(771-2395) Replacement of wheel bolts

|

MODIFICATION INSTRUCTION

|

|

Bulletin Nbr:

|

771-2395

|

|

Date:

...........

|

Mars 2003

|

|

Market:

|

enligt lista

|

|

|

Replacement of wheel bolts

|

|

Product Safety Campaign 150 13

|

Cars in stock must be rectified before delivery.

A personal communication must be sent to the owners of cars already delivered requesting them to get in touch with the nearest Saab garage as soon as possible to have the fault rectified.

Saab 9-5 M98-M03 up to and including Vehicle Identification Number 33015271 and with standard brakes (front brake disc diameter 285 mm). The procedure in this MI must only be carried out on cars where pressed steel and aluminium wheels are used alternately.

The contact surface to the brake disc is smaller on a pressed steel wheel than on an aluminium wheel. When wheels with pressed steel rims are fitted, corrosion and dirt formation can occur on the free surfaces on the brake disc.

When aluminium wheels are later fitted the rim's contact surface ends up on the layer formed which leads to settlement and reduced grip in the joint. This can result in the joint beginning to move with possible fatigue of the wheel bolts as a result.

40-400 133 021 Kit, wheel bolts

|

Note

|

|

Wheel bolt kits are confined to the spare parts warehouse in Nyköping and will be released periodically after evaluation of order volumes.

|

16-30 06 442 White high-pressure paste, (enough for 5-10 cars)

|

3.

|

Clean the contact surface between the rim and the brake disc from dirt and corrosion.

