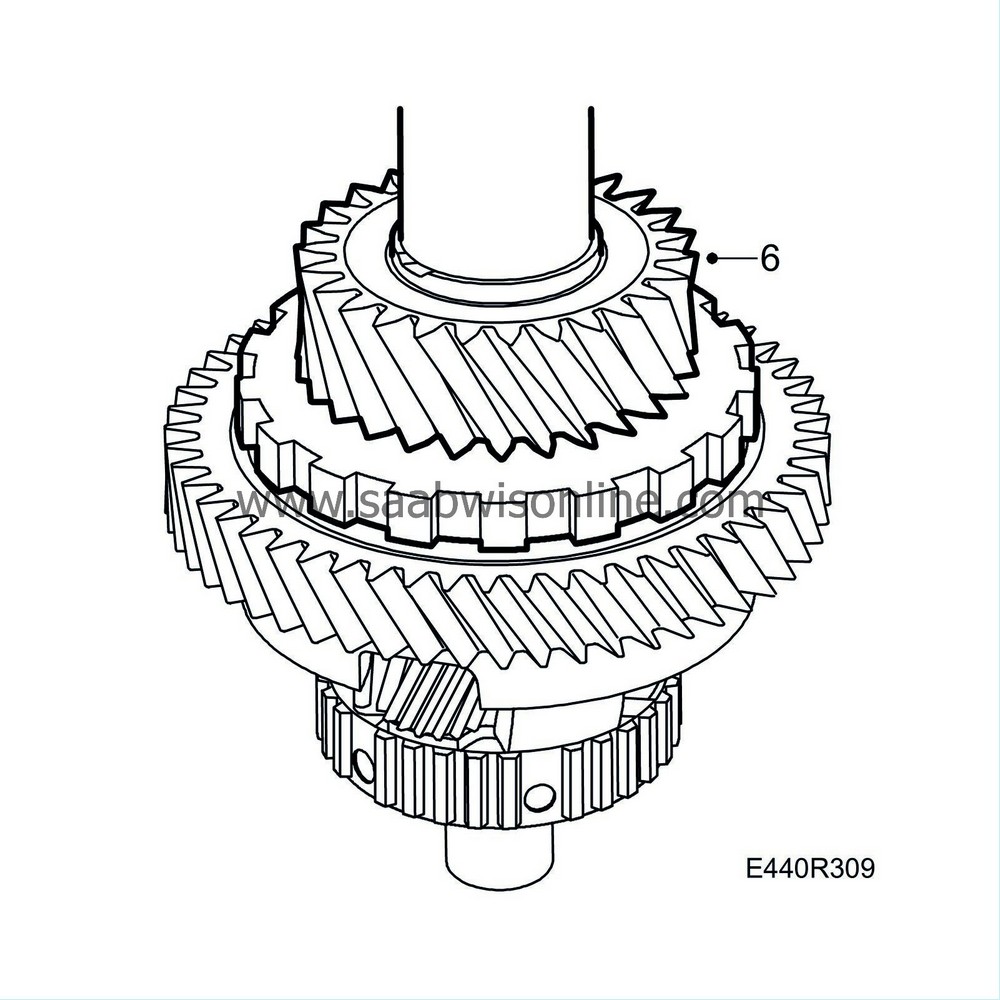

Carefully press in the pinion with

87 91 204 Sleeve, bearing race

.

|

|

| 7. |

Press the bearing race onto the output shaft. Fit the bearing in the same position as previously.

|

|

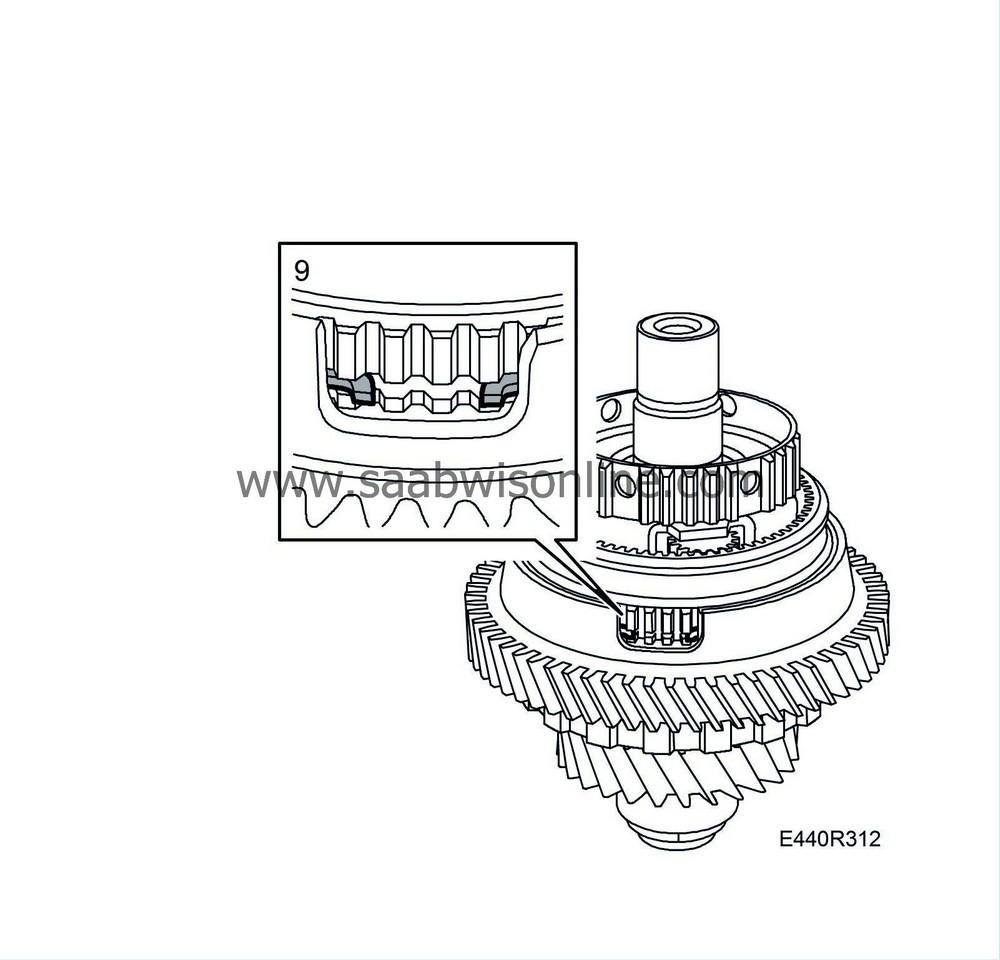

| 9. |

Turn the planetary gear over and fit the ring gear. Squeeze the circlip and let the gear fall into place.

|

||||||||||