|

|

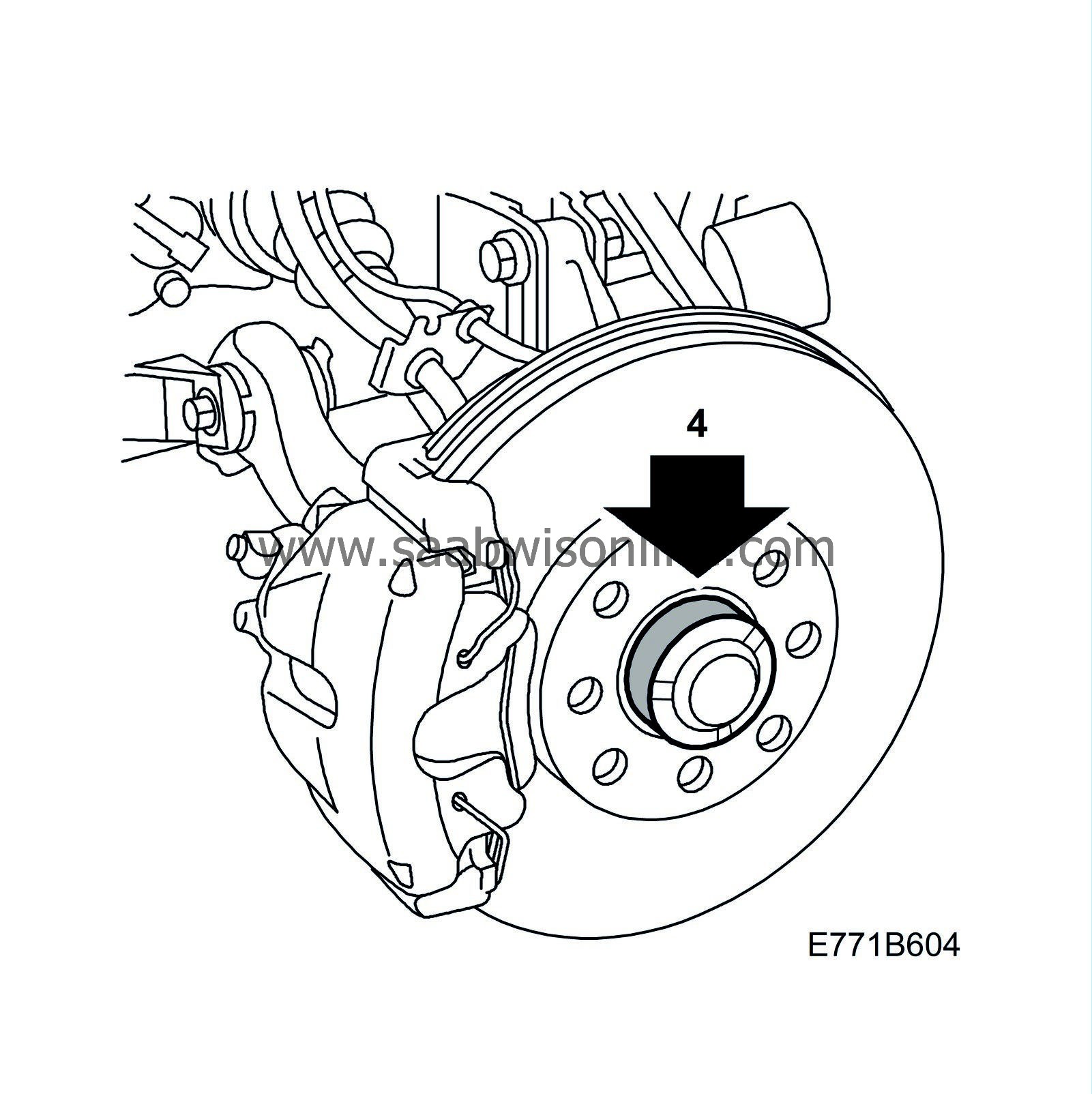

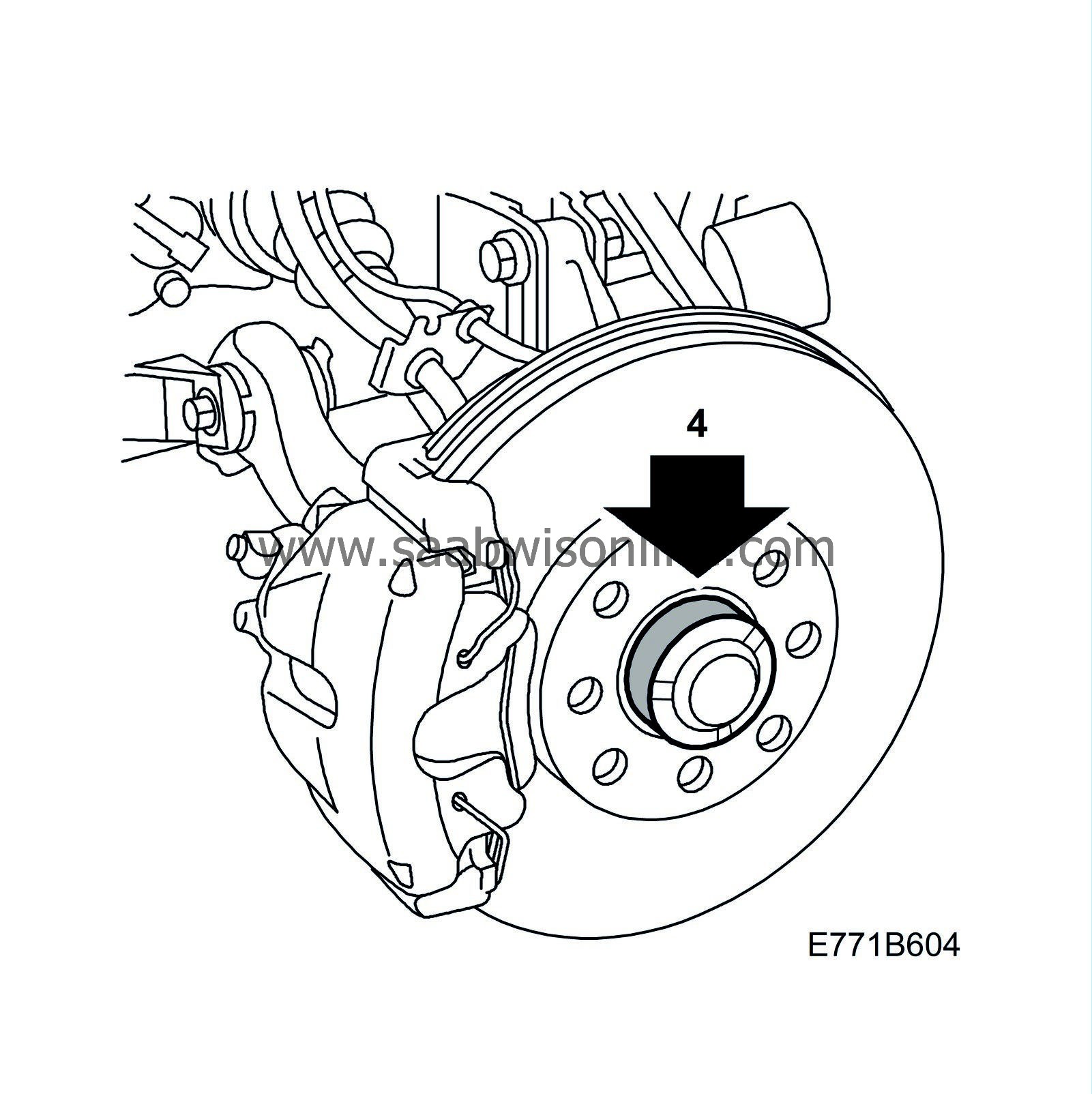

4.

|

Apply 30 06 442 White high-pressure paste to the hub.

|

|

5.

|

Hang the wheel in place, fit the new wheel bolts and tighten them alternately by hand so that the wheel is centred.

|

|

6.

|

Tighten the bolts alternately twice (pressed steel wheel three times).

Tightening torque

aluminium rim 110 Nm (81 lbf ft).

pressed steel rim 50 Nm +2x90°, max. 110 Nm (37 lbf ft +2x90°, max. 81 lbf ft)

|

Note

|

|

In order to avoid the bolts being tightened too hard when fitting pressed steel wheels, tightening through a further quarter-turn must be carried out using a torque wrench set at 110 Nm (81 lbf ft). If the torque wrench indicates that 110 Nm (81 lbf ft) is attained then the tightening through a further quarter-turn must be stopped.

|

|

|

7.

|

Carry out steps 2-6 on the other wheels.

|

Note

|

|

Wheel bolt kits are confined to the spare parts warehouse in Nyköping and will be released periodically after evaluation of order volumes.

|

|

|

Time/Warranty information

|

See separate information